Preparation method of Ageratina-adenophora-base high-specific-area activated carbon

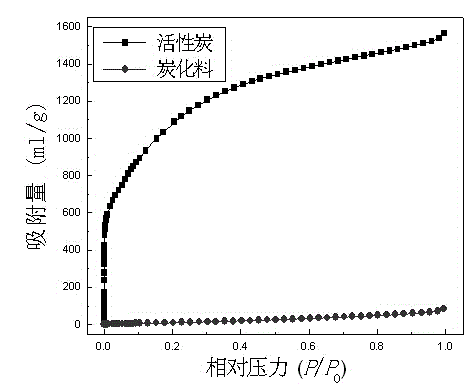

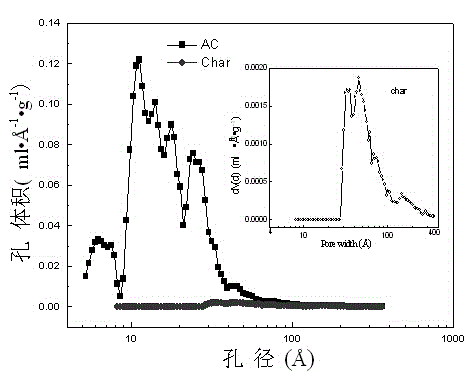

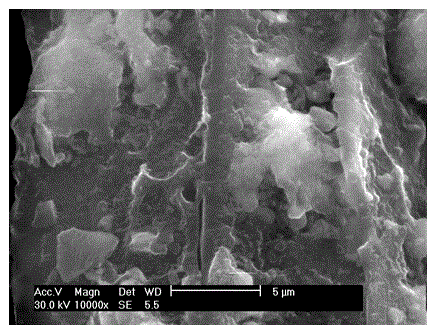

A high specific surface area, Eupatorium adenophorum technology, applied in the field of environmental protection, can solve the problems of not achieving good results, achieve the effect of rational utilization, saving time and improving activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, the Eupatorium adenophorum was dried at 80℃ for 25min to remove water, then put it into the carbonization furnace, raised to 400℃ at a heating rate of 5℃ / min, kept and carbonized for 30 minutes, after cooling with the furnace, it was taken out to obtain the carbonized material; The material is crushed to 600um as the activation raw material. The KOH and the carbonized material are mixed in a solid phase with a mass ratio of 2.0:1 and are uniformly loaded into a ceramic crucible and put into a microwave high temperature reactor; 2 min of nitrogen is passed into the furnace to empty the furnace The inner air is heated for 18min under the condition of microwave power of 5kW; when heated to 8min, CO is quickly blown into the 5min tube connected to the bottom of the ceramic crucible 2 , And turn on the 100W ultrasonic generator at the same time, turn off the microwave device and ultrasonic generator after heating, transfer the material to a beaker with tap water for wash...

Embodiment 2

[0033] First, the Eupatorium adenophorum was dried at 80°C for 30 minutes to remove water, and then put into a carbonization furnace, heated to 450°C at a temperature increase rate of 10°C / min, kept carbonized for 35 minutes, and taken out after the furnace was cooled to obtain a carbonized material; Crush to 800um as the activating raw material, mix KOH and carbonized material with a mass ratio of 2.5:1 into the ceramic crucible and put it into the microwave high-temperature reactor; pass nitrogen gas for 2 minutes to exhaust the air in the furnace , Heating for 18 minutes under the condition of microwave power of 8kW; when the microwave is heated to 8 minutes, the pipe connected to the bottom of the reaction vessel is blown in for 5 minutes and CO is blown in 2 , Turn on the 200W ultrasonic generator at the same time, turn off the microwave device and ultrasonic generator after heating, transfer the materials to a beaker with tap water for washing, then use hydrochloric acid wi...

Embodiment 3

[0036] First, Eupatorium adenophorum was dried at 80℃ for 45min to remove water, then put it into a carbonization furnace, raised to 500℃ at a heating rate of 15℃ / min, kept and carbonized for 40 minutes, and was taken out after the furnace was cooled to obtain a carbonized material; The material is crushed to 1000um as the activation raw material. The KOH and the carbonized material are mixed in a solid phase with a mass ratio of 1:3 and uniformly loaded into the ceramic crucible and put into the microwave high temperature reactor; 2min of nitrogen is passed into the furnace to empty the furnace Air is heated for 14 minutes under the condition of microwave power of 10kW; when the microwave is heated to 9 minutes, the pipe connected to the bottom of the reaction vessel is blown into CO2 for 5 minutes, and the 300W ultrasonic generator is turned on. After heating, the microwave device and ultrasonic generator are turned off. The materials are transferred to a beaker filled with ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com