Automatic large coil material packaging equipment

A technology of coil material and equipment, which is applied in the field of automatic packaging equipment, can solve the problem of not being suitable for large coil materials, and achieve the effects of simple operation, simple equipment structure and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

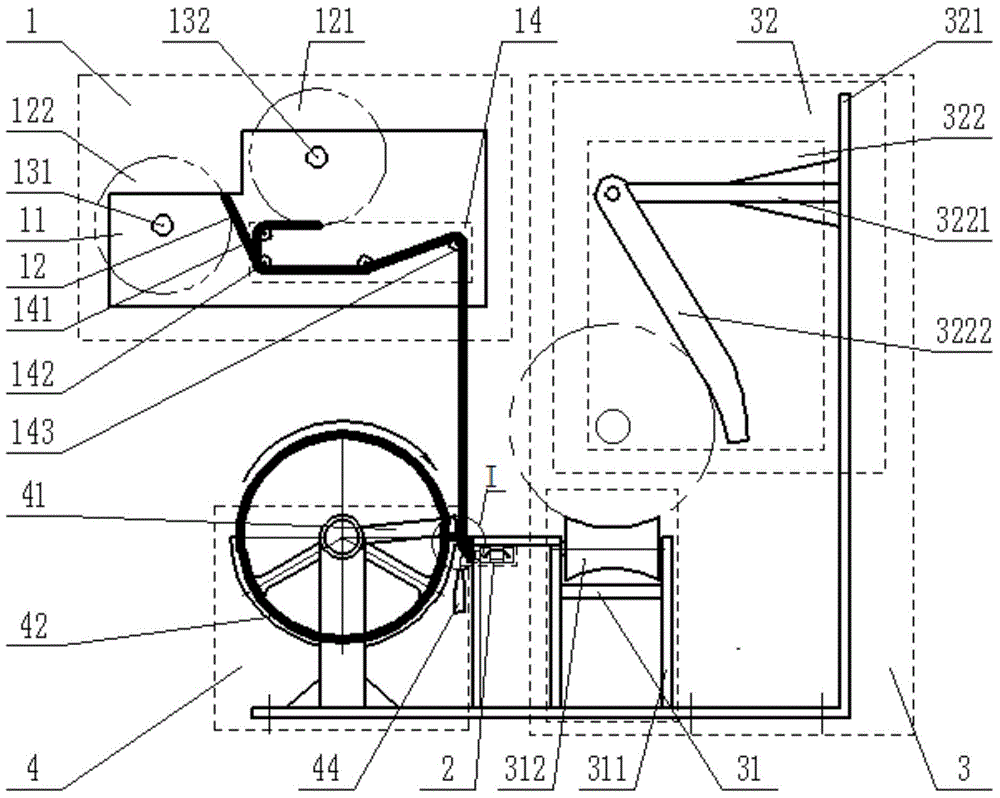

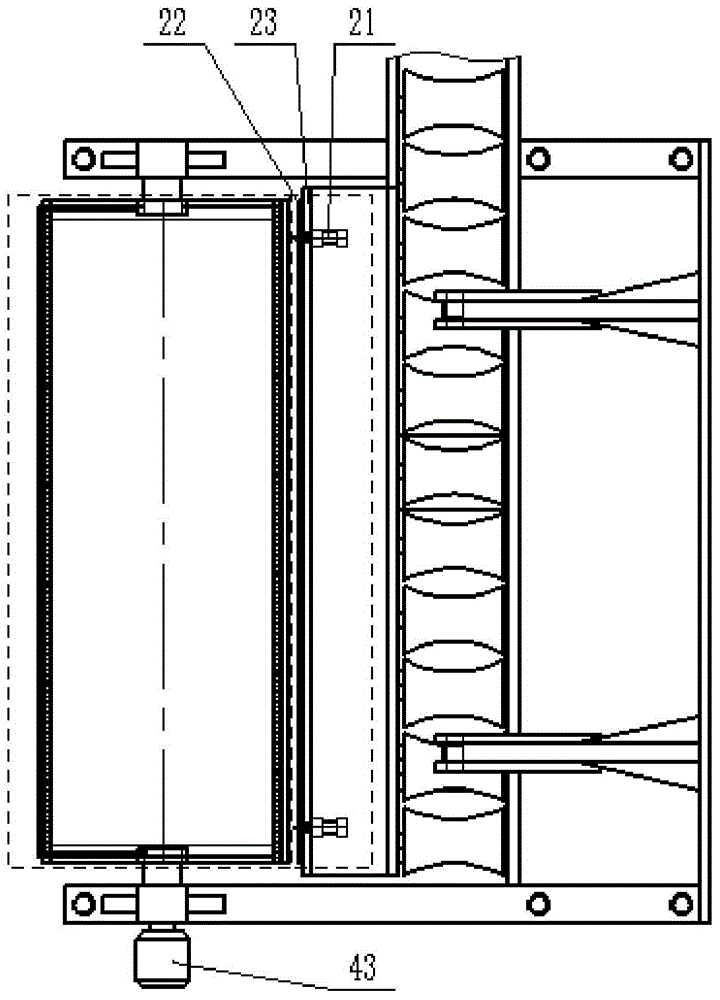

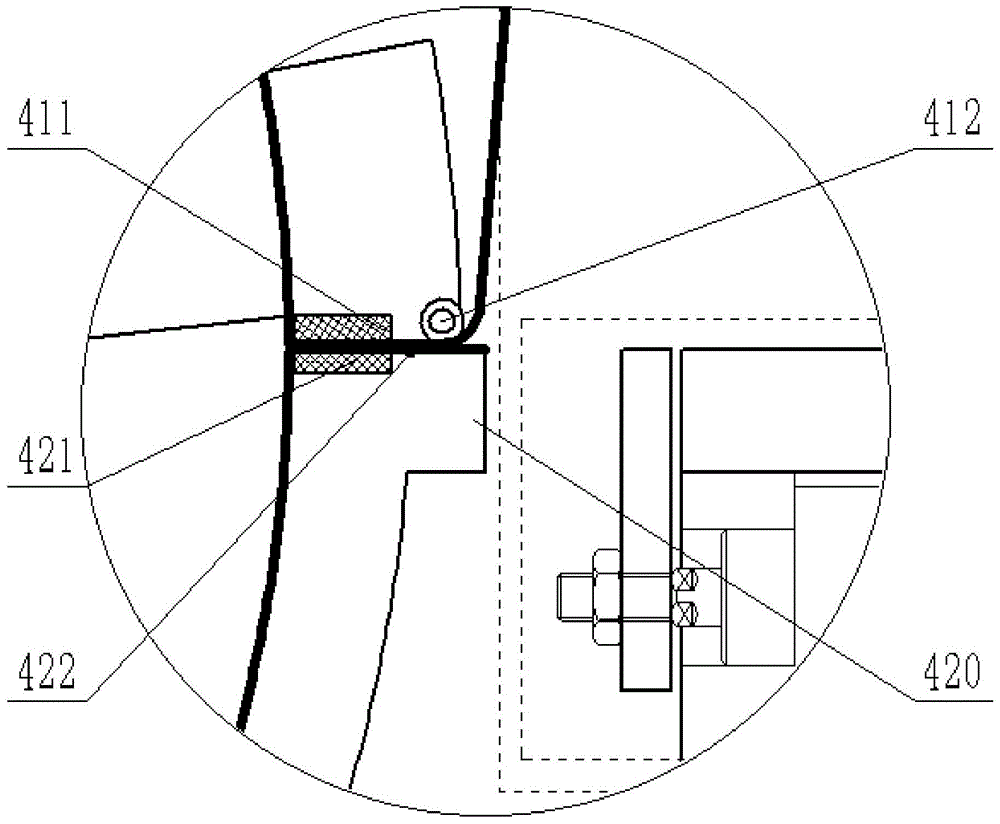

[0025] Embodiment 1 Large-scale coil material automatic packaging equipment, the overall schematic diagram of the large-scale coil material automatic packaging equipment is as follows figure 1 As shown, the top view of the large-scale automatic packaging equipment for roll materials other than the quick roll change device is as follows figure 2 As shown, the compression, heat sealing, and cut-off local enlarged diagrams are shown in image 3 shown.

[0026] The large roll material automatic packaging equipment provided by the present invention includes a film feeding device 1, a pressing device 2, a feeding device 3, and a coating device 4

[0027]The feeding device 3 includes a feeding conveyor 31 and a rolling module 32, the feeding conveyor is an idler-type feeding conveyor, and the feeding conveyor includes a conveyor frame body 311 and an idler roller 312 1. The conveying frame body includes a bracket and two horizontally installed and parallel roller mounting frames, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com