Patents

Literature

160results about How to "Meet the temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Convertor steelmaking method capable of reducing slag quantity

ActiveCN102212640AProtective liningReduce metal splashManufacturing convertersProcess efficiency improvementDolomiteScrap

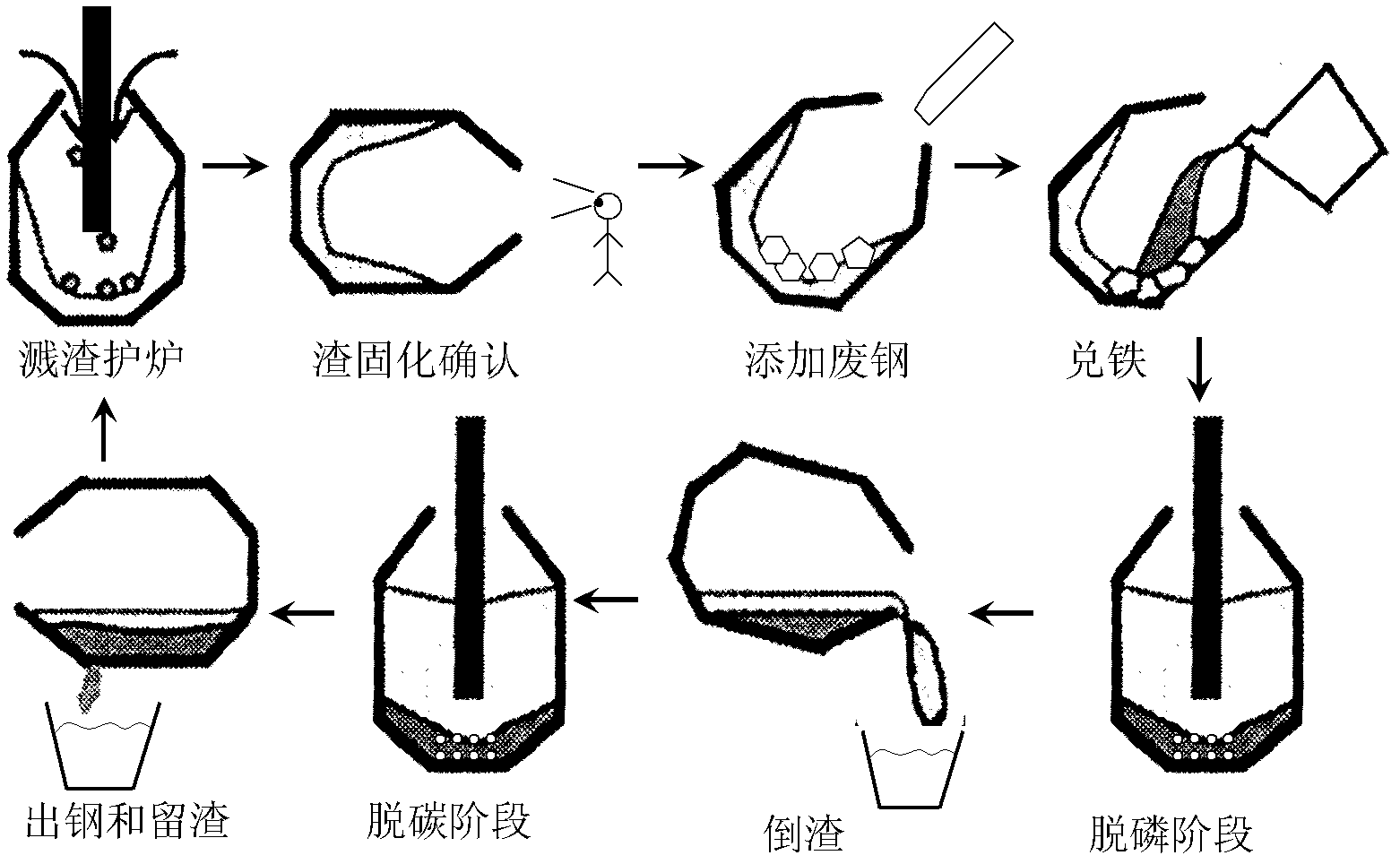

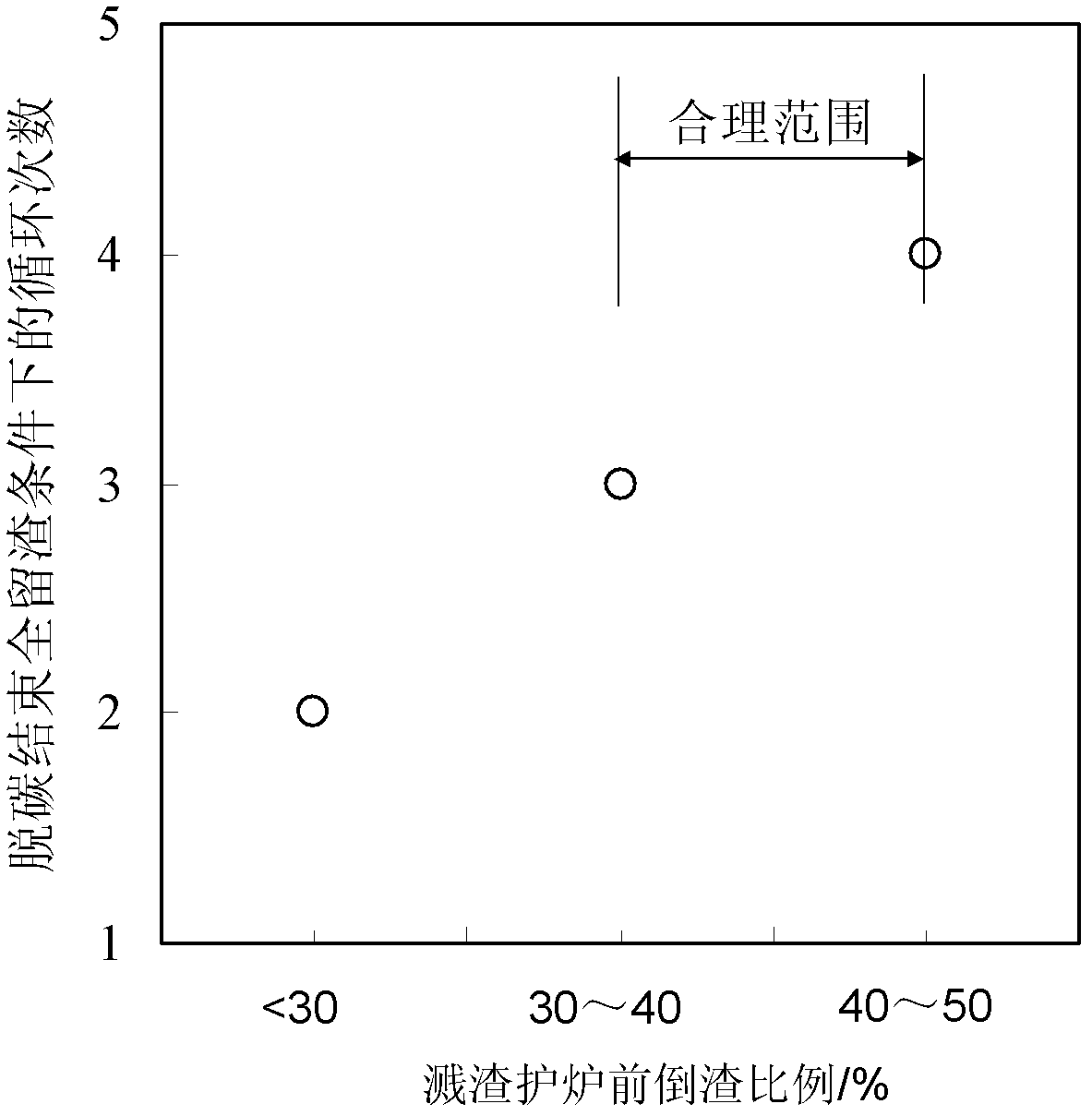

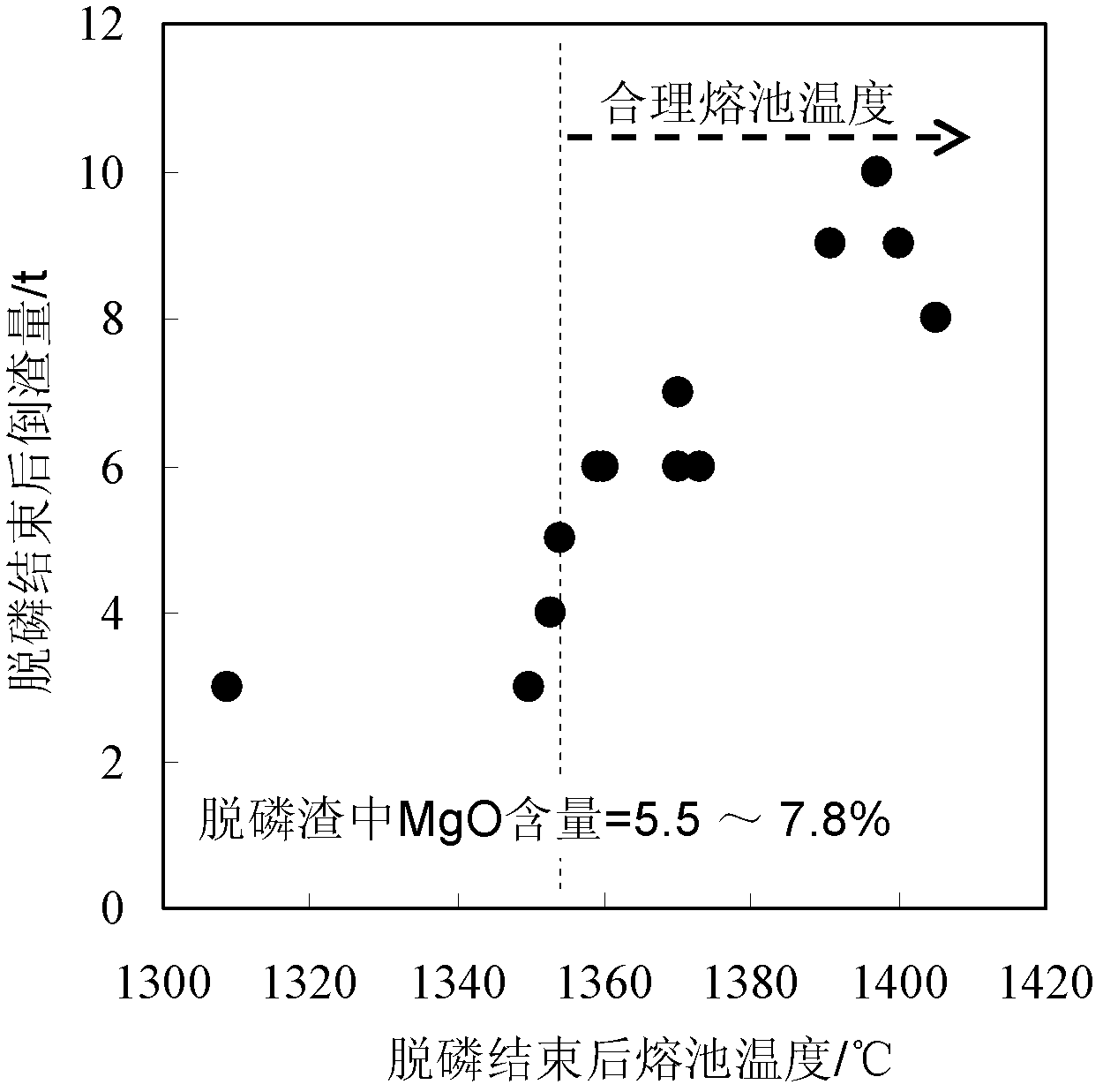

The invention belongs to the technical field of convertor steelmaking, and provides a convertor steelmaking method capable of reducing slag quantity. The process flow disclosed by the invention is circular process flow starting with step of protecting a furnace by slag splashing and ending with the step of remaining slag in the furnace. The process flow specifically comprises the following eight stages: protecting a furnace by slag splashing; curing liquid slag in the furnace; adding scrap steel; adding molten iron; blowing-dephosphorizing at a first stage; deslagging in the middle; blowing-decarbonizing at a second stage; tapping; and remaining slag in the furnace. Compared with the conventional convertor steelmaking process, the convertor steelmaking provided by the invention has the beneficial effects that lime consumption is lowered by 40.5%, light-roasting dolomite consumption is lowered by 76.8%, and the total consumption of the lime and light-roasting dolomite is lowered by 55.5% on the premise that phosphorus content at the end point is not more than 0.015%.

Owner:SHOUGANG CORPORATION

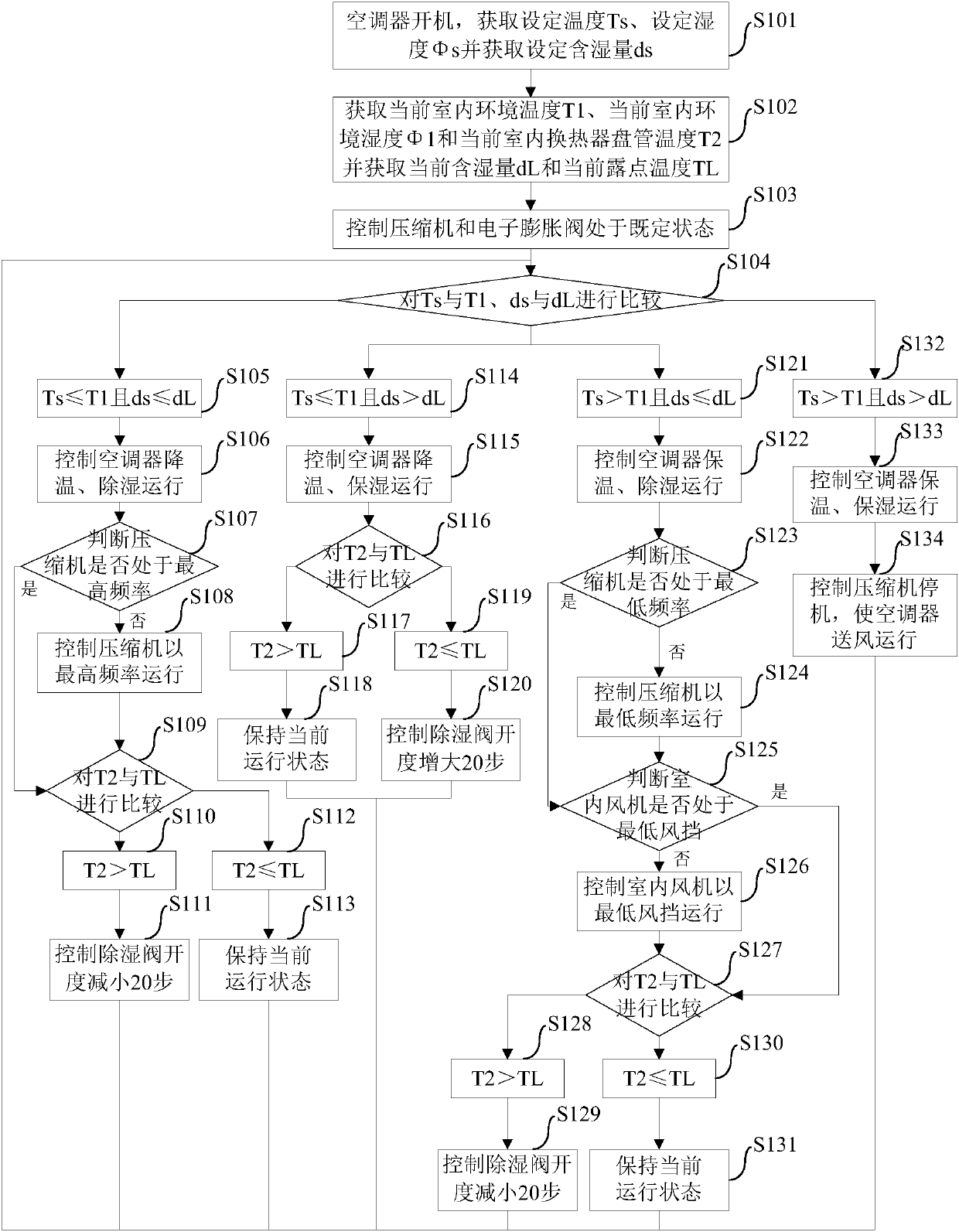

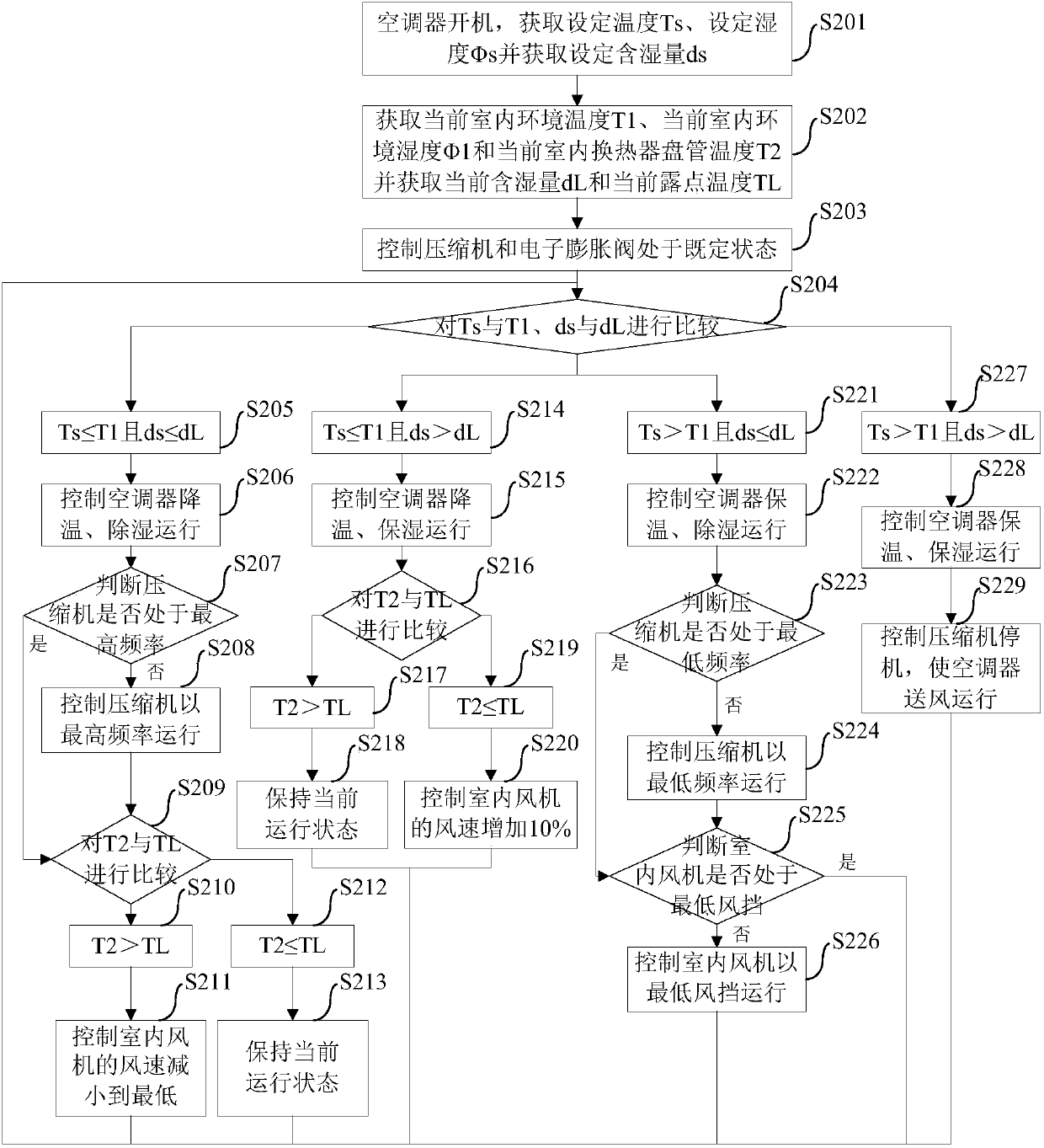

Air conditioner and control method and device thereof

ActiveCN107869826AMeet the temperatureFulfil requirementsMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringMoisture

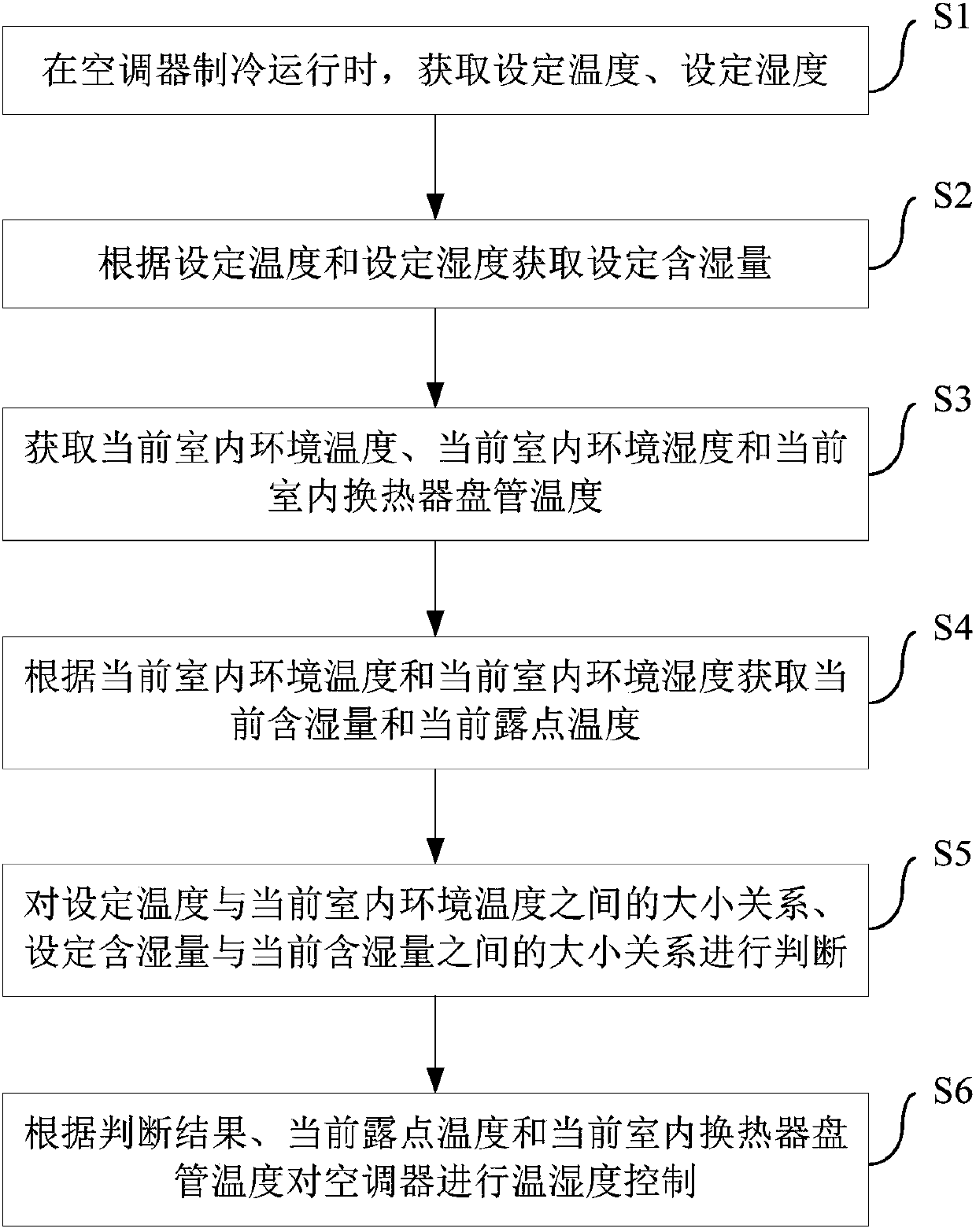

The invention discloses an air conditioner and a control method and device thereof. The control method comprises the following steps: when the air conditioner is in cold running, obtaining a set temperature and a set humidity; obtaining a set moisture content according to the set temperature and the set humidity; obtaining a current indoor environmental temperature, a current indoor environmentalhumidity and a current indoor heat exchanger coil pipe temperature; obtaining a current moisture content and a current dew point temperature according to the current indoor environmental temperature and the current indoor environmental humidity; judging a size relation between the set temperature and the current indoor environmental temperature and a size relation between the set humidity and thecurrent moisture content; and carrying out temperature and humidity control on the air conditioner according to a judgment result, the current dew point temperature and the current indoor heat exchanger coil pipe temperature. According to the control method disclosed by the invention, the air conditioner can simultaneously meet comfortable requirements of a user for the temperature and the humidity, and the cost can be reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

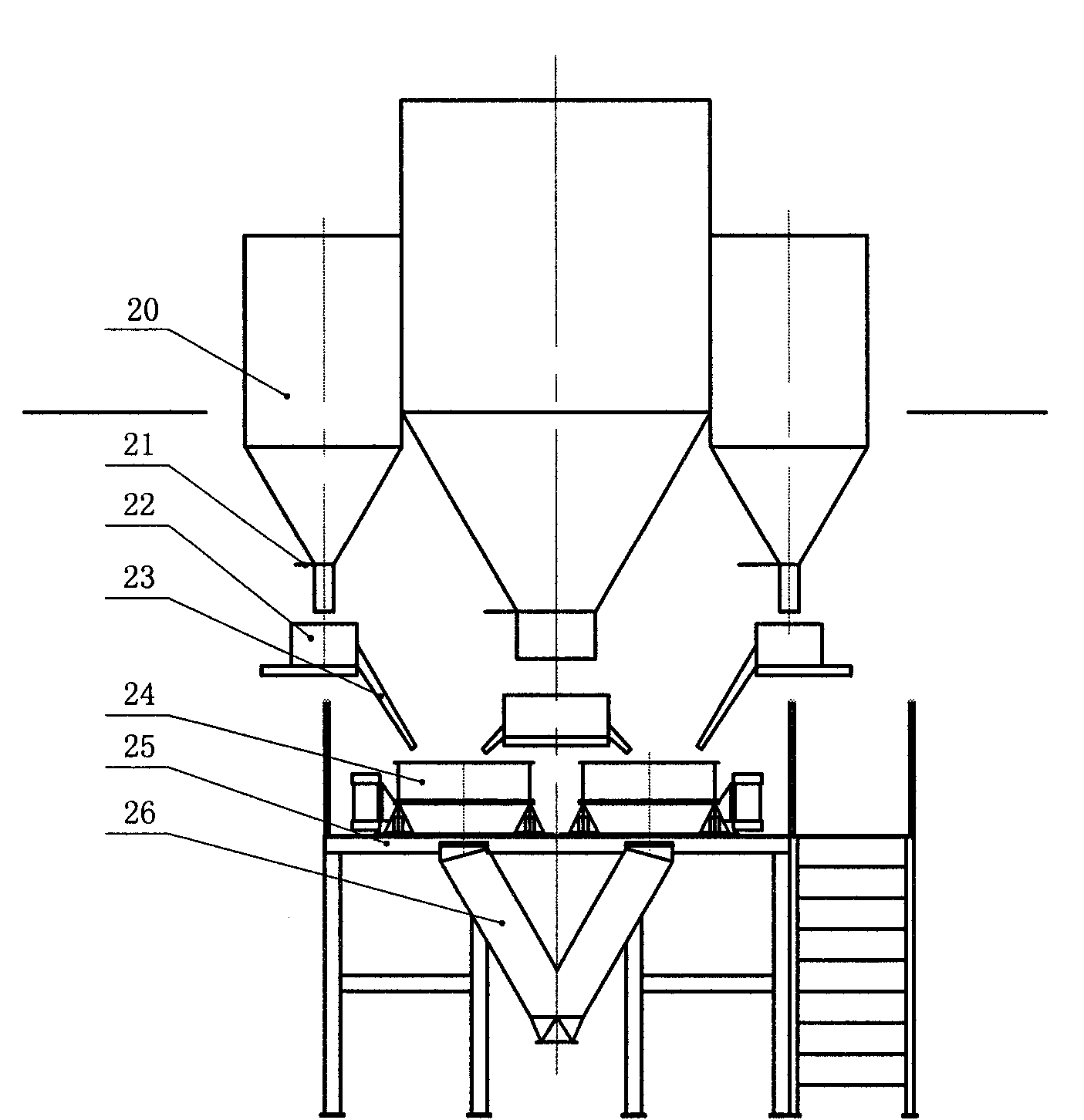

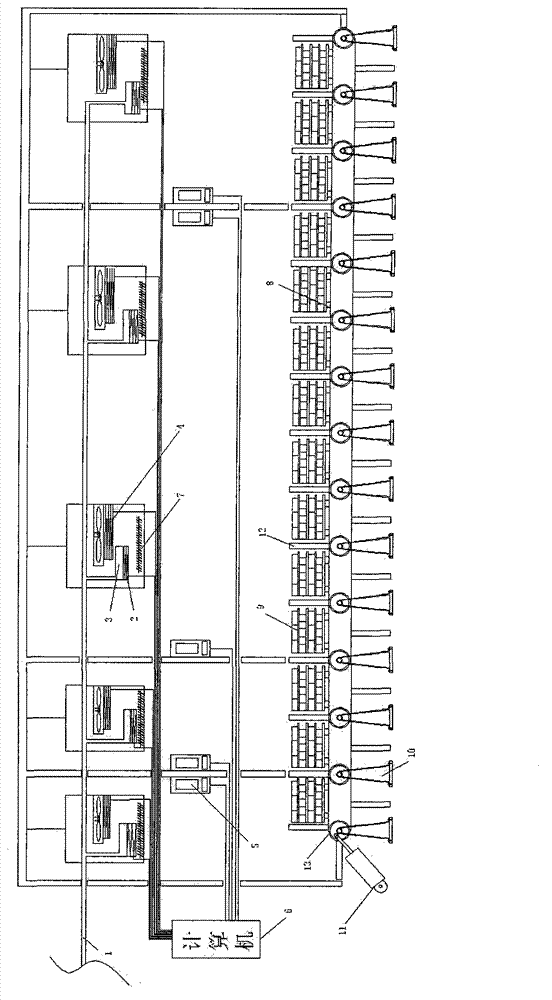

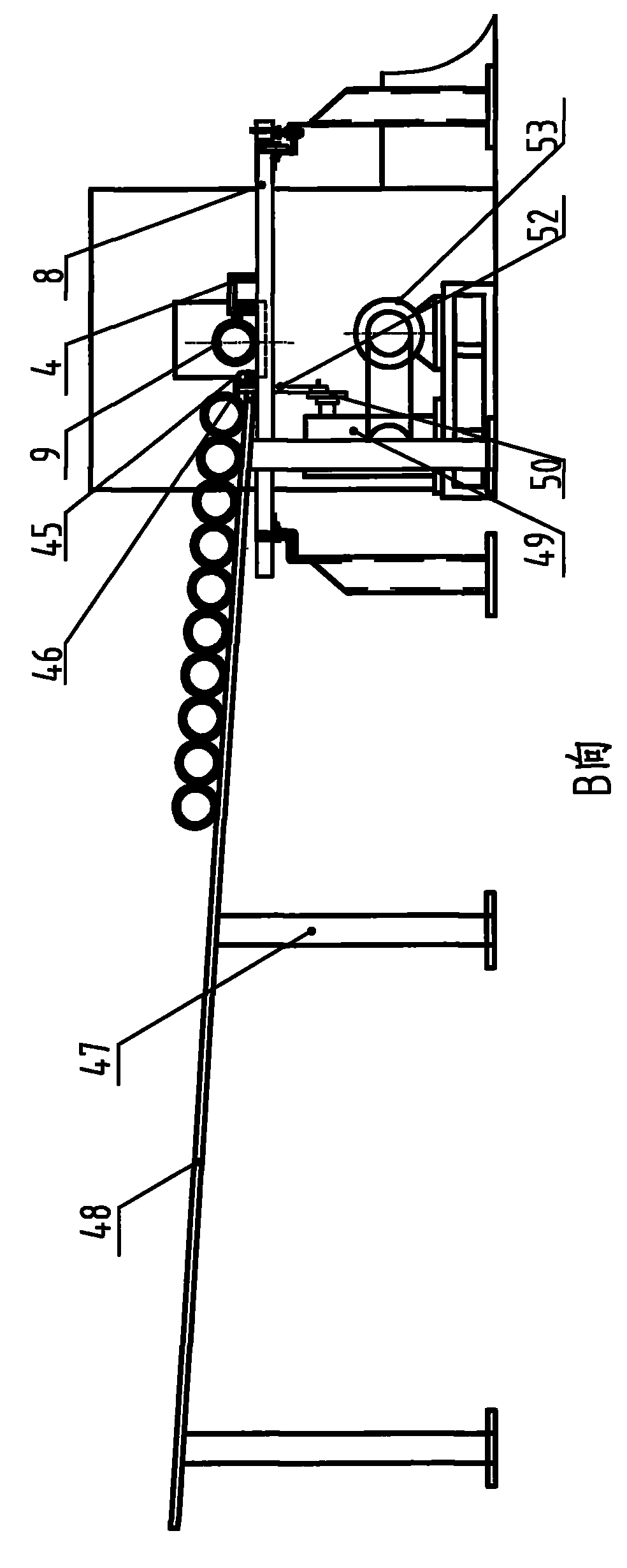

Cereal coarse grain instant noodle processing production line

InactiveCN102058056AGuaranteed uptimeReduce labor intensityDough shaping and cutting apparatusDough extruding machinesAutomatic controlPositive pressure

The invention relates to a cereal coarse grain instant noodle processing production line, comprising a mixing drum, a flour mixing machine, a hoisting machine, a flour feeding machine, an extrusion moulding machine, a quantitative cutting machine, a row combining machine, a pneumatic stopping device, a row separating device, a flour steaming machine, a drying machine, a cooling machine, an inspection conveyor, a packaging machine and a finished product conveyor which are sequentially connected, wherein an automatic weighing blanking device and a positive pressure conveying device are arranged in the procedure before the procedure of the flour mixing machine; a flour softening machine is arranged between the flour mixing machine and the hoisting machine; the extrusion moulding machine is one with automatically controlled temperature and curing degree; the quantitative cutting machine is of high accuracy type; the row separating device is of pneumatic type; the drying machine is a multi-section temperature and humidity controllable drying machine; and a transition conveyor is arranged between the cooling machine and the inspection conveyor. The invention can complete integration continuous production including burdening, conveying powder, mixing flour, softening flour, extruding and curing, high accuracy quantitative cutting, stewing and curing, multi-section drying, cooling and finished product packaging.

Owner:SHENGCHANGDA MACHINERY TIANJIN

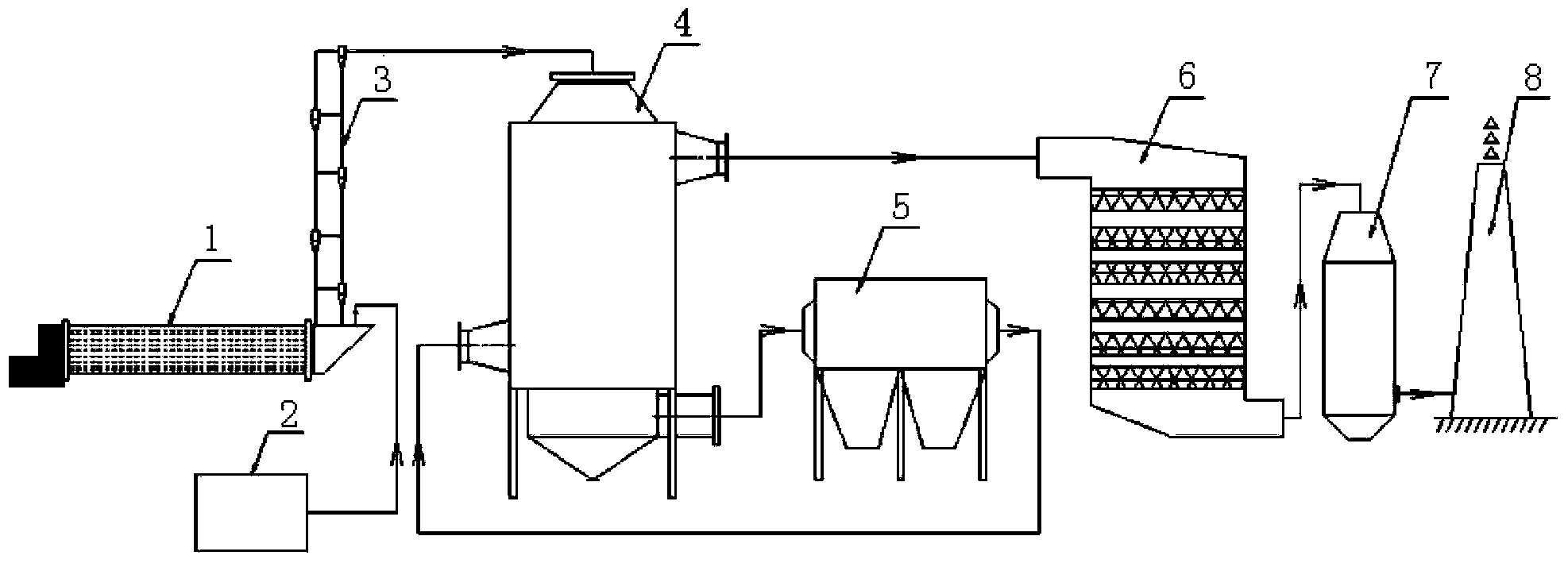

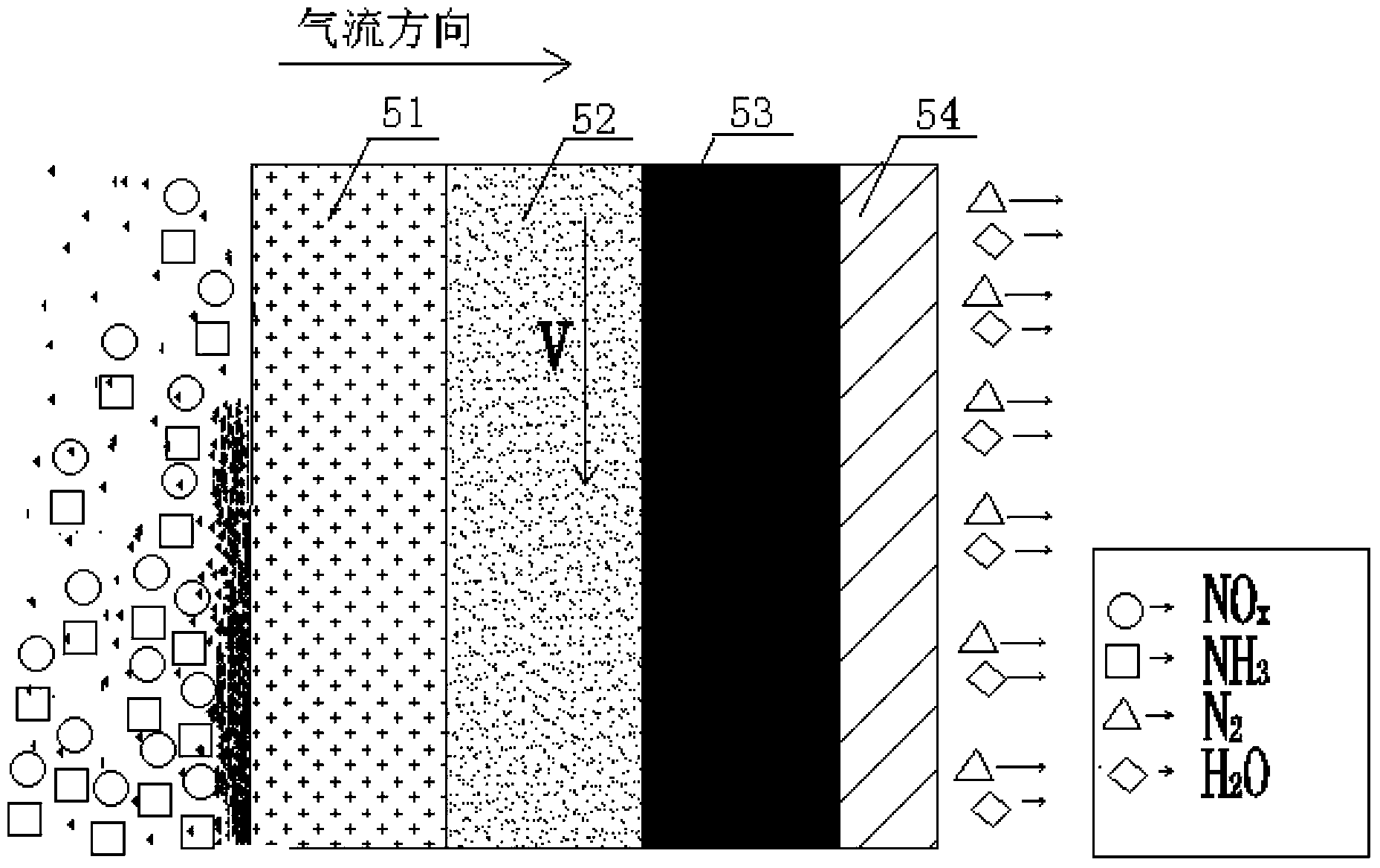

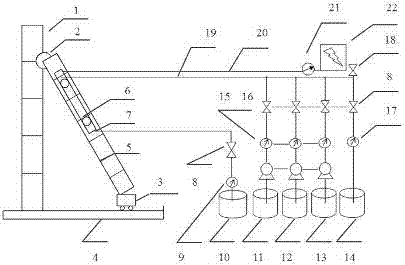

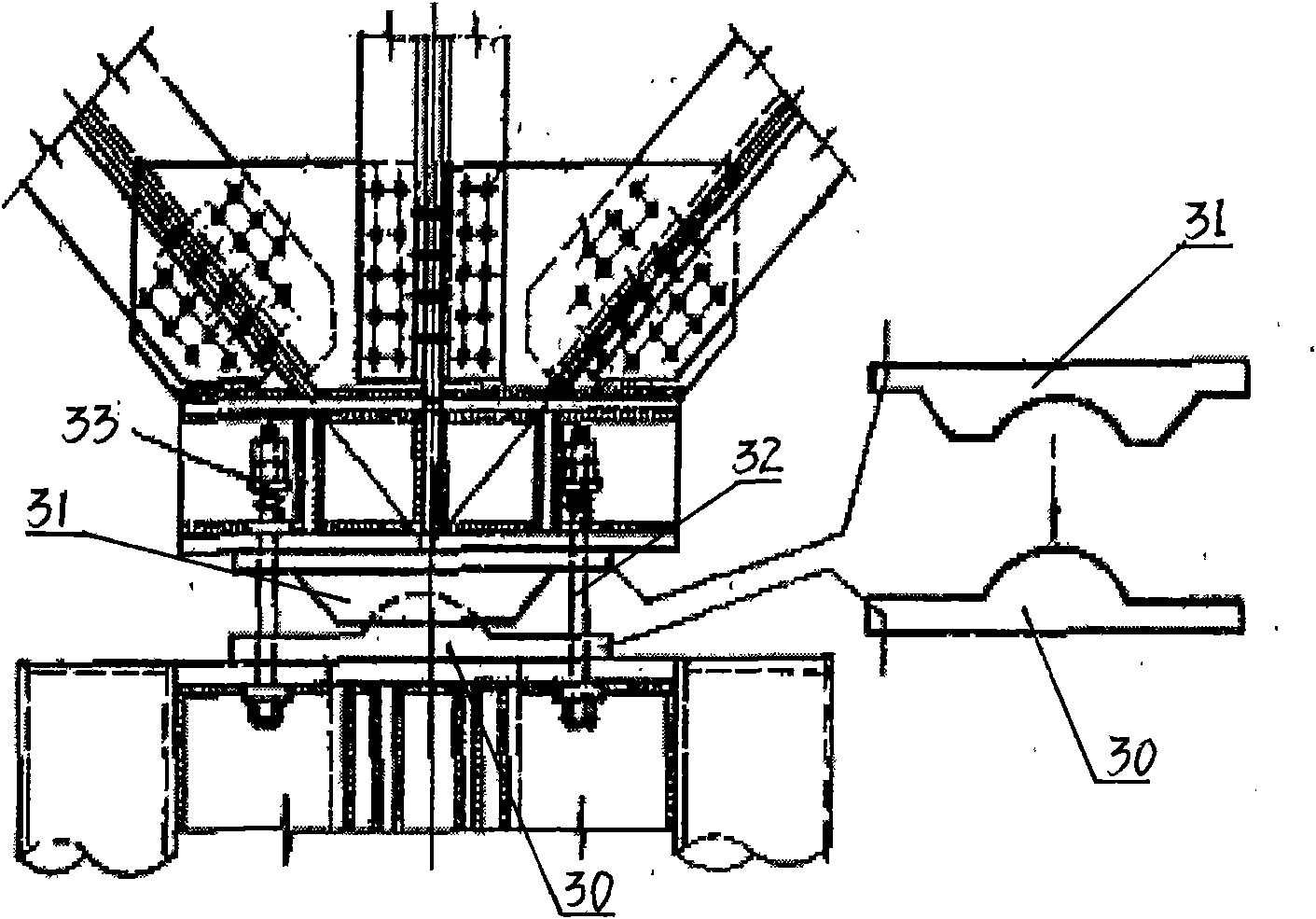

SCR (Selective Catalytic Reduction) denitration device for NOx control of rotary cement kiln

InactiveCN103406006AImprove denitrification efficiencyReduce wearCombination devicesLighting and heating apparatusFlue gasProcess engineering

The invention discloses an SCR (Selective Catalytic Reduction) denitration device for NOx control of a rotary cement kiln, wherein the rotary cement kiln is connected with a heat exchanger; a reducing agent injection system is arranged at the kiln tail part of the rotary cement kiln; the flue gas outlet of the rotary cement kiln is connected with the high-temperature flue gas inlet of the heat exchanger; the low-temperature flue gas outlet of the heat exchanger is connected to the flue gas inlet of a bag type dust collector; the outlet of the bag type dust collector is connected to the low-temperature flue gas inlet of the heat exchanger; the high-temperature flue gas outlet of the heat exchanger is connected to the flue gas inlet of an SCR reactor; the flue gas inlet of a desulfurizing tower is connected with the flue gas outlet of the SCR reactor. The three denitration technologies of SNCR (Selective Non-Catalytic Reduction), integrated dust collection and denitration and SCR are combined so that the flue gas of the rotary cement kiln is denitrated three times; specifically, firstly, NOx in the high-temperature flue gas has a selective non-catalytic reaction with a reducing agent at the tail of the kiln; secondly, the bag type dust collector provided with a denitration-functional catalytic filter bag is used for dust removal and secondary denitration; finally, the third time of denitration is performed in the SCR reactor; as a result, the denitration efficiency is greatly improved.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

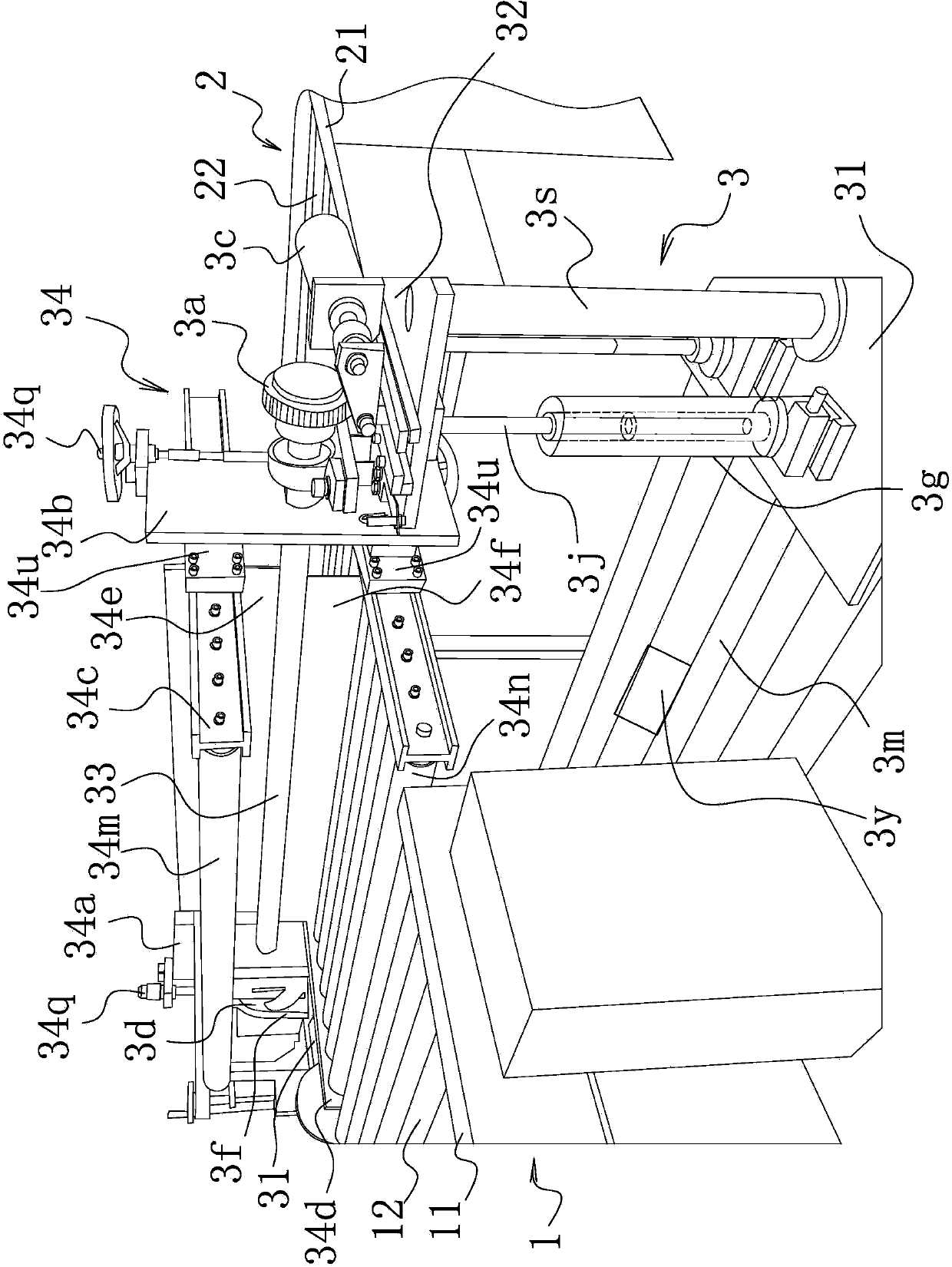

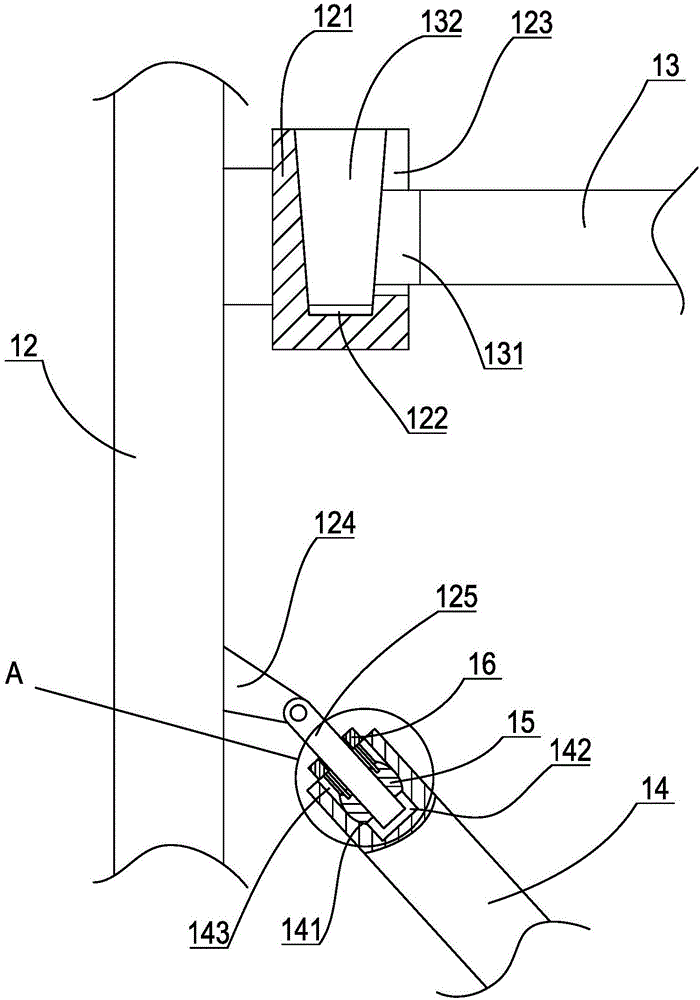

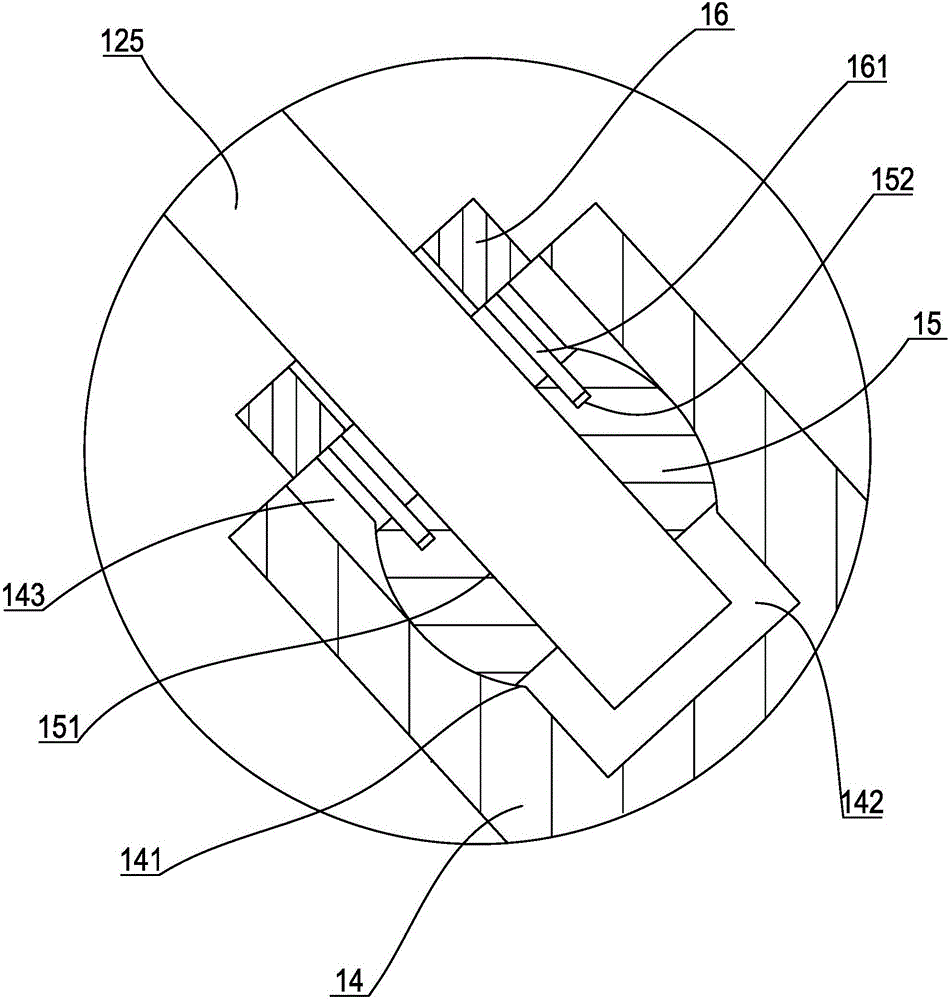

Conveying mechanism with turnover function

InactiveCN104192549AMeet the requirements of manufacturingGuaranteed temperatureConveyor partsManipulator

Owner:福建鑫天宏电子科技有限公司

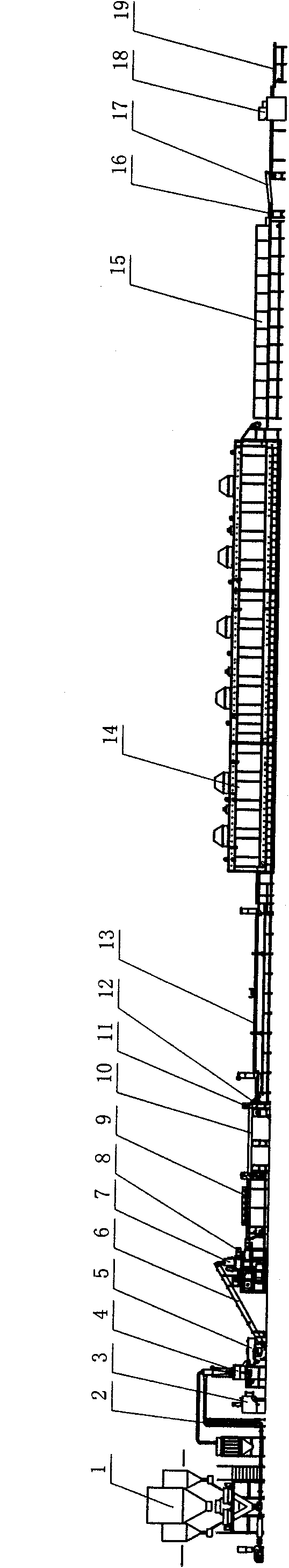

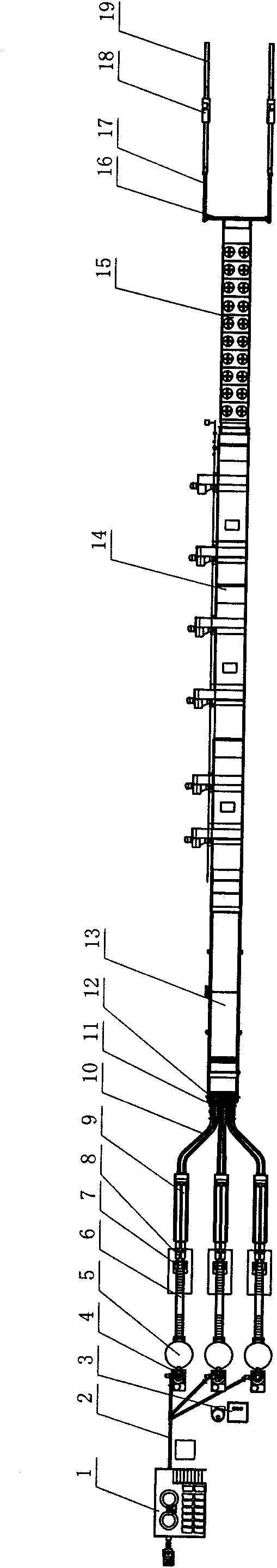

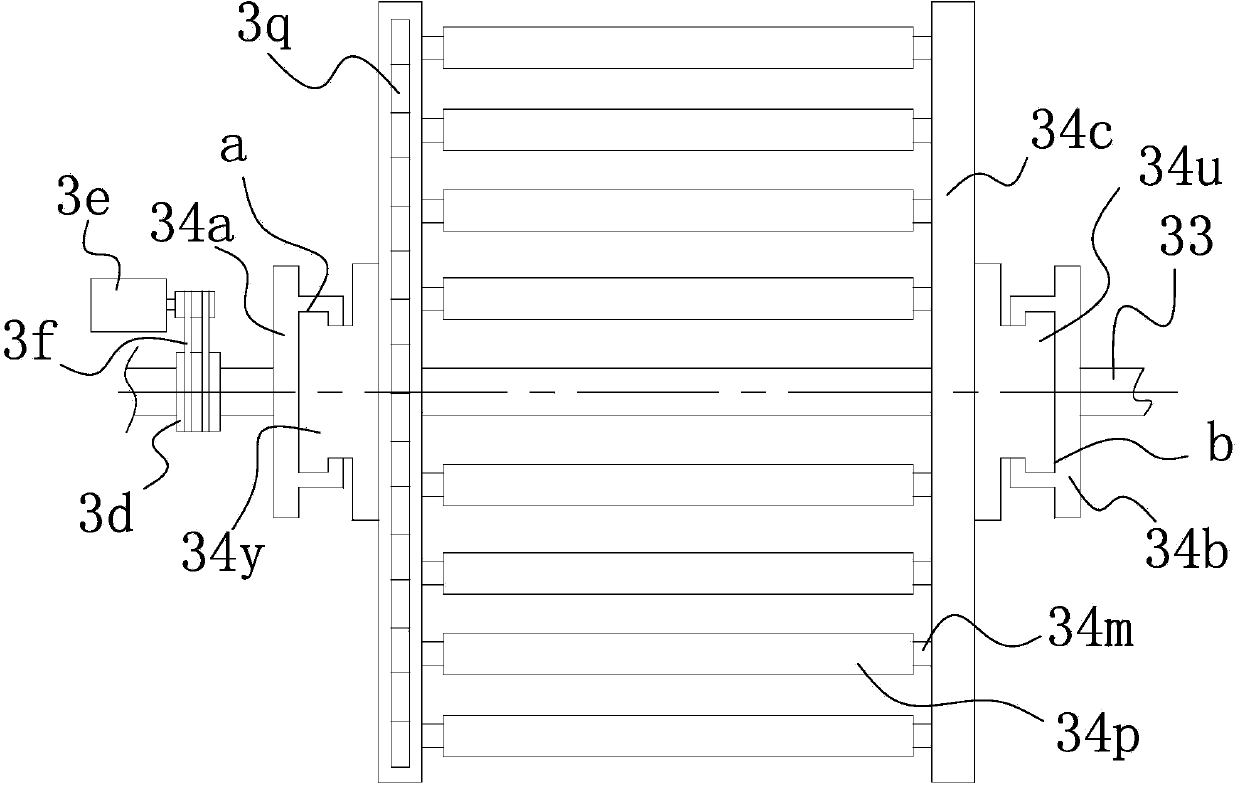

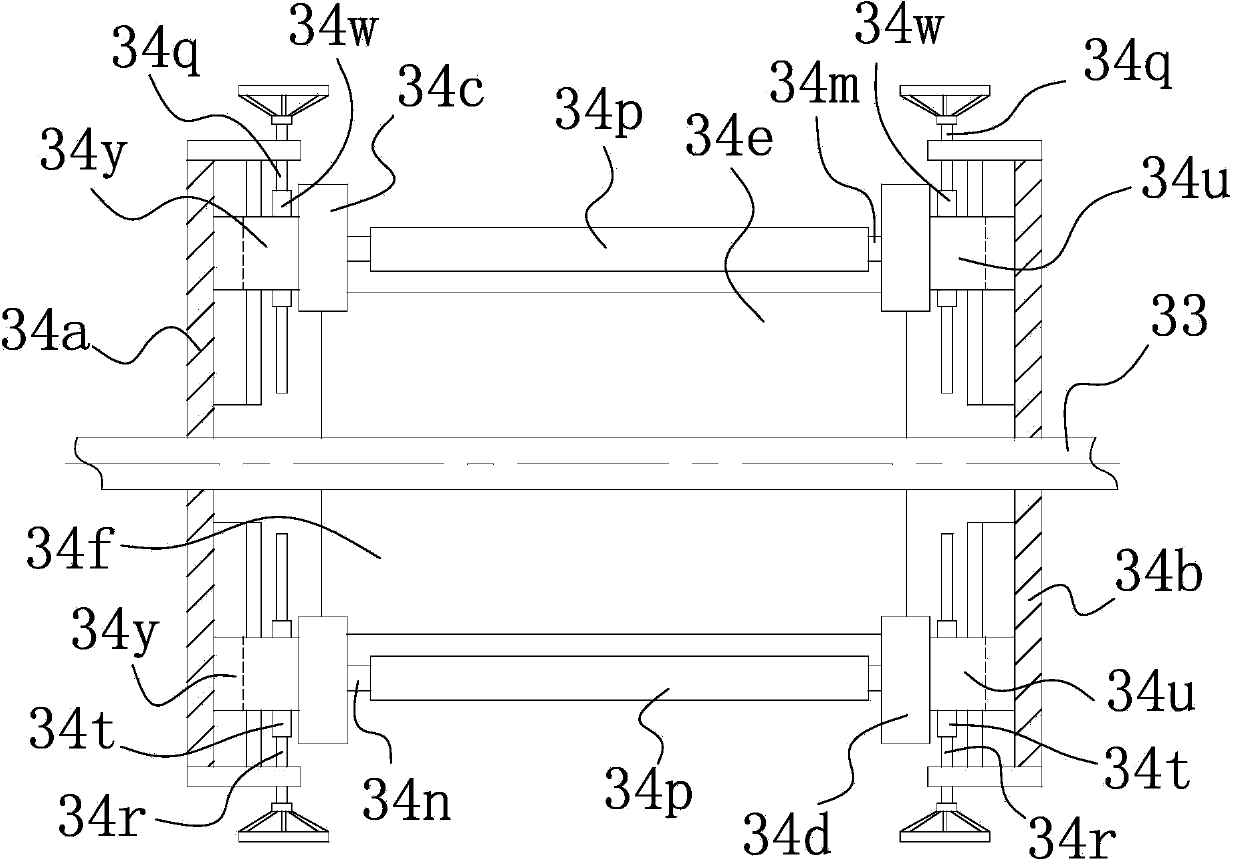

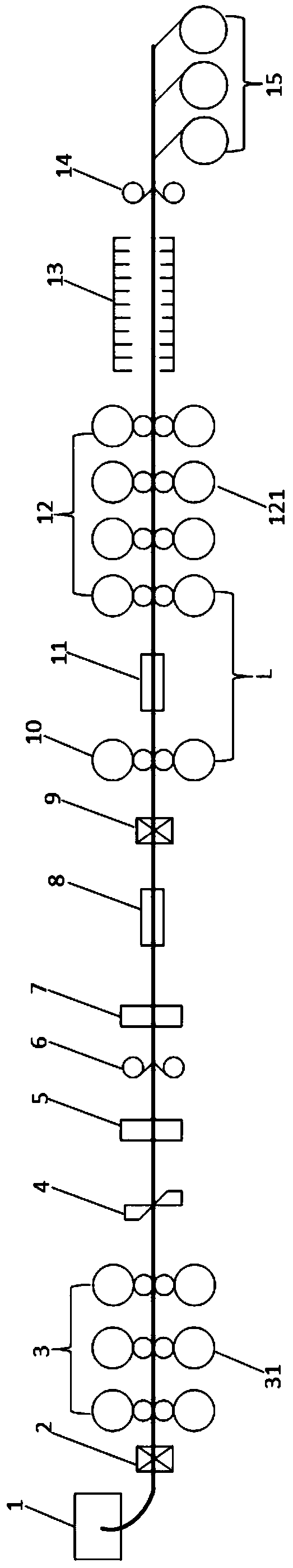

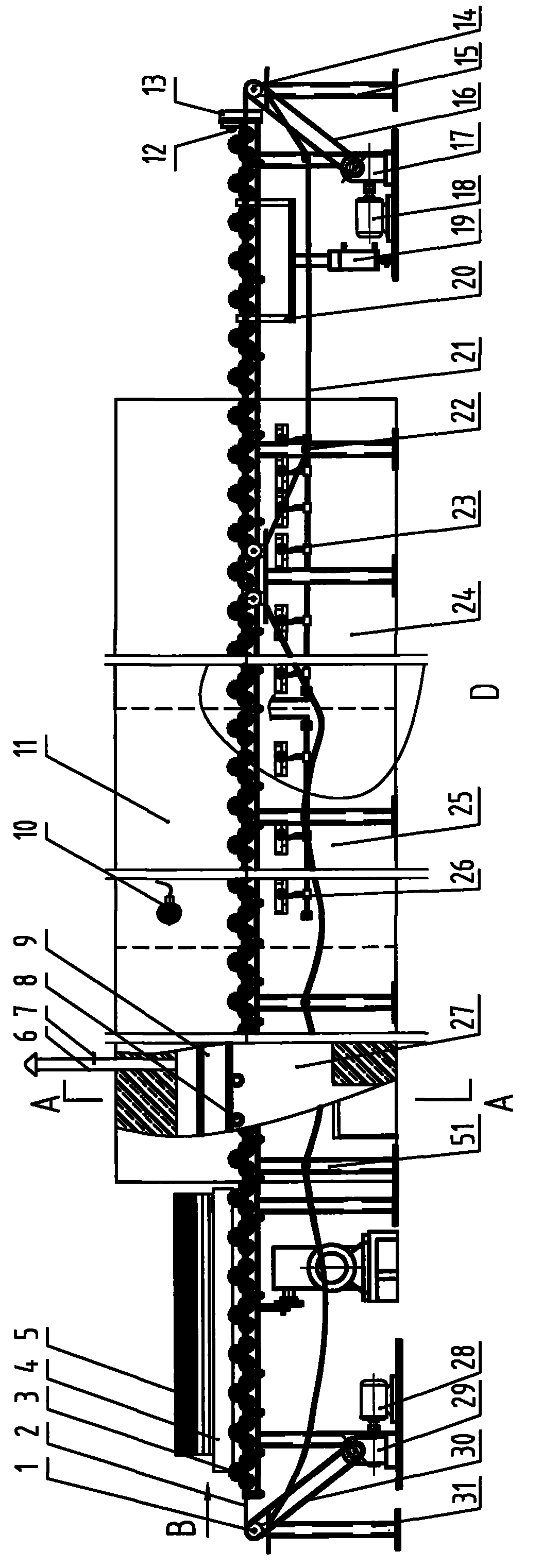

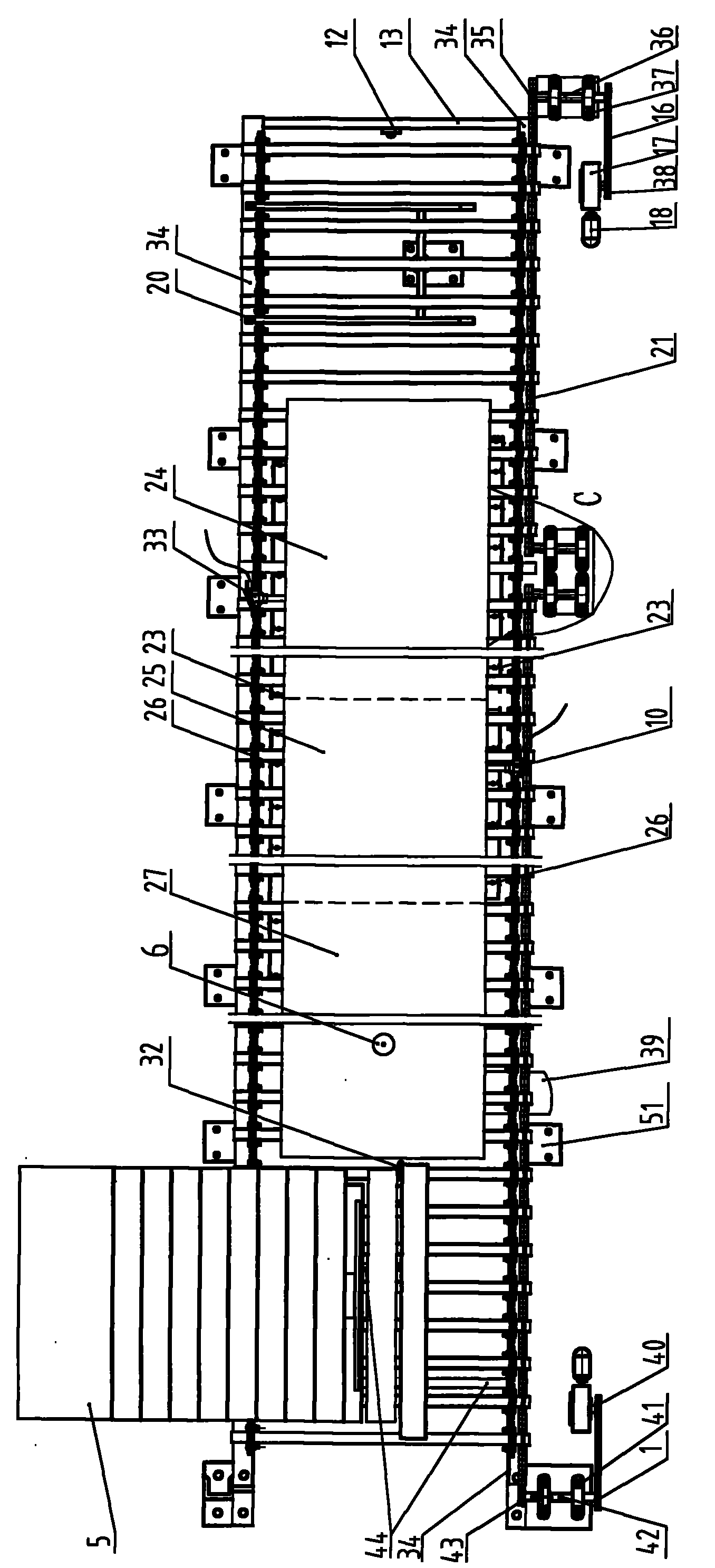

Low-carbon steel continuous casting and rolling production line and production technology thereof

PendingCN108526221AMeet the temperatureFulfil requirementsMetal rolling arrangementsSlab casterHigh pressure water

The invention discloses a low-carbon steel continuous casting and rolling production line and a production technology thereof. The low-carbon steel continuous casting and rolling production line and the production technology thereof are applied to the technical field of steel rolling. The production line comprises a slab continuous casting machine, a high-pressure water rough descaling device, a roughing rolling unit, a swing shear, a pushing-out and sheet stacking device, a rotating drum flying shear, a waste material removal device, an induction heating furnace, a high-pressure water fine descaling device, a middle rolling rack, a middle water cooling device, a finishing rolling unit, a laminar flow cooling device, a high-speed flying shear and a recoiling machine. The finishing rollingunit comprises four finishing rolling racks. The distance L between the middle rolling rack and the centre line of the first finishing rolling rack ranges from 10 m to 20 m. According to the low-carbon steel continuous casting and rolling production line and the production technology thereof, by means of reasonable production line arrangement and the proper production technology, the low-temperature rolling and high-temperature recoiling requirements for ferrite rolling are guaranteed; the sufficient finishing rolling total reduction rate is guaranteed; complete transforming, from austenite toferrite, of strip steel before being subjected to finishing rolling is completed; the finishing rolling is conducted in a ferrite zone, and thus real-sense ferrite rolling conducted through the continuous casting and rolling production line is achieved.

Owner:CISDI RES & DEV CO LTD

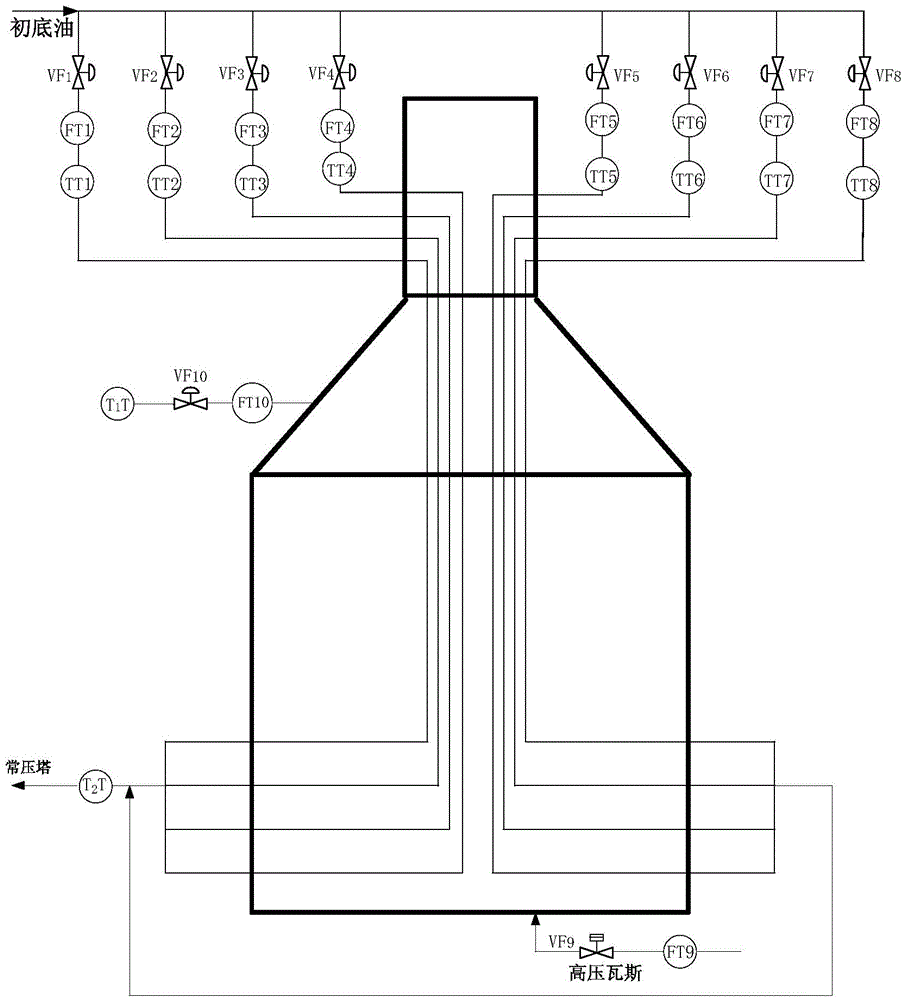

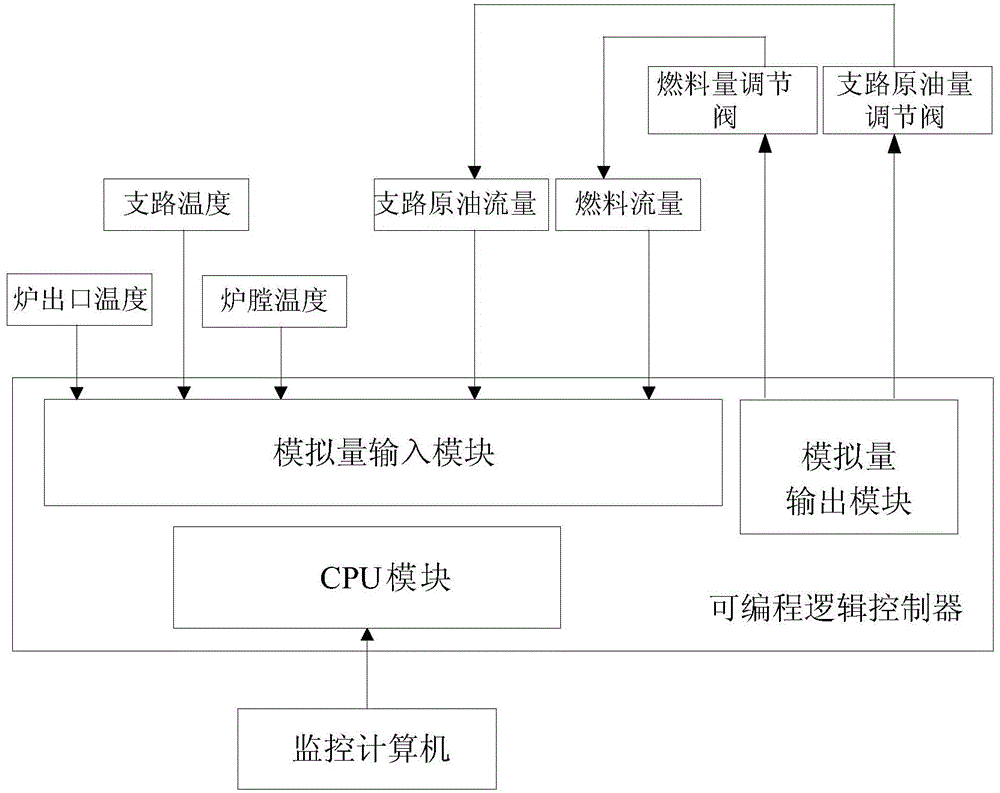

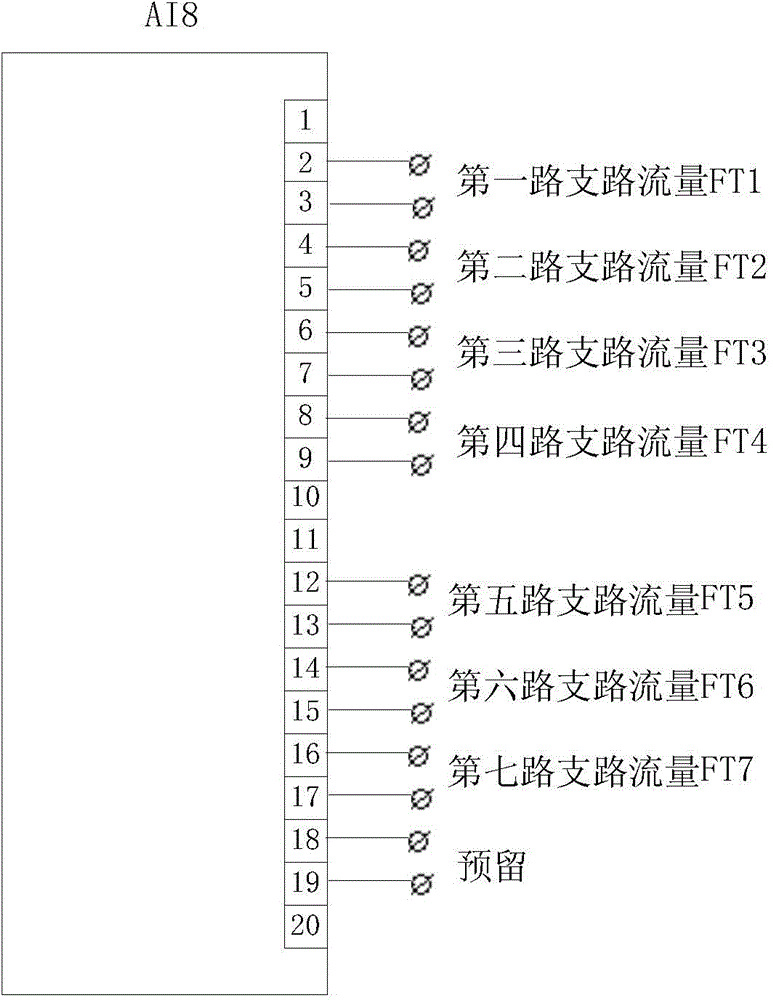

Method and device used for compound control of crude oil heater temperature

ActiveCN104101105AUniform temperatureReach the goal of saving energy and reducing consumptionFluid heatersProgrammable logic controllerEconomic benefits

The invention discloses a method used for compound control of the crude oil heater temperature. The method is characterized in that a heater outlet temperature set point regulator is used for heater outlet Tsp (temperature set point) regulation on the basis of heater serial control and branch temperature balance model prediction control. The invention further discloses a device used for compound control of the crude oil heater temperature. The device comprises a programmable logic controller, heater branch crude oil flow meters, branch temperature meters, a heater outlet temperature meter, a hearth temperature meter, a heater fuel flow meter, a branch crude oil quantity regulating valve, a fuel quantity regulating valve and a supervisory control computer, and a heater branch temperature balance advanced controller and the heater outlet temperature set point regulator are installed on the supervisory control computer. The method and the device have the advantages that on the conditions that crude oil is diverse and changeable in property, the heater outlet temperature can be stabilized, outlet temperature balance among branches can be achieved, energy consumption can be reduced, and enterprise economic benefit is increased.

Owner:南京富岛信息工程有限公司

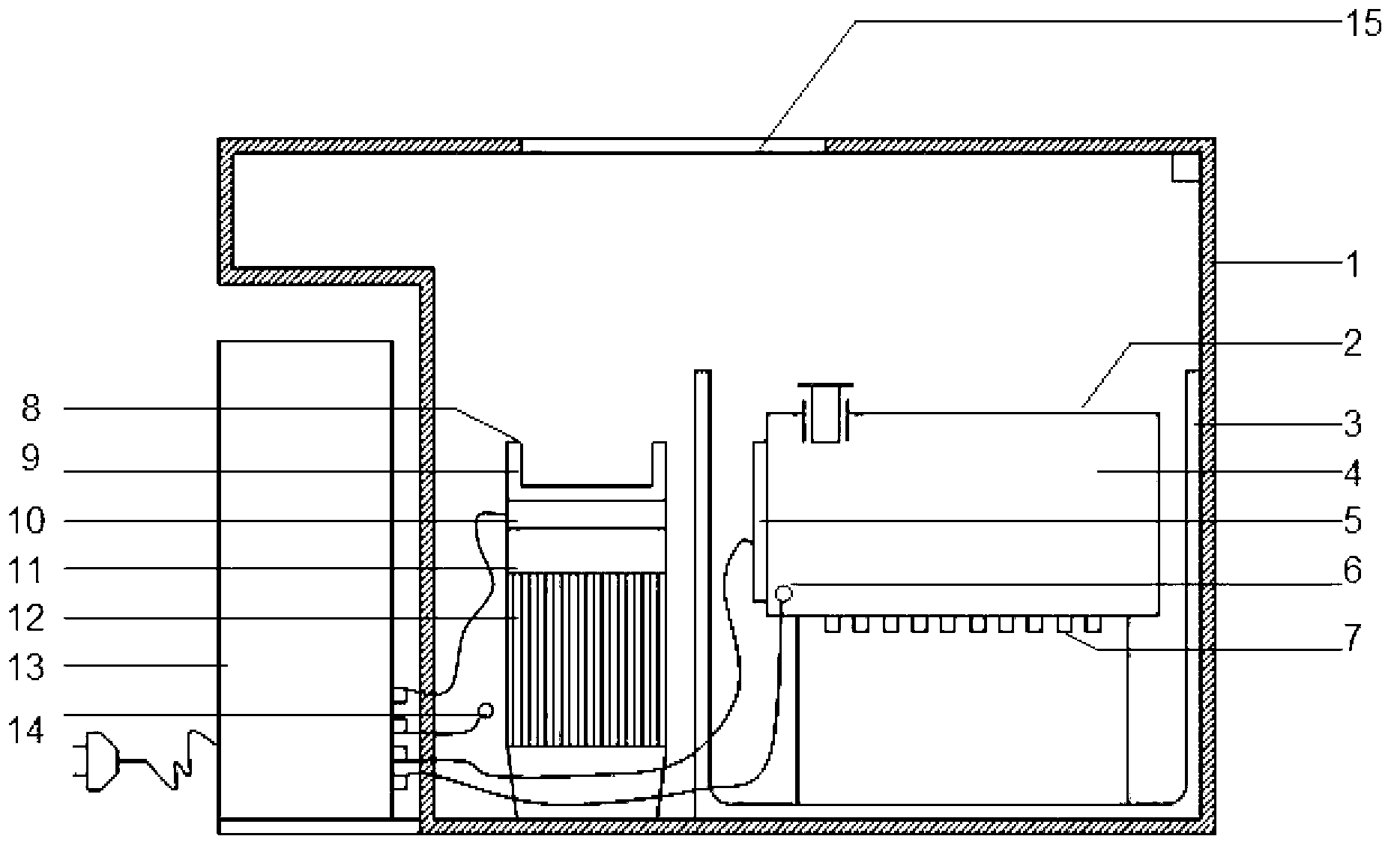

Device for semiconductor refrigeration and heating of fruit juice and ice cream

PendingCN107616292AChange temperatureAdjustable temperatureFrozen sweetsStrainersFruit juiceEngineering

The invention discloses a juicer with a heat-preserving barrel and capable of manufacturing ice cream. The juicer comprises a juicer main body and the heat-preserving barrel, wherein the heat-preserving barrel and the juicer main body are connected into a whole, or are in plugging cooperation through male and female connectors; and the bottom part of the heat-preserving barrel is provided with a semiconductor refrigeration and heating chip used for refrigerating or heating an object in the heat-preserving barrel. The device provided by the invention can realize the purpose of changing the temperature of fruit juice according to self-requirements by addition of the semiconductor refrigeration and heating chip for refrigeration and heating of the heat-preserving barrel. The device avoids discomfort of people during drinking of the fruit juice in different seasons due to influence of an external temperature. After semiconductor refrigeration and heating, the temperature of the heat-preserving barrel can be adjusted, an a heat-preserving material or a vacuum layer can preserve heat for the heat-preserving barrel.

Owner:ZHEJIANG GEMCORE TECH

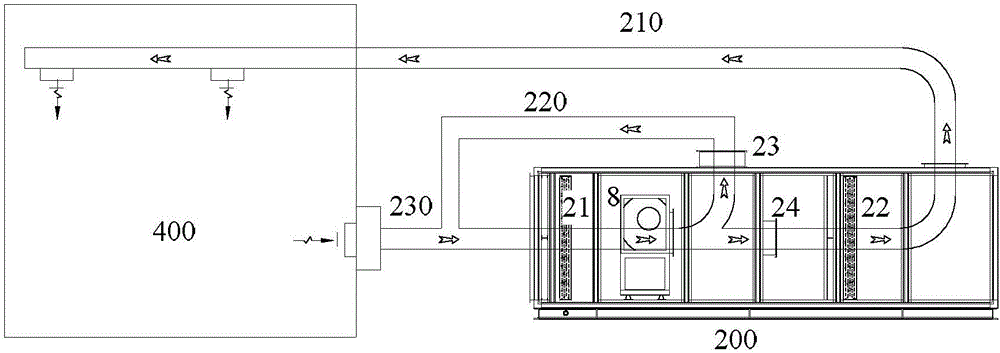

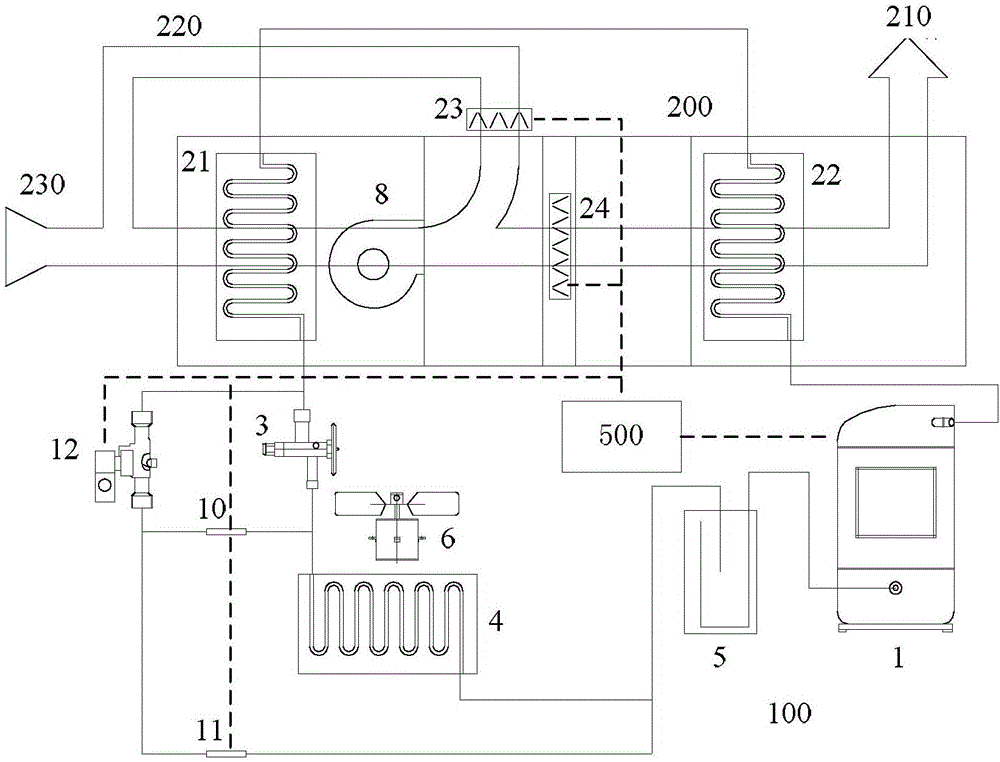

Control method and control device of heat pump type dual-cycle hot air drying system

ActiveCN106643107AImprove energy efficiencyGuaranteed temperature change requirementsMechanical apparatusHeat pumpsAir volumeEngineering

The invention provides a control method and a control device of a heat pump type dual-cycle hot air drying system and relates to an air or gas supply or control device for drying a solid material or product, in particular to a control method and a control device of a heat pump type dual-cycle hot air drying system. The control method comprises the following steps that a temperature control parameter is configured, and a preset temperature control curve parameter is saved; air outlet temperature and drying room temperature and humidity are detected and monitored; the set temperature is dynamically adjusted according to a preset temperature control curve; a dual-cycle dynamic operating mode of the system is selected according to current set temperature. The control device utilizes a microprocessor to achieve program control, an inner cycle loop for large-volume circulation is established, condensing latent heat of a refrigerant is fully absorbed to improve basic air temperature, and high-temperature hot air is obtained through secondary heat exchange of an air supply circulation loop; the air outlet volume is automatically adjusted and controlled by adopting dual-path air volume to ensure the change demand for air outlet temperature and drying room temperature. The reliability of the product can be ensured, the unit energy efficiency can be also achieved, and the purpose of energy consumption is reduced.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

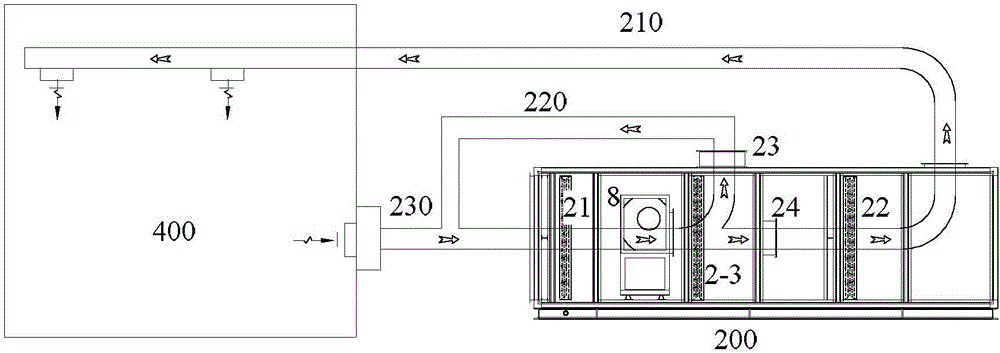

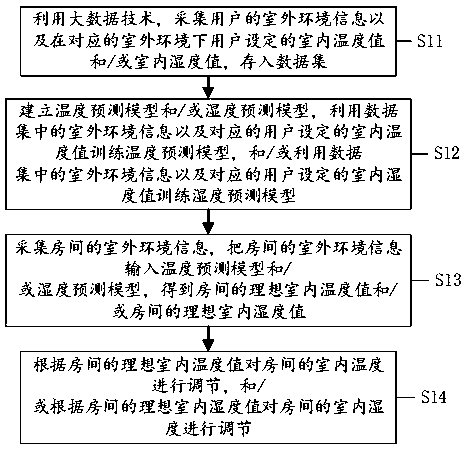

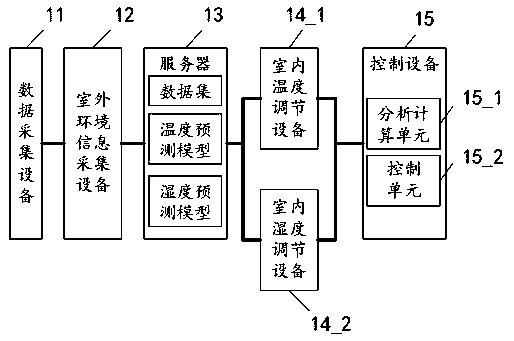

Method and system for controlling indoor environment parameters

InactiveCN109945439AImprove experienceMeet the temperatureMechanical apparatusSpace heating and ventilation safety systemsValue setData acquisition

The invention discloses a method and system for controlling indoor environment parameters. The outdoor environment information of a user and the indoor temperature value and / or indoor humidity value set by the user under the corresponding outdoor environment are collected through big data, then a temperature prediction model and / or a humidity prediction model are / is trained, the ideal indoor temperature value and / or the ideal indoor humidity value of a room are / is obtained according to the outdoor environment information of the room, and the indoor temperature and / or indoor humidity of the room are / is adjusted according to the ideal indoor temperature value and / or the ideal indoor humidity value of the room. The requirements of human bodies for different ideal indoor temperature values and / or ideal indoor humidity values corresponding to different outer environment conditions can be met, and user experience can be improved.

Owner:龙马智芯(珠海横琴)科技有限公司

Novel intelligent automatic humidity and temperature kiln inside curing system and method for cement product

InactiveCN103029208AReduce lossDoes not affect transmissionCeramic shaping apparatusTemperature controlCarbonization

The invention provides a novel intelligent automatic humidity and temperature kiln inside curing system for a cement product. The system comprises a curing kiln; four heat-insulation soft spaced sections are arranged in a sealed kiln body and correspond to four curing periods of the cement product respectively; and the four curing periods include a pre-curing period, a heating period, a heat preservation period and a cooling period. The method comprises the following concrete steps: 1) determining the time of the four curing periods, setting the conveying speed of a plate conveying chain belt to be a constant value, and enabling the curing time ratio of the four heat-insulation soft spaced sections to be equal to the length ratio of the four heat-insulation soft spaced sections; and 2) setting the temperature and the humidity in each of the four heat-insulation soft spaced sections through a steam humidification device and a warm wind temperature control machine respectively. According to the curing system and method, the hydration and carbonization processes of the concrete cement product can be accelerated, the curing cycle can be shortened, and the problem of quality influence due to a series of factors such as cracking, deformation, collapse and the like can be solved.

Owner:天津恩赐晋华建材有限公司

A preparing method of a long-acting organic fertilizer

InactiveCN106518216AFermentation rate inhibitionRealize recycling of resourcesBio-organic fraction processingAlkali orthophosphate fertiliserGuanoCompost

A preparing method of a long-acting organic fertilizer is provided and belongs to the technical field of agrochemistry. According to the method, a humus forming amount is increased through raw material formula regulation, microbial inoculum improvement to inhibit acidification and ammonification, an aerobic compost fermentation process is accelerated through equipment of a compost process, and ammonia nitrogen in fermentation tail gas is recovered to prepare guano phosphorite. The method has characteristics of high innovation, simple steps, a low equipment investment, and convenient preparation, and the produced organic fertilizer is stable and long-acting in fertility, high in humus contents and good in environment benefit and has good popularization value.

Owner:NANCHANG UNIV

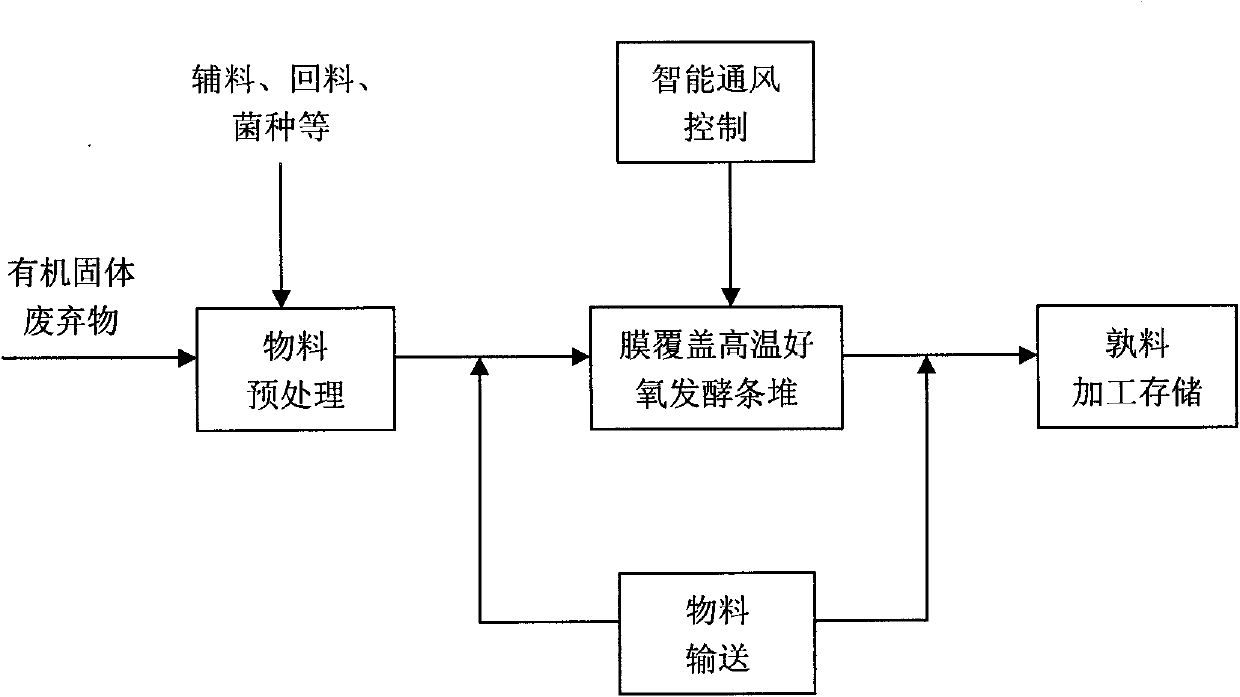

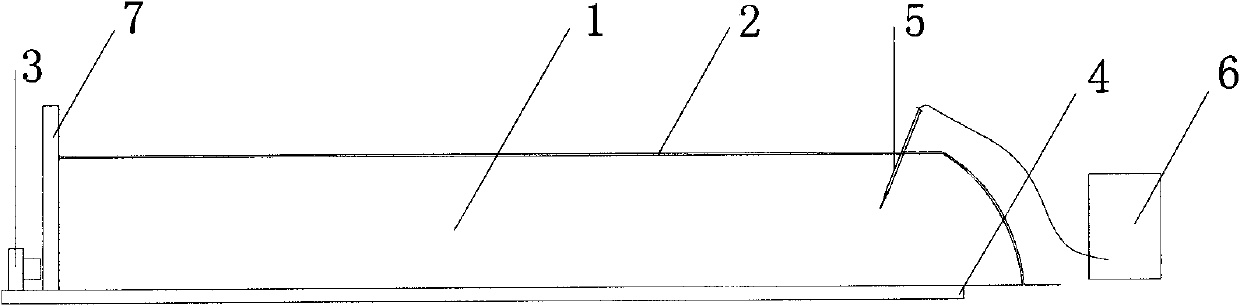

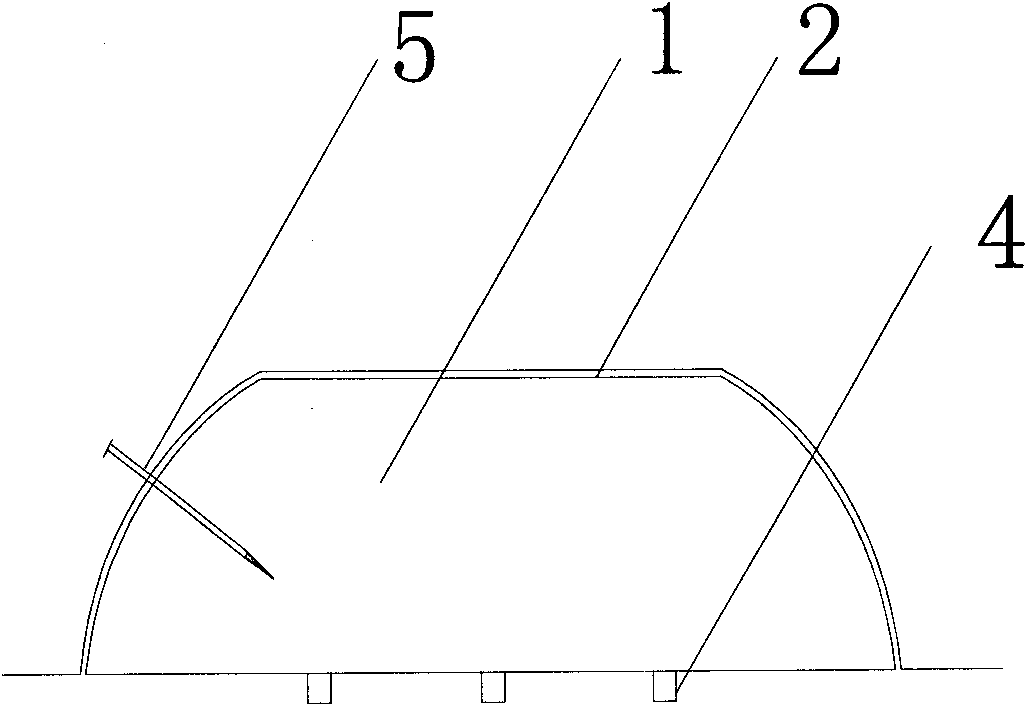

Organic solid waste film covering high-temperature aerobic fermentation method

InactiveCN101792339AThermal insulationReduce the impactBio-organic fraction processingClimate change adaptationControl systemAgricultural engineering

The invention relates to the technical field of organic solid waste processing, in particular to an organic solid waste film covering high-temperature aerobic fermentation method. The fermentation method is characterized in that the organic solid waste is pretreated; the pretreated material is piled in strip pile; the material strip pile is provided with a sensor and covered with a waterproof breathable film; a blower and an air-pipe under the material are used for supplying oxygen to the material; an intelligent ventilating control system is used for optimizing the fermentation process; after the material is fully decomposed, the waterproof breathable film on the material strip pile is removed, and then the material strip pile is transported into a clinker storing or processing area. Compared with the prior art, the fermentation method has short building period, few disposable investment, flexible construction, low operating cost, small odor influence, rain-proof, wind prevention and heat preservation effect and can protect the material from being affected by outside weathers.

Owner:SHANGHAI YUANJUN ENVIRONMENTAL PROTECTION TECH CO LTD

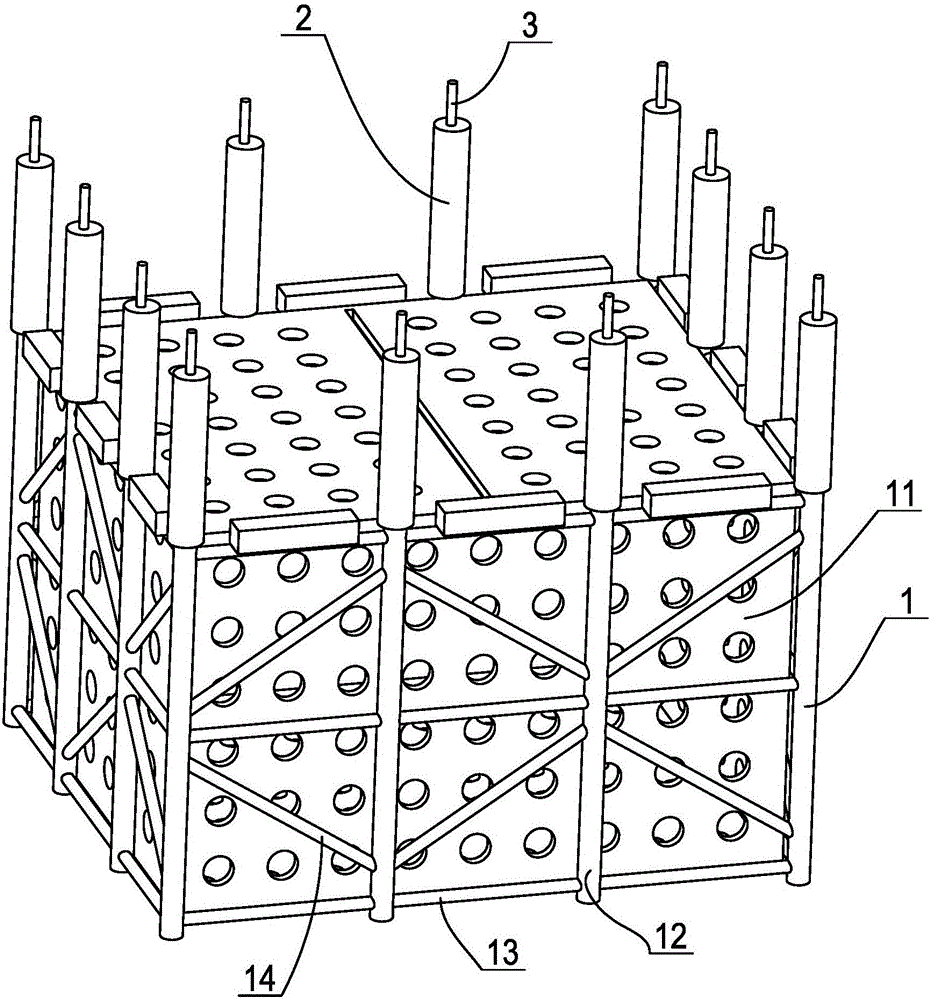

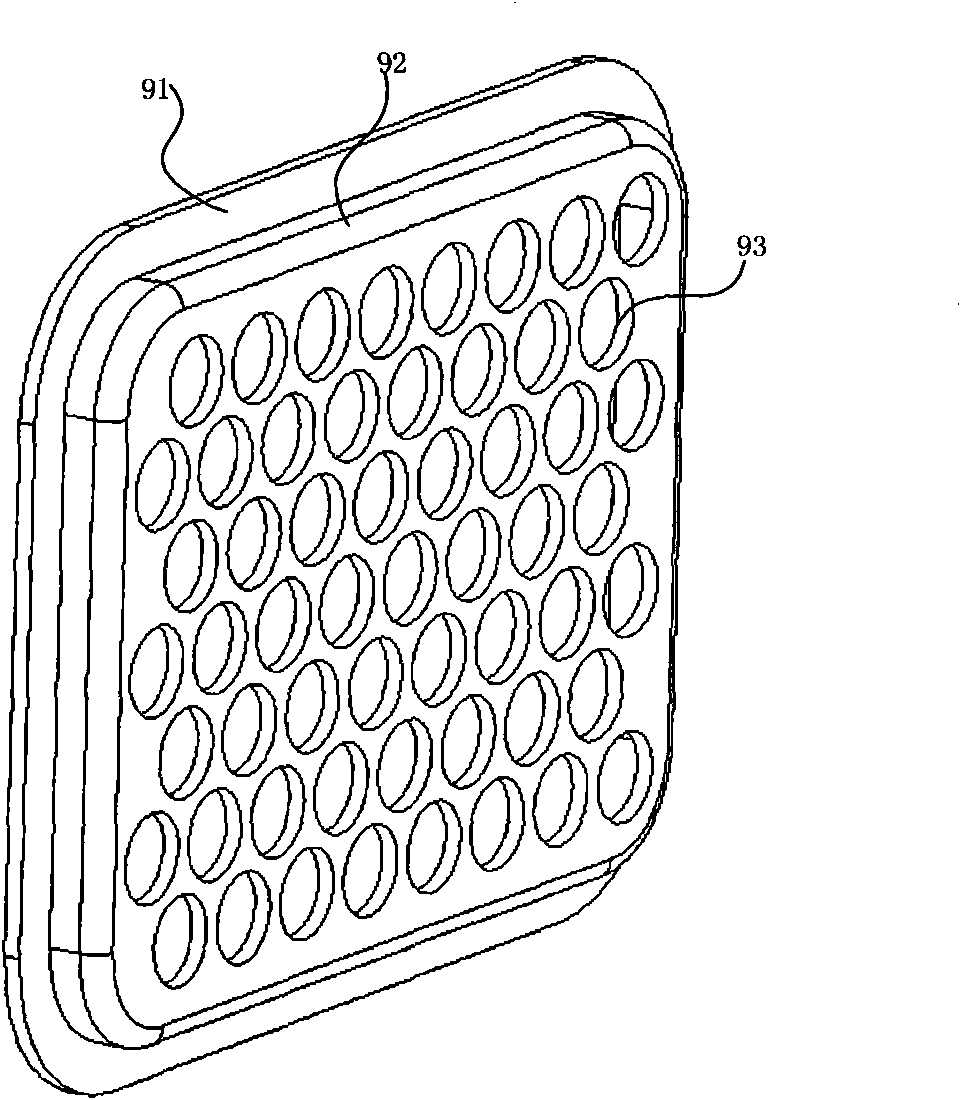

Lifting net cage suitable for marine culture

ActiveCN106818578ADepth adjustmentReduce air pressureClimate change adaptationPisciculture and aquariaMarine cultureMarine aquaculture

The invention discloses a lifting net cage suitable for marine culture. The net cage comprises a plate body. The periphery borders are arranged at the edge of the inner side surface of the plate body. A guide hole is arranged in the center of the plate body. A button rod is arranged in the guide hole in a sliding mode. The end protruding out of the plate body, of the button rod is provided with a reset button. An annular press strip is arranged at the end surface of the periphery borders. An annular sealing groove is formed in the end surface of the annular press strip. Several positioning blind holes are formed in the length direction of the bottom surface in intervals, the positioning blind holes are in the forms of an inverse frustum, an elastic sealing gasket is arranged in the annular sealing groove. A gap exists between the sealing gasket and the side surface of the annular sealing groove. The positions corresponding to the blind holes, of the bottom surface of the sealing gasket are provided with positioning nails which are matched with the positioning blind holes. The positions corresponding to the positioning nails, of the front surface of the sealing gasket are provided with installation blind holes which extend into the positioning nails. The invention brings convenience to the installation of a control panel, guarantees the correct positioning of the sealing gaskets, at the same time, the reset button can flexibly function, and the service life of sealing parts can be prolonged.

Owner:ZHEJIANG OCEAN UNIV

Heat-generating phase-change core-sheath fiber and preparation method thereof

InactiveCN107587207APlay the function of far infrared heatingImprove comfortFilament/thread formingConjugated synthetic polymer artificial filamentsFiberInfrared

The invention discloses a heat-generating phase-change core-sheath fiber and a preparation method thereof. Under infrared ray irradiation, the fiber sheath undergoes light-heat conversion to self-produce heat, in a low temperature environment, the converted heat can be transmitted to the fiber core layer to cause fiber core layer phase change so that a certain effect of automatic compensation of heat dissipated by the core layer is obtained, when the environment temperature is high, the core layer can absorb heat and form a liquid phase so that heat is stored, and when the environment temperature is low, the phase change material of the fiber core layer is changed from the liquid state into a solid state and releases heat so that intelligent temperature regulation is realized. The preparation method can prepare the novel fiber having a far infrared heating function and a core layer thermal insulation function. The fiber can be used for development of a novel fabric material in the fields of active heat-generating thermal insulation, temperature adjustment thermal insulation materials and smart clothing, satisfy multifunctional requirements on two-way temperature adjustment, activetemperature compensation, intelligent thermal conductivity and human health care of the novel fiber material and greatly improve the comfort and environmental temperature adaptability of the traditional clothing.

Owner:SINOPEC YIZHENG CHEM FIBER +1

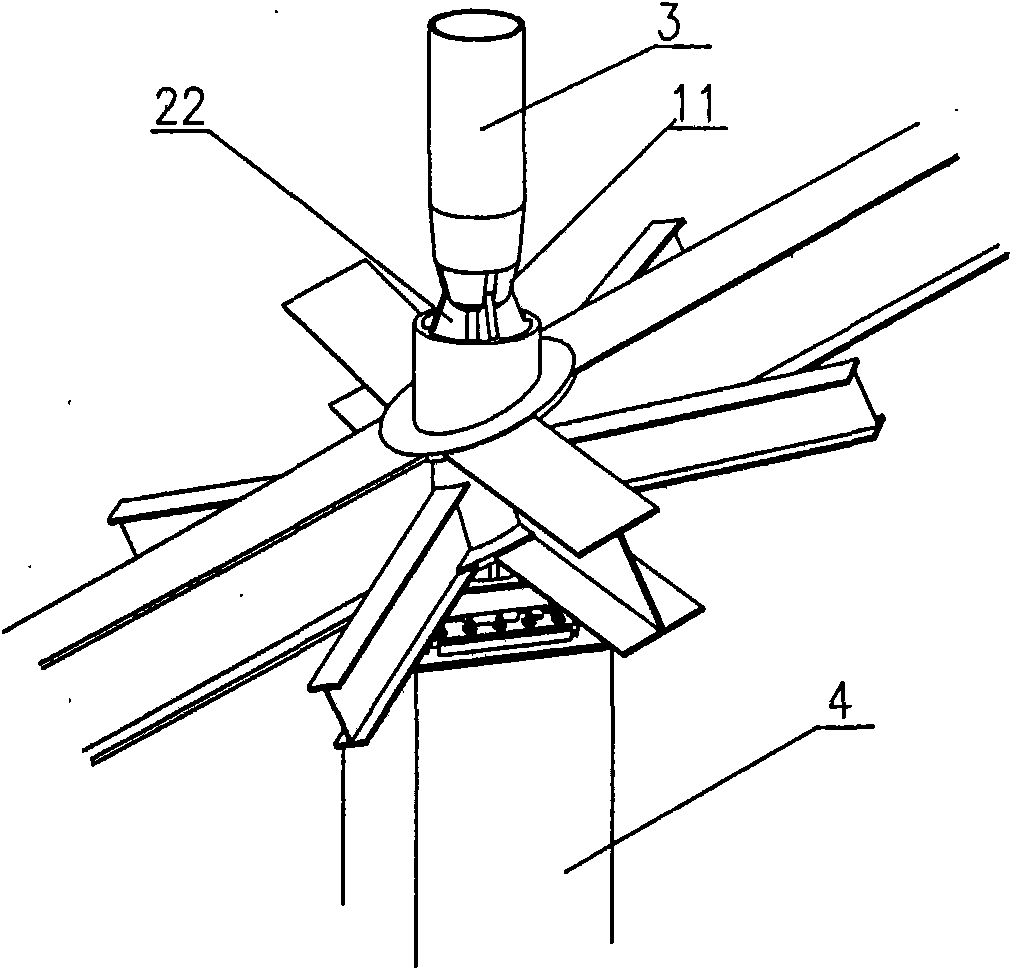

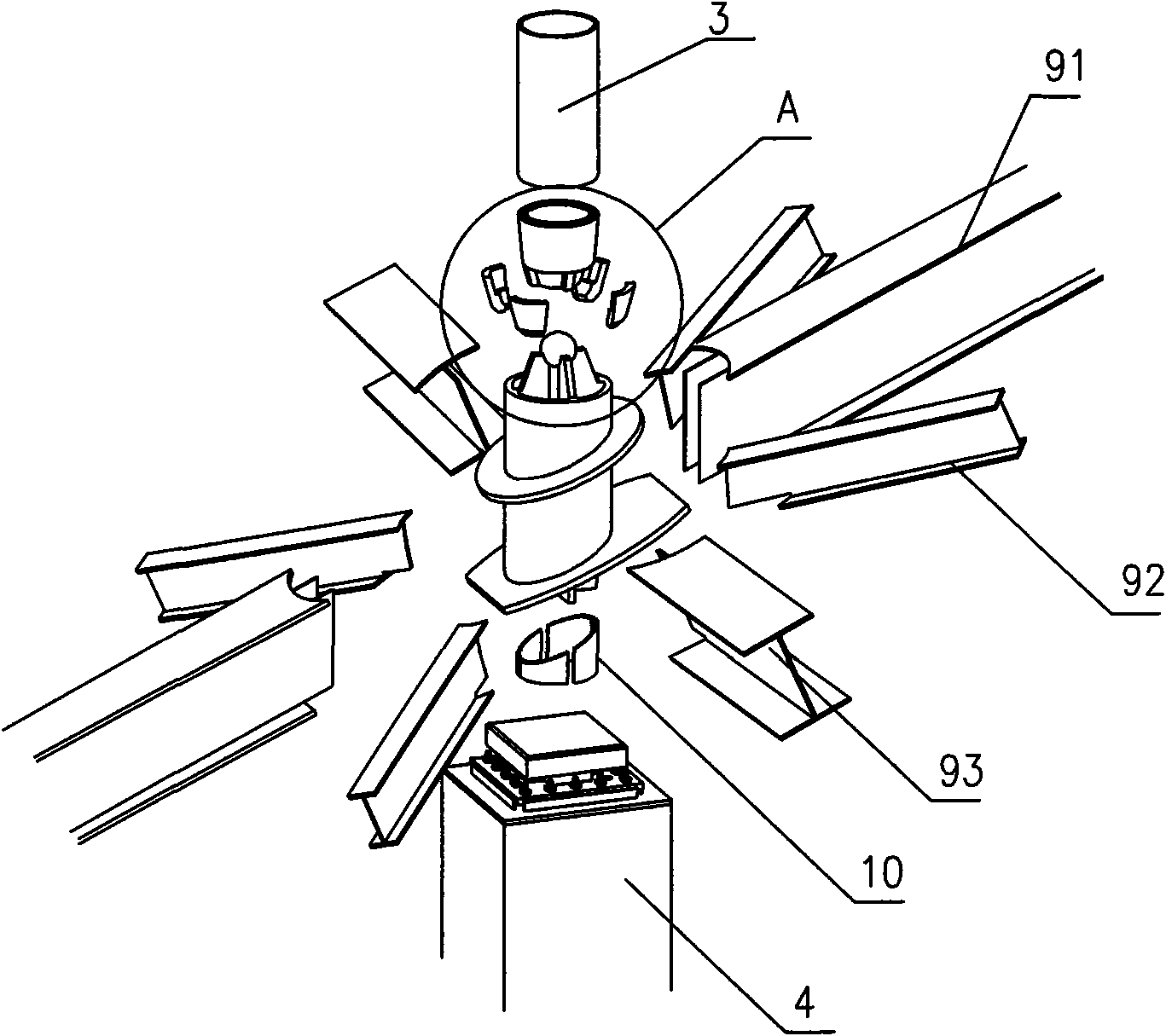

Energy-saving gas conditioning furnace and thermal processing method for hot rolling of seamless steel pipes

InactiveCN102094114AIncrease productionHeating evenlyFurnace typesHeat treatment furnacesTemperature controlElectrical control

The invention relates to an energy-saving gas conditioning furnace and thermal processing method for the hot rolling of seamless steel pipes, which belongs to the field of thermal processing of seamless steel pipes and specifically relates to a gas conditioning furnace and process capable of implementing quenching and tempering processes of seamless steel pipes. The gas conditioning furnace comprises a kiln body (11) and a roller way transmission part, and is characterized in that the front end of the kiln body (11) is provided with an automatic feeding device (5), both sides of the kiln body(11) are respectively provided with the roller way transmission part and a temperature control device, and an electrical control device is arranged outside the kiln body (11). The method comprises the following steps: moving seamless steel pipes into the kiln body (11) by means of the automatic feeding device (5), gradually and sufficiently heating in the kiln body (11), quickly moving the seamless steel pipes (9) into a straightener by means of a quick transmission device, and performing straightening and quenching procedures. By adopting gas heating, electric power consumption is reduced, so that the production scale can be expanded; the kiln body ensures that the seamless steel pipes can be sufficiently and uniformly heated in the kiln body; the seamless steel pipes can be quickly discharged from the kiln body by the quick transmission device, thereby satisfying the optimal temperature required for the quenching and tempering processes; and the invention has the advantages of shortaverage time for finishing the conditioning process, low cost and the like.

Owner:SHANDONG ZHENGCHANG COAL MACHINERY

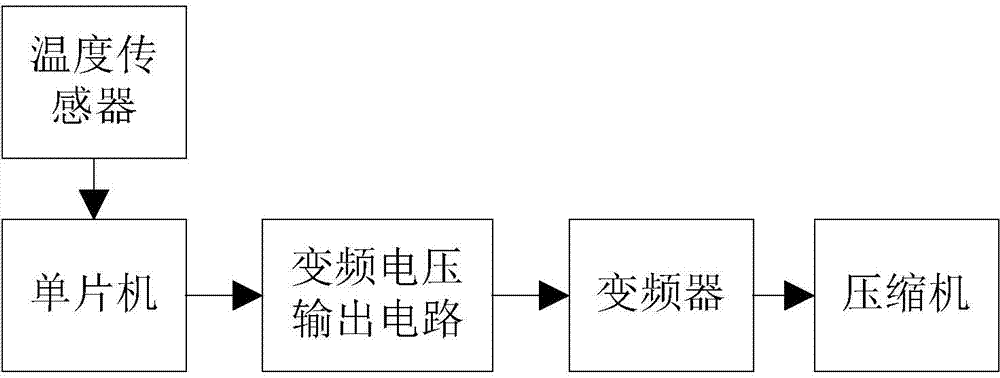

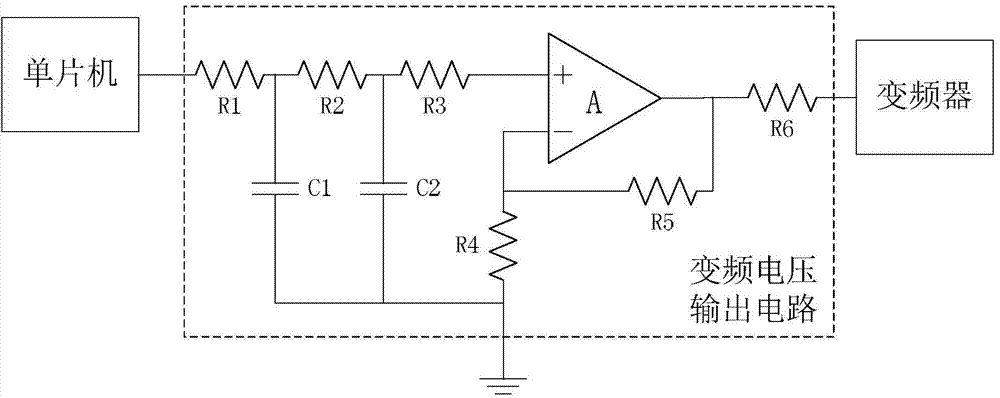

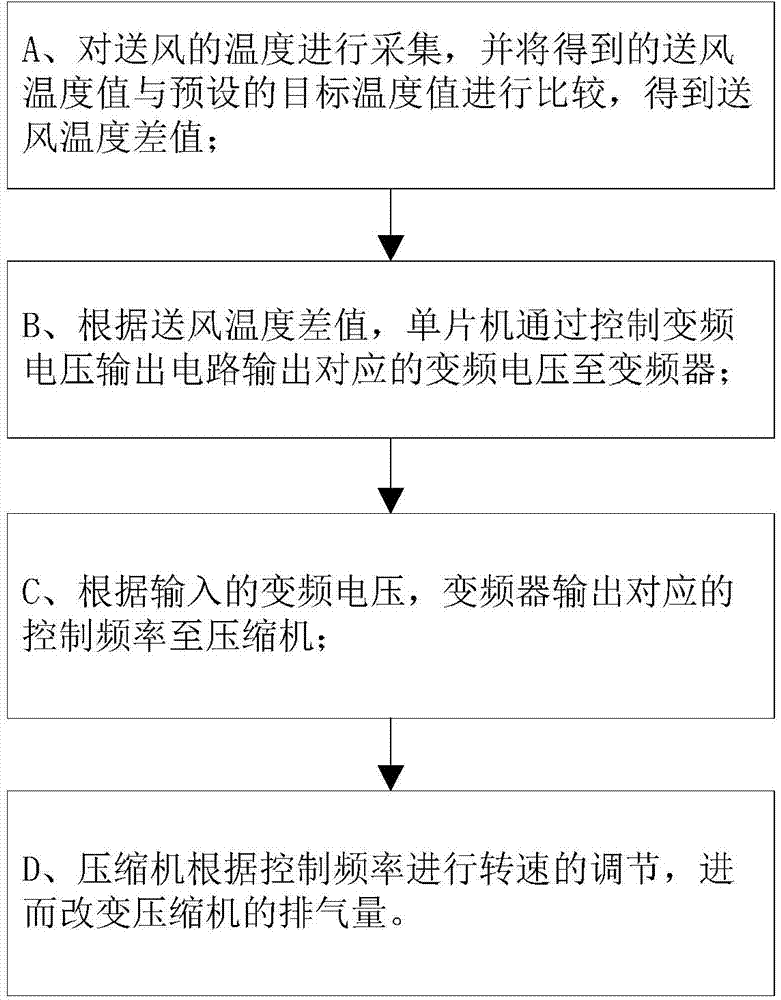

Variable-frequency control system and variable-frequency control method for heat pump

ActiveCN104266424AReduce power consumptionSimple circuit connectionRefrigeration safety arrangementVariable frequency controlFrequency changer

The invention discloses a variable-frequency control system and a variable-frequency control method for a heat pump. The system comprises a temperature sensor, a single chip, a variable-frequency voltage output circuit, a frequency converter and a compressor, wherein the output end of the temperature sensor sequentially passes through the single chip, the variable-frequency voltage output circuit and the frequency converter and then is connected with the output end of the compressor. The method comprises the following steps of: acquiring an air supply temperature, and comparing the obtained air supply temperature value with a preset target temperature value to obtain an air supply temperature difference value; outputting a corresponding variable-frequency voltage to the frequency converter by the single chip through controlling the variable-frequency voltage output circuit; outputting a corresponding control frequency to the compressor by the frequency converter according to the input variable-frequency voltage; adjusting a rotational speed by the compressor according to a control frequency, and then changing the gas displacement of the compressor. The system and the method disclosed by the invention meet the needed temperature, and are capable of effectively reducing the power consumption generated during the running of a unit, and capable of being widely applied to the field of variable-frequency technologies for heat pumps.

Owner:GUANGDONG PHNIX ECO ENERGY SOLUTION

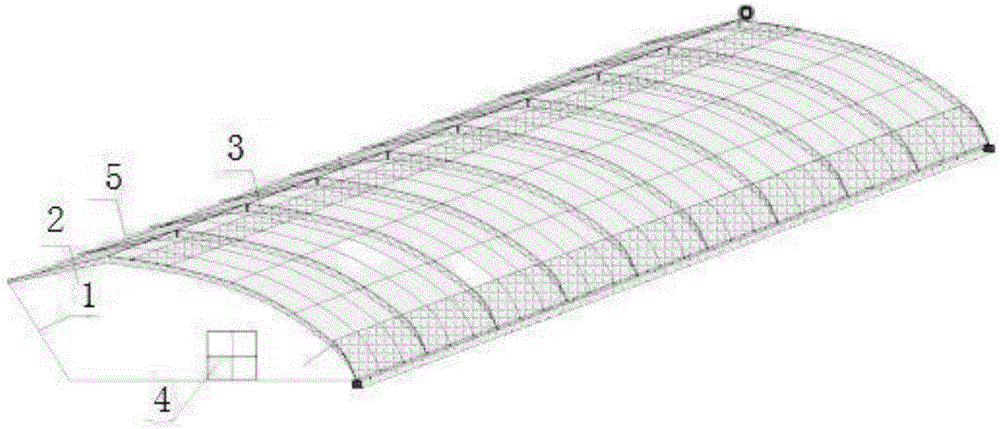

Greenhouse and application thereof in fruit tree cultivation

InactiveCN106069366AReduce construction costsSolve the problem of facility constructionClimate change adaptationGreenhouse cultivationFruit treeGreenhouse

The invention discloses a greenhouse, and belongs to the technical field of agricultural facilities and fruit tree cultivation. The greenhouse comprises a back mud wall, side walls arranged on the two sides of the back mud wall and a greenhouse framework. The invention further discloses a method for cultivating fruit trees through the greenhouse. The method comprises the steps of how to cultivate and manage the fruit trees through the greenhouse in seven growth and development periods of fruit tree growth. By applying the greenhouse and the cultivation method to cultivate the fruit trees, high-quality ecological fruits can be produced, the greenhouse building cost can be greatly reduced, and the purposes of high-quality fruit tree cultivation and high yield are achieved.

Owner:云南省农业科学院园艺作物研究所

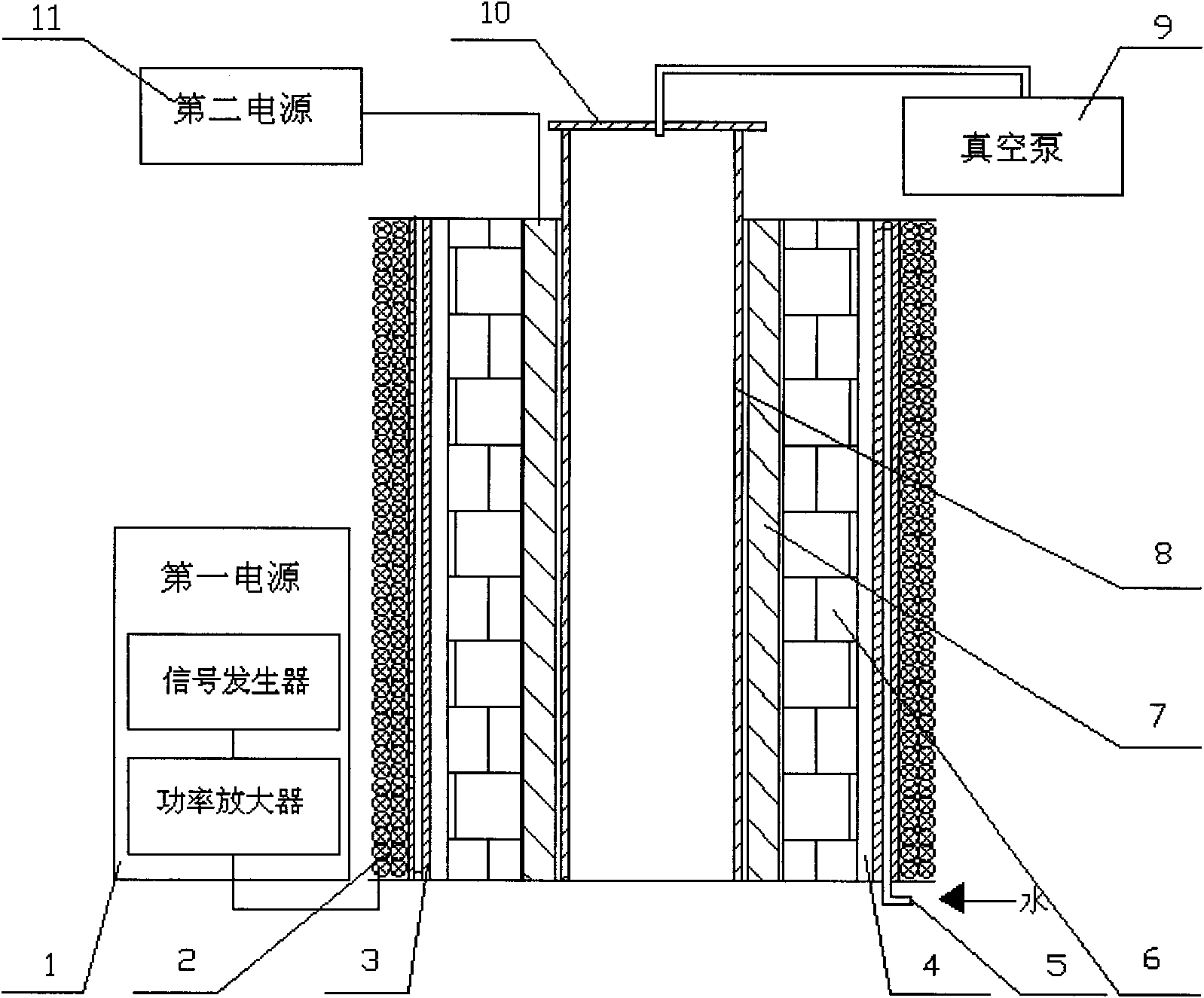

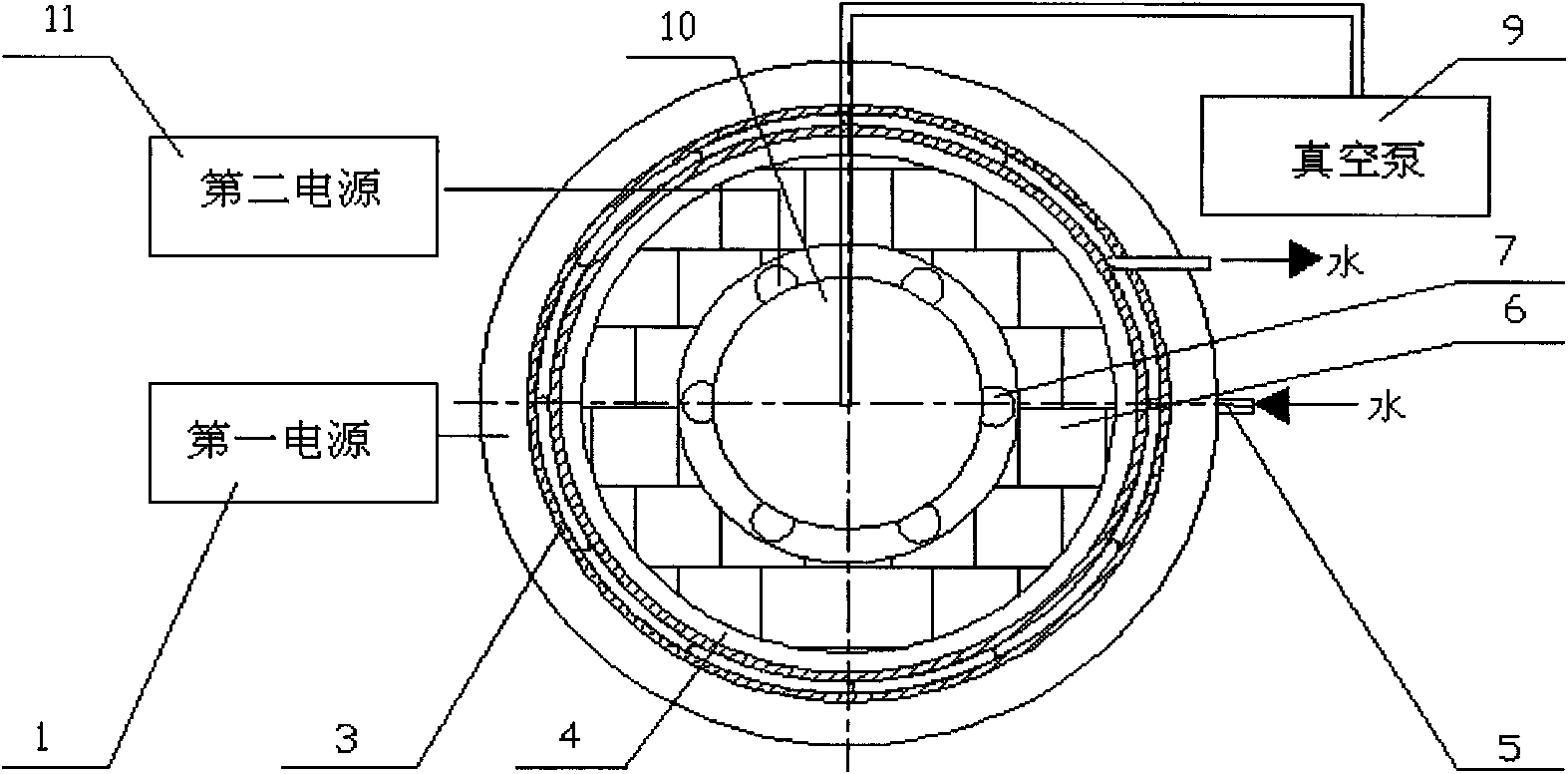

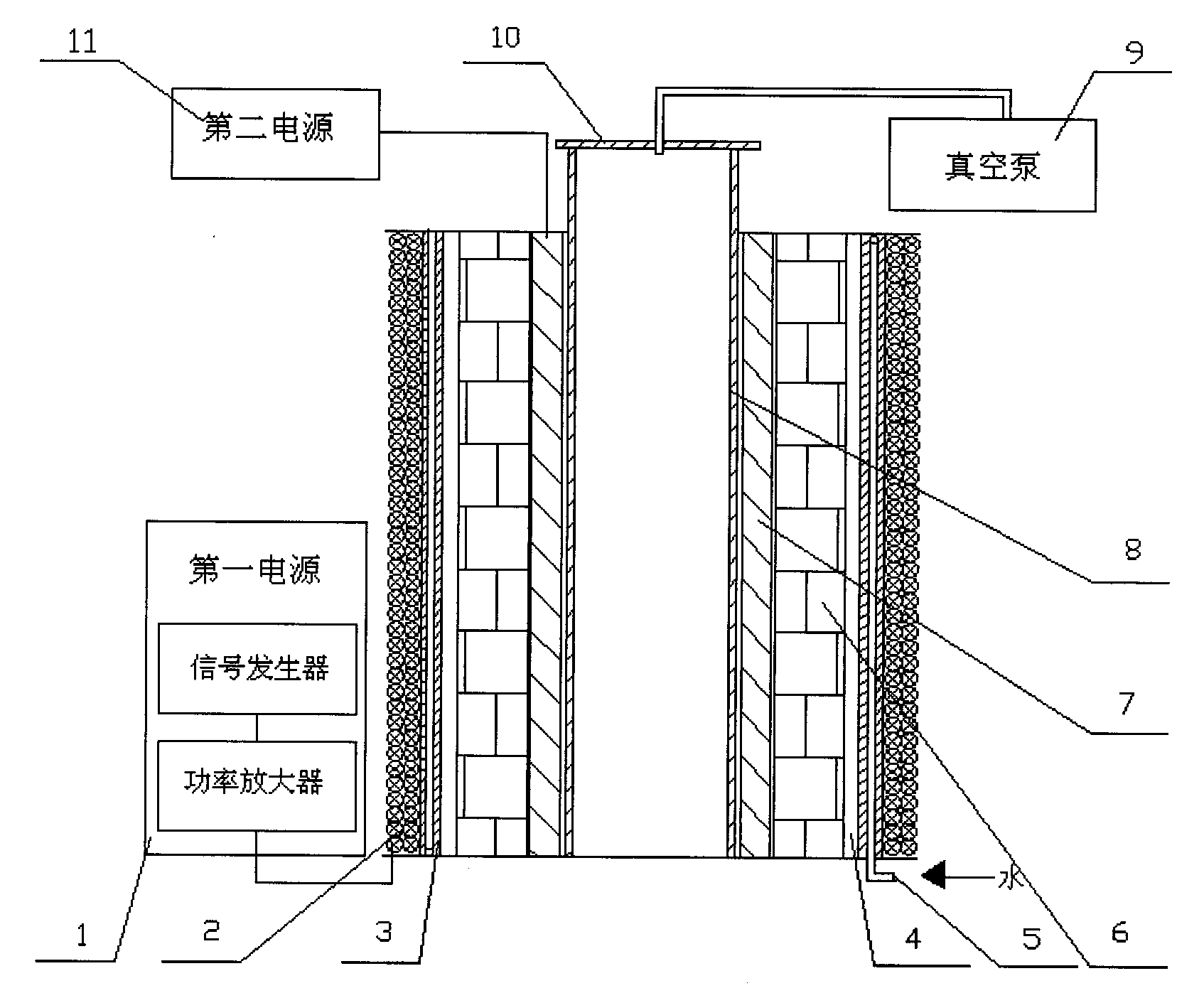

High-temperature atmosphere furnace with electromagnetic field

InactiveCN101881555APlay the role of heat insulationTemperature rises steadilyMuffle furnacesRetort furnacesElectricityInsulation layer

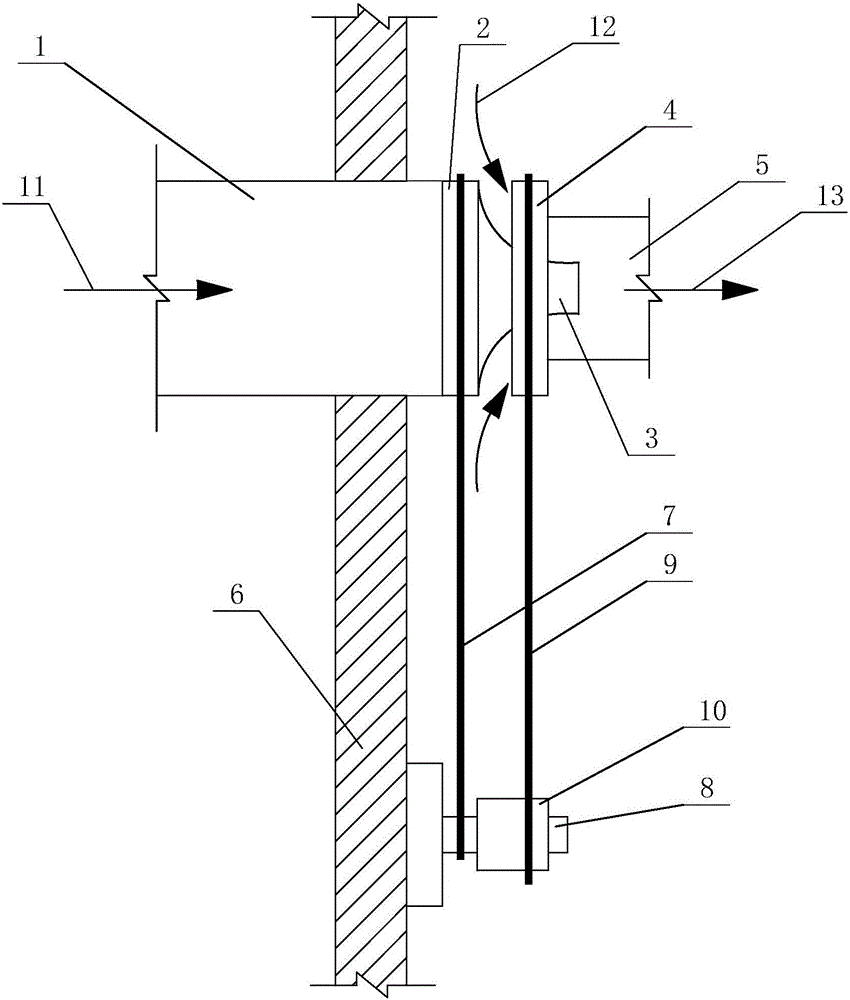

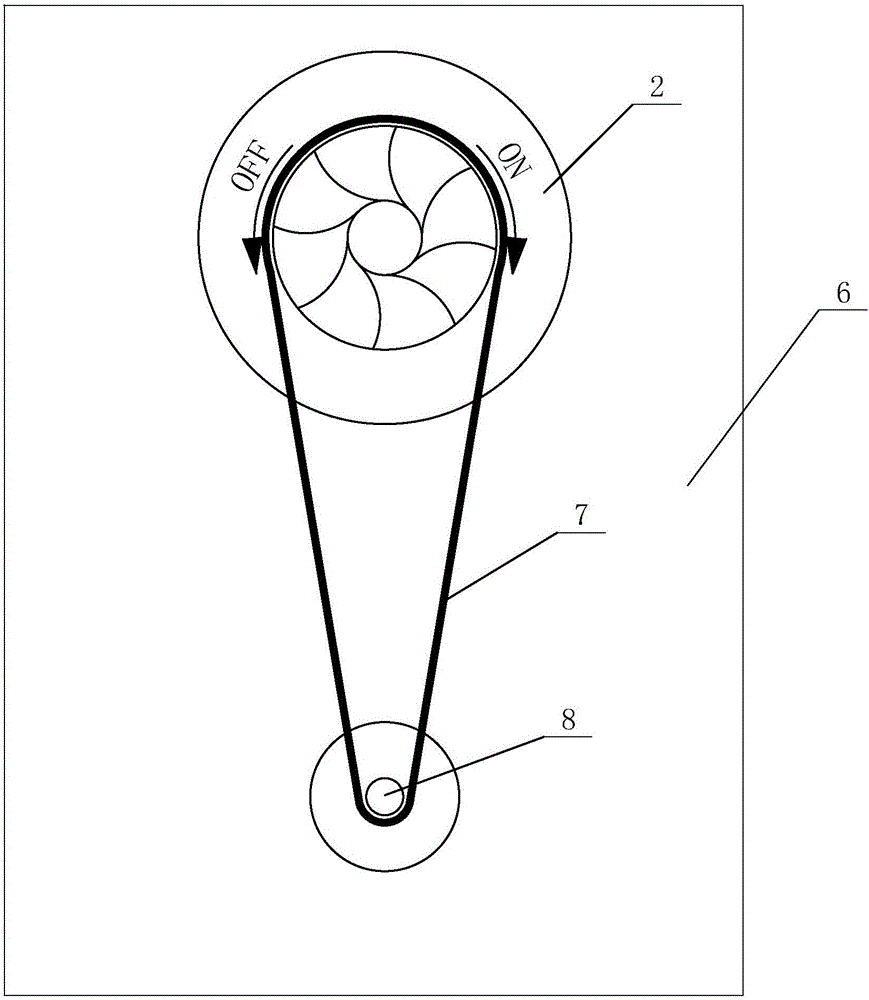

The invention relates to a high-temperature atmosphere furnace with an electromagnetic field. The technical scheme is that the high-temperature furnace comprises a first power supply 1, a coil 2, a furnace shell 3, a heat insulation brasque 6, heating elements 7, a furnace hearth 8 and a vacuum pump 9, wherein the furnace shell 3 is an interlayer shell which is internally provided with a cooling water pipe 5, the external wall of the furnace shell 3 is wound with the coil 2, the coil 2 is electrically connected with the first power supply 1, an air heat insulation layer 4 is arranged between the inner wall of the furnace shell 3 and the external wall of the heat insulation brasque 6, 4-8 heating elements 7 are respectively arranged in the inner wall of the heat insulation brasque 6 and the external wall of the furnace hearth 8, the heating elements 7 are connected with a second power supply 11, the upper end of the furnace hearth 8 is provided with a furnace cover 10 with cold water, and the vacuum pump 9 is communicated with the furnace hearth 8 through the furnace cover 10 with cold water through a passage. The invention can control the atmosphere by the adjustable electromagnetic field, has the temperature of 1800 DEG C, and can meet the requirements of smelting and material industry to the electromagnetic field, temperature and different atmosphere.

Owner:WUHAN UNIV OF SCI & TECH

Air outlet device capable of adjusting induced fresh air system

ActiveCN105674465AReduce the temperatureReduce humidityDucting arrangementsLighting and heating apparatusPositive pressureEngineering

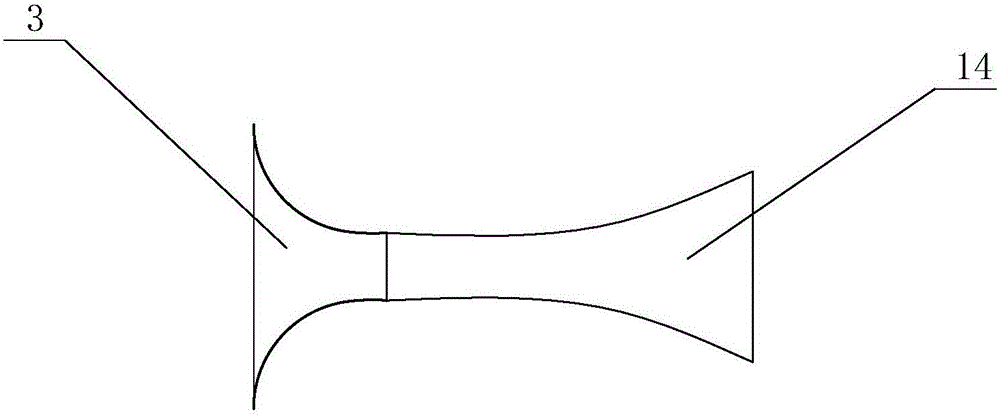

The invention discloses an air outlet device capable of adjusting an induced fresh air system. The air outlet device comprises a fresh air duct, a first iris valve, a first conical nozzle, a second iris valve and a mixed air duct, wherein the inner diameter at the air outlet end of the first conical nozzle is smaller than that of the air inlet end of the first conical nozzle. According to the air outlet device, outdoor air ejected from the first conical nozzle is fully and evenly mixed with indoor air of negative pressure backflow through the induced injection principle, and then the mixed air is exhausted indoors, so that the temperature and humidity of original outdoor air are lowered or increased; mixed gas has appropriate temperature and humidity, and therefore discomfort caused by the air outlet mode of an original positive pressure type fresh air system is reduced, and practicability of the air outlet device is improved.

Owner:禹城市瑞诚新能源科技有限公司

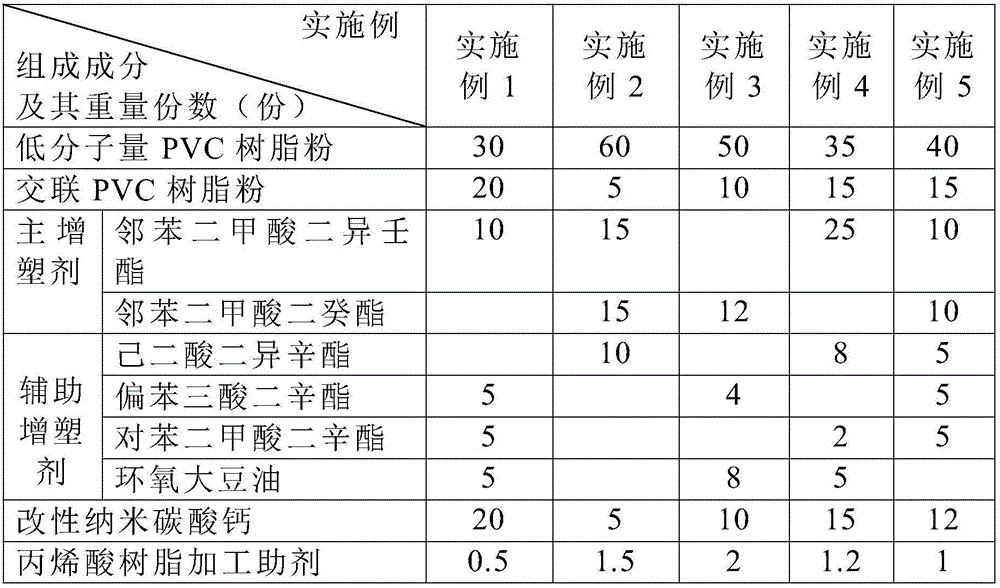

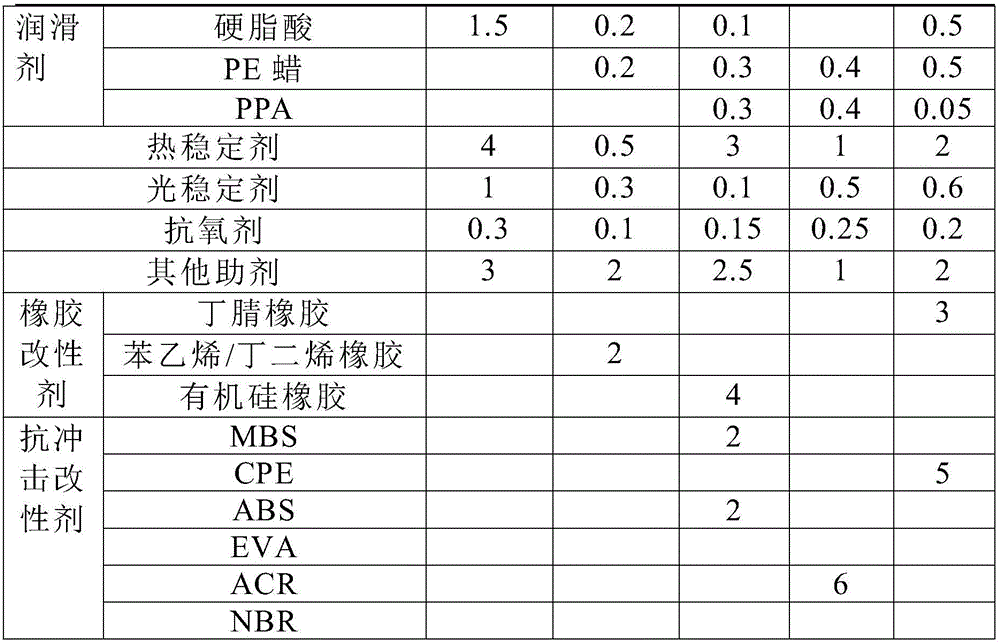

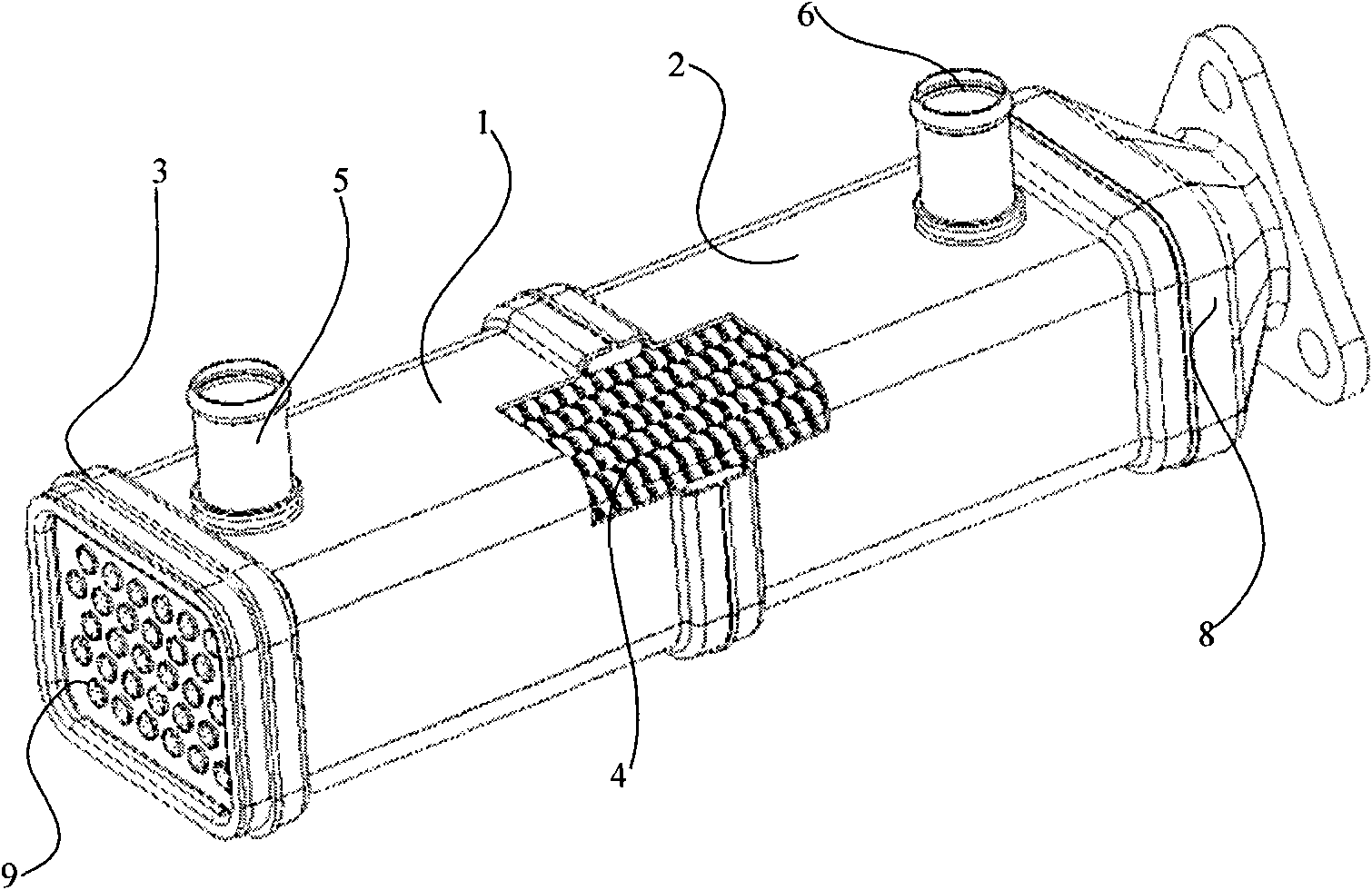

Injection molding grade PVC composite material high in mobility and melt strength

The invention relates to an injection molding grade PVC composite material high in mobility and melt strength and belongs to the technical field of macromolecules. The composite material comprises, by weight parts, 30-60 parts of low molecular weight PVC resin powder, 5-20 parts of crosslinking PVC resin powder, 10-30 parts of main plasticizer, 10-20 parts of secondary plasticizer, 0.5-20 parts of nano calcium carbonate, 0.5-2 parts of high melt strength processing agent, 0.4-1.5 parts of lubricant, 0.5-4 parts of heat stabilizer, 0.1-1 part of light stabilizer, 0.1-0.3 part of antioxidant and 1-3 parts of other auxiliaries. Melt strength and mechanical properties of the PVC composite material are improved while high mobility is guaranteed. The injection molding grade PVC composite material can adapt to injection molding products of various sizes and shapes and can meet requirements of low plastic temperature and short plastic cycle.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

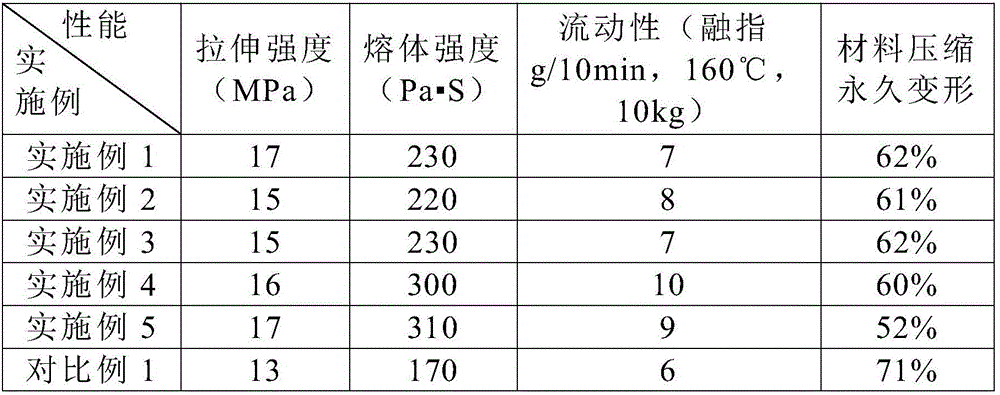

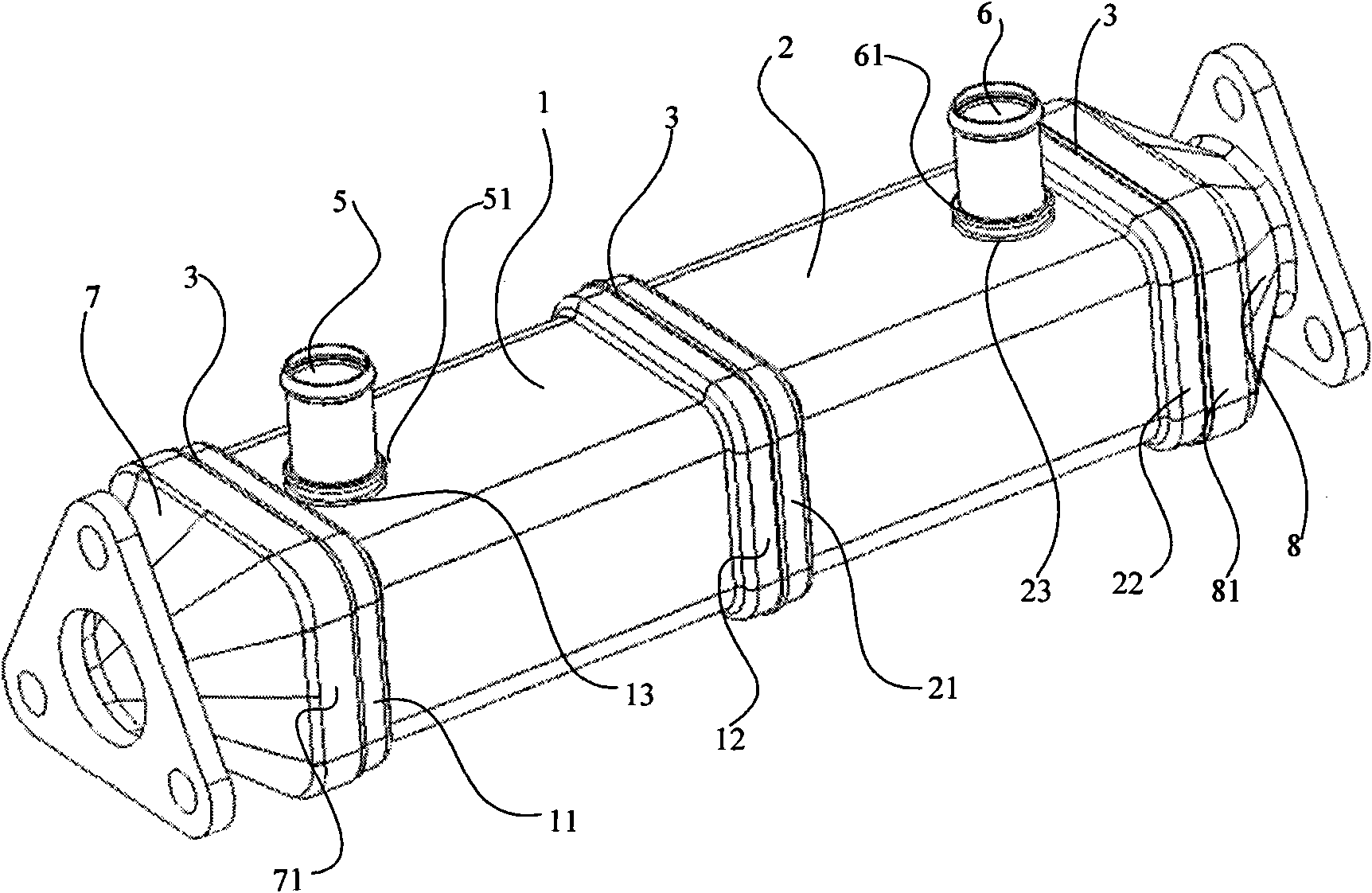

Exhaust gas recirculation cooler for medium and heavy-duty vehicle with ridge ring

ActiveCN101576029AIncrease productivitySuitable for mass productionInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesEngineering

The invention relates to an exhaust gas recirculation cooler for medium and heavy-duty vehicles with ridge rings, comprising a pipe shell, two pipe plates arranged at two ends of the pipe shell, and a water inlet pipe and a water outlet pipe that are arranged on the side surface of the pipe shell; a plurality of heat exchanging pipes for circulating exhaust gas are arranged between two pipe plates at two ends of the pipe shell; two pipe plates are connected with an air inlet pipe box and an air outlet pipe box respectively; the pipe shell is enclosed by the metal plates with the thickness less than 2mm; the section of the pipe shell is a rectangle and the exterior thereof is also a rectangle; the pipe shell is connected by a single section or multi-sections; the total appearance length of the single-section pipe shell or the multi-section pipe shell is more than 1 time of the width or height; and the ridge rings are used for connecting the pipe shell and the air inlet pipe box or the air outlet pipe box and connecting all pipe shell sections of the multi-section pipe shell. The cooler connects the fission pipe shells and the pipe shell and the pipe box by ridge rings, thus leading the strength of the cooler to be increased and the structural design to be compacter, and improving the whole performance. As the cooler is provided with the ridge rings, the assembly difficulty is reduced and the processing precision is improved simultaneously.

Owner:辽宁联友博科技有限公司

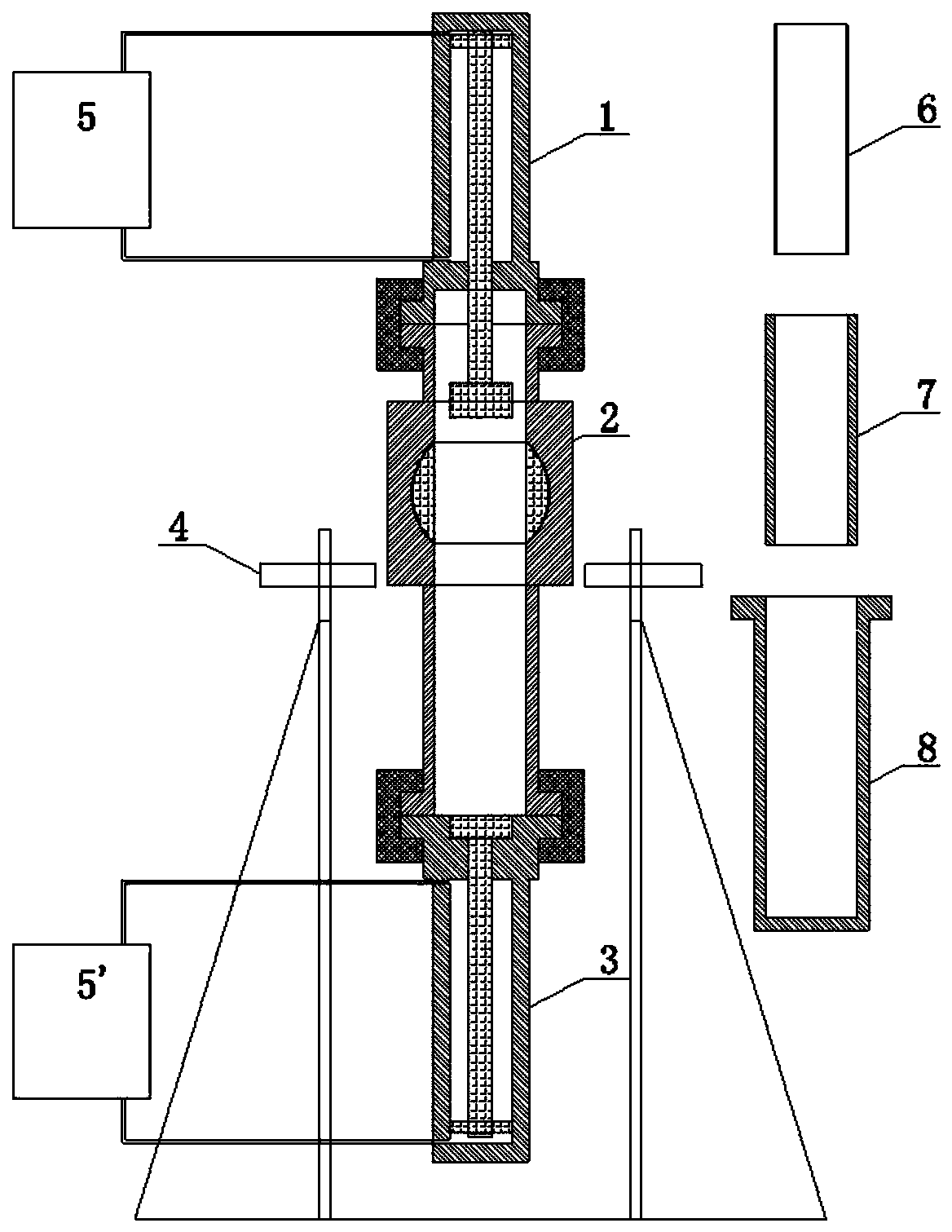

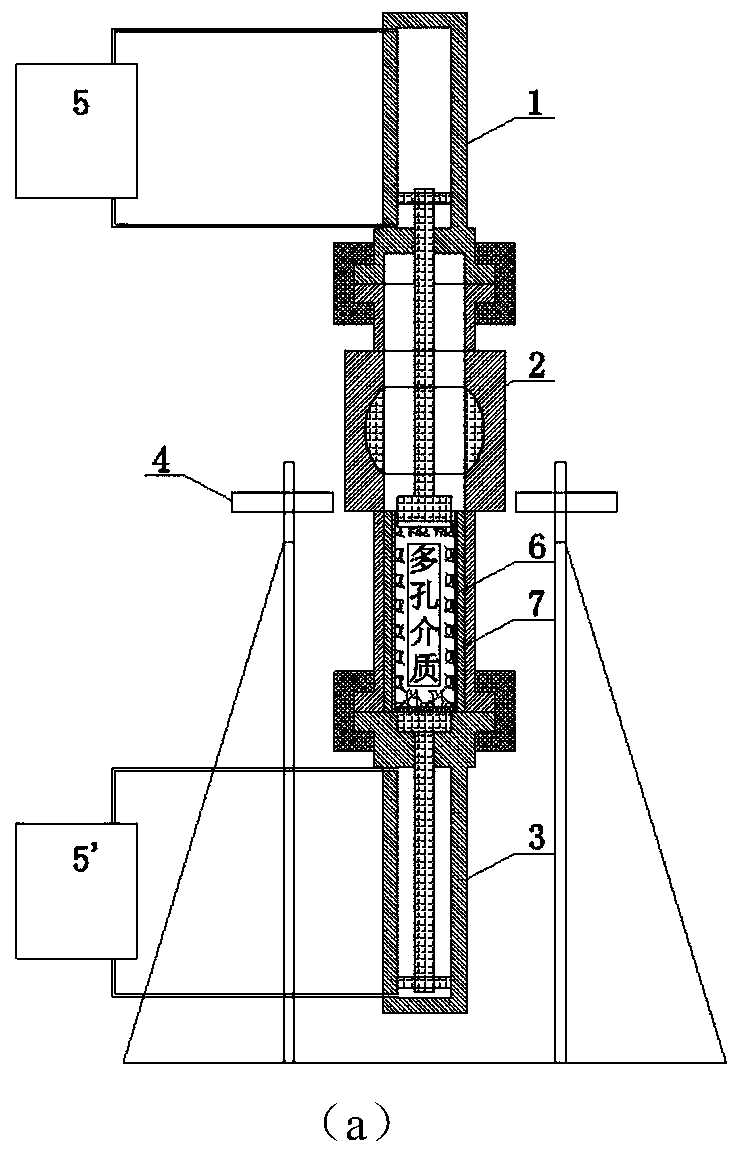

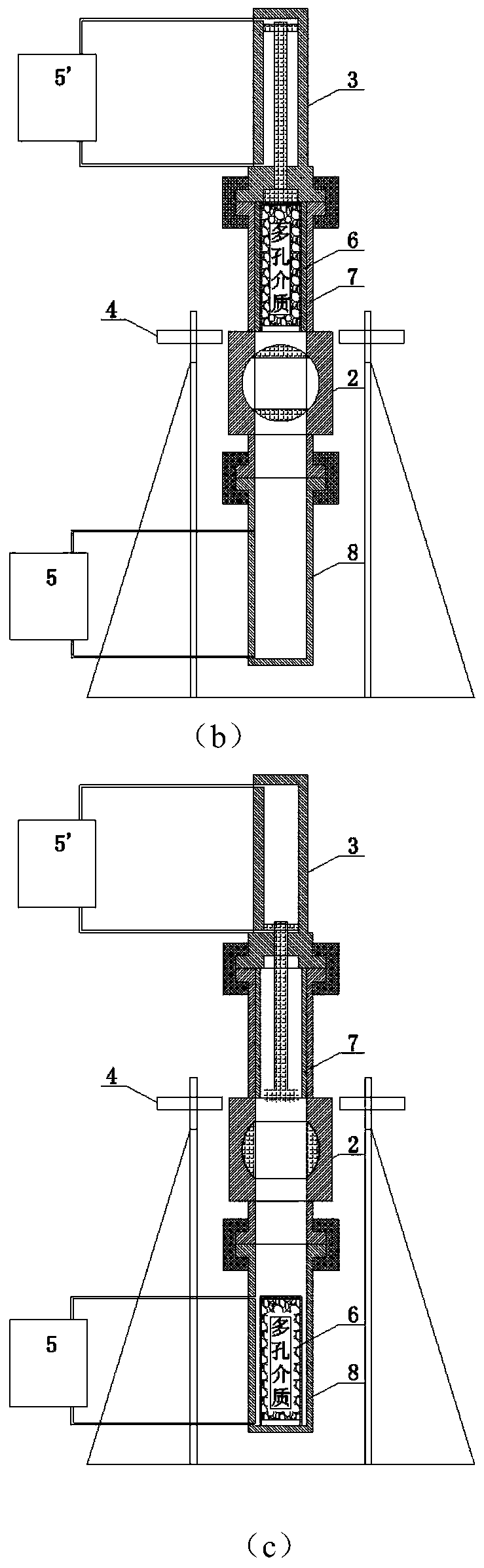

Device and method capable of generating natural gas hydrate through confining pressure and transferring and decomposing under pressure maintaining

The invention discloses a device and a method capable of generating natural gas hydrate by confining pressure and carrying out pressure-maintaining transfer decomposition. The device comprises a reaction kettle capable of simulating natural gas hydrate generation and pressure maintaining transfer under the stratum confining pressure condition, the bottom of the reaction kettle is connected with asecond two-way hydraulic cylinder, a pressure maintaining ball valve with the same drift diameter as the inner diameter of the kettle is arranged at the top end of the reaction kettle, and the other end of the pressure maintaining ball valve is connected with a first two-way hydraulic cylinder; the first bidirectional hydraulic cylinder and the second bidirectional hydraulic cylinder are respectively connected with a hydraulic station; and the reaction kettle is fixed on a support capable of rotating up and down at 180 degrees. The device can be used for simulating and generating the natural gas hydrate under the stratum confining pressure condition, pressure maintaining transfer of the natural gas hydrate is achieved, decomposition visualization of the natural gas hydrate is achieved, andmore real, more comprehensive and lower-cost guidance is provided for decomposition research of the natural gas hydrate.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Device and method for leakage volume detection simulating oil well pump work environment

InactiveCN107246262APrecise temperature controlMeet the temperatureConstructionsWater storage tankThermal insulation

The invention provides a device and a method for leakage volume detection simulating oil well pump work environment. The device comprises a sliding support, a wellbore simulation system, a fluid supply system, and a thermal insulation system. The sliding support can realize to measure corresponding static leakage volume of an oil well pump. The wellbore simulation system is characterized by simulating a wellbore. A simulated wellbore is internally provided with a to-be-checked oil well pump, and a liquid inlet is connected with a metering device. The fluid supply system comprises a thickened oil tank, a thin oil tank, a water storage tank, and a gas storage tank. The thickened oil tank, the thin oil tank, and the water storage tank are connected with a booster pump, a liquid flowmeter, a switch valve, and a liquid inlet pipeline in sequence. The booster pump increases liquid pressure to pressure of the inlet of the oil well pump. The gas storage tank is connected with a gas flowmeter and a switching valve in sequence, and is communicated with the liquid inlet pipeline. The tail end of the pipeline is connected with an air release valve. The thermal insulation system provides a power supply through a distribution box, a temperature controller adjusts temperature, and the system is connected with the simulated wellbore through a cable. The device and the method can measure leakage volume under real formation environment of the oil well pump by simulating complex formation fluid.

Owner:SOUTHWEST PETROLEUM UNIV

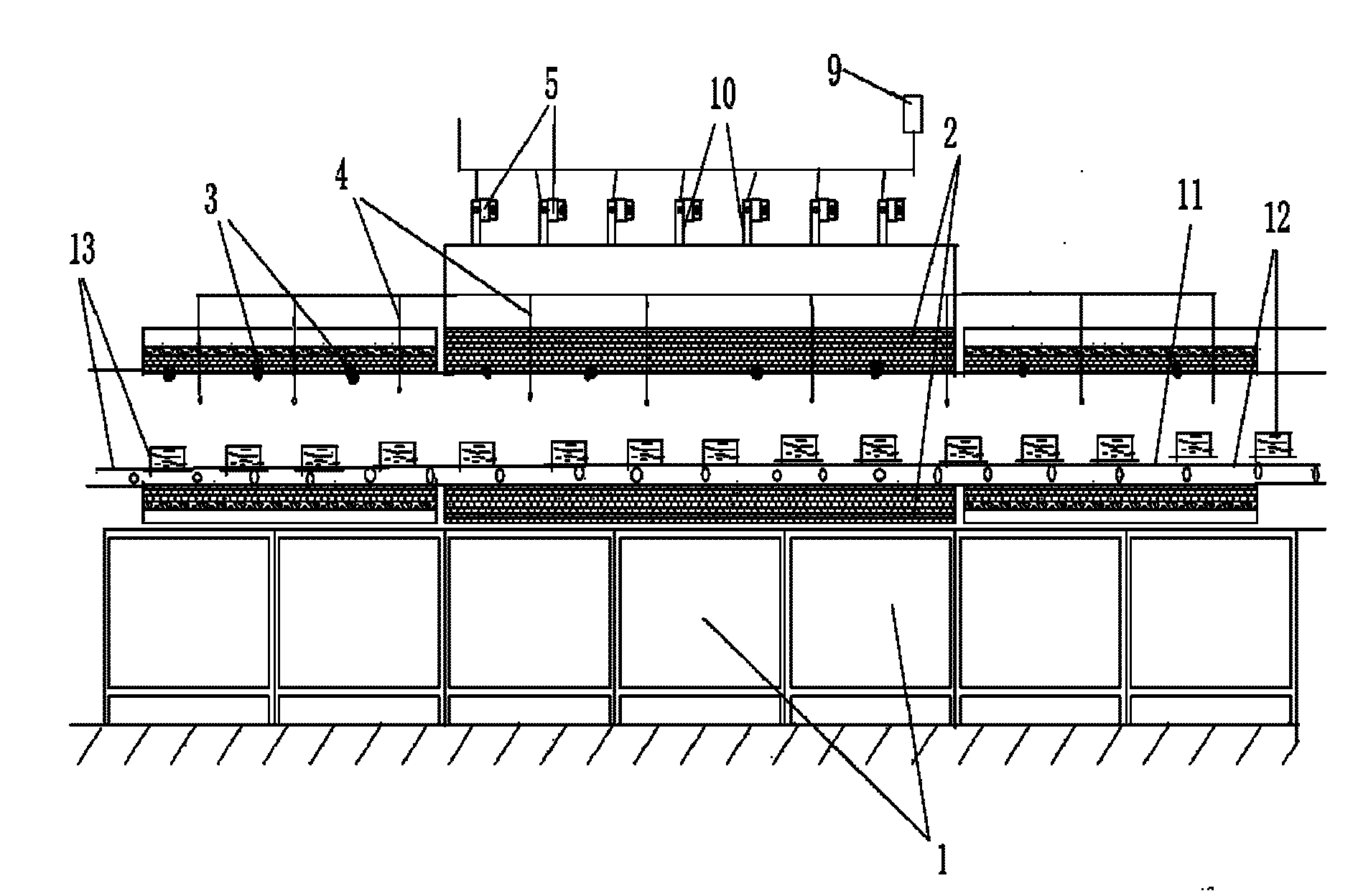

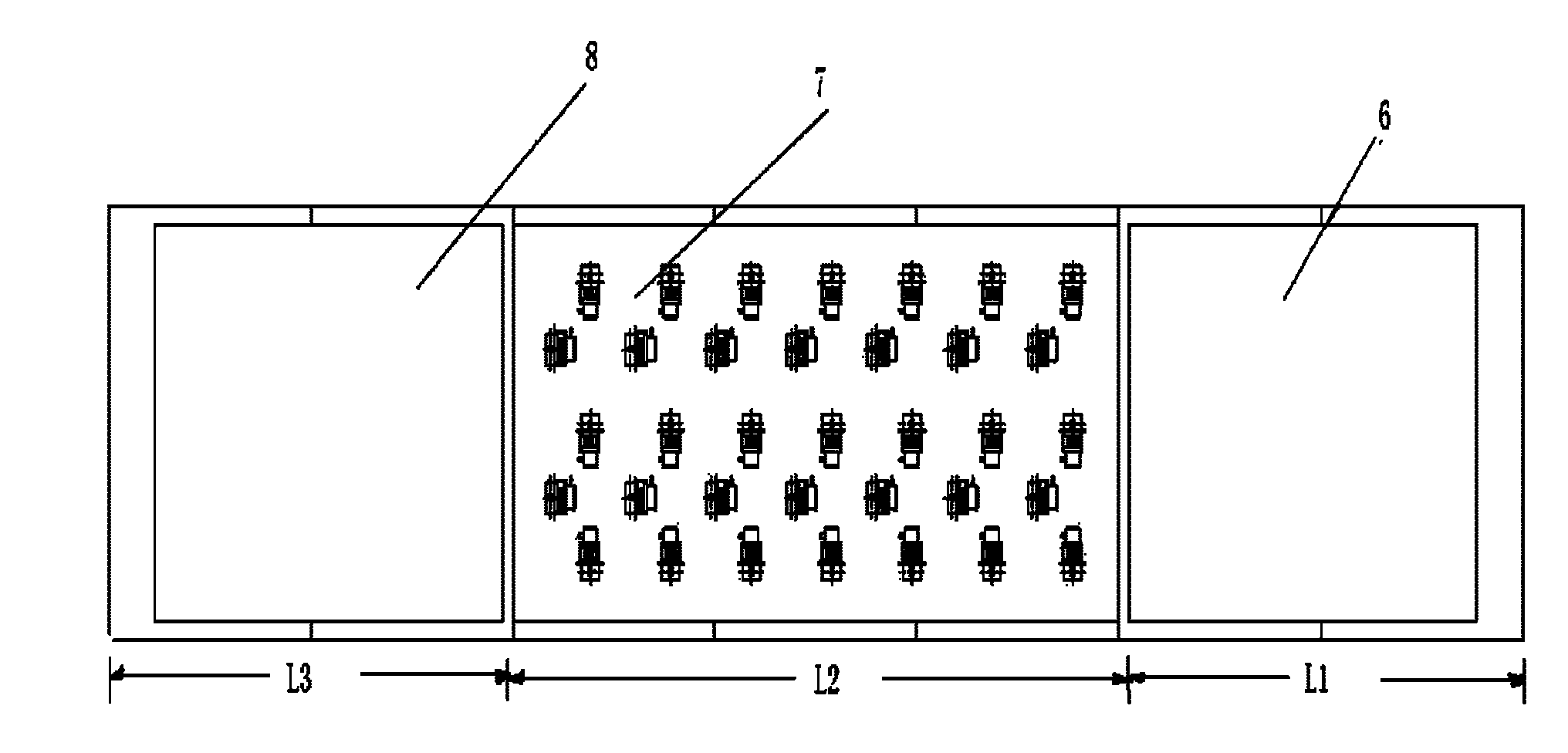

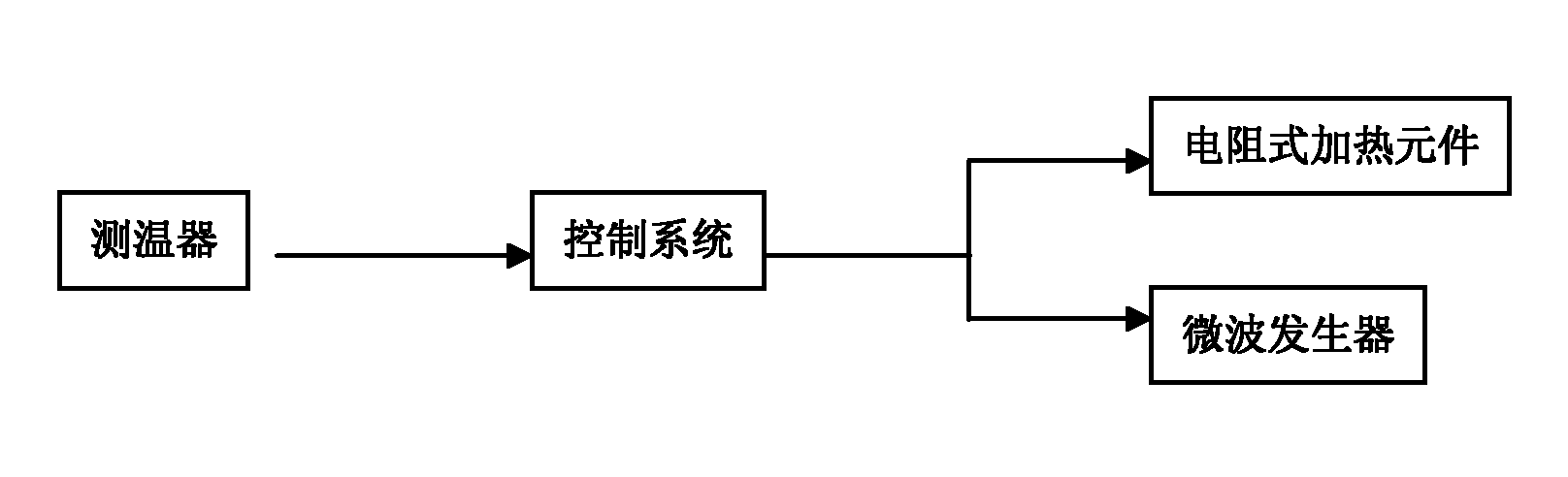

Continuous type microwave auxiliary sintering furnace and method

InactiveCN102243020AAdjustable cooling speedPrevent leakageFurnace typesElectric heating for furnacesMetallurgyControl system

The invention relates to a continuous type microwave auxiliary sintering furnace which comprises a furnace body, a temperature detector arranged in the furnace body, a material transmission device installed in the furnace body, a water-cooling heat-removal system and a control system, wherein the water-cooling heat-removal system and the control system are arranged outside the furnace body; the furnace body is successively composed of a first microwave choke section, a microwave auxiliary heating section and a second microwave choke section, resistance-type heating elements are installed in the furnace body walls of the first microwave choke section and the second microwave choke section, a resistance-type heating element is installed in the furnace body wall of the microwave auxiliary heating section, and microwave generators are installed on the exteriors of the furnace body walls. The invention discloses a continuous type microwave auxiliary sintering method which comprises the following steps: drying the furnace body of each section by virtue of electrical heating, and heating the microwave auxiliary heating section until the temperature is below 50-100 DEG C required for sintering a sintered material; carrying out microwave heating and the electrical heating until the temperature of the microwave auxiliary heating section is increased to the temperature required for sintering the sintered material and keeping the temperature constant; and then sintering the material.

Owner:CHENGDU JINGYUAN NEW MATERIALS TECH

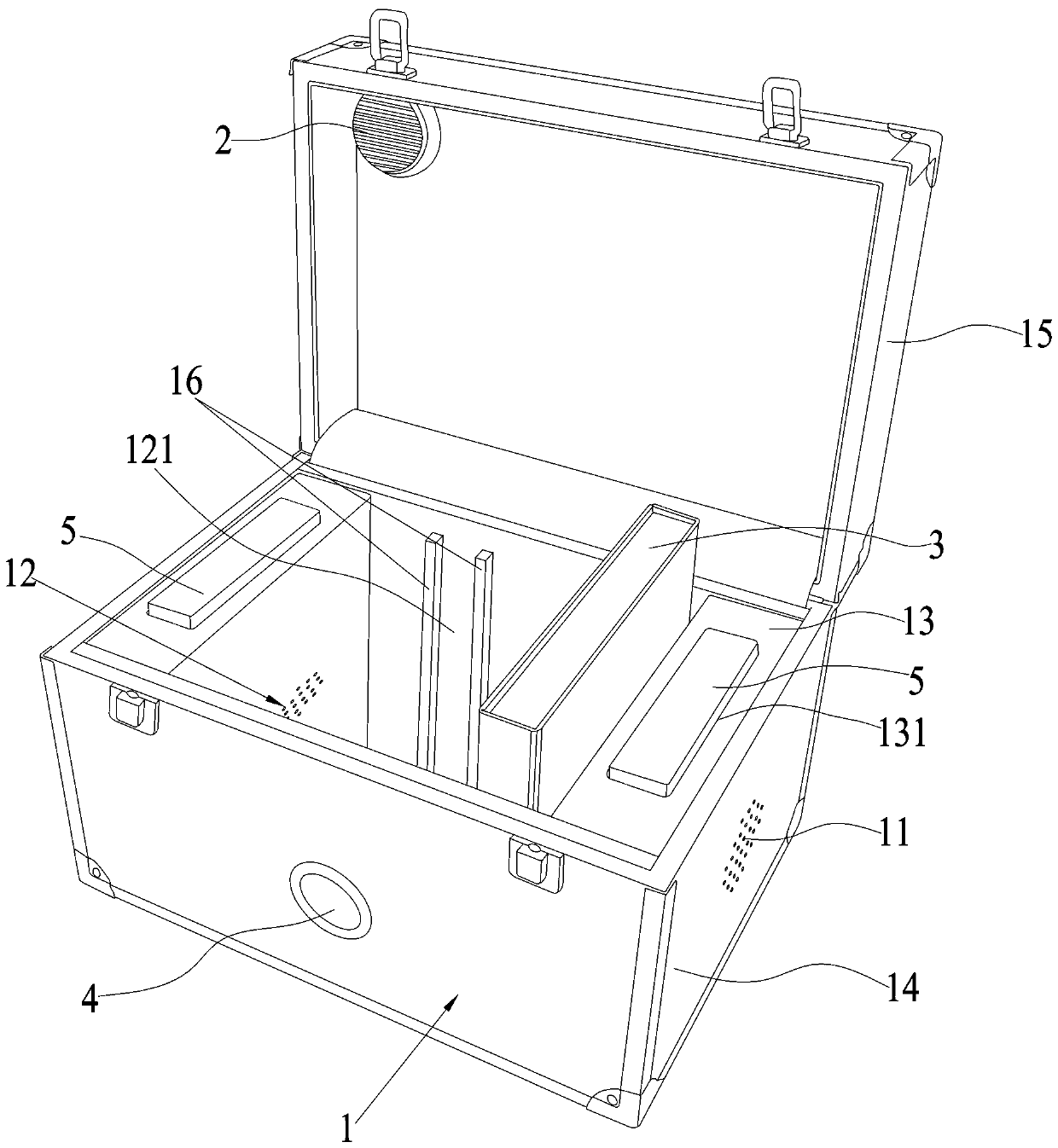

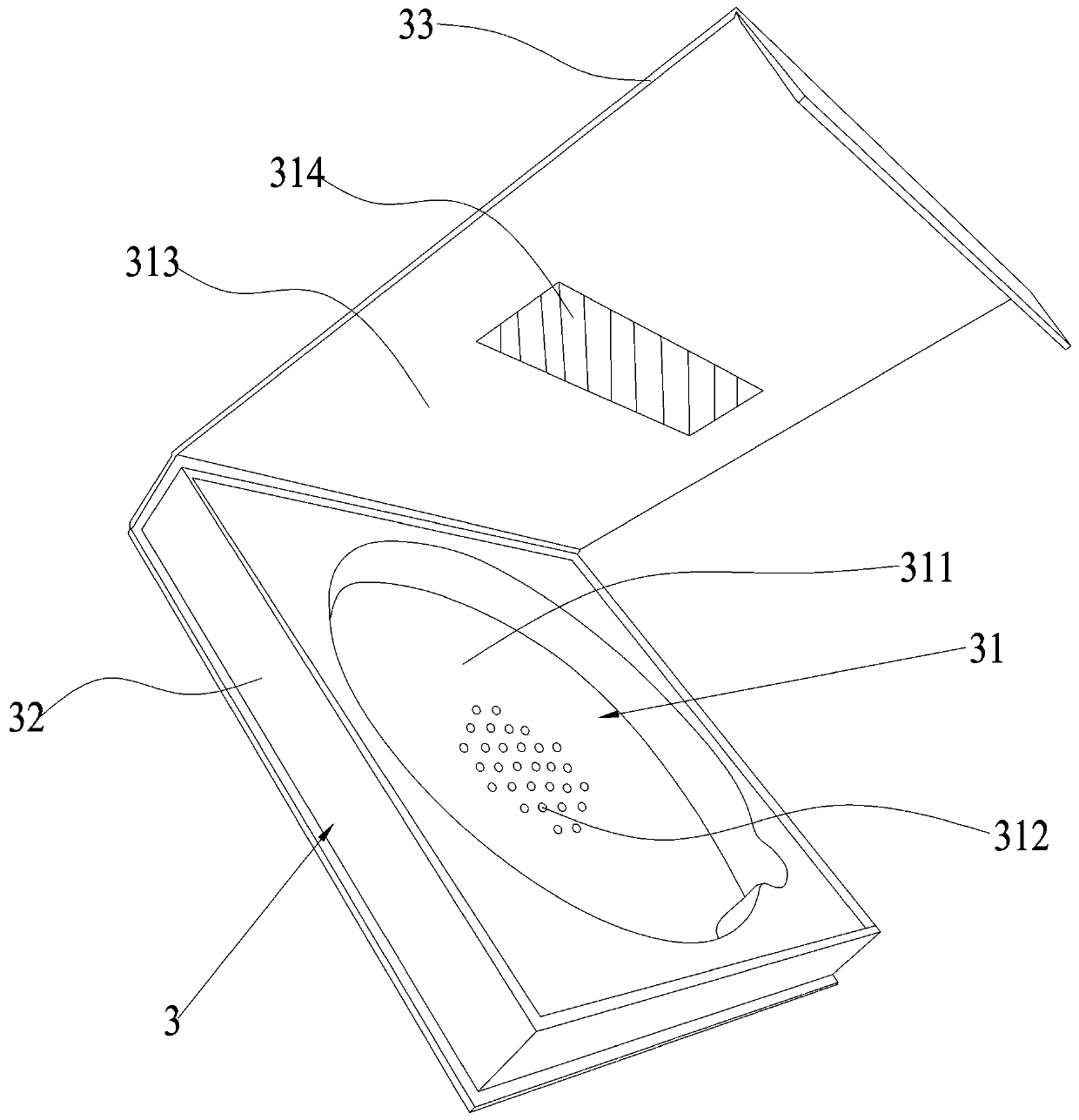

Babysitting machine for bamboo rat babies

InactiveCN102934615AMeet the temperatureMeet needsAnimal feeding devicesAnimal housingTemperature controlElectronic temperature

The invention discloses a babysitting machine for bamboo rat babies. The babysitting machine comprises a box body, a baby storage basket, a constant-temperature nursing tank, a heater and an electronic temperature controller, wherein the electronic temperature controller is installed outside the box body; a sealable transparent observation window is arranged on the box body; the baby storage basket and the heater are installed in the box body; the constant-temperature nursing tank is installed in the baby storage basket; and the electronic temperature controller is respectively connected with the heater and the constant-temperature nursing tank via circuits. According to the invention, the electronic temperature controller is used for implementing integrated temperature control on the double circuits of the babysitting machine, and thus the babysitting machine is capable of meeting the different needs of the bamboo rat babies on the temperature in the box body and the temperature of milk; moreover, the babysitting machine has three functions of heat preservation, moisture preservation and nursing, thus being capable of completely replacing a mother rat to nurse the rat babies; and various trace elements needed by the growth of the bamboo rat babies can be added in the artificial milk, and the babysitting machine can ensure that the babies can drink enough milk.

Owner:张古权

Room-temperature-cured epoxy resin cast cushion block and preparation method thereof

InactiveCN102372464ASolve the problem of inconvenient constructionSolve sticky surfaceEpoxyToughening

The invention belongs to a filling material used for fixing equipments, and especially relates to a room-temperature-cured epoxy resin cast cushion block and a preparation method thereof. According to existing technologies, the fixation of machineries with relatively large weights requires a large amount of bolts, such that the operation is difficult; in an environment with severe corrosion, fixing bolts are likely to be corroded, and the strengths of the bolts are reduced. The a room-temperature-cured epoxy resin cast cushion block provided by the invention is composed of, by weight: 100 parts of epoxy resin, 0 to 20 parts of a toughening agent, 0 to 3 parts of a diluent, 50 to 100 parts of active silicon micro-powder, 5 to 25 parts of an active crystal whisker material, 0 to 3 parts of titanium dioxide, 0 to 3 parts of a pigment, 0 to 1 part of an antifoaming agent, and 5 to 15 parts of a curing agent. The invention is advantaged in that: the surface properties of the product provided by the invention are stable, the product is not easy to contract, and the service life of the product is long. The cushion block can be cured under room temperature, such that the preparation method is simple. With the cushion block, the equipment can be firmly fixed, and requirements under vessel rocking and corrosion conditions can be satisfied.

Owner:SHANGHAI TITANOS IND

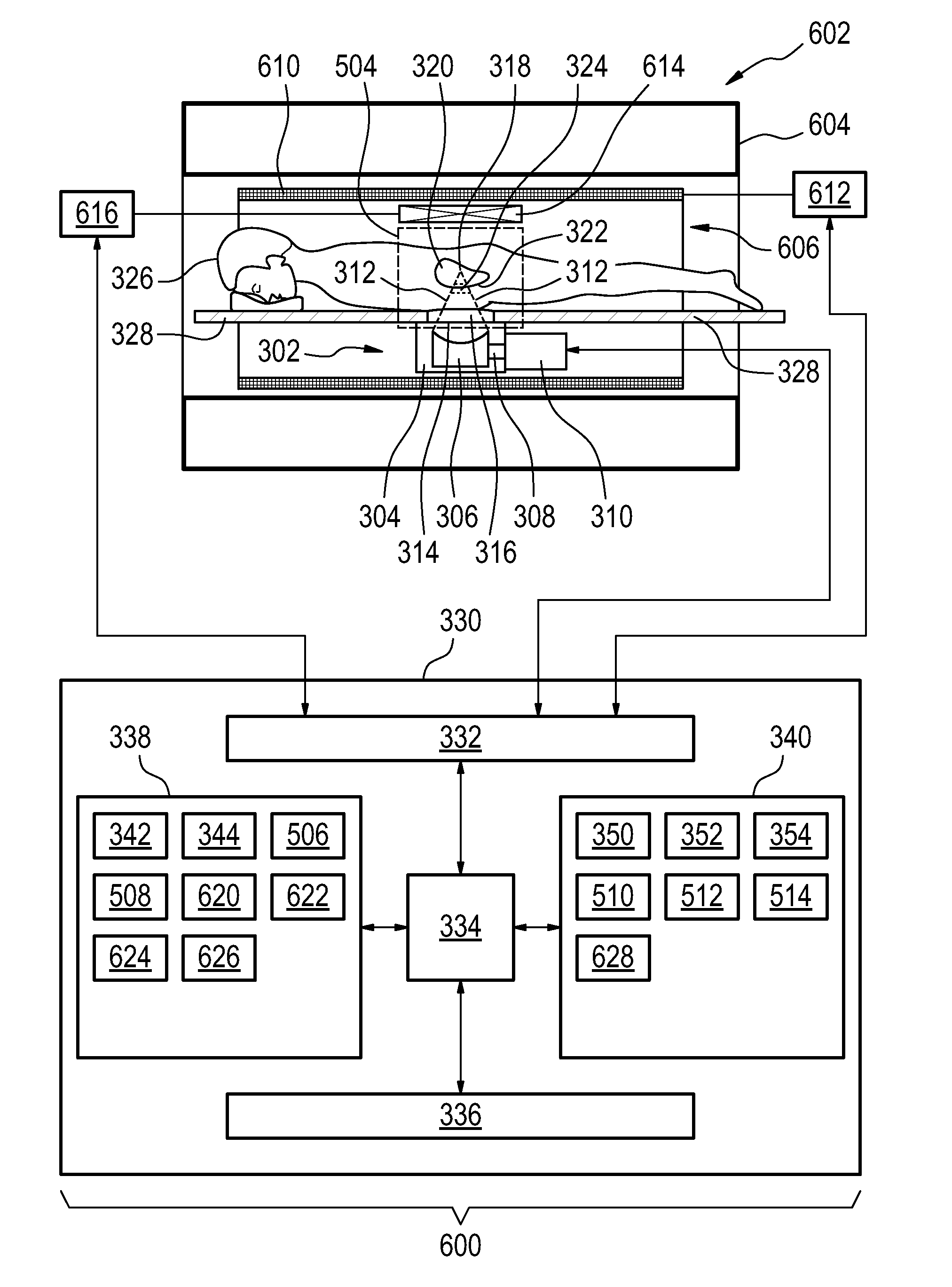

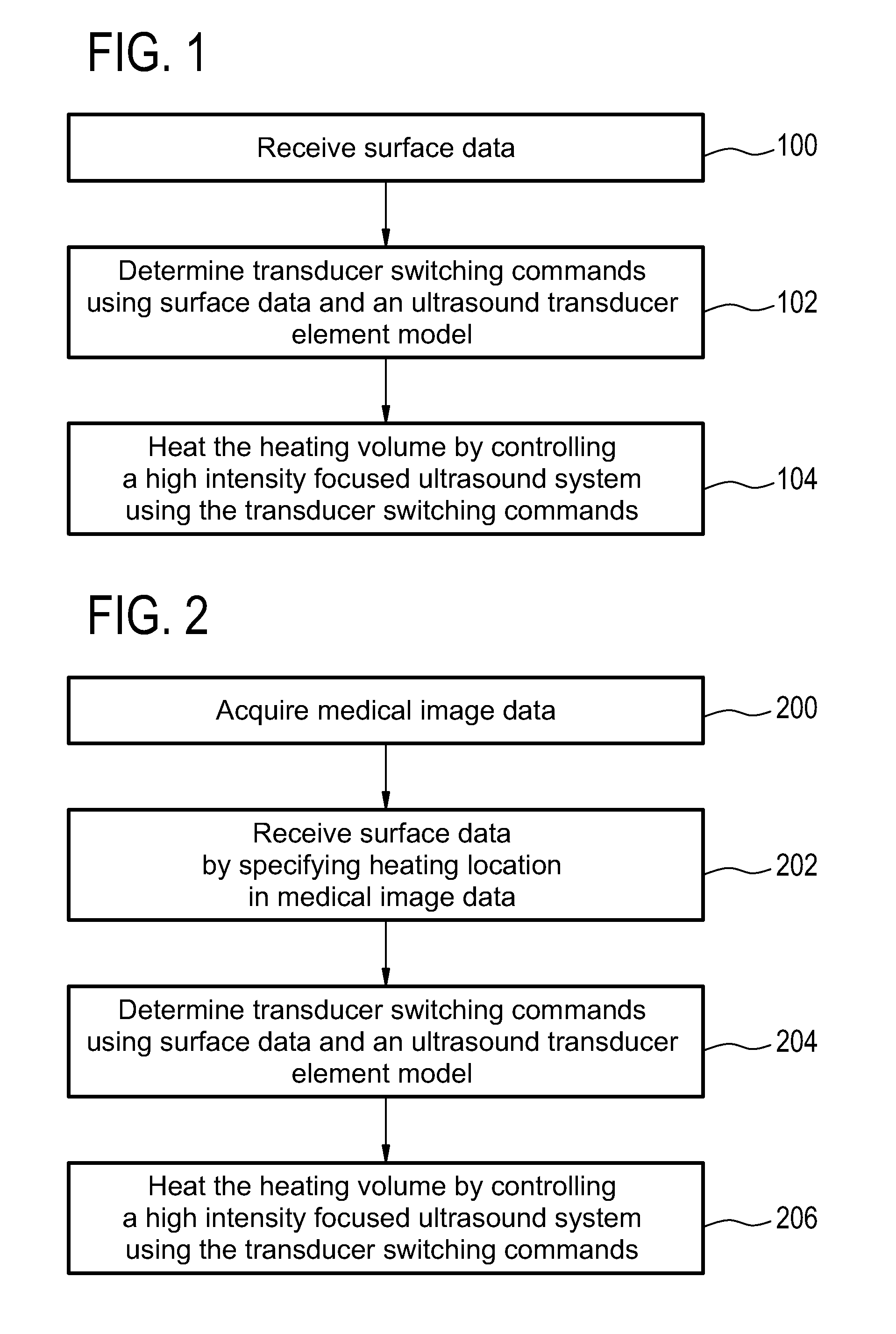

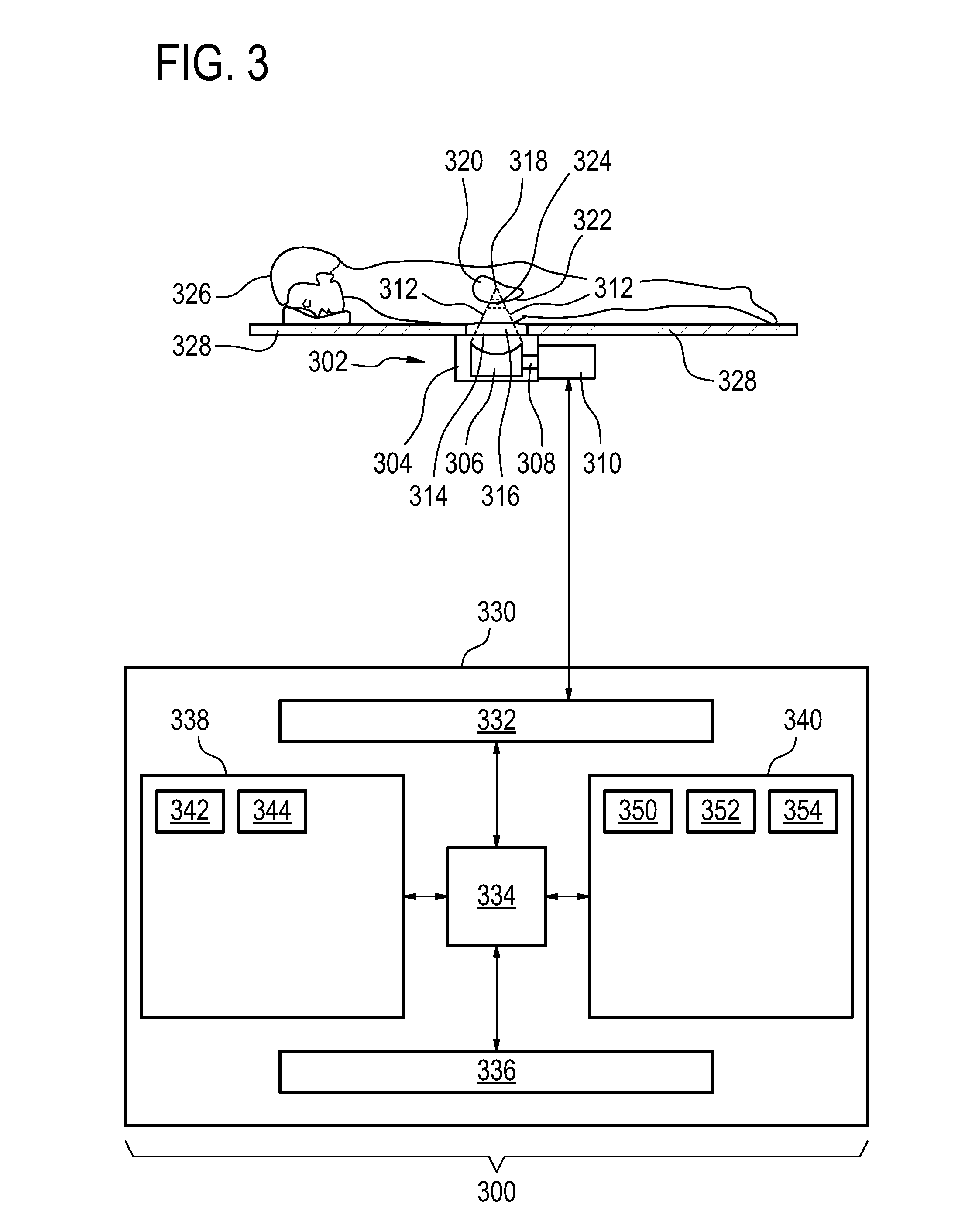

Medical apparatus for heating a heating volume defined by a surface

InactiveUS20150133826A1Reduce amountIncrease in numberUltrasound therapyChiropractic devicesHigh-intensity focused ultrasoundLocation data

The invention provides for a medical apparatus (300, 500, 600) comprising a high intensity focused ultrasound system (302), a memory containing instructions, and a processor. Execution of the instructions causes the processor to receive (100,202) surface data (342) descriptive of the location of a surface (322). The surface data defines the location of the heating volume. Execution of the instructions further cause the processor to determine (102, 204) a set of transducer switching commands (344) using the heating location data and an ultrasound transducer element model (352) and control (104, 206) the high intensity focused ultrasound system with the set of transducer switching commands to heat the heating volume. The set of transducer switching commands comprises an intensity level for the multiple ultrasound transducer elements either above or below a predetermined intensity for controlling a cross sectional shape of the heating volume to encompass the surface.

Owner:KONINKLJIJKE PHILIPS NV

Universal spherical joint supporter with anti-loosening position-limiting structure

ActiveCN101560793AGood architectural effectSmall building effectBuilding constructionsPull forceVertical edge

A universal spherical joint supporter with an anti-loosening position-limiting structure comprises a main spherical joint structural part consisting of a main top base with a concave spherical surface and a main bottom base with a convex spherical surface; the main bottom base consists of a base body, at least three reinforced plates and a steel ball; the steel ball is a convex ball component arranged in the bottom base; the reinforced plates are distributed in the bottom base radially and vertically by taking the vertical middle axis line of the steel ball as a central line; each reinforced plate is provided with a vertical edge closely to the middle axial line of the steel ball; a spherical concave position used for bearing the steel ball is arranged on an upper plate of the reinforced plate closely to the middle axis line by taking the spherical center of the steel ball as a center, and a convex claw is arranged in a space between every two adjacent reinforced plates on the main bottom base correspondingly to the lower circumference of the main top base, thus forming the position-limiting structure of the spherical joint. The position-limiting structure can play roles of preventing loosening, restricting the rotation of the top base around the axis line and bearing the pulling force and has excellent bearing performance; and when the position-limiting structure bears the pulling force, the spherical joint part can rotate slightly and simultaneously.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Puer tea storing container

PendingCN108674827AOxygen contentMeet the temperatureBio-packagingClosure with auxillary devicesRoom temperatureEngineering

The invention discloses a Puer tea storing container. The Puer tea storing container comprises a storing box, a humidifier and hollow tea cake boxes, wherein convection holes are correspondingly formed in at least two side surfaces of the storing box; a storing chamber which communicates with the convection holes is formed in the storing box and is divided into a plurality of separating layers; the hollow tea cake boxes are arranged in the separating layers of the storing chamber; a storing space for storing tea is formed in each hollow tea cake box; a first hollow through hole is formed in the first sidewall of each storing space; a second hollow through hole is formed in the second sidewall, opposite to the first sidewall, of each storing space; and the humidifier is arranged in the storing box. With the adoption of the Puer tea storing container, oxygen in a storing environment can be increased, and the storing environment temperature is kept consistent with the room temperature, and moreover, the humidity in the storing environment can be adjusted.

Owner:HUAXIANG YUAN TEA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com