Energy-saving gas conditioning furnace and thermal processing method for hot rolling of seamless steel pipes

A seamless steel pipe, energy-saving technology, applied to heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of uneven heating, large power loss, long intermittent time, etc., to achieve sufficient and uniform heating, good heat treatment effect, and high thermal energy Take advantage of the full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

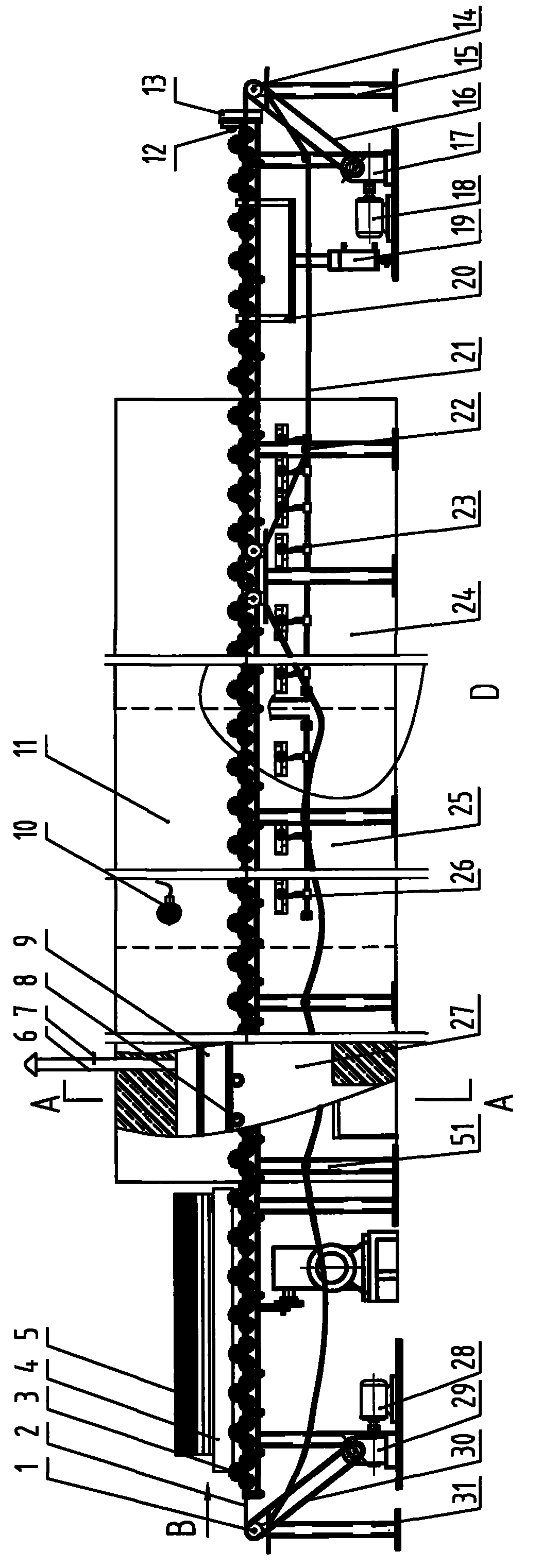

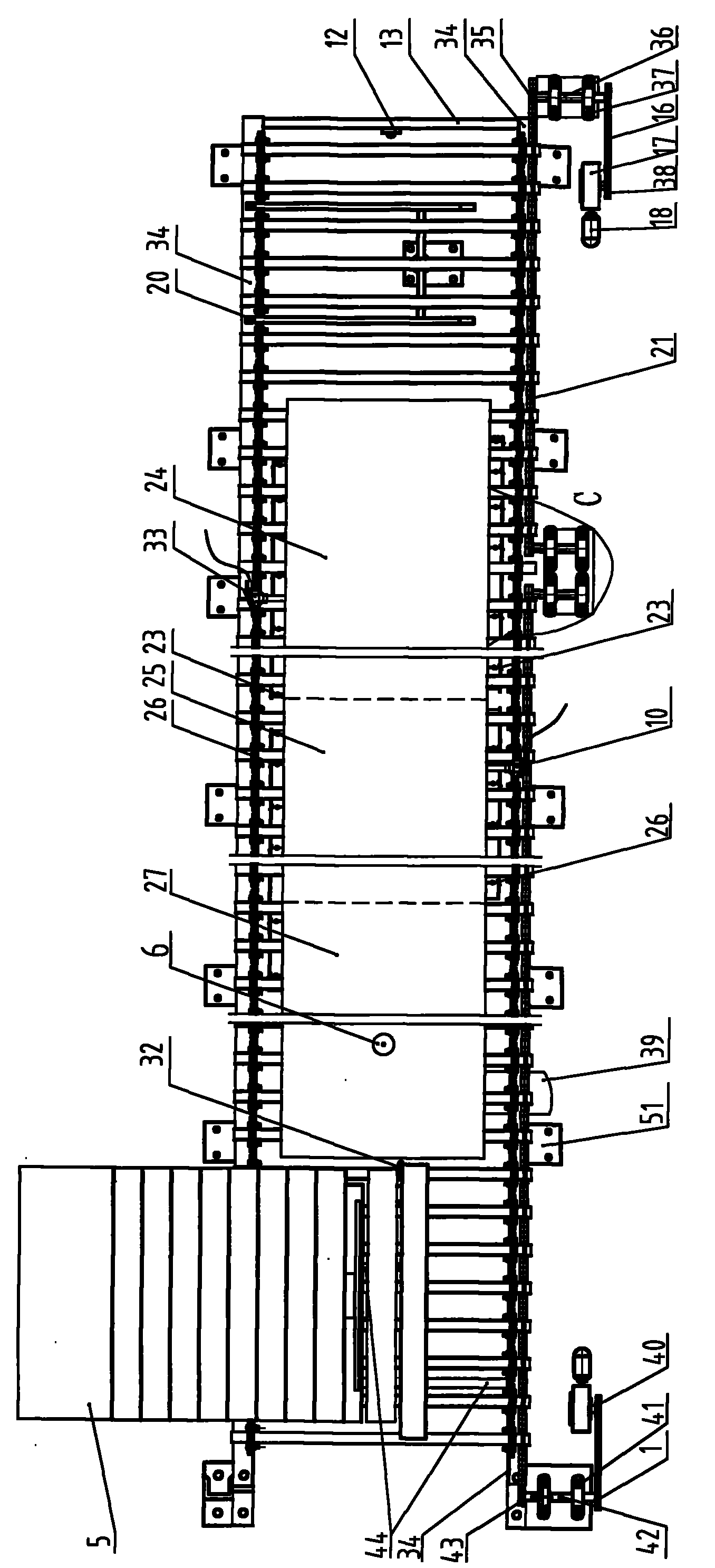

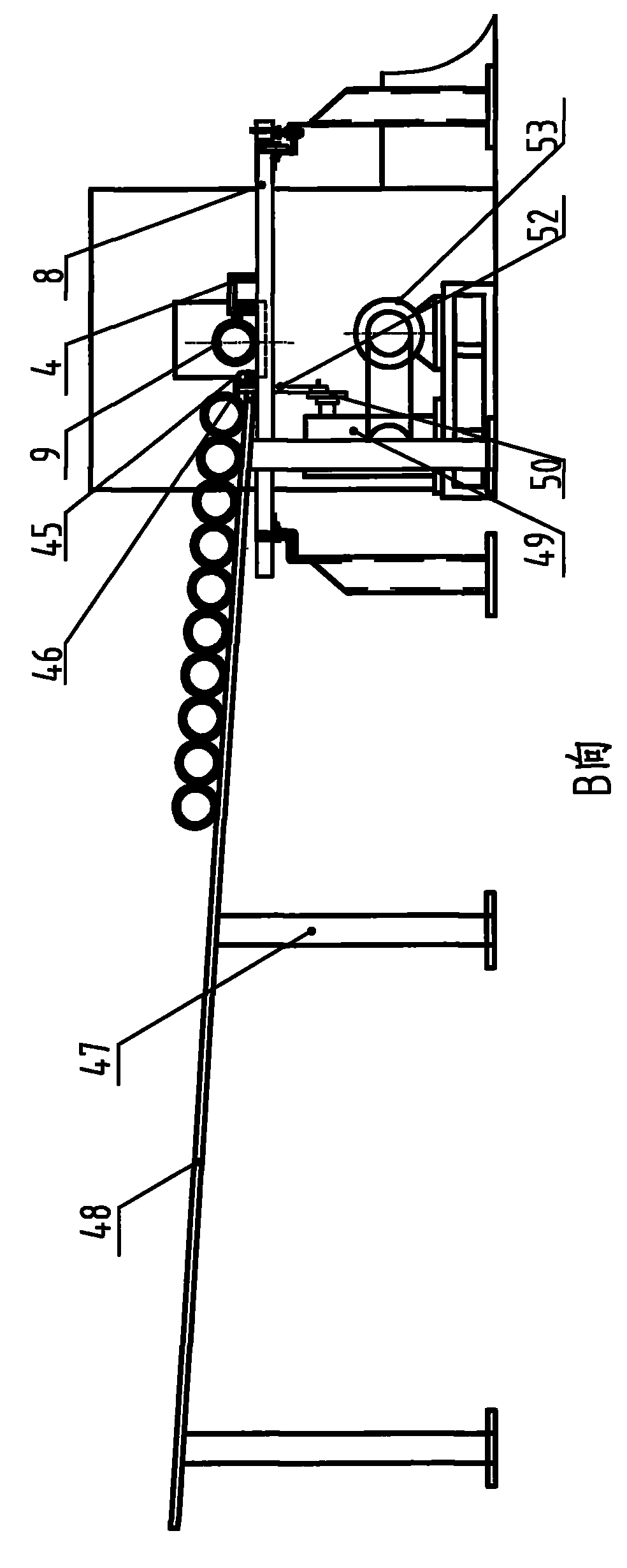

[0053] Attached below Figure 1-8 The present invention is described further:

[0054] Such as Figure 1-8 Shown:

[0055] The energy-saving hot-rolled seamless steel pipe gas conditioning furnace of the present invention mainly includes a kiln body 11, a roller table transmission part, an automatic feeding device 5, a temperature control device, a fast transmission device, and an electrical control system.

[0056] Such as Figure 1~2 Shown:

[0057] The kiln body 11 is sequentially divided into a preheating zone 27, a heating zone 25, and a high temperature zone 24 along the feeding and discharging direction, and a flue 39 and a chimney 6 are respectively arranged at the bottom and top of the front end of the preheating zone 27.

[0058] The roller table transmission part is installed on both sides of the kiln body 11, and its two ends extend out of the kiln body 11, including the transmission roller 8, the sprocket 3, the support bearing 54, the anti-wear ring 55, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com