Continuous type microwave auxiliary sintering furnace and method

A microwave-assisted, sintering furnace technology, applied in the direction of furnace, electric furnace heating, furnace components, etc., can solve the problems of difficult material heating, difficult microwave, uniformity, etc., to achieve uniform heating, prevent microwave leakage, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

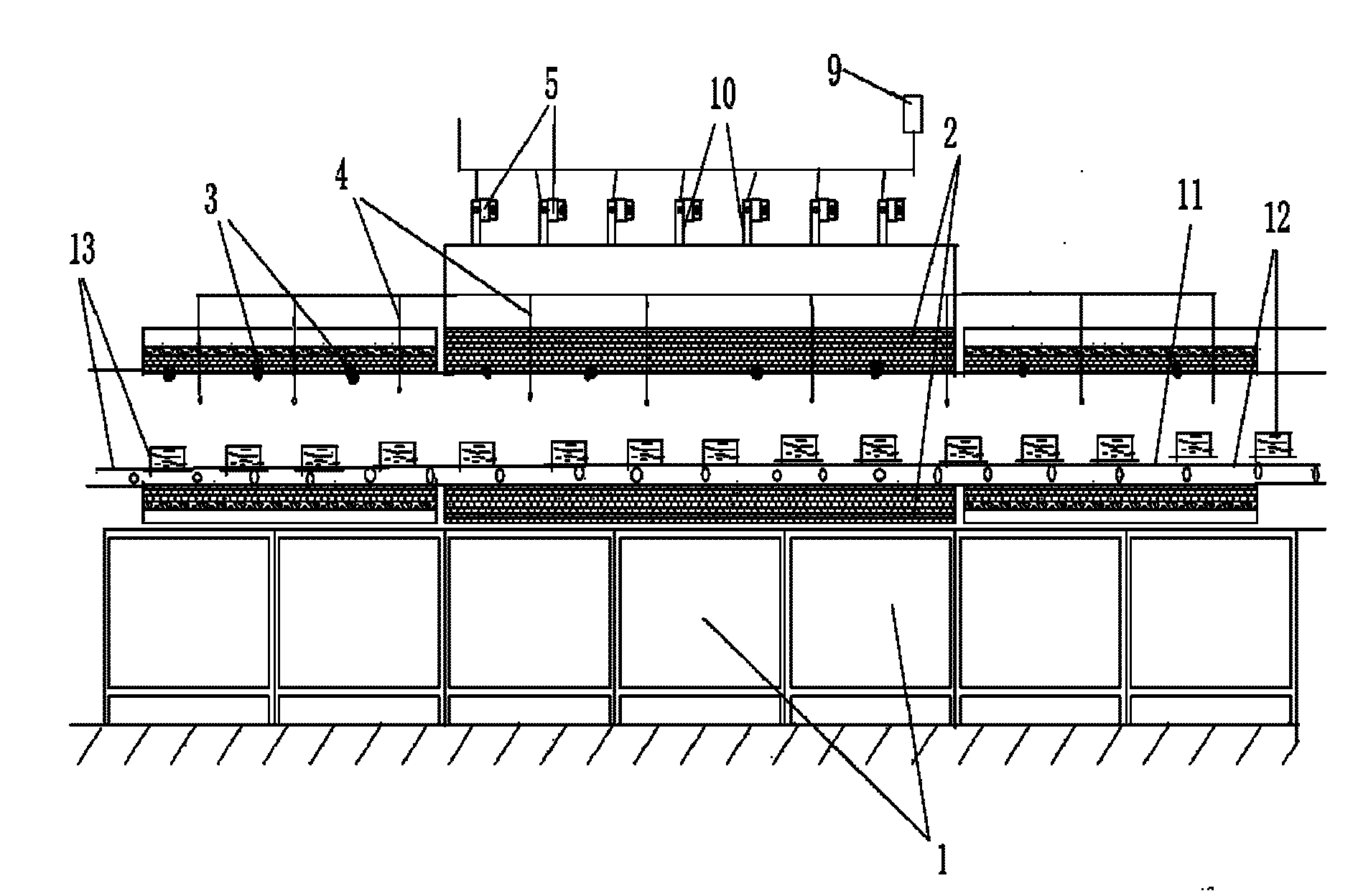

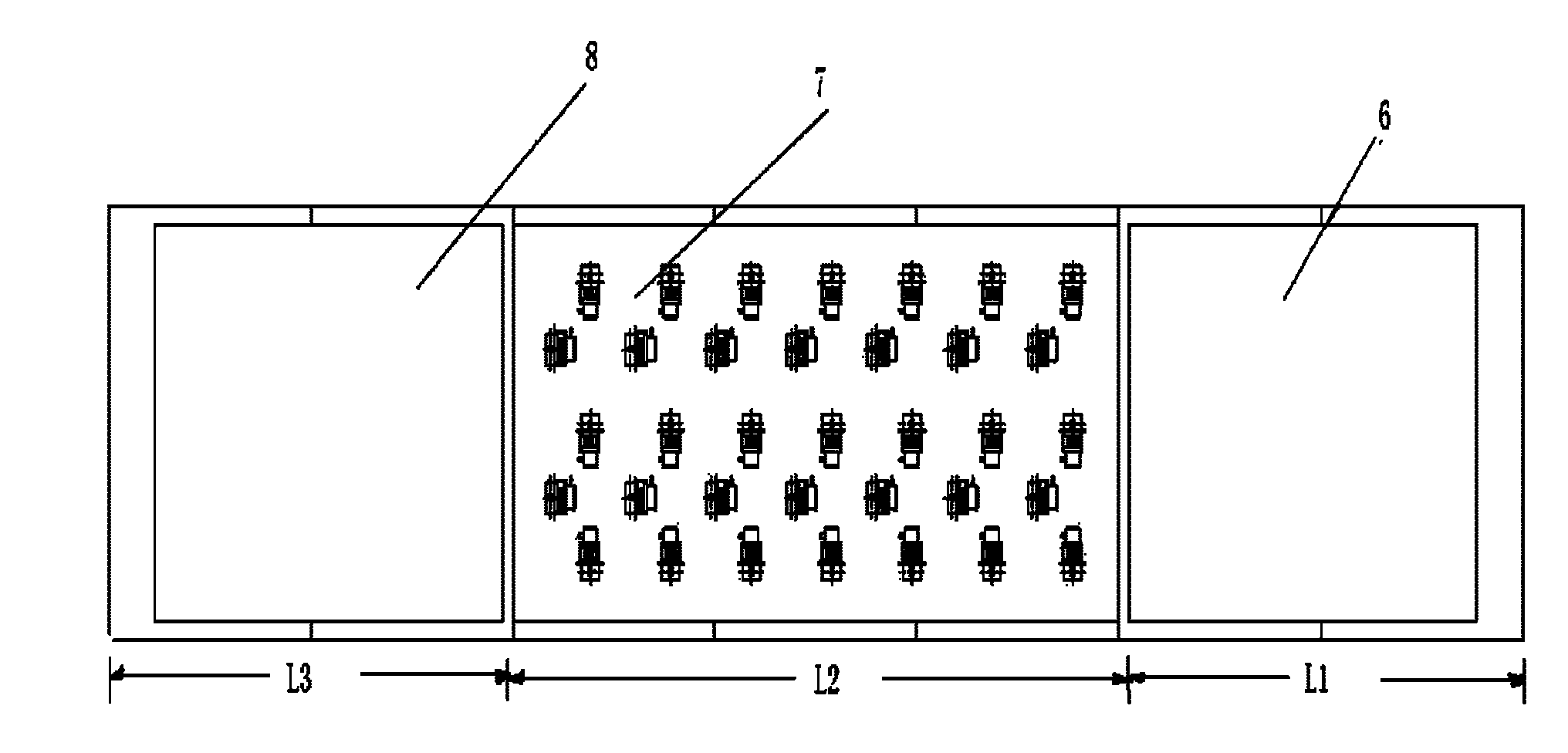

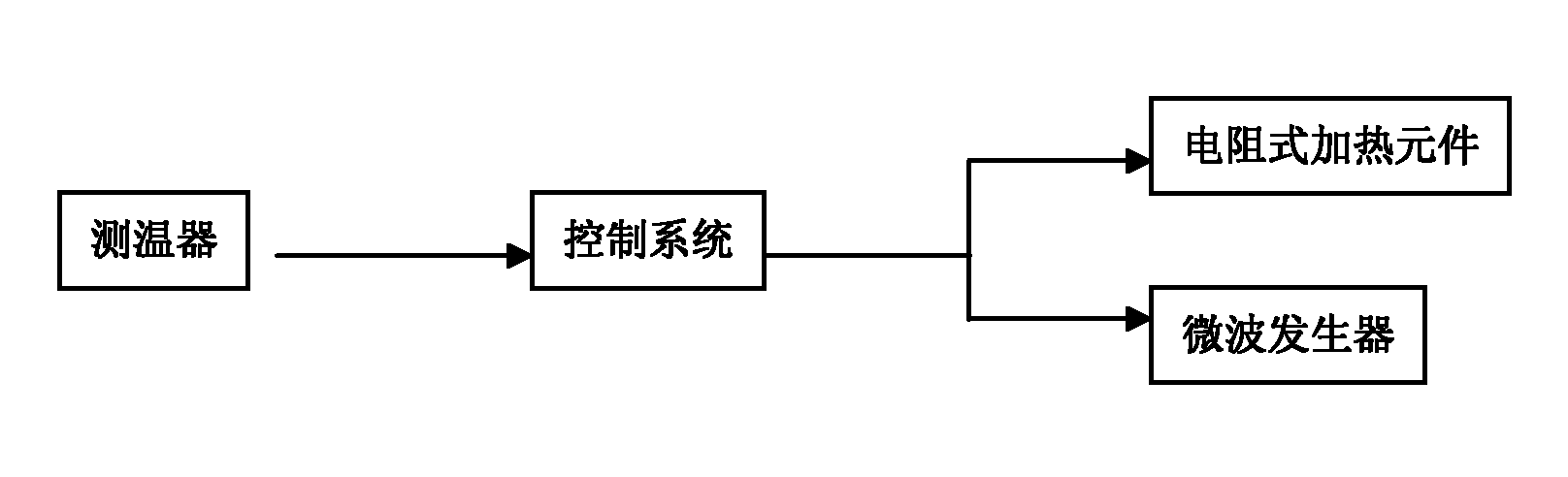

[0034] In this embodiment, the structure of the continuous microwave assisted sintering furnace is as follows figure 1 , figure 2 As shown, it includes a furnace body 1, a thermal insulation layer 2 arranged on the inner wall of the furnace body, a temperature detector 4 arranged in the furnace body, a material transmission device 11 installed in the furnace body, and a water-cooling heat dissipation system 9 arranged outside the furnace body. and control system. The furnace body is a kiln-type structure, which is composed of a first microwave choke section 6, a microwave auxiliary heating section 7 and a second microwave choke section 8 in sequence along the length direction, and the port of the first microwave choke section 6 is sealed and connected There is a feed system 12, and the port of the second microwave choke section 8 is sealed and connected with a discharge system 13; the length L of the first microwave choke section 6 1 = 2L 2 , the length L of the second mic...

Embodiment 2

[0037] In this embodiment, the structure of the continuous microwave assisted sintering furnace is as follows figure 1 , figure 2 As shown, it includes a furnace body 1, a thermal insulation layer 2 arranged on the inner wall of the furnace body, a temperature detector 4 arranged in the furnace body, a material transmission device 11 installed in the furnace body, and a water-cooling heat dissipation system 9 arranged outside the furnace body. and control system. The difference from Example 1 is that the number and arrangement of microwave generators in the microwave-assisted heating section of the furnace body are determined according to the microwave power density gradient in the furnace chamber of the microwave-assisted heating section. Such as Figure 4 As shown, the length L of the middle section 14 of the microwave-assisted heating section of the furnace body 4 =1 / 2L 2 , the length L from the left end of the middle section of the microwave-assisted heating section t...

Embodiment 3

[0039] This embodiment uses the continuous microwave assisted sintering furnace with the structure described in Example 1, and the length L of the microwave assisted heating section 7 2 =10.8 meters, the length L of the first microwave choke section 6 1 =21.6 meters, the length L of the second microwave choke section 8 3 =10.8 meters, adopt the sintering method of the present invention to sinter battery cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , the operation steps are as follows:

[0040] (1) Drying and heating of the furnace body

[0041] Turn on the power, operate the control system, start the resistance heating elements of the first microwave choke section, the microwave auxiliary heating section and the second microwave choke section, and heat the furnace body of each section to 200°C at a heating rate of 5°C / hour Keep warm for 8 hours, dry the furnace body; then raise the temperature of the microwave auxiliary heating section to 880°C at a heating rate of 10°C / h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com