Inner formwork for hollow stand column

A technology of inner formwork and column, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of low rigidity and poor stability of inner formwork, achieve good stability and adjust heat dissipation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

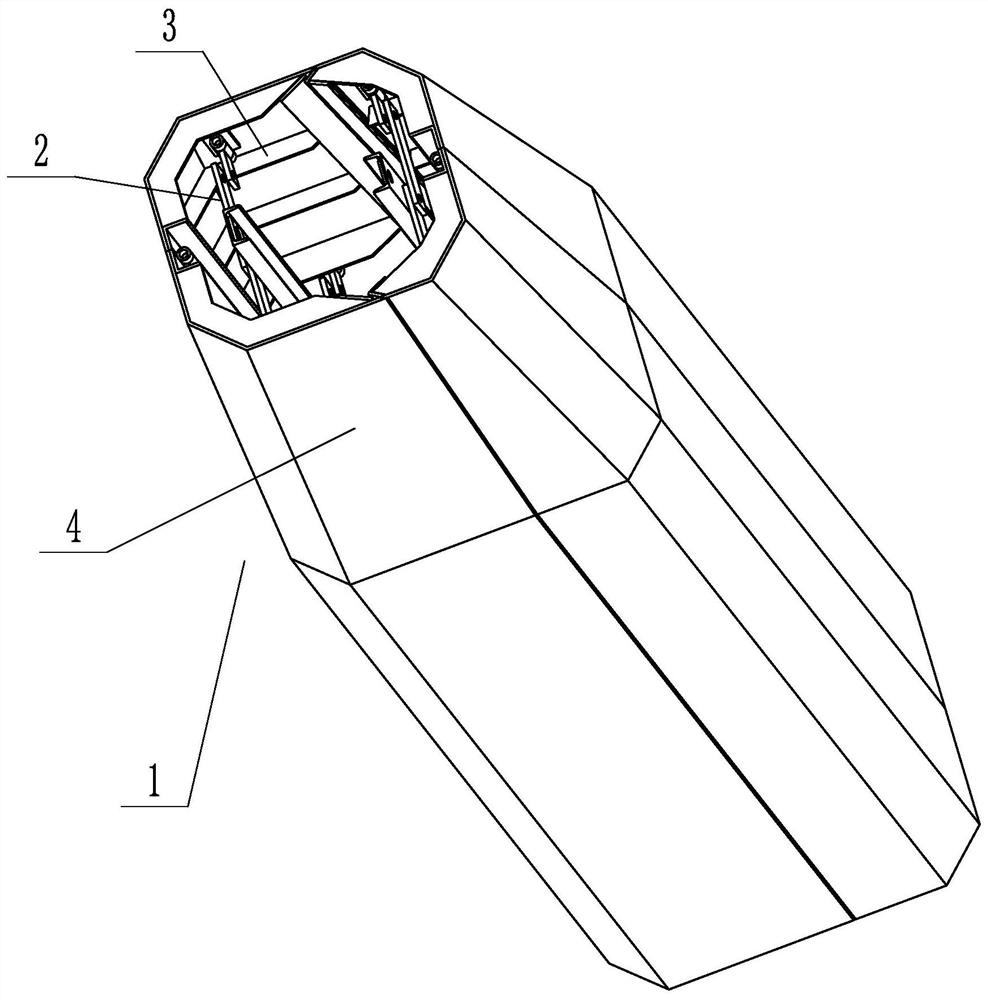

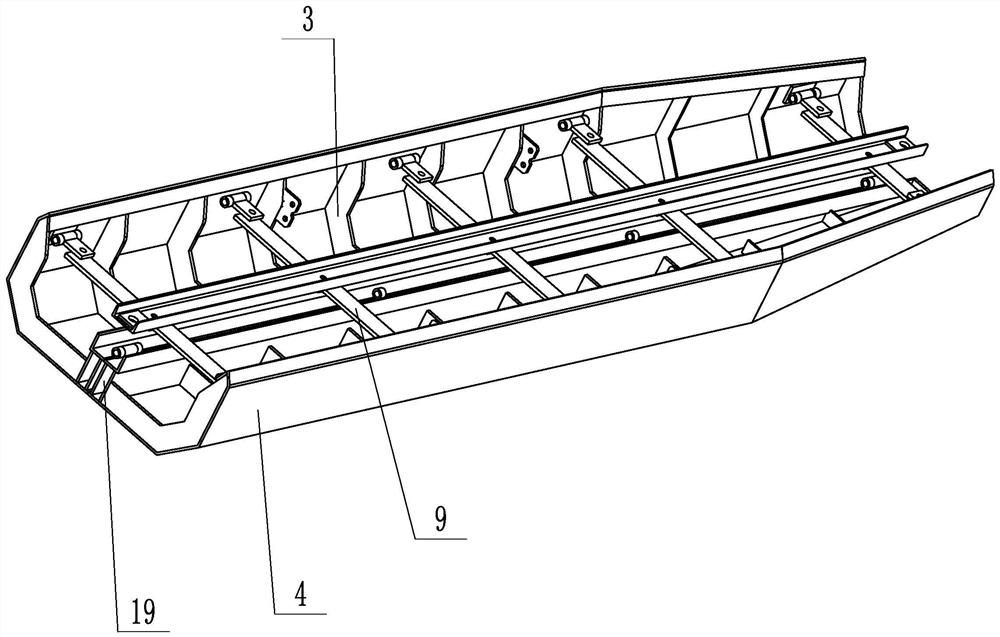

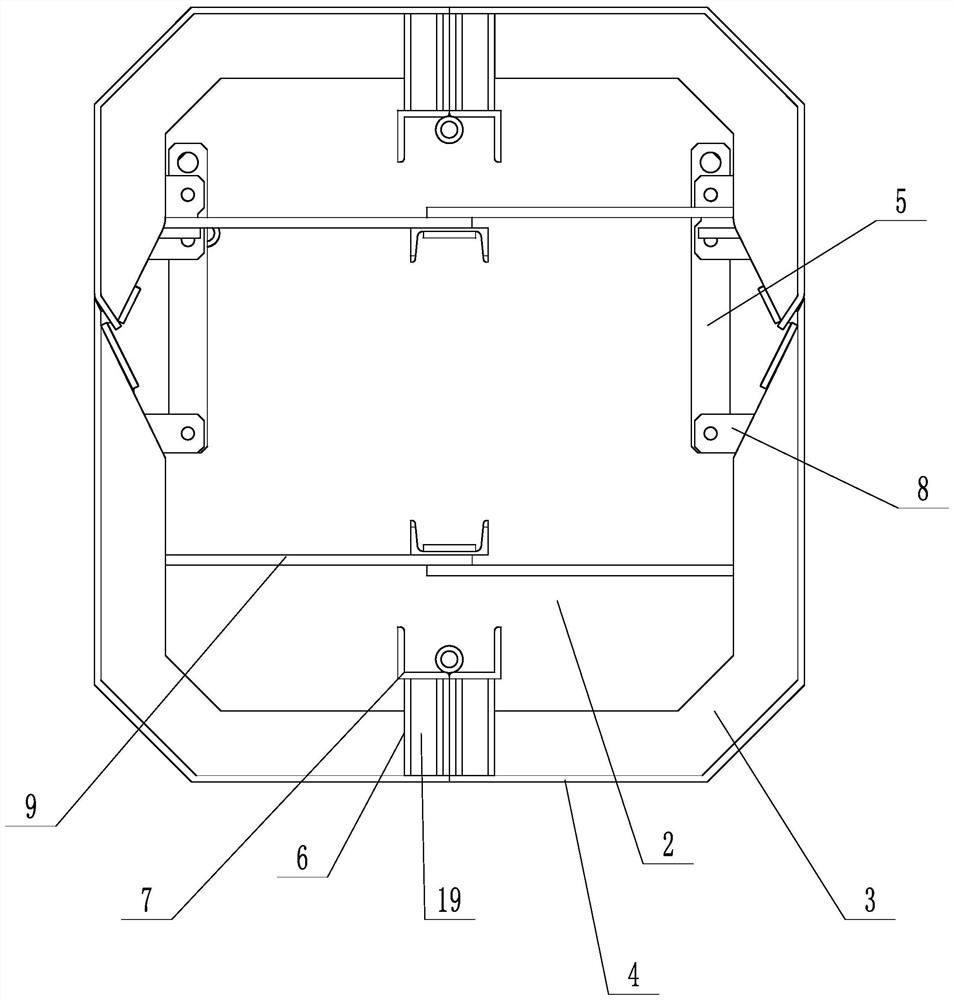

[0023] see Figure 1 to Figure 5 , an inner formwork for a hollow column, which is formed by splicing two half-moulds;

[0024] The mold half includes a housing 1 with a U-shaped cross section, pull rods 2 for connecting the sidewalls on opposite sides of the housing 1, and several rods fixed on the inner wall of the housing 1 to increase the stability of the housing 1. Stiffener 3;

[0025] The corresponding ends of the shells 1 of the two half-moulds abut against each other, a positioning rod 5 is arranged between the half-moulds, one end of the positioning rod 5 is connected to one of the half-moulds, and the other end of the positioning rod 5 is connected to the other Half mold connection;

[0026] The housing 1 is fixedly connected by two half-shells 4 with an L-shaped cross section through a connecting mechanism.

[0027] The connecting mechanism includes two connecting heads fixedly connected to the edge of the corresponding half shell 4, and the two connecting heads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com