Injection molding grade PVC composite material high in mobility and melt strength

A technology of high melt strength and composite materials, applied in the field of polymers, can solve the problems of low injection molding temperature, short molding cycle, difficult to solve the production stability of injection molding appearance defects, etc., to improve heat resistance, improve fluidity, Effect of improving melt strength and mechanical properties

Active Publication Date: 2017-05-24

NINGBO TAIYONG AUTOMOTIVE PARTS

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the complexity of auto parts and other injection molding products, the size and shape of the products are varied, especially some extra-small or extra-large products (such as ultra-small triangular windows and super-large triangular windows) and the design of product variable cross-section, Coupled with the pursuit of low injection molding temperature and short molding cycle, it brings many challenges to PVC injection molding materials

Simply by improving fluidity or adjusting mold design, it is difficult to solve the appearance defects of injection molding and ensure production stability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

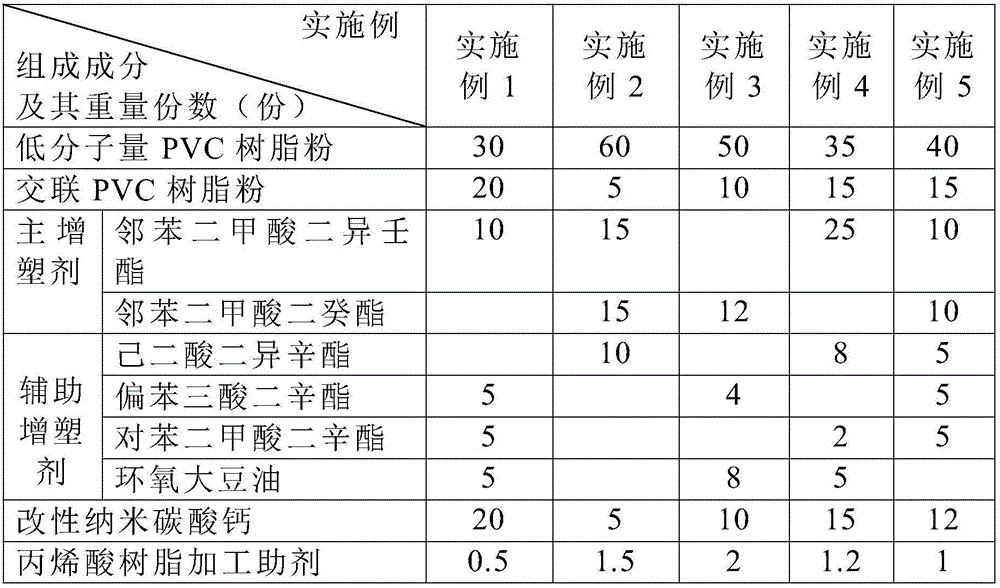

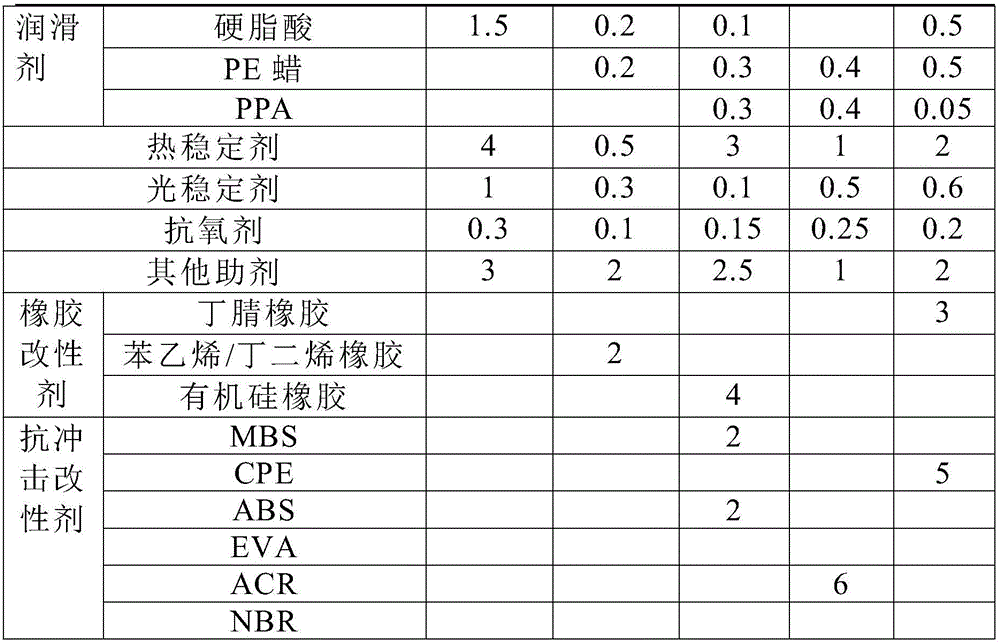

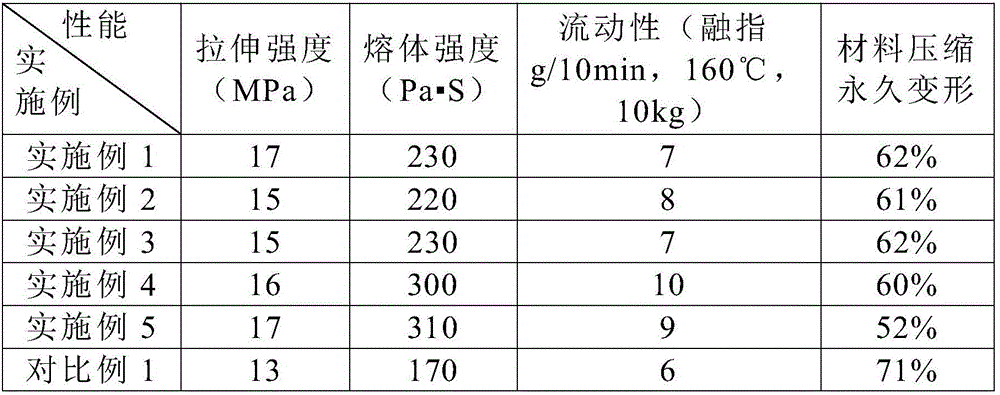

[0031] The injection molding grade PVC composite material of the present invention with high fluidity and high melt strength can be obtained by conventional injection molding process according to the component ingredients of the injection molding grade PVC composite material described in Table 1, Examples 1-5.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an injection molding grade PVC composite material high in mobility and melt strength and belongs to the technical field of macromolecules. The composite material comprises, by weight parts, 30-60 parts of low molecular weight PVC resin powder, 5-20 parts of crosslinking PVC resin powder, 10-30 parts of main plasticizer, 10-20 parts of secondary plasticizer, 0.5-20 parts of nano calcium carbonate, 0.5-2 parts of high melt strength processing agent, 0.4-1.5 parts of lubricant, 0.5-4 parts of heat stabilizer, 0.1-1 part of light stabilizer, 0.1-0.3 part of antioxidant and 1-3 parts of other auxiliaries. Melt strength and mechanical properties of the PVC composite material are improved while high mobility is guaranteed. The injection molding grade PVC composite material can adapt to injection molding products of various sizes and shapes and can meet requirements of low plastic temperature and short plastic cycle.

Description

technical field [0001] The invention relates to an injection molding grade PVC composite material with high fluidity and high melt strength, which belongs to the technical field of macromolecules. Background technique [0002] PVC is the English abbreviation of polyvinyl chloride. PVC modified materials are cheap, rich in raw materials, and easy to process. They are widely used in industries such as automobiles, construction, home appliances, and cables. They are currently one of the most produced plastics in the world. Injection molding technology is the most commonly used means of plastic processing and molding. With the continuous development of injection molding technology, injection molding technology is constantly pursuing lower injection molding temperature and shorter injection molding cycle to reduce energy consumption and increase production capacity. Therefore, the requirements for injection molding materials are also constantly increasing to meet low temperature ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08L51/04C08L23/28C08L55/02C08L23/08C08L51/00C08L9/02C08K13/06C08K9/10C08K3/26C08K5/12C08K5/11

CPCC08K2201/003C08K2201/011C08K2201/014C08L27/06C08L2205/025C08L2205/03C08L2205/035C08L2207/02C08L2207/53C08L51/04C08L23/286C08L55/02C08L23/0853C08L51/003C08L9/02C08K13/06C08K9/10C08K2003/265C08K5/12C08K5/11

Inventor 方超李文斌张顺

Owner NINGBO TAIYONG AUTOMOTIVE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com