Exhaust gas recirculation cooler for medium and heavy-duty vehicle with ridge ring

A technology of exhaust gas recirculation and cooler, which is applied in the direction of exhaust gas recirculation, heat exchanger shell, machine/engine, etc. The structure is cumbersome and other problems, and the overall reliability is improved, the processing accuracy is improved, and the performance requirements are met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

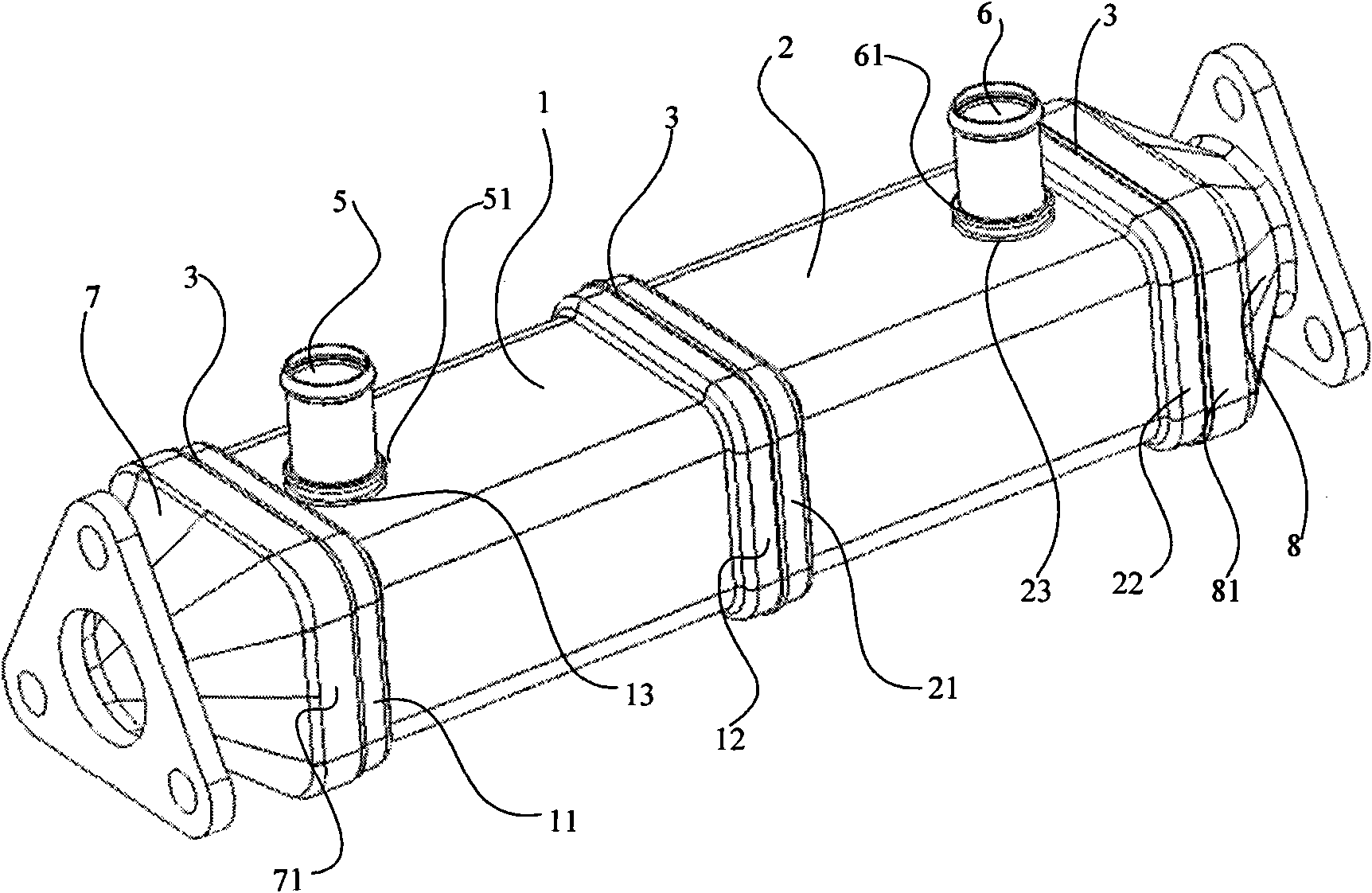

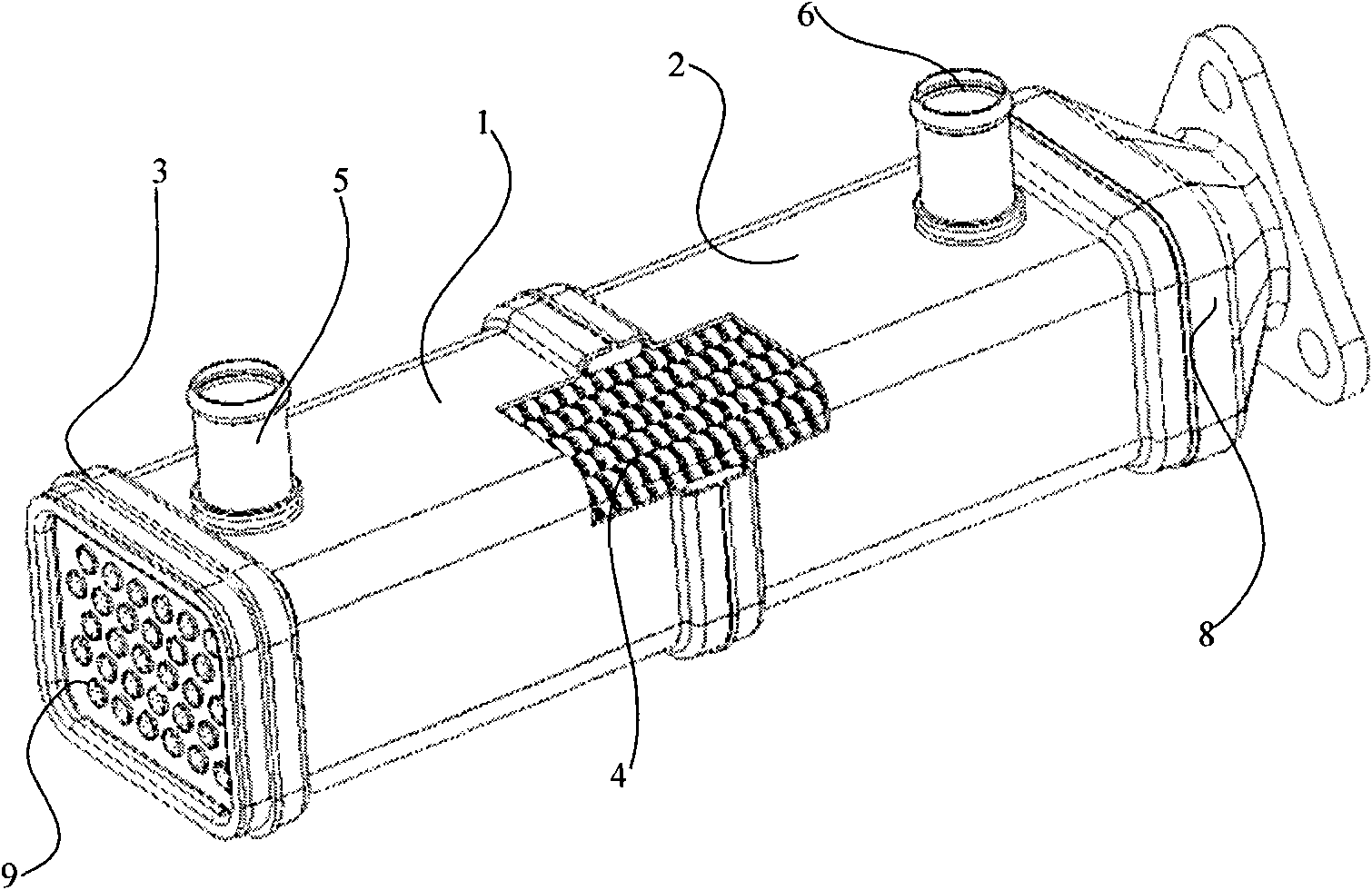

[0024] This embodiment is an exhaust gas recirculation cooler for medium and heavy vehicles with a ridge ring, such as figure 1 , 2 shown. The cooler includes: tube shells 1, 2 as the main body, tube sheets 9 installed at both ends of the tube shell, and water inlet pipes 5 and outlet pipes 6 on the side of the tube shell, and installed between the two tube sheets at both ends of the tube shell. There are a plurality of heat exchange tubes 4 for circulating exhaust gas, and two tube sheets are respectively connected with the intake pipe box 7 and the exhaust pipe box 8. The tube shell is surrounded by a metal plate with a thickness less than 2 mm. The cross-section of the shell is rectangular, and the shape is also rectangular. The shell can be a single section, or it can be formed by connecting multiple sections. High, between the pipe shell and the intake pipe box or the exhaust pipe box, and between the pipe shells of the multi-section pipe shells are connected by a ridge...

Embodiment 2

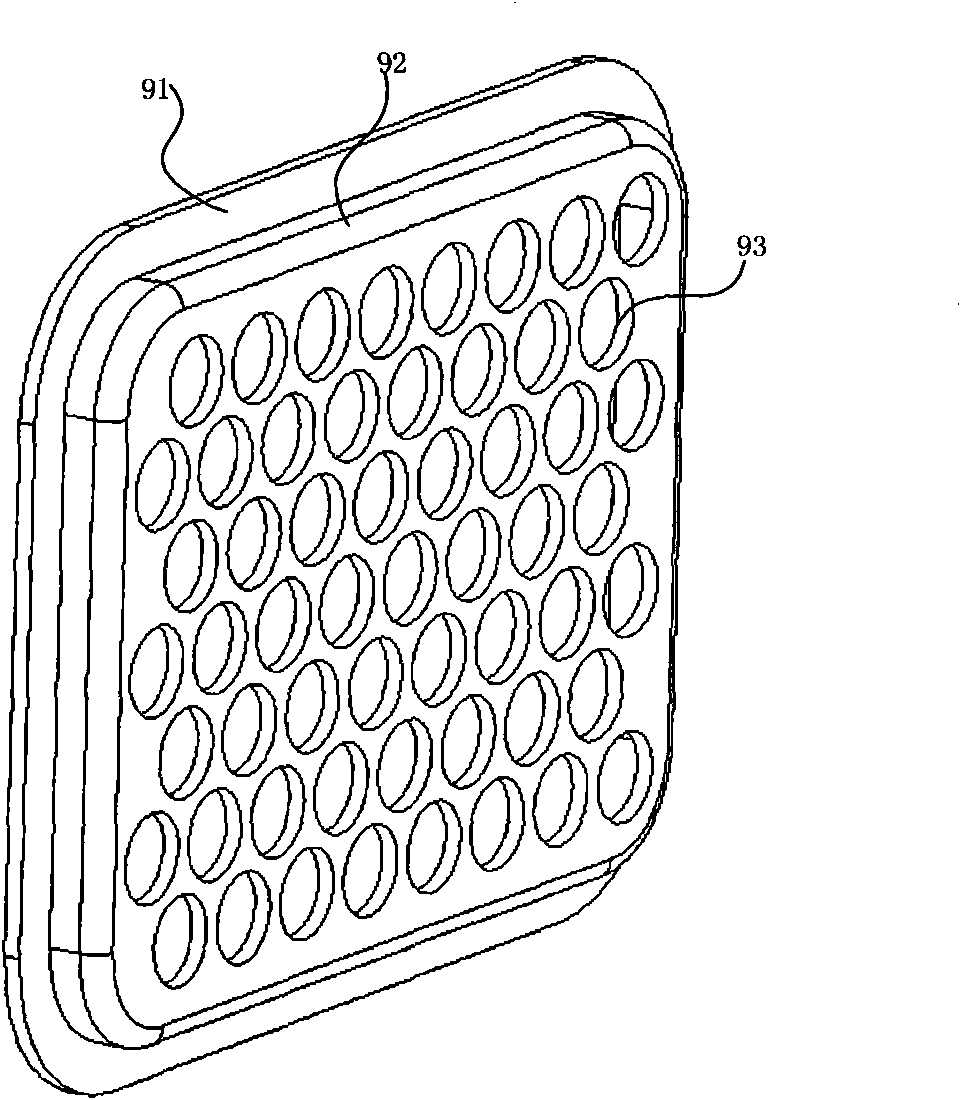

[0035] This embodiment is an improvement of the first embodiment, and is a refinement of the embodiment about the ridge ring. The ridge ring described in this embodiment is a rectangular metal ring. There is a circular raised ridge in the middle of the outer surface of the rectangular metal ring, and two annular surfaces for inserting pipe shells or intake pipe boxes and exhaust pipe boxes are formed on both sides of the raised ridge.

[0036] Such as Figure 5 Shown is the spine ring according to this embodiment, comprising an annular protrusion 32 and two annular faces 31,33. The ridge ring has the following functions: first, the ridge ring is the connection between the split shells; second, the ridge ring is the connection between the shell and the tube box; third, the split shell passes through the ridge After the rings are connected as a whole, the overall strength of the tube shell can be enhanced; fourth, the protrusions in the ridge ring facilitate the assembly of the...

Embodiment 3

[0038] This embodiment is a refinement of the previous embodiment, and is concerned with the refinement of the end of the package using a ridge ring. The tube shell described in this embodiment is plugged into the annular surface of the ridge ring after being flared at the end.

[0039] In order to strengthen the connection strength between the ridge ring and the shell, the ends of the split shell are all flared, such as figure 1 As shown in 11, 12, 21, 22, it is convenient for the connection of the two; similarly, the ridge ring is directly inserted into the connection ends 71, 81 of the pipe box, so that the overall connection of the cooler is more firm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com