Novel intelligent automatic humidity and temperature kiln inside curing system and method for cement product

A cement product and maintenance system technology, applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of long investment recovery time, high cost, and low yield, and achieve the effects of shortening maintenance time, increasing strength, and uniform water replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

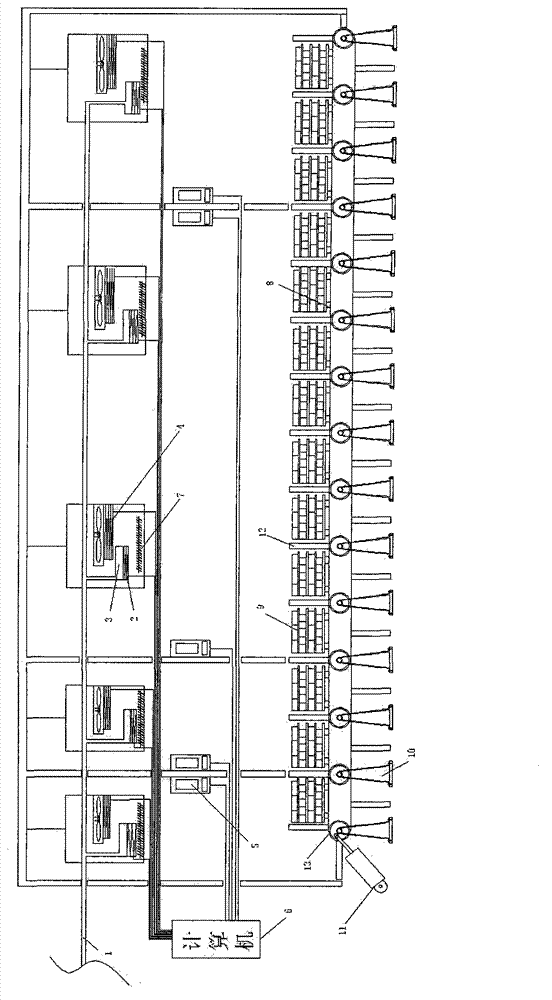

[0017] Such as figure 1 As shown, the intelligent and automatic maintenance system for cement products in a humid-heat kiln includes a curing kiln. The interior of the closed kiln body composed of partition boards and composite panels is sealed with plastic film; the sealed kiln body is equipped with 4 heat-insulating soft partitions, and the 4 heat-insulating soft partitions correspond to the four curing periods of cement products, that is, pre- In the maintenance period, heating period, constant temperature period and cooling period, each insulation soft partition is equipped with a temperature and humidity detector 5, a steam humidifier and a warm air temperature controller 4, and the steam humidifier is located in the warm air temperature controller 4. At the air outlet, the steam humidifying device includes a water tank 3 and a heater 2, the water tank 3 communicates with the water pipe 2 passing through 4 heat-insulating soft partitions, the temperature and humidity dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com