Organic solid waste film covering high-temperature aerobic fermentation method

An organic solid and aerobic fermentation technology, which is applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of high fermentation efficiency and low operation cost, achieve optimal fermentation process, less one-time investment, Effect of reducing generation of bad smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

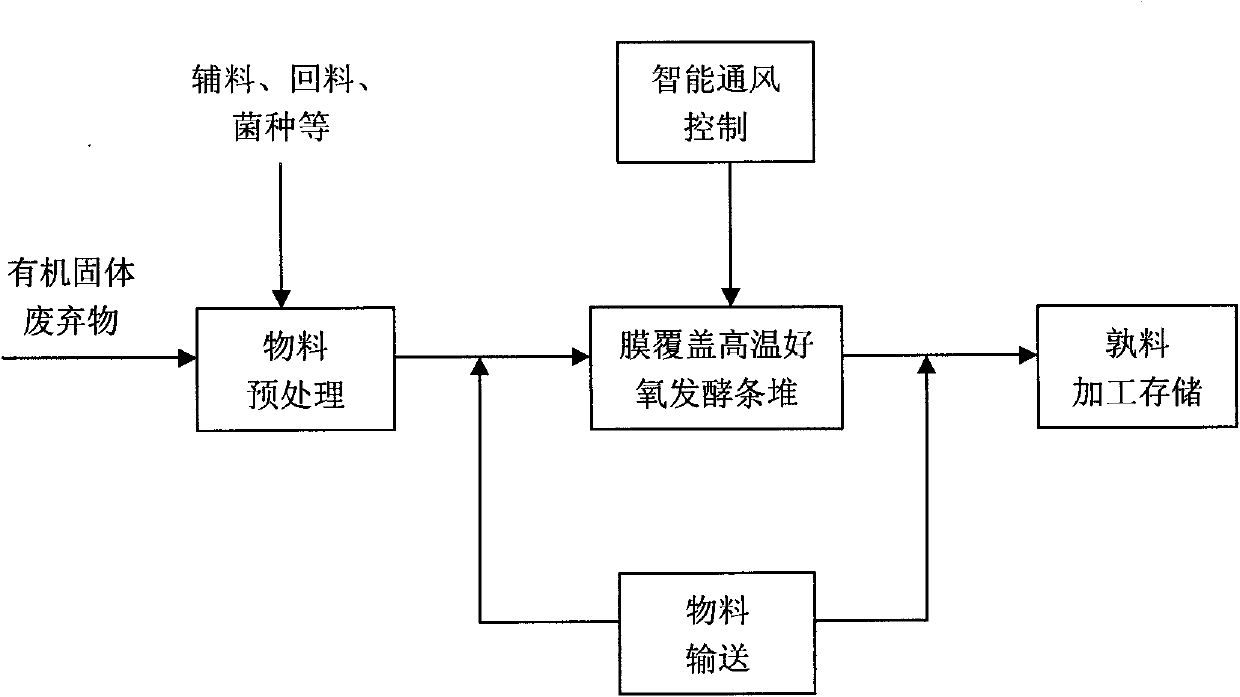

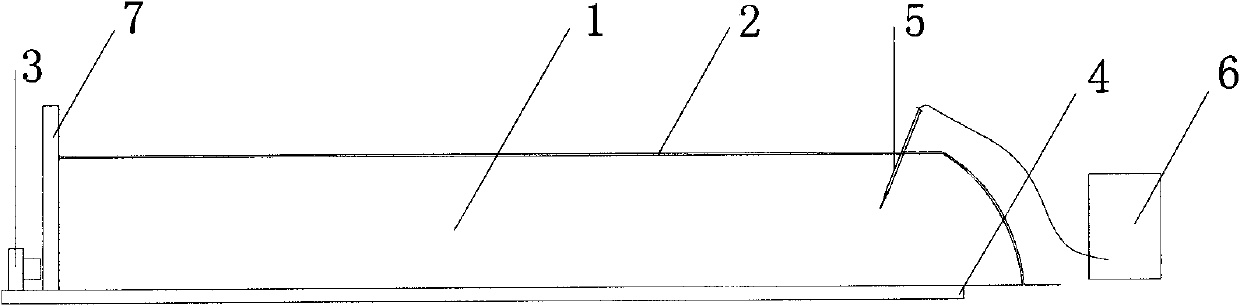

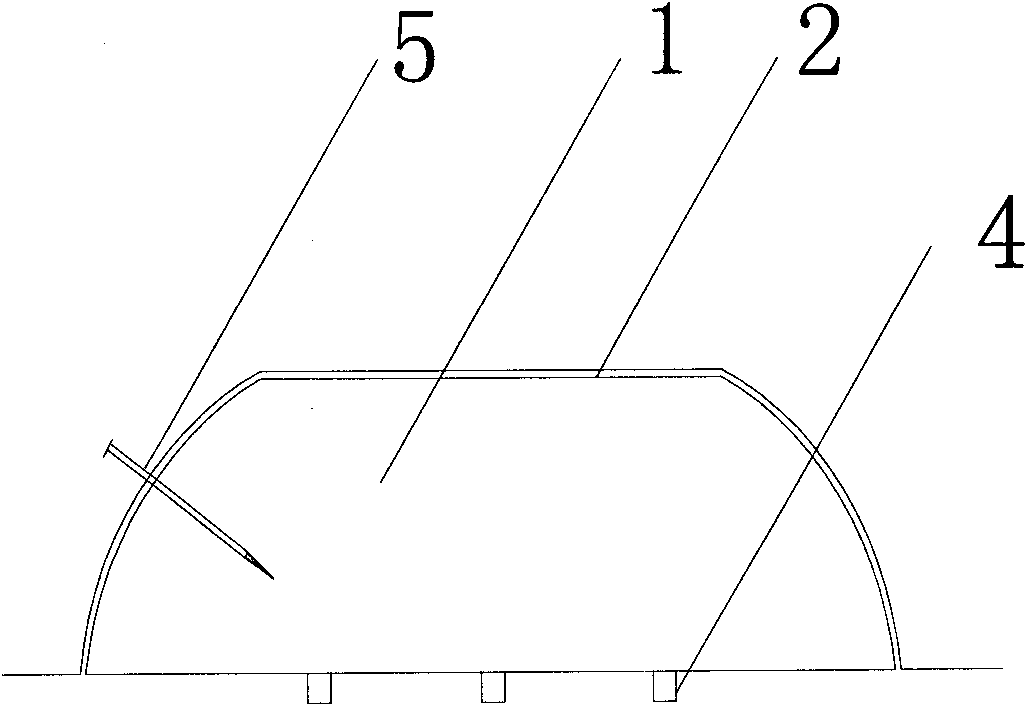

[0014] See attached figure 1 , figure 2 with image 3 Shown, the present invention is further described, and the present invention is realized through the following steps:

[0015] The first step is to pre-treat organic solid waste. According to the nature of organic solid waste and fermentation requirements, the organic solid waste is sorted, crushed, mixed with auxiliary materials, recycled materials, strains, etc., and the moisture, C / N, particle size, porosity, etc. are adjusted to make the organic solid waste The pretreated material meets the fermentation requirements.

[0016] The second step is to build a membrane covering the stack of high-temperature aerobic fermentation strips. Use conveying equipment, such as conveyors, distribution machines, forklifts, etc., to transport the pretreated materials to the fermentation site, pile them into strips above the ventilation pipes in the fermentation area, and cover the material strips with waterproof and breathable memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com