Convertor steelmaking method capable of reducing slag quantity

A converter steelmaking and slag production technology, which is used in the manufacture of converters, the improvement of process efficiency, and the production of lime, can solve the problems of large consumption of lime and light-burning dolomite, and is beneficial to splashing slag to protect the furnace and protect the Furnace lining, the effect of reducing metal splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The experiment was carried out in a 210-ton top-bottom combined blowing converter. Table 1 shows the conditions of molten iron and steel scrap in the furnace, Table 2 shows the conditions of auxiliary materials for steelmaking, Table 3 shows the amount of slag splashing per ton of steel, and Table 4 shows the parameters of the steelmaking process.

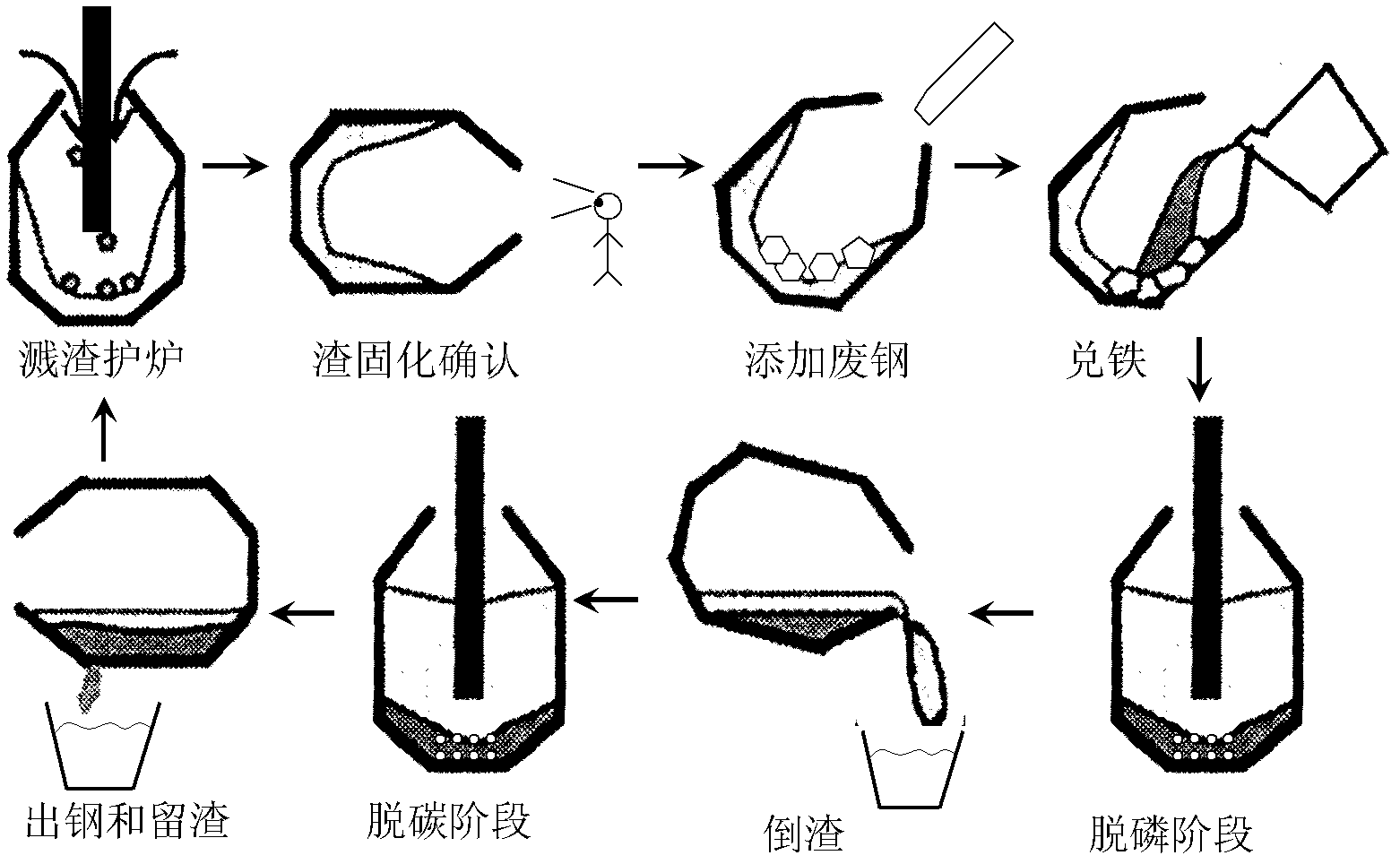

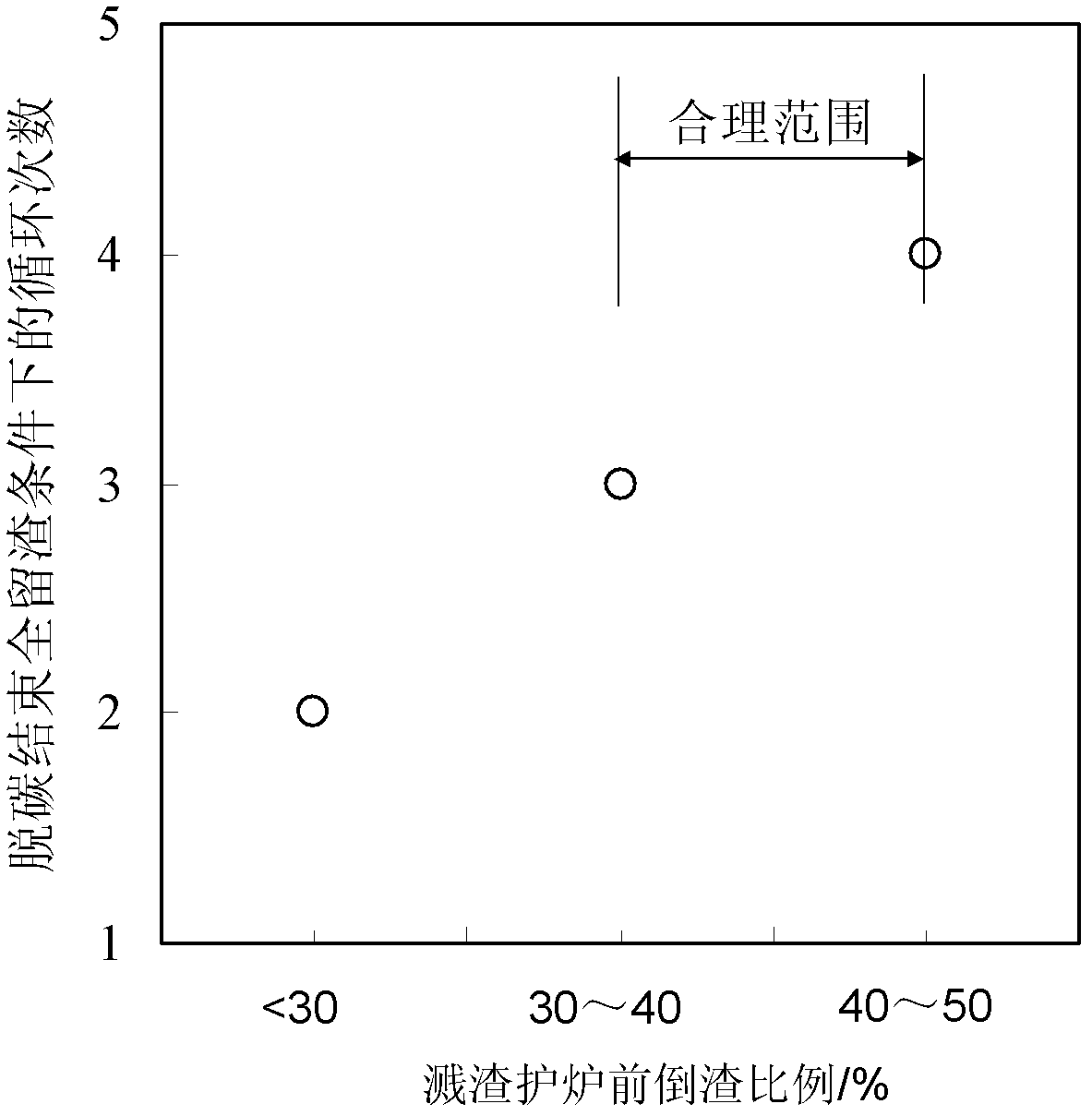

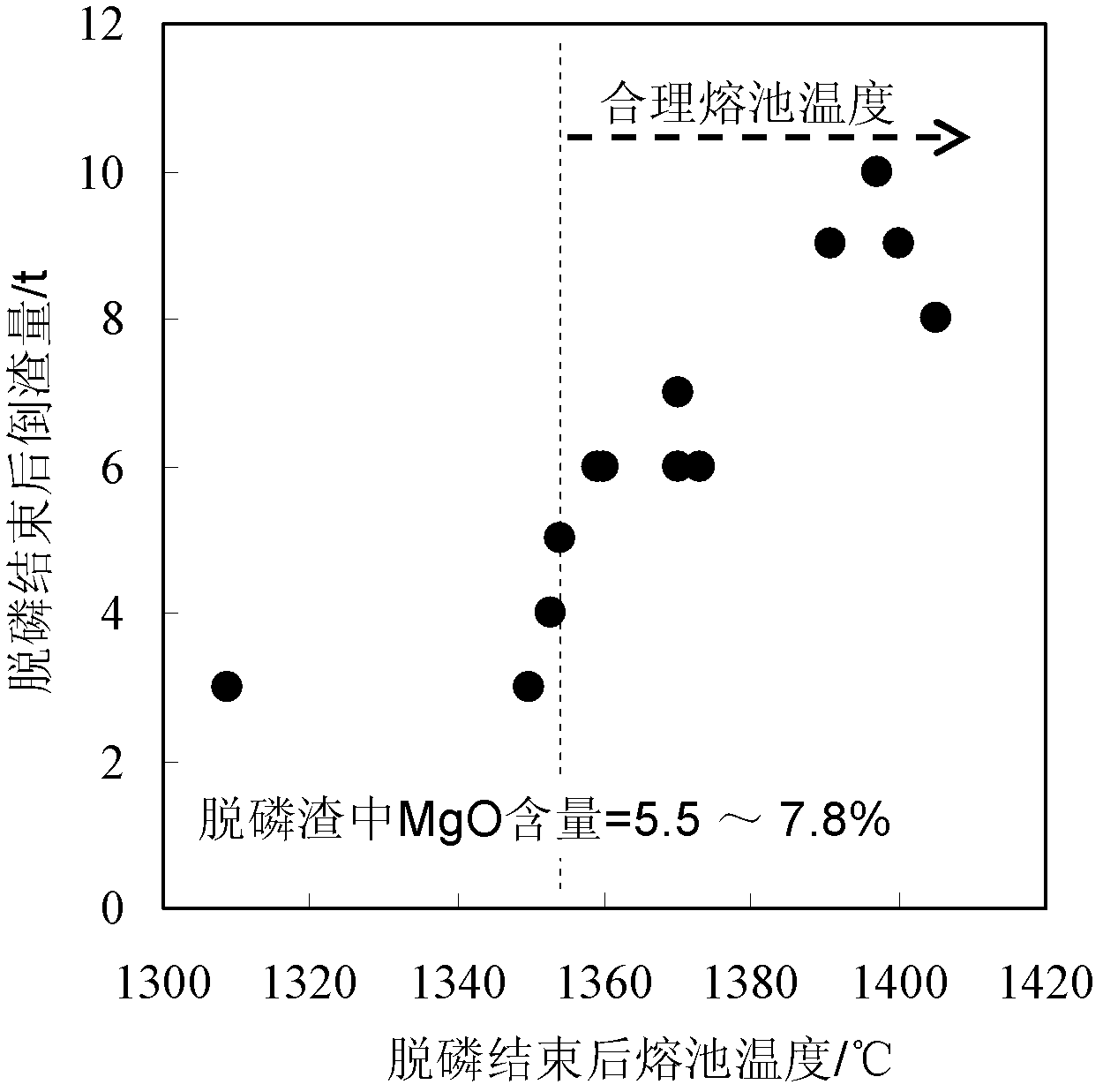

[0049] The SGRP technological process of the present invention is as figure 1 As shown, the process flow is a cyclic process, the starting point is slag splashing to protect the furnace, and the end point is slag remaining in the furnace; the furnace is protected by slag splashing, the liquid slag in the furnace is solidified, scrap steel is added, molten iron is added, and the first stage blowing - It consists of eight stages: dephosphorization stage, intermediate slag dumping, second stage blowing-decarburization stage, tapping and furnace slag retention. Use the slag left in the furnace to protect the furnace by slag spla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com