Maintenance method for converter lining

A converter lining and converter technology, applied in the manufacture of converters, etc., can solve problems affecting the service life of converters and maintenance costs, casting machine flocculation or alarm accidents, difficulty in converting converter slag, etc., to achieve convenient and rapid maintenance of furnace lining, The effect of shortening the repairing time and improving the working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Taking 120t converter iron lump slag repairing furnace as an example in a certain factory

[0037] A maintenance method for a converter lining, comprising the following steps:

[0038] 1) Prepare 3 tons of dry and clean iron blocks in advance;

[0039] 2) The end point of the converter is as follows: in the previous furnace for repairing, the temperature at the end point of tapping is controlled at 1647°C, and the oxygen at the end point is 289ppm; the composition of the final slag is 42.4% CaO, SiO 2 content of 12.8%, MgO content of 11.2%, TFe content of 14.9%, P 2 o 5 The content is 2.25%, the other content is 16.45%, and the alkalinity is 3.3;

[0040] 3) After removing the clean steel, adjust the viscosity of the slag by splashing slag to protect the furnace. After 2 minutes of slag splashing, the viscosity is suitable;

[0041] 4) Retain about 5t of slag when pouring slag;

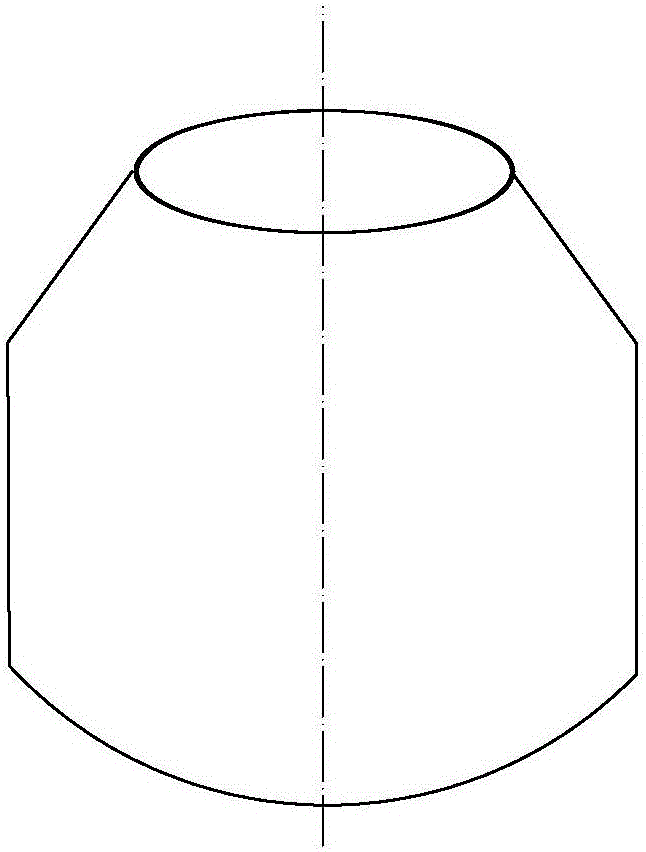

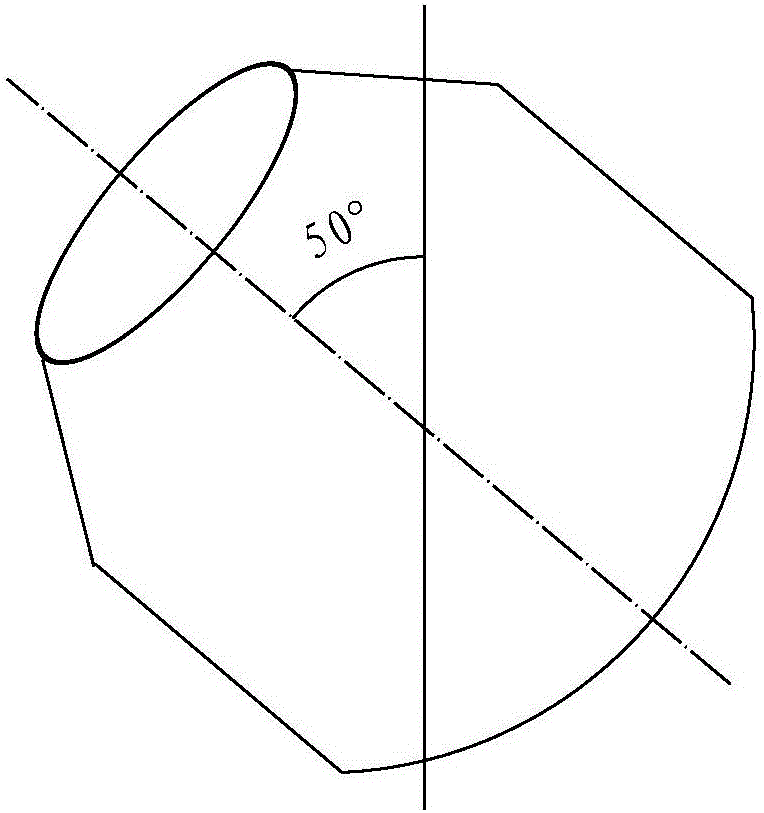

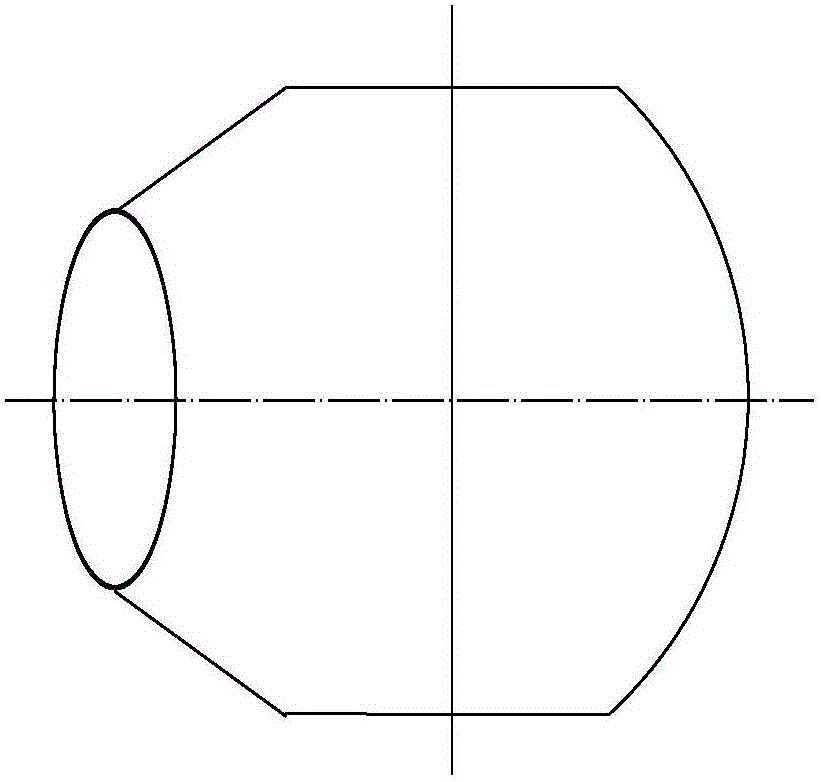

[0042] 5) Take the vertical upward position of the converter mouth as the 0° position,...

Embodiment 2

[0048] Take the 120t converter iron lump slag mending furnace as an example.

[0049] A maintenance method for a converter lining, comprising the following steps:

[0050] 1) In the previous furnace of the refurbishment, the temperature at the end point of tapping is controlled at 1640°C, and the oxygen at the end point of the converter is controlled at 350ppm, so that the steel is completely tapped;

[0051] 2) Control the final slag composition of the converter. After the clean steel is produced, keep 5.5% of the slag in the furnace, and adjust the viscosity of the slag by splashing the slag to protect the furnace. After 2 minutes of slag splashing, the viscosity is suitable; 2 content of 13.5%, MgO content of 11%, TFe content of 21.9%, P 2 o 5 The content is 1.89%, the other content is 11.21%, and the alkalinity is 3.0;

[0052] 3) Pour the dry and impurity-free iron nuggets prepared in advance for repairing the furnace evenly into the severely eroded part of the slag pour...

Embodiment 3

[0059] Take 120t converter iron lump slag mending furnace as an example.

[0060] A maintenance method for a converter lining, comprising the following steps:

[0061] 1) In the previous furnace of the refurbishment, the temperature at the end of tapping is controlled at 1650°C, and the oxygen at the end of the converter is controlled at 350ppm, so that the steel is completely tapped;

[0062] 2) Control the final slag composition of the converter. After the clean steel is produced, keep 6 tons of slag in the furnace, and adjust the viscosity of the slag by splashing slag to protect the furnace. After 2 minutes of slag splashing, the viscosity is suitable; 2 content of 11.5%, MgO content of 8.8%, TFe content of 10.3%, P 2 o 5 The content is 3.01%, the alkalinity is 3.85, and the other content is 20.09%;

[0063] 3) Pour the dry and impurity-free iron nuggets prepared in advance for repairing the furnace evenly into the severely eroded part of the slag pouring surface in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com