A kind of molten steel jacket at the top feeding place of oxygen-enriched side-blowing furnace

A side-blown furnace and molten steel jacket technology, applied in the field of copper smelting equipment, can solve the problems of shortened life of the side-blown furnace, erosion and corrosion of the furnace roof, difficult installation and disassembly, etc., and achieve the effect of simple structure, protective inner lining, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

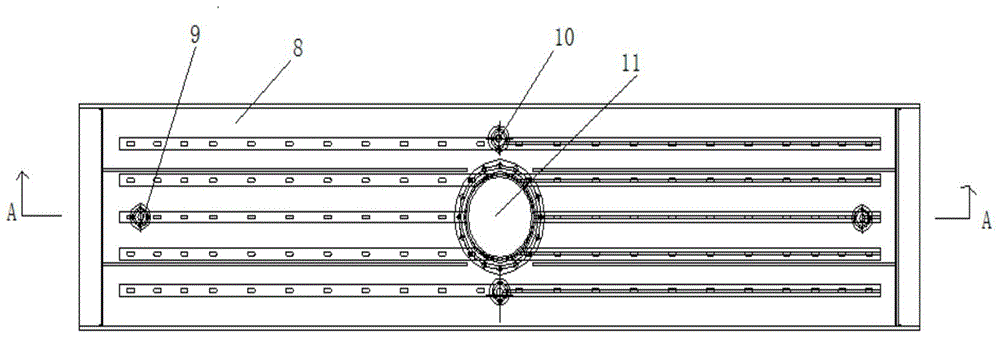

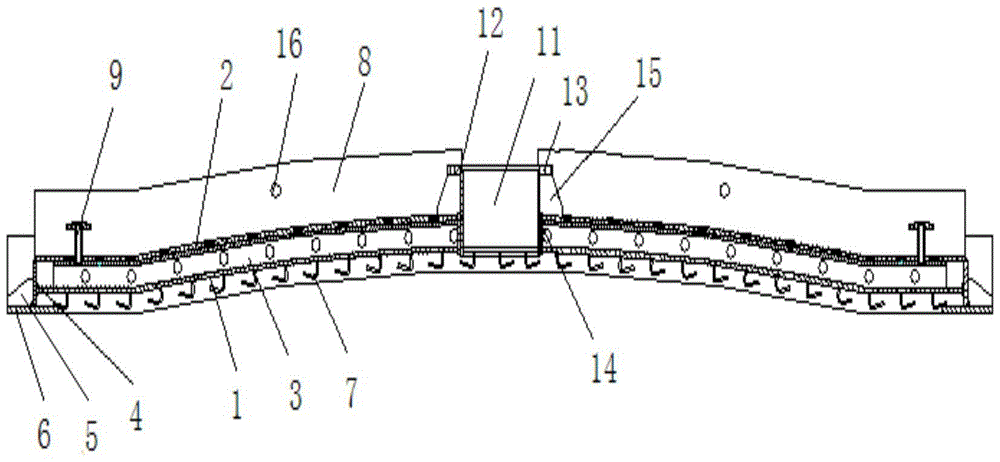

[0012] Referring to the accompanying drawings, a molten steel jacket at the top feed of an oxygen-enriched side-blowing furnace includes a bottom plate 1 and a cover plate 2, the bottom plate 1 and the cover plate 2 form a cavity, and the outer side of the bottom plate 1 and the cover plate 2 is connected with a rib plate 3 with holes , the two ends of the base plate 1 are connected to the vertical plate 4, the vertical plate 4 is connected to the bottom steel plate 6 through the triangular rib plate 5, a number of claw hooks 7 are arranged under the bottom plate 1, and the claw hooks 7 are arranged at equal intervals, and the cover plate 2 A top rib 8 is provided above, and a water inlet pipe 9 and an outlet pipe 10 are provided on the outer side of the top of the cover plate 2. The center of the bottom plate 2, the cover plate 3 and the top rib 8 is provided with a through hole 11 corresponding to the feeding port. The through hole 11 is provided with a fixing device 12, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com