Preparation method of polyvinyl chloride kitchen/bath board

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied to flat products, applications, household appliances, etc., can solve problems such as large-scale stable and unified production, brittle and easy-to-break boards, and unreliable density. Improve product quality, reduce product density, and increase the effect of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

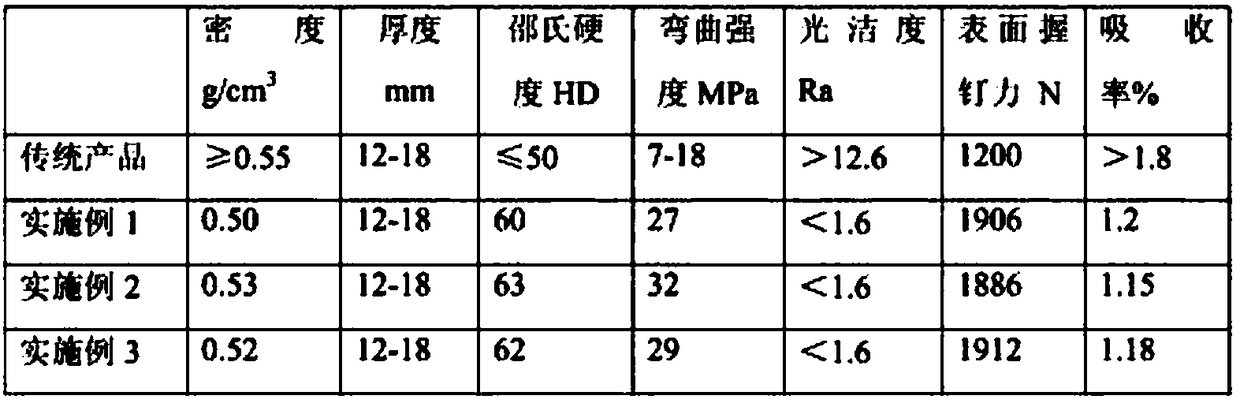

Examples

Embodiment 1

[0014] The polyvinyl chloride kitchen and bathroom board is composed of the following raw materials in parts by weight: 60 parts of polyvinyl chloride SG8 type resin, 40 parts of heavy calcium, 20 parts of recycled materials, 7 parts of foam regulator P90, 2.7 parts of lead salt stabilizer 0.5 parts, internal lubricant SP-60 0.2 parts, polyethylene wax 0.2 parts, micronized polyethylene wax N-14P 0.2 parts, plasticizer OA6 0.1 parts, exothermic AC foaming agent 0.5 parts, endothermic type NS- 1.2 parts of 603 foaming agent, 0.15 parts of fluorescent whitening agent, and 1 part of rutile; among them, heavy calcium needs to be activated before use.

[0015] The preparation method of described polyvinyl chloride kitchen and toilet board, comprises the following steps:

[0016] Put the materials into the hot mixing pot in the order of recycled material-plasticizer-polyvinyl chloride resin-heavy calcium-regulator-polyvinyl chloride resin-heavy calcium-recycled material, stir and he...

Embodiment 2

[0018] The polyvinyl chloride kitchen and bathroom board is composed of the following raw materials in parts by weight: 80 parts of polyvinyl chloride SG8 type resin, 60 parts of heavy calcium, 40 parts of recycled materials, 9 parts of foam regulator P90, 2.9 parts of lead salt stabilizer 0.6 parts, internal lubricant SP-60 0.3 parts, polyethylene wax 0.3 parts, micronized polyethylene wax N-14P 0.25 parts, plasticizer OA6 0.15 parts, exothermic AC foaming agent 0.6 parts, endothermic type NS- 1.4 parts of 603 foaming agent, 0.2 parts of fluorescent whitening agent, and 2 parts of rutile; among them, heavy calcium needs to be activated before use.

[0019] The preparation method of described polyvinyl chloride kitchen and toilet board, comprises the following steps:

[0020] Put the materials into the hot mixing pot in the order of reclaimed material-plasticizer-polyvinyl chloride resin-heavy calcium-regulator-polyvinyl chloride resin-heavy calcium-recycled material, stir for...

Embodiment 3

[0022] The polyvinyl chloride kitchen and bathroom board is composed of the following raw materials in parts by weight: 70 parts of polyvinyl chloride SG8 type resin, 50 parts of heavy calcium, 30 parts of recycled materials, 8 parts of foam regulator P90, 2.8 parts of lead salt stabilizer 0.55 parts of internal lubricant SP-60, 0.25 parts of polyethylene wax, 0.23 parts of micronized polyethylene wax N-14P, 0.12 parts of plasticizer OA6, 0.55 parts of exothermic AC foaming agent, endothermic NS- 1.3 parts of 603 foaming agent, 0.18 parts of fluorescent whitening agent, and 1.5 parts of rutile; among them, heavy calcium needs to be activated before use.

[0023] The preparation method of described polyvinyl chloride kitchen and toilet board, comprises the following steps:

[0024] Put the materials into the hot mixing pot in the order of recycled material-plasticizer-polyvinyl chloride resin-heavy calcium-regulator-polyvinyl chloride resin-heavy calcium-recycled material, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com