Method for utilizing sulfate slag and red mud comprehensively

A technology of sulfuric acid slag and red mud, applied in the field of metallurgy, can solve the problems such as the comprehensive utilization of red mud and sulfuric acid slag needs to be studied, the sulfuric acid slag has not been developed and utilized, and the low-iron red mud cannot be directly utilized, etc. High viscosity and easy bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Experimental raw materials:

[0044] The chemical composition of red mud is: TFe content 27.50%, CaO content 20.30%, Na 2 O content 2.29%;

[0045] Sulfuric acid slag, its chemical composition is: TFe content 48.71%, S content 1.25%;

[0046] Reduced coal.

[0047] experimental method:

[0048] (1) drying the red mud to obtain red mud with a water content of 5% by weight.

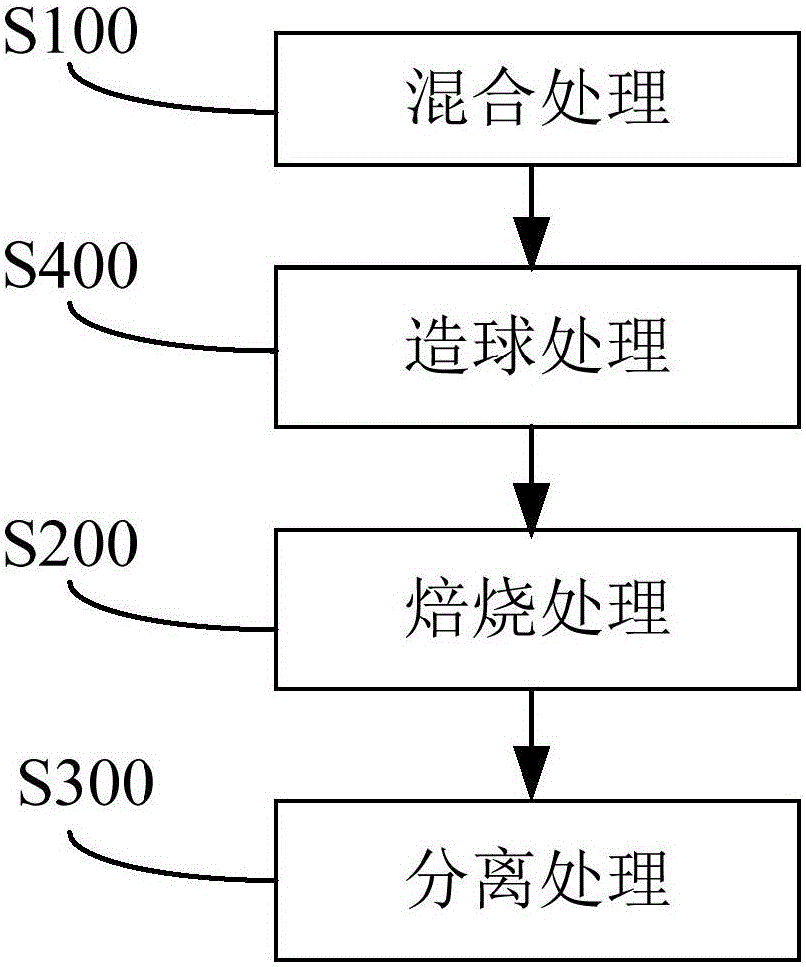

[0049] (2) Mix the dried red mud and sulfuric acid slag at a mass ratio of 1:1, and add reduced coal with a C / O ratio of 1.0 to obtain a mixed material.

[0050] (3) Make the mixed material into pellets.

[0051] (4) The pellets are dried and subjected to reduction roasting to obtain metallized pellets with a metallization rate of 92.34%.

[0052] (5) Separating the metallized pellets to obtain iron powder and tailings, wherein the iron grade of iron powder reaches 91.13%, the iron recovery rate reaches 92.45%, the sulfur content of iron powder is 0.056%, and the removal of sulfur The rate rea...

Embodiment 2

[0054] Experimental raw materials:

[0055] The chemical composition of red mud is: TFe content 12.97%, CaO content 40.25%, Na 2 O content 2.93%;

[0056] Sulfuric acid slag, its chemical composition is: TFe content 53.51%, S content 1.22%;

[0057] Reduced coal.

[0058] experimental method:

[0059] (1) drying the red mud to obtain red mud with a water content of 10% by weight.

[0060] (2) Mix the dried red mud and sulfuric acid slag at a mass ratio of 1:2, and add reduced coal with a C / O ratio of 1.2 to obtain a mixed material.

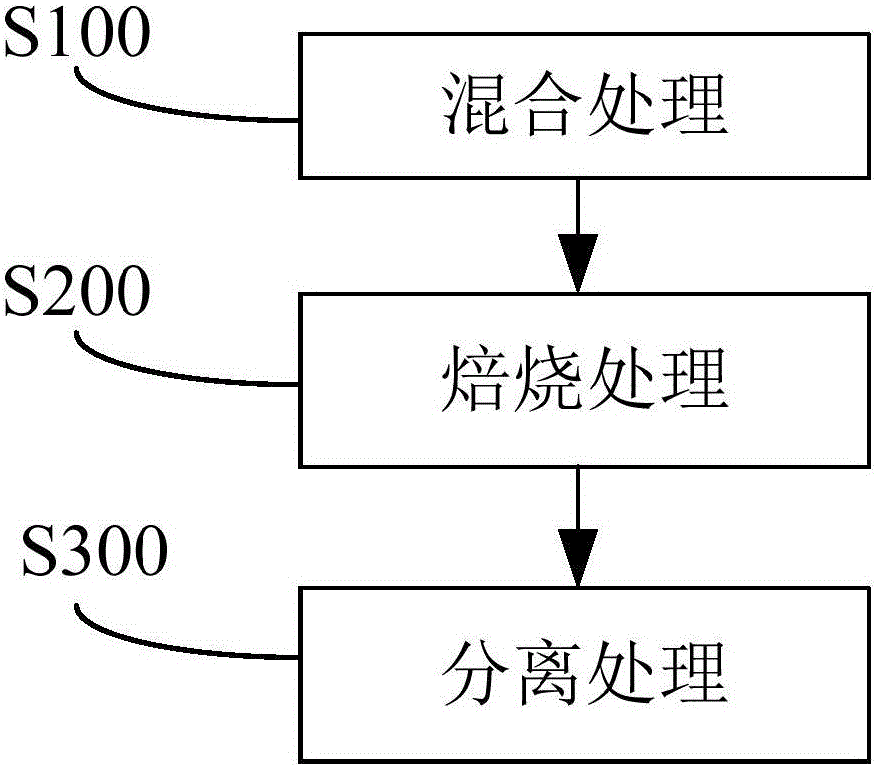

[0061] (3) The mixed material is reduced and roasted to obtain a reduced product with a metallization rate of 91.73%.

[0062] (4) Separating the product to obtain iron powder and tailings, wherein the iron grade of iron powder reaches 92.21%, the iron recovery rate reaches 91.72%, the sulfur content of iron powder is 0.042%, and the sulfur removal rate reaches 95.87% %.

Embodiment 3

[0064] Experimental raw materials:

[0065] Red mud, its chemical composition is: TFe content 7.21%, CaO content 49.50%, Na 2 O content 1.73%;

[0066] Sulfuric acid slag, its chemical composition is: TFe content 59.87%, S content 2.7%;

[0067] Reduced coal.

[0068] experimental method:

[0069] (1) drying the red mud to obtain red mud with a water content of 10% by weight.

[0070] (2) Mix the dried red mud and sulfuric acid slag at a mass ratio of 1:3, and add reduced coal with a C / O ratio of 1.5 to obtain a mixed material.

[0071] (3) Make the mixed material into pellets.

[0072] (4) The pellets are dried and subjected to reduction roasting to obtain metallized pellets with a metallization rate of 92.24%.

[0073] (5) Separating the metallized pellets to obtain iron powder and tailings, wherein the iron grade of the iron powder reaches 92.21%, the iron recovery rate reaches 92.77%, the iron recovery rate reaches 91.53%, and the sulfur content of the iron powder is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com