Method and device for high temperature sterilization by using steam explosion

A blasting equipment and high-temperature sterilization technology, applied in heating and other directions, can solve the problems of easy agglomeration and long time of the culture medium, and achieve the effects of shortening the sterilization cycle, reducing the damage rate, and shortening the high temperature maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

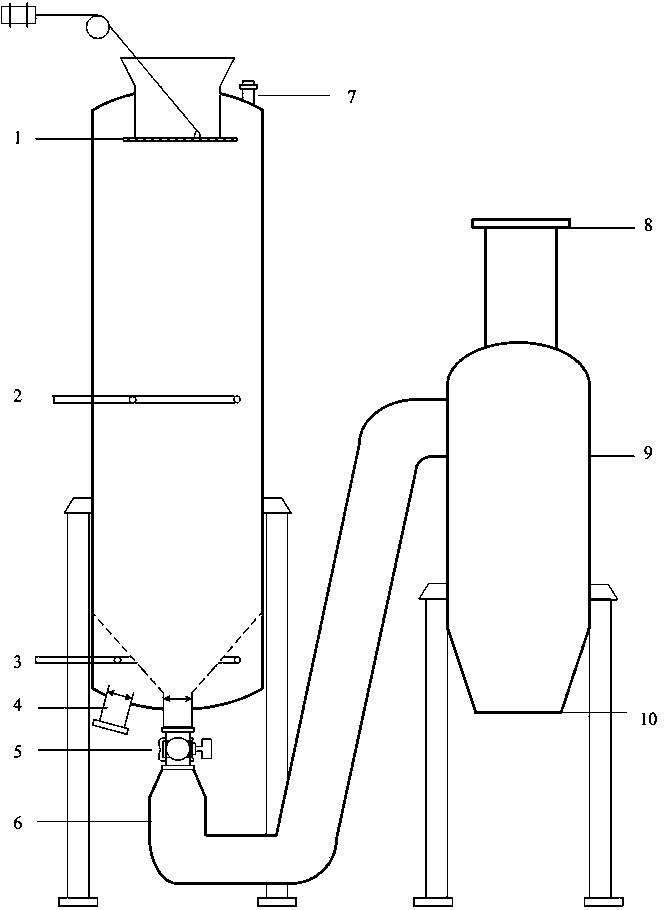

[0019] The bran soybean meal medium is sterilized by steam explosion high-temperature sterilization equipment, and then solid-state fermentation is used to produce feed additives.

[0020] The steam explosion equipment with a height-to-diameter ratio of 1:0.25, a diameter of 1.2m, and a cylinder height of 4.8m is used. The culture medium is composed of bran and soybean meal, the mass ratio of which is 9:1. After the two are fully mixed, 1.1 times (mass ratio) of inorganic salt solution is added. The composition of the inorganic salt solution is: (NH 4 ) 2 SO 2 ,,10 g / L, KH 2 PO 4 , 20 g / L, MnSO 4 , 0.4 g / L, CaCO 3 40 g / L, pH6.5-7.0.

[0021] Before the medium is sterilized, the equipment and pipelines should be sterilized first. Open the steam inlet valve (2) or (3) and the discharge valve (5), and the high-temperature steam is introduced from the steam generator, which is the steam explosion equipment and the feeding pipeline (6), the receiving tank (9), and the disch...

Embodiment 2

[0024] The steam explosion high temperature sterilization equipment is used to sterilize the steam explosion corn stalk and wheat bran medium, and then solid-state fermentation to produce cellulase.

[0025] The steam explosion equipment with a height-to-diameter ratio of 1:0.25, a diameter of 1.2m, and a cylinder height of 4.8m is used. The culture medium consists of steam-exploded corn stalks and wheat bran, the mass ratio of which is 4:1. After the two are fully mixed, 2.5 times (mass ratio) of inorganic salt solution is added. The composition of the inorganic salt solution is: (NH 4 ) 2 SO 4 , 15 g / L; MgSO 4 , 6 g / L; KH 2 PO 4 , 3 g / L.

[0026] Before the medium is sterilized, the equipment and pipelines should be sterilized first. Open the steam inlet valve (2) or (3) and the discharge valve (5), and the high-temperature steam is introduced from the steam generator, which is the steam explosion equipment and the feeding pipeline (6), the receiving tank (9), and the ...

Embodiment 3

[0029] Steam explosion high-temperature sterilization equipment is used to sterilize steam-exploded wheat straw and wheat bran medium, and then solid-state fermentation to produce cellulase.

[0030] The steam explosion equipment with a height-to-diameter ratio of 1:0.25, a diameter of 1.2m, and a cylinder height of 4.8m is used. The culture medium consists of steam-exploded wheat straw and wheat bran with a mass ratio of 4:1. After the two are fully mixed, 2.5 times (mass ratio) of inorganic salt solution is added. The composition of the inorganic salt solution is: (NH 4 ) 2 SO 4 , 15 g / L; MgSO 4 , 6 g / L; KH 2 PO 4 , 3 g / L.

[0031] Before the medium is sterilized, the equipment and pipelines should be sterilized first. Open the steam inlet valve (2) or (3) and the discharge valve (5), and the high-temperature steam is introduced from the steam generator, which is the steam explosion equipment and the feeding pipeline (6), the receiving tank (9), and the discharge port ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com