A multi-layer board, a method for producing a multi-layer board, and a slitting device for a multi-layer board veneer

A production method and multi-layer board technology, which is applied in the jointing of wooden veneers, other plywood/plywood appliances, manufacturing tools, etc., can solve problems such as poor quality, warping, and poor flatness of plywood, and achieve nail-holding The effect of strong force and preventing overall deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] The present invention proposes a kind of production method of multi-layer board, comprises the steps:

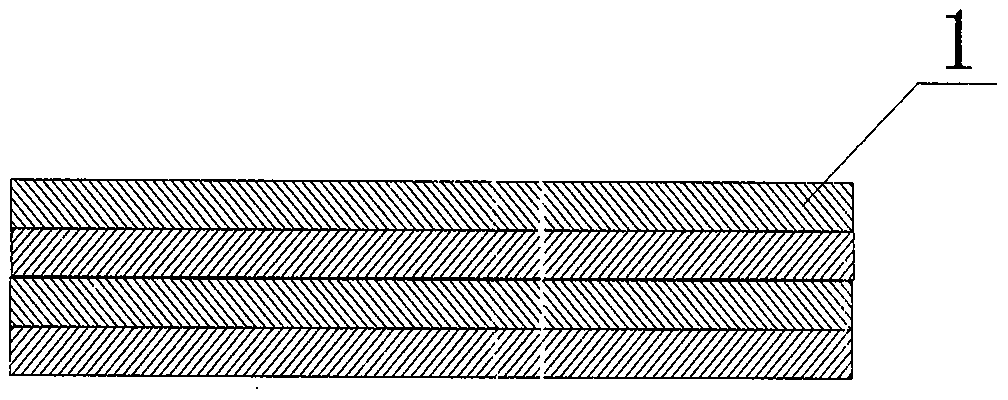

[0026] 1) Sorting the veneers by grade, screening the first-level veneers, the veneer 1 can be a poplar first-grade veneer, poplar rotary-cut (veneer has multiple wood species) veneers;

[0027] 2) Dry the veneer after air-cooling to keep the moisture content of the veneer at 7%-14%;

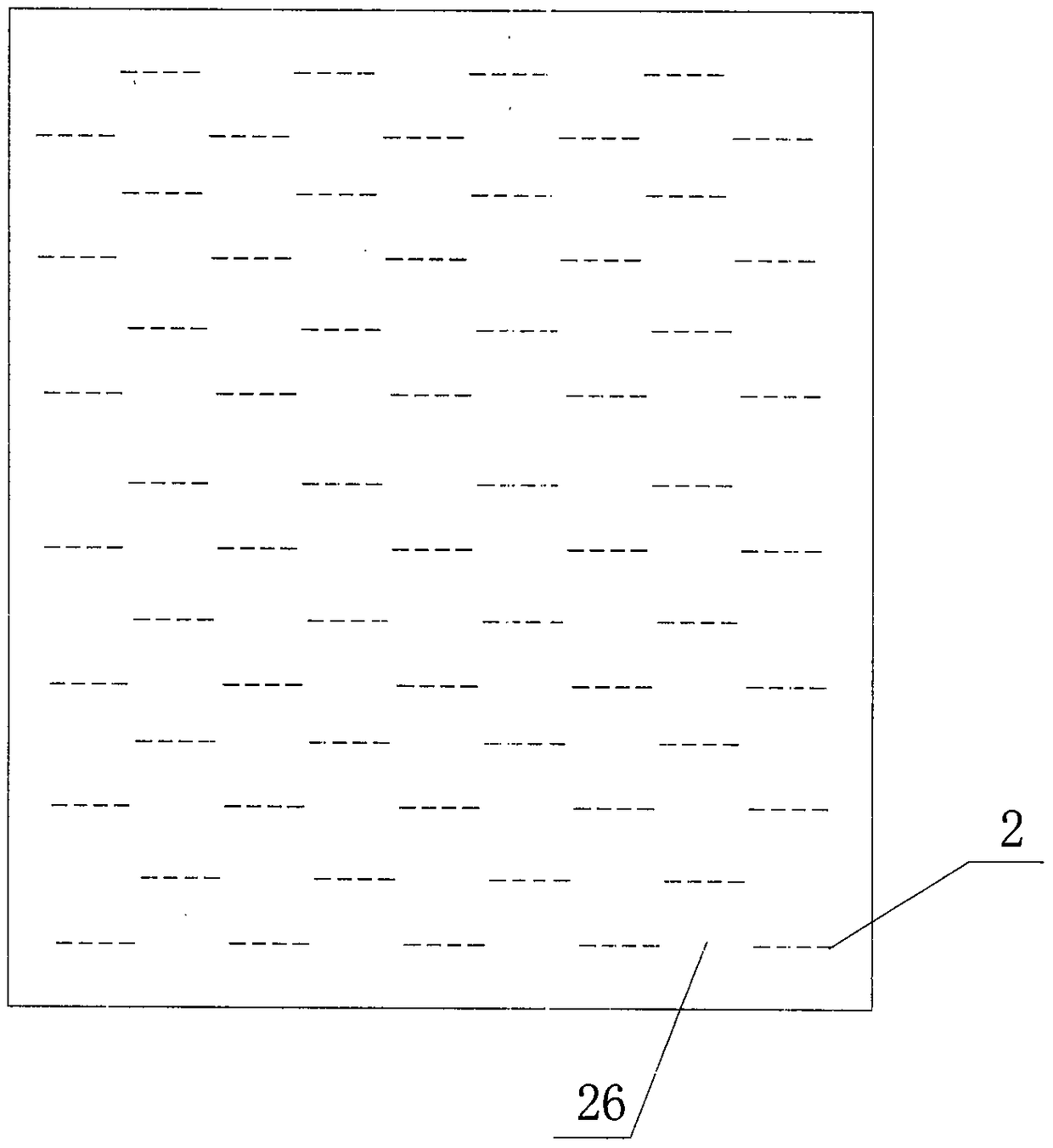

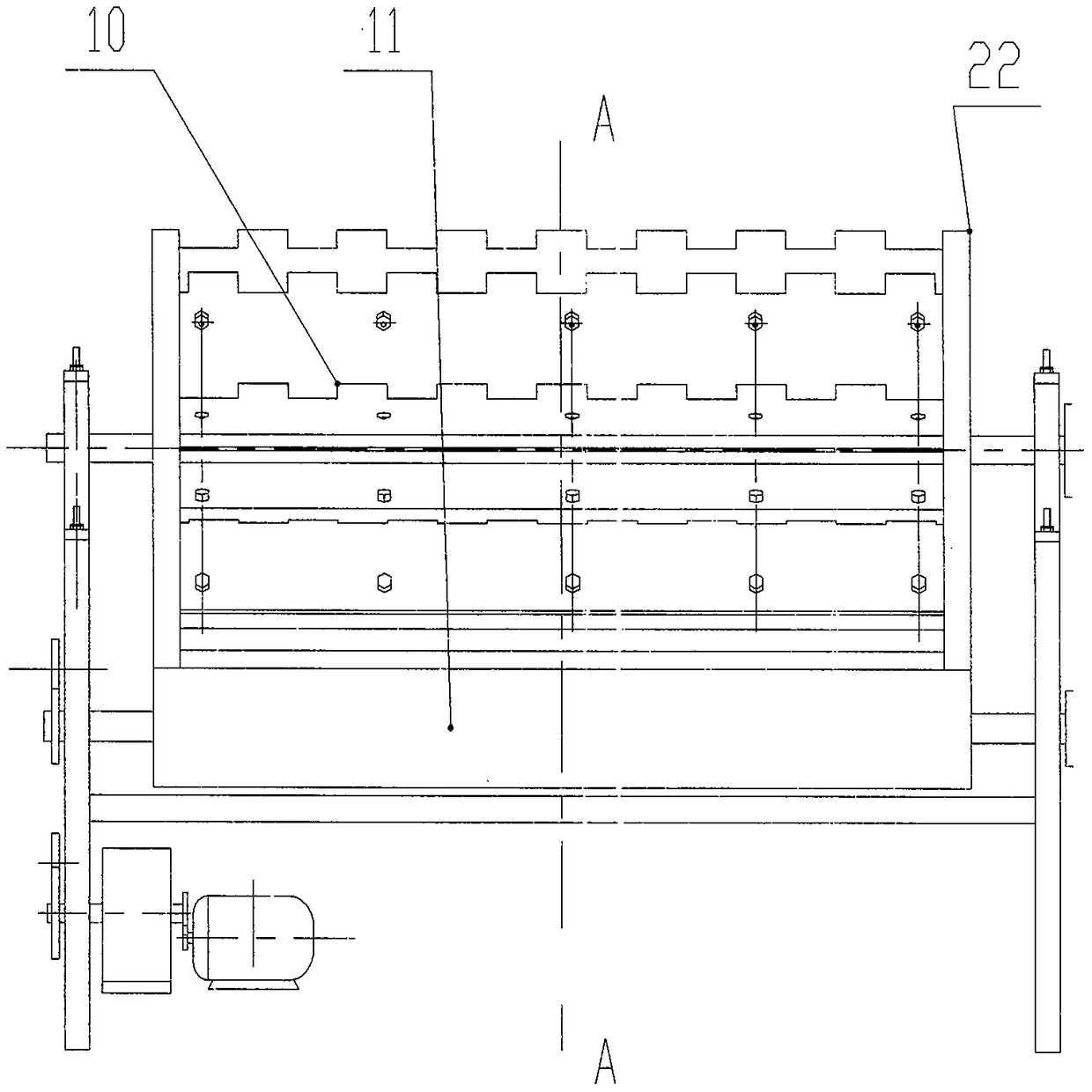

[0028] 3) Set several rows of slits 2 along the length of the veneer. Each row of slits includes several slits arranged at intervals on the same straight line. The specifications of each slit are the same, and the interval between each slit is 26 is the same as the length of the slit, and there is a distance between two adjacent rows of slits. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com