Fireproof and soundproof floor board based on sulfur-oxygen-magnesium materials and preparation method thereof

A magnesium oxysulfide material, fire-proof and sound-proof technology, which is applied to floors, ceramic products, and other household appliances, etc., can solve the problems of no load-bearing and sound-proof effects, difficulty in processing floor boards, and inability to prevent fire and moisture, etc., and achieve good sound-proof effects , increase toughness and processability, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

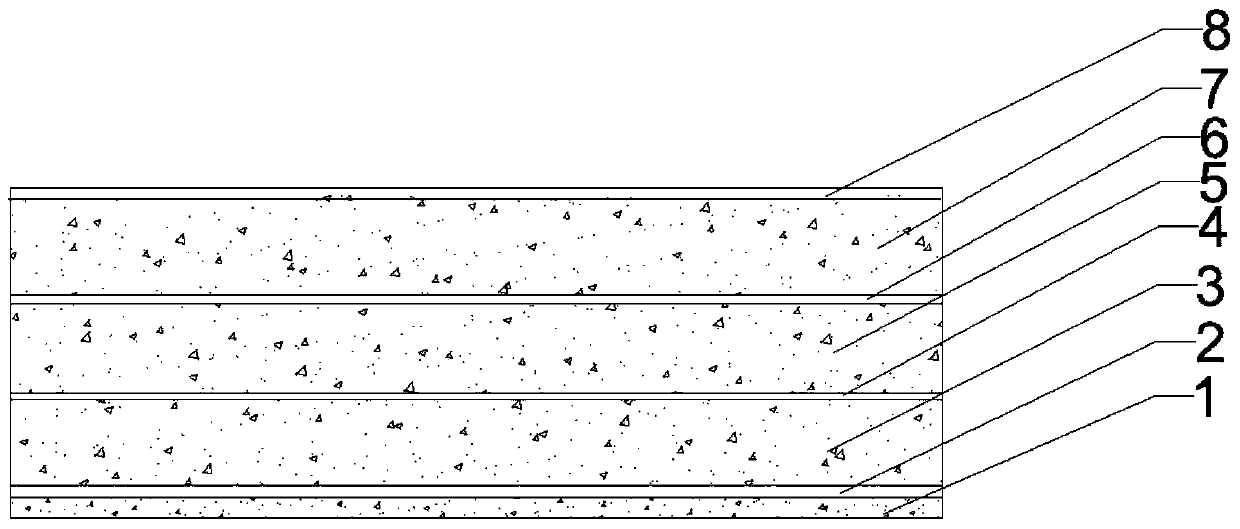

Image

Examples

preparation example Construction

[0067] The preparation method of the fire-proof and sound-proof floor board based on the magnesium oxysulfide material comprises the following steps: preparing surface paste, preparing medium paste, board making, primary curing, fully automatic demoulding, secondary curing, and cutting.

[0068] When preparing the flour paste, take 200-350 parts by weight of magnesium sulfate solution and 1-5 parts by weight of magnesium oxysulfate modifier and mix and stir for 2 minutes, then put 300 parts by weight of magnesium oxide and 1-5 parts by weight of pigment into the mixed slurry , after stirring for 4min, the batter was prepared.

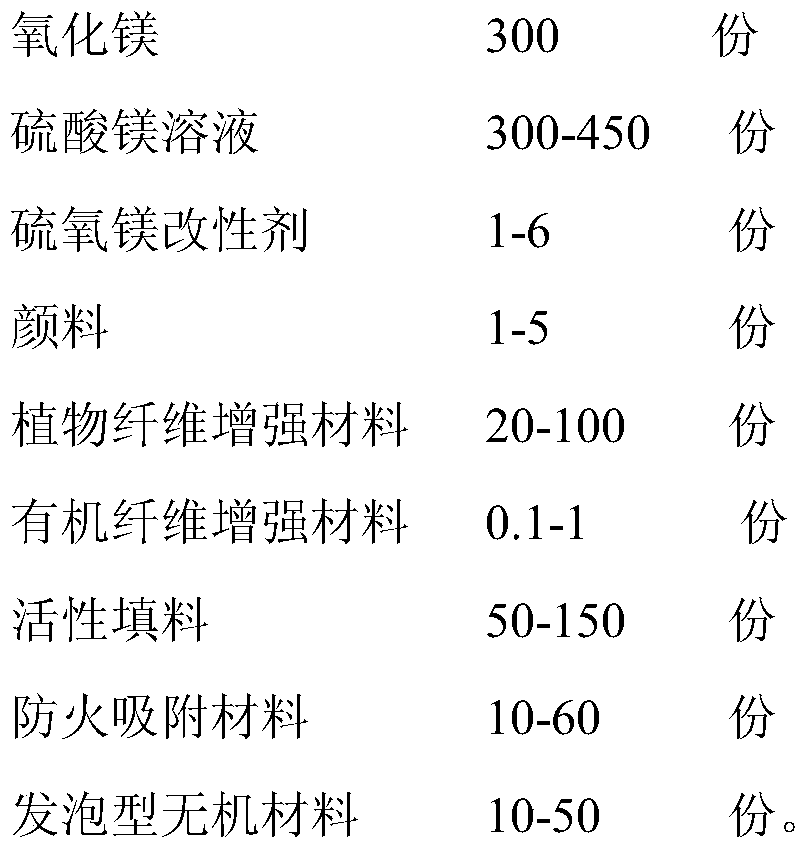

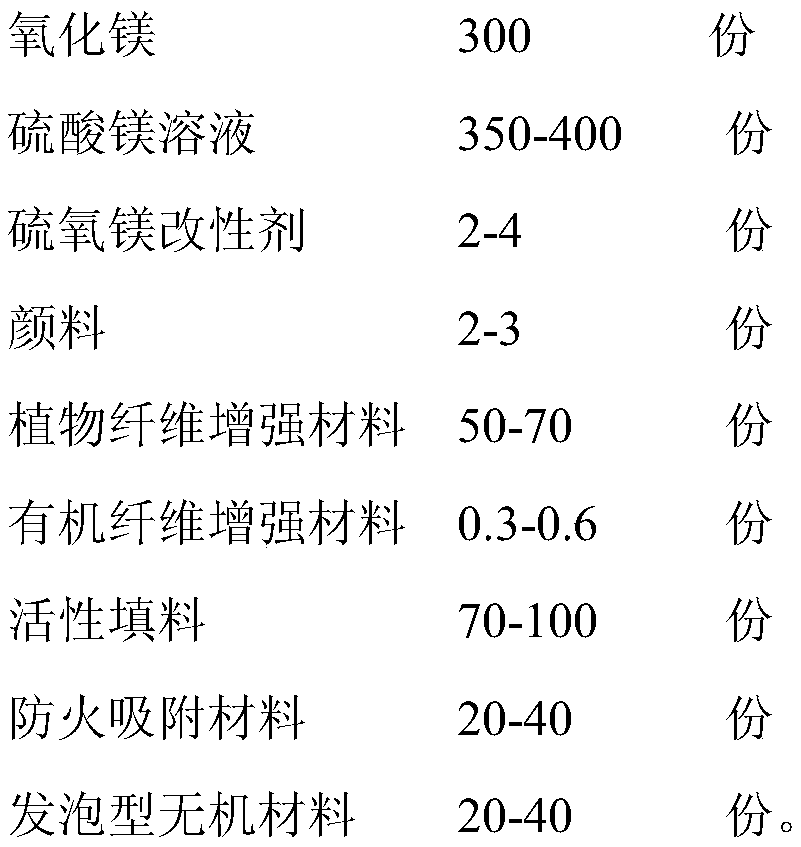

[0069] When preparing medium slurry, take 300-450 parts by weight of magnesium sulfate solution and 1-6 parts by weight of magnesium oxysulfide modifier and mix and stir for 2 minutes, then add 0.1-1 parts by weight of organic fiber reinforcement and stir for 1 minute; then add 20 parts by weight - 100 parts by weight of plant fiber reinforcing material...

Embodiment 1

[0074] Take 275 parts by weight of 27 ° Bé magnesium sulfate solution and 3 parts by weight of magnesium oxysulfate modifier and mix and stir for 2 minutes, then put 300 parts by weight of magnesium oxide and 3 parts by weight of pigment into the mixed slurry, and stir for 4 minutes to prepare the noodle slurry.

[0075] After getting the 27 ° of Bé magnesium sulfate solution of 375 weight parts and the magnesium oxysulfate modifier of 4 weight parts and mixing and stirring 2min, add the 8mm polypropylene fiber that has 0.5 weight part and stir 1min; Then add the bamboo powder of 20 weight parts, 300 parts by weight of magnesium oxide, 3 parts by weight of pigments, 35 parts by weight of diatom mud, 100 parts by weight of fly ash, and 30 parts by weight of expanded perlite, each raw material is put into and stirred at intervals of 1 minute, until all are put in Then continue to stir for 2min, and finally make the medium slurry.

[0076] Spread glass mesh fiber cloth on the tem...

Embodiment 2

[0079] Take 275 parts by weight of 27 ° Bé magnesium sulfate solution and 3 parts by weight of magnesium oxysulfate modifier and mix and stir for 2 minutes, then put 300 parts by weight of magnesium oxide and 3 parts by weight of pigment into the mixed slurry, and stir for 4 minutes to prepare the noodle slurry.

[0080] Get the 27 ° of Bé magnesium sulfate solution of 375 weight parts and after the magnesium oxysulfate modifier of 4 weight parts mix and stir 2min, add the 8mm polypropylene fiber that has 0.5 weight part and stir 1min; Then add the bamboo powder of 40 weight parts, 300 parts by weight of magnesium oxide, 3 parts by weight of pigments, 35 parts by weight of diatom mud, 100 parts by weight of fly ash, and 30 parts by weight of expanded perlite, each raw material is put into and stirred at intervals of 1 minute, until all are put in Then continue to stir for 2min, and finally make the medium slurry.

[0081] Spread glass mesh fiber cloth on the template to form t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com