Method for manufacturing high-density glue permeated plate in mould pressing solid wood

A manufacturing method and high-density technology, applied to flat products, pressure impregnation, wood processing equipment, etc., can solve the problems of waterproof, fire prevention, crack prevention, poor nail holding ability, etc., and achieve woody appearance and strong nail holding power. Good stability, shortening the effect of glue penetration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

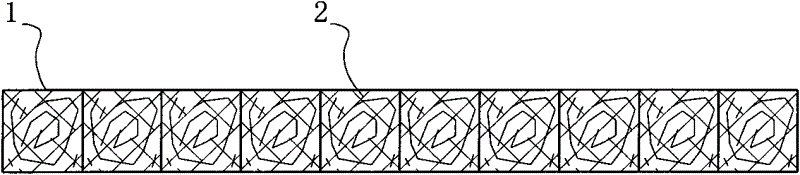

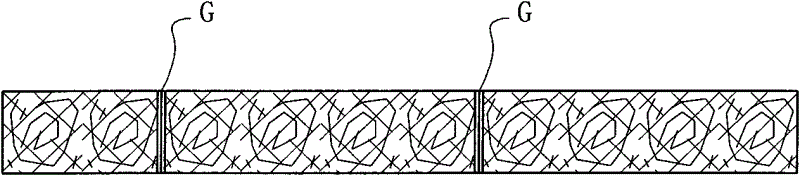

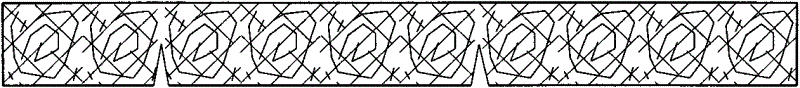

[0011] See attached figure 1 , 2 , 3, 4, 5, a kind of manufacturing method of molded solid wood medium-high-density plywood disclosed by the present invention is characterized in that: put the lower density plank or wooden strip 1 in the high-pressure container to pressurize beyond the atmospheric pressure Glue penetration, so that the thermosetting glue solution with fireproofing agent and a certain temperature can quickly penetrate the thickness of the board and blend into the fibrous tissue of the wood at a rate of 9% to 18% of the weight of the formed board. After the wooden boards or wooden strips 1 taken out of the tank are dried at low temperature, they are molded in a hot press according to the compression ratio that can be compressed into medium and high density boards, so that the thermosetting glue 2 can penetrate into the wooden boards or wooden boards. Solid wood medium and high density plywood between strips 1 fiber tissue.

[0012] The method involved in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com