Self-insulating composite wallboard and production method

The technology of a composite wallboard and a production method is applied in the field of thermal insulation wallboard to achieve the effects of convenient slotting and pipe layout, strong nail holding force and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Follow the steps below to produce self-insulating composite wallboard:

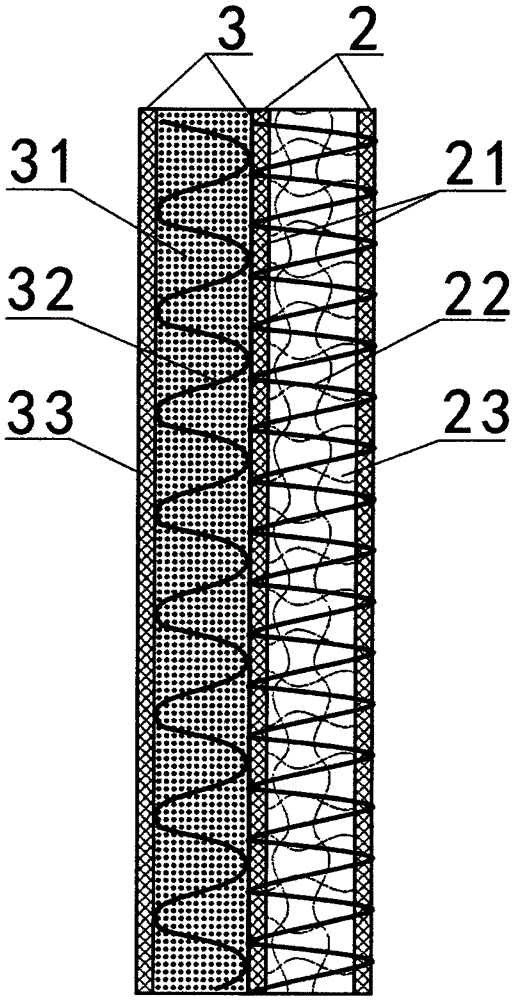

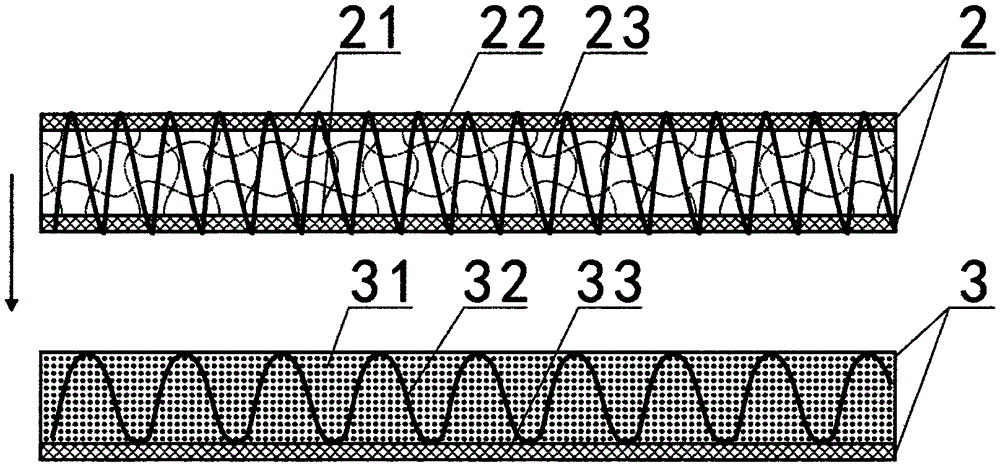

[0026] (1) Use inorganic alkali-resistant sewing thread 22 to combine two layers of basalt fiber mesh cloth (and image 3 Corresponding to the outer grid cloth 21) and the rock wool board sandwiched in it (with image 3 Corresponding to the middle plate 23) stitched together, and placed in the grouting mold;

[0027] (2) Preparation of cement-based mortar: prepare the following materials in parts by mass: 15 parts of styrene-acrylic emulsion, 20 parts of quartz sand, 10 parts of fly ash, 20 parts of cement, 1 part of organic polyether ester, 10 parts of calcium silica powder, 0.5 part of wood fiber, 1 part of dispersible latex powder, 1 part of ethylene glycol, and the mass of water is limited to the appropriate concentration of the cement-based mortar; mix the above-mentioned raw materials and stir evenly to obtain a slurry-like cement-based mortar;

[0028] (3) Pour the slurry-like cement-based morta...

Embodiment 2

[0034] Follow the steps below to produce self-insulating composite wallboard:

[0035] (1) Use inorganic alkali-resistant sewing thread 22 to combine two layers of carbon fiber mesh cloth (and image 3 Corresponding to the outer mesh cloth 21) and the glass wool board sandwiched in it (with image 3 Corresponding to the middle plate 23) stitched together, and placed in the grouting mold;

[0036] (2) Preparation of cement-based mortar: prepare the following parts by mass: 25 parts of acrylic silicone acrylic emulsion, 40 parts of quartz sand, 20 parts of fly ash, 40 parts of cement, 3 parts of mineral oil, 20 parts of calcium silica powder, wood 1 part of fiber, 5 parts of dispersible latex powder, 5 parts of ethylene glycol, and the mass of water is limited to the appropriate concentration of the cement-based mortar; mix the above-mentioned raw materials and stir evenly to obtain a slurry-like cement-based mortar ;

[0037] (3) Pour the slurry-like cement-based mortar into the gr...

Embodiment 3

[0043] Follow the steps below to produce self-insulating composite wallboard:

[0044] (1) Use inorganic alkali-resistant sewing thread 22 to combine two layers of alkali-resistant glass fiber mesh (and image 3 Corresponding to the outer mesh cloth 21) and the extruded polystyrene board sandwiched therein (with image 3 The middle plate 23 corresponding to) is stitched together and placed in a grouting mold;

[0045] (2) Preparation of cement-based mortar: prepare the following materials in parts by mass: 20 parts of acrylic silicone acrylic emulsion, 30 parts of quartz sand, 15 parts of fly ash, 30 parts of cement, 2 parts of organic polyether ester, 15 parts of calcium silica powder , 0.8 parts of wood fiber, 3 parts of dispersible latex powder, 3 parts of ethylene glycol, and the mass parts of water are limited to the appropriate concentration of the cement-based mortar; mix the above-mentioned raw materials and stir evenly to obtain slurry cement Base mortar

[0046] (3) Pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com