Formaldehyde-free fiber material and formation method thereof, as well as fiber decorative material and manufacturing method thereof

A fiber material and fiber technology, applied in the field of formaldehyde-free fiber material and its formation, can solve the problems of bamboo wood resources consumption, waste of bamboo wood resources, narrow use range, etc., achieve large commercial value, suitable for large-scale industrial production, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

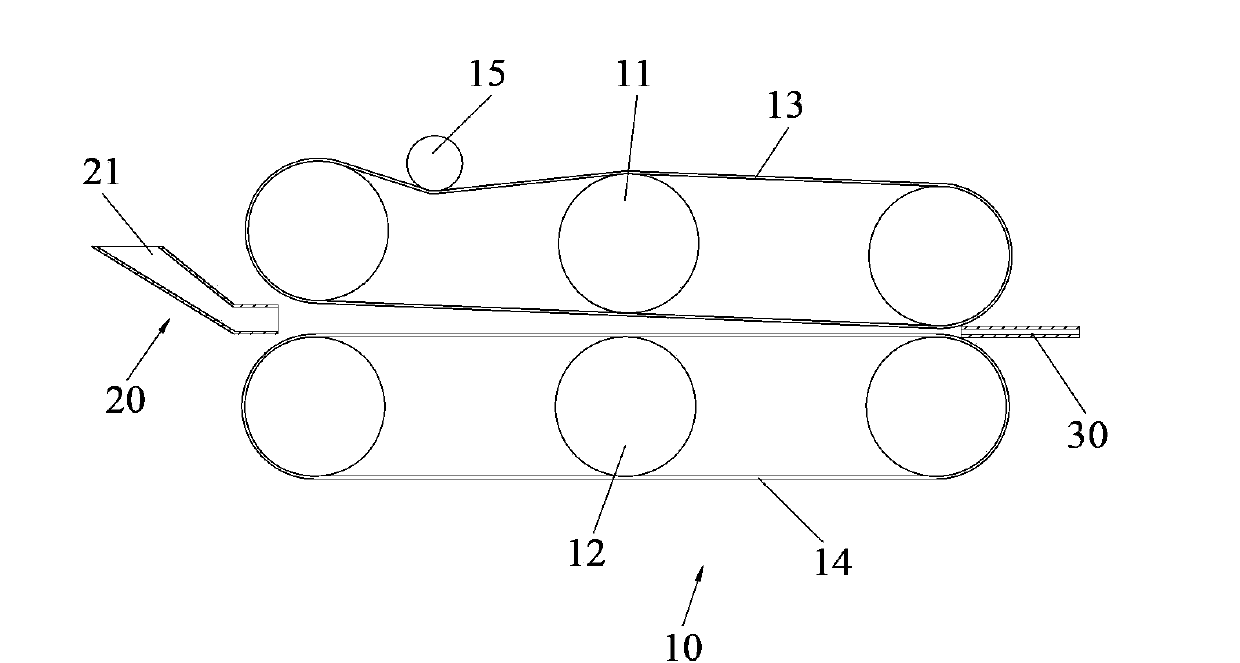

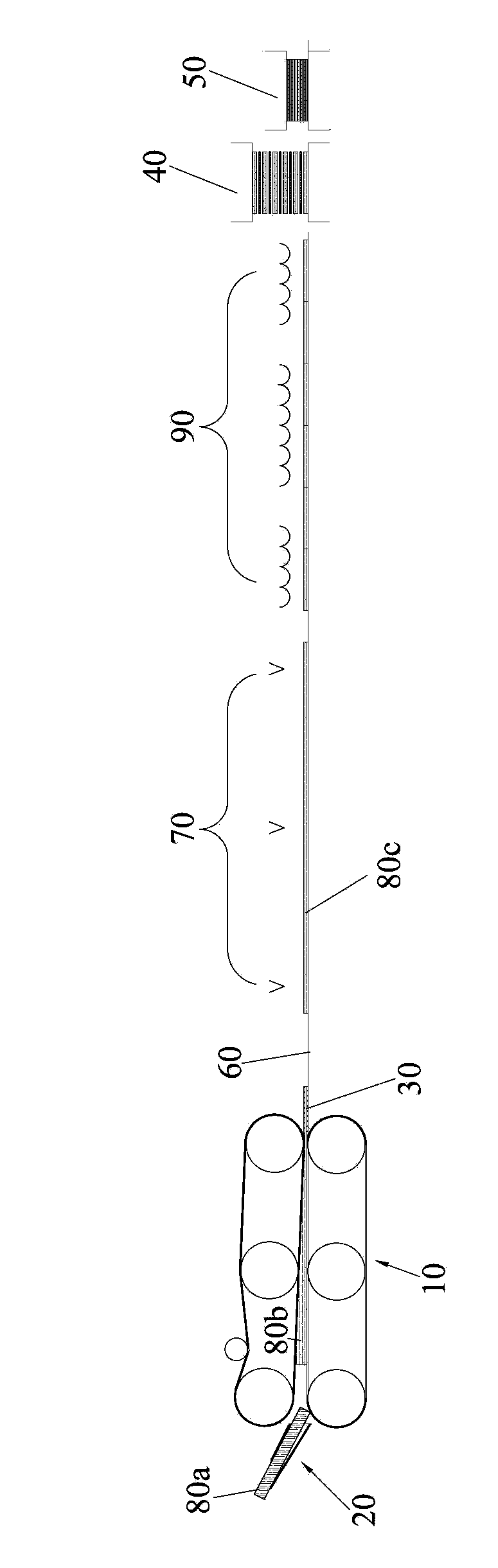

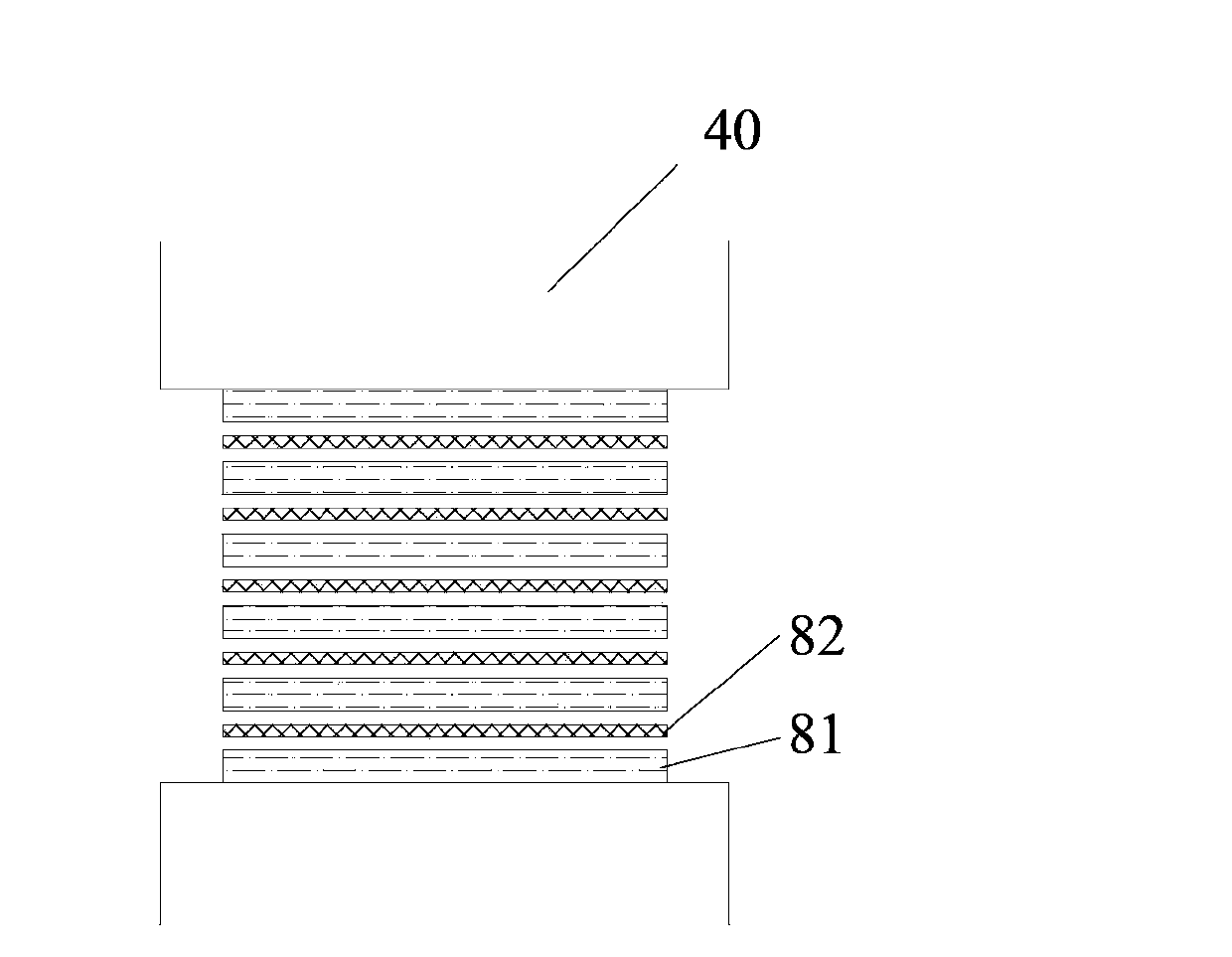

[0122] According to the aforementioned figure 2 The process shown uses Salix twigs to form formaldehyde-free fiber materials, wherein the conditions for milling are such that the diameter of the fibers of the Salix branches after milling is 0.05 mm (85-88% by weight of the fibers remain cohesive after milling) , through the formaldehyde-free binder Hansi T extruded from the glue spraying device, the fibers of the milled willow branches are bonded into a whole (that is, they are bonded to each other along the length of the fiber filaments), and dried The device dries the milled salix branches after adding the formaldehyde-free binder so that the water content of the milled salix branches is 3% by weight, and then the dried and bonded salix branches are dried and bonded by the cutting device. The shredded willow branches together are cut into the shredded shredded shreds (thickness is 0.1cm) of the required size, and then the shredded shredded shreds (thickness is 0.1cm) are la...

Embodiment 2

[0124] Formaldehyde-free fiber material is formed according to the method of embodiment 1, and difference is, the condition of silk rolling makes the diameter of the fiber silk of the salix branch after silk milling be 0.001mm (the fiber silk of 83-85% by weight after silk milling keeps adhesion ), wherein the internal bonding strength of the obtained formaldehyde-free fiber material is 0.85MPa, and other performance indicators such as static bending strength, surface bonding strength, water absorption thickness expansion rate, density deviation, etc. are better than those of the prior art wood-based panels The standard is sufficient to meet the requirements of GB / T11718-1999 on the physical and mechanical performance indicators of indoor panels.

Embodiment 3

[0126] Formaldehyde-free fiber material is formed according to the method of embodiment 1, and difference is, the condition of rolling silk makes the diameter of the fiber silk of the salix branch after silk rolling be 0.1mm (the fiber silk of 88-90% by weight after silk rolling keeps adhesion ), wherein the internal bonding strength of the obtained formaldehyde-free fiber material is 0.8 MPa, and other performance indicators such as static bending strength, surface bonding strength, water absorption thickness expansion rate, density deviation, etc. are better than those of the prior art wood-based panels The standard is sufficient to meet the requirements of GB / T11718-1999 on the physical and mechanical performance indicators of indoor panels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Internal binding strength | aaaaa | aaaaa |

| Internal binding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com