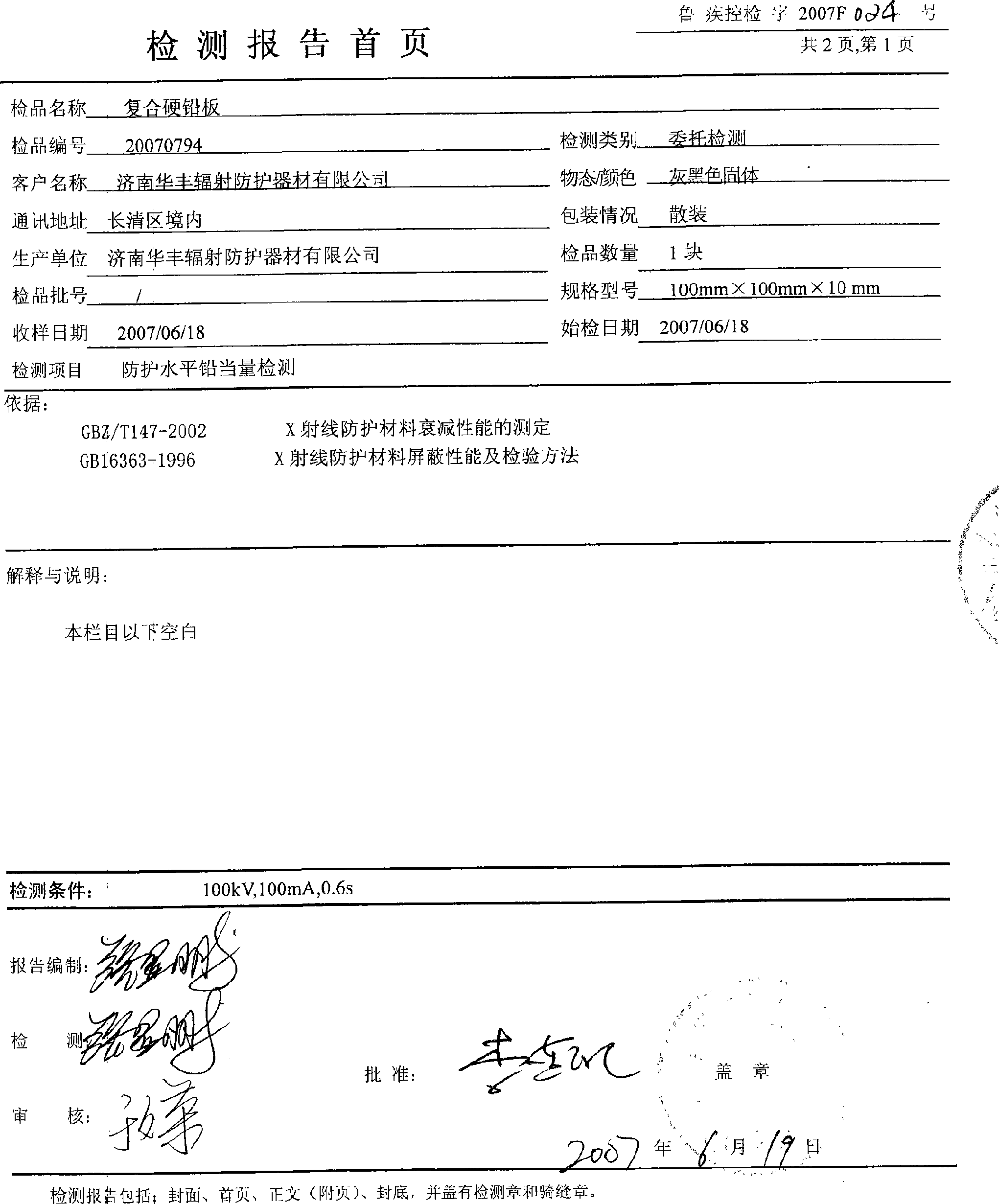

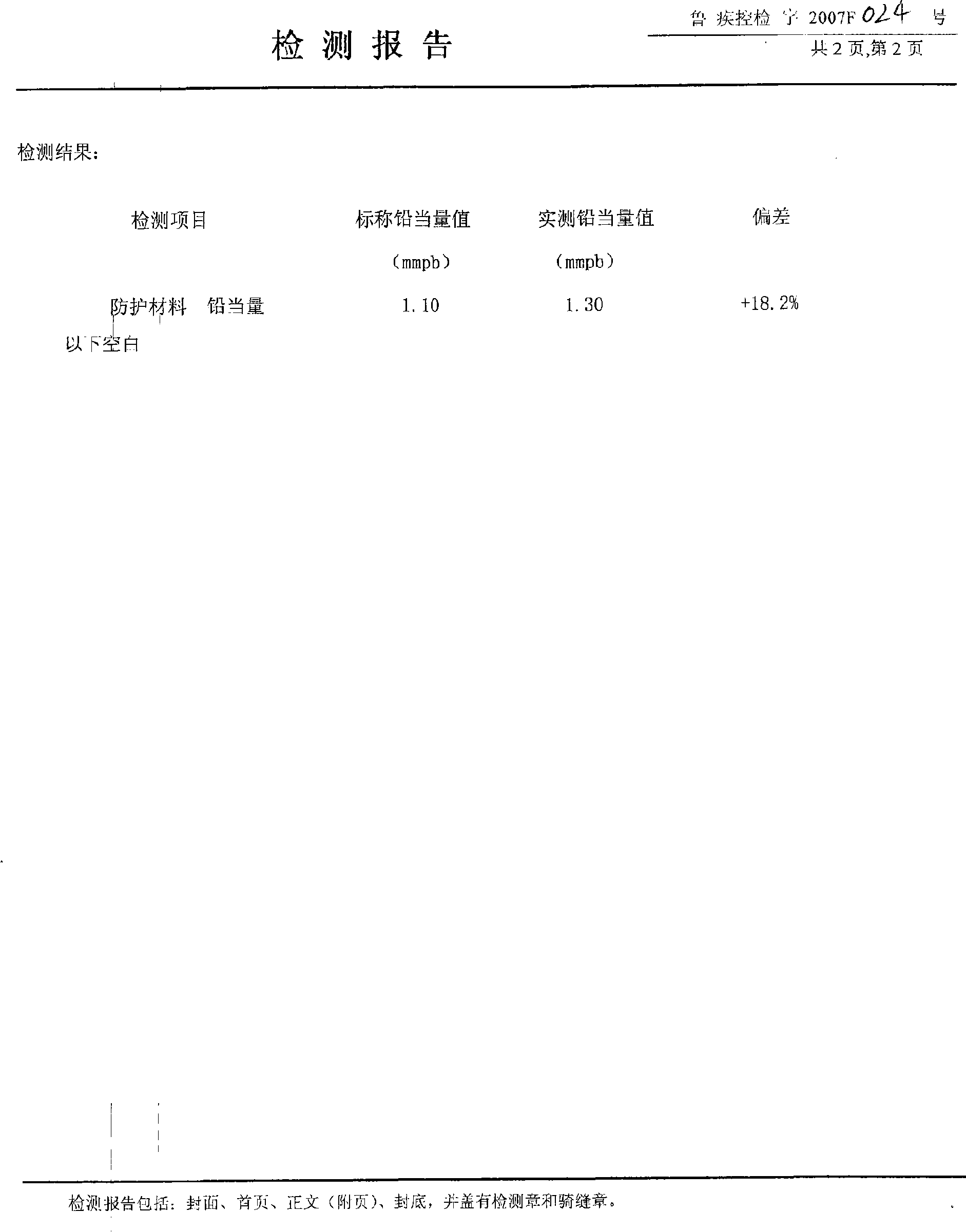

Protective plate material for X ray

A technology of X-ray and plate, which is applied in the field of X-ray protective plate and its production, can solve the problems of affecting the service life of the protective plate, poor protective effect at nail holes, and low mechanical performance of pure lead, so as to shorten the production cycle and improve the protective effect Strong, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with practical examples.

[0030] The board is composed of six layers of materials, the composition ratio of the top layer and the bottom layer is the same, and the weight ratio of lead sulfide and / or lead chloride, magnesium sulfate, water, and lightly burned magnesium is 5:2:2:4; The component distribution ratio is the same, and the weight ratio of lead sulfide and / or lead chloride, magnesium sulfate, water and light burned magnesium is 10:3:3:6.

[0031] In the agitating mixer, according to the weight ratio of the top layer of the plate and the bottom layer of lead sulfide and / or lead chloride, magnesium sulfate, water, and light burnt magnesium as 5:2:2:4, first put in a proportioned amount of magnesium sulfate For solids, add water in the same ratio and stir evenly; then add lead sulfide and / or lead chloride and light-burned magnesium according to the ratio, and continue to stir and mix until it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com