Leadless radiation protection barium plate and method for producing the same

A lead-free, barium salt technology, applied in shielding, nuclear engineering, reactors, etc., can solve the problems of limited use, high production cost, heavy metal pollution, etc., to achieve stable protection performance, stable geometric dimensions, and reduce protection costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

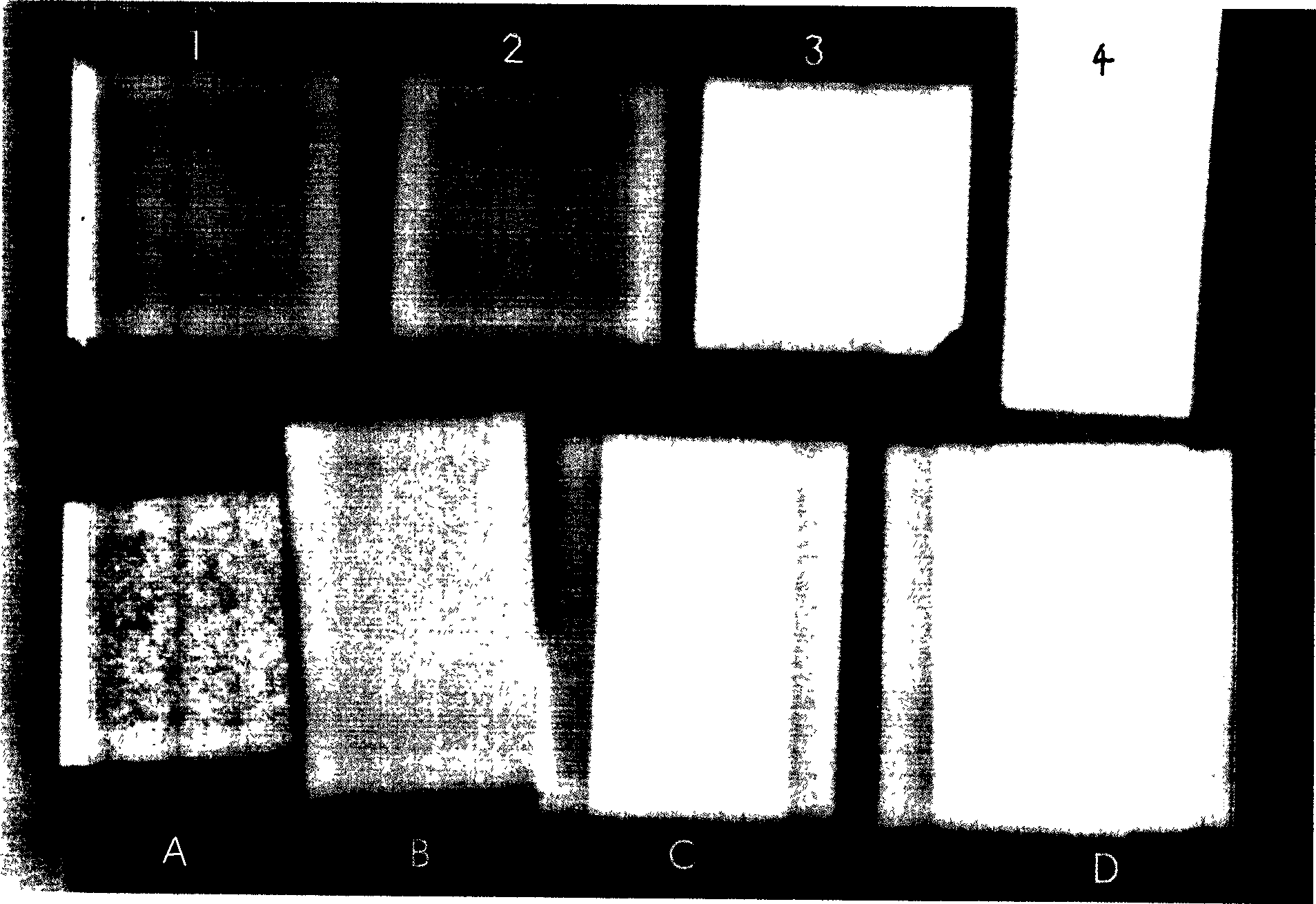

Image

Examples

Embodiment 1

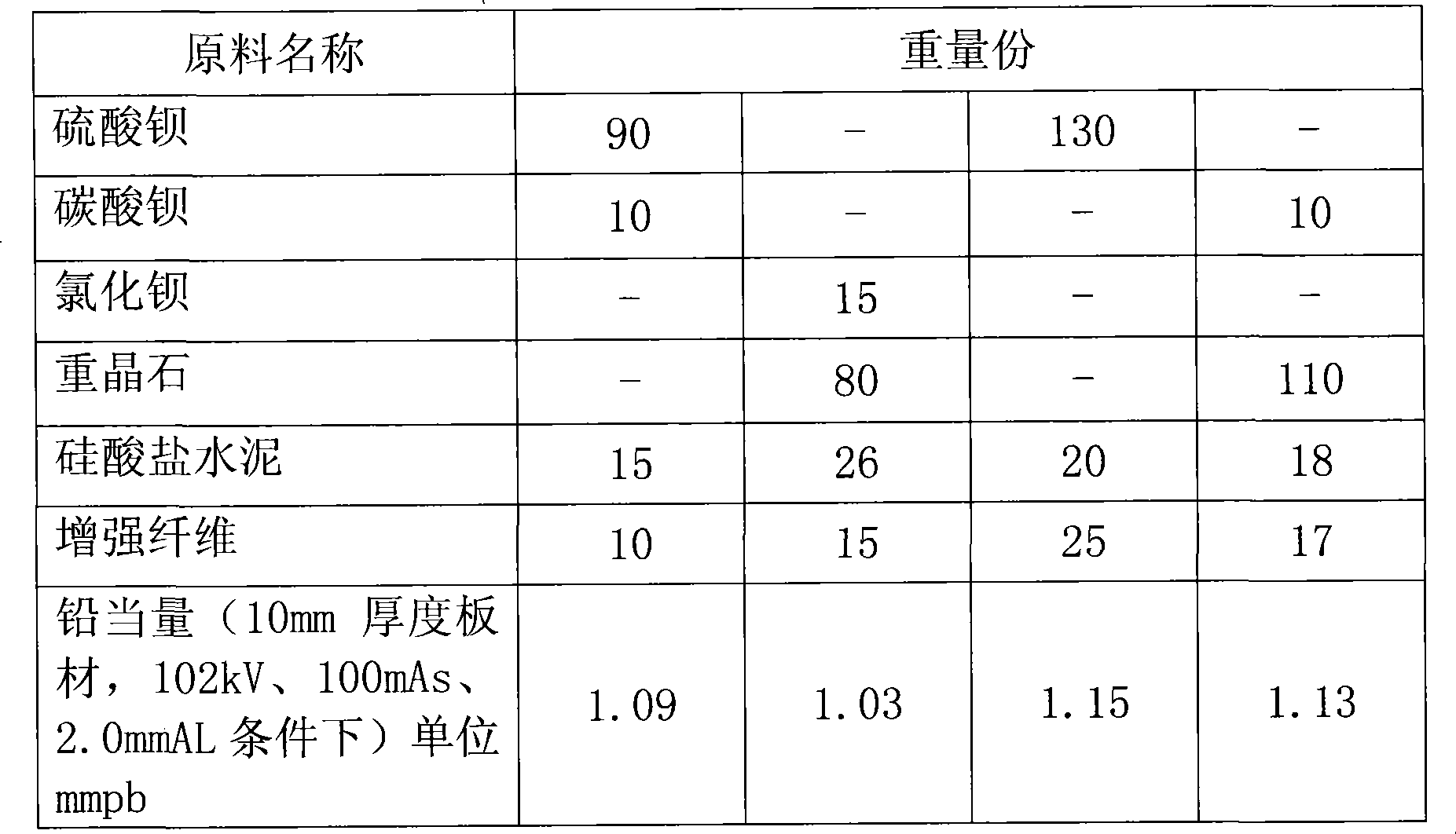

[0032] The lead-free radiation protection barium plate is made of barium sulfate with a particle size of 400 meshes, Portland cement with a label of 425, and pulp fibers. The raw material components are (parts by weight):

[0034] Portland cement: 25

[0035] Pulp Fiber: 12

[0036] The production method of lead-free ray shielding barium plate comprises the following steps:

[0037] (1) mix barium sulfate and Portland cement in proportion, add water and beat in a beater to make a slurry with a concentration of 30%;

[0038] (2) Pulp fiber is beaten into slurry;

[0039] (3) mixing the slurry of step (1) with the slurry of step (2), adding water and stirring evenly to obtain a mixed slurry with a concentration of 15%;

[0040] (4) the mixed slurry of step (3) is made into the sheet material of 8mm thickness on the rotary net machine, cutting molding;

[0041] (5) 12 layers of plates prepared in step (4) are superimposed, and pressurized on a pre...

Embodiment 2

[0045] Lead-free radiation protection barium plate, the raw material is composed of barite with a particle size of 300 mesh, Portland cement with a label of 525, plant fiber, and asbestos. The raw material components are (parts by weight):

[0046] Barite: 130

[0047] Portland cement: 30

[0048] Vegetable Fiber: 20

[0049] Asbestos: 5

[0050] The production method of lead-free ray shielding barium plate comprises the following steps:

[0051] (1) mix barite and Portland cement in proportion, add water and beat in a beater to make a slurry with a concentration of 25%;

[0052] (2) Plant fibers and asbestos are beaten into slurry;

[0053] (3) mixing the slurry of step (1) with the slurry of step (2), adding water and stirring evenly to obtain a mixed slurry with a concentration of 20%;

[0054] (4) the mixed slurry of step (3) is made into a plate with a thickness of 10mm on the rotary screen machine, and cut into shape;

[0055] (5) 10 layers of plates prepared in st...

Embodiment 3

[0059] The lead-free ray shielding barium plate is made of barium sulfate and barium chloride with a particle size of 500 mesh, Portland cement with a label of 325, and reinforcing fibers. The raw material components are (parts by weight):

[0062] Portland cement: 35

[0063] Vegetable fiber: 28

[0064] The production method of lead-free ray shielding barium plate comprises the following steps:

[0065] (1) mix barium salt and Portland cement in proportion, add water and beat in a beater to make a slurry with a concentration of 20%;

[0066] (2) Plant fibers are beaten into slurry;

[0067] (3) mixing the slurry of step (1) with the slurry of step (2), adding water and stirring evenly to obtain a mixed slurry with a concentration of 10%;

[0068] (4) the mixed slurry of step (3) is made into a plate with a thickness of 12mm on the rotary screen machine, and cut into shape;

[0069] (5) 10 layers of plates prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com