Assemblied polyvinyl chloride building engineering shuttering

A technology of polyvinyl chloride and construction engineering, which is applied in the field of engineering templates for building concrete pouring construction, can solve the problems of steel templates sticking to dust, difficulty in cleaning, low strength, and high manpower costs for operations, so as to be beneficial to natural ecology and environmental protection, Corrosion resistance and high impact strength, the effect of improving the turnover rate of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

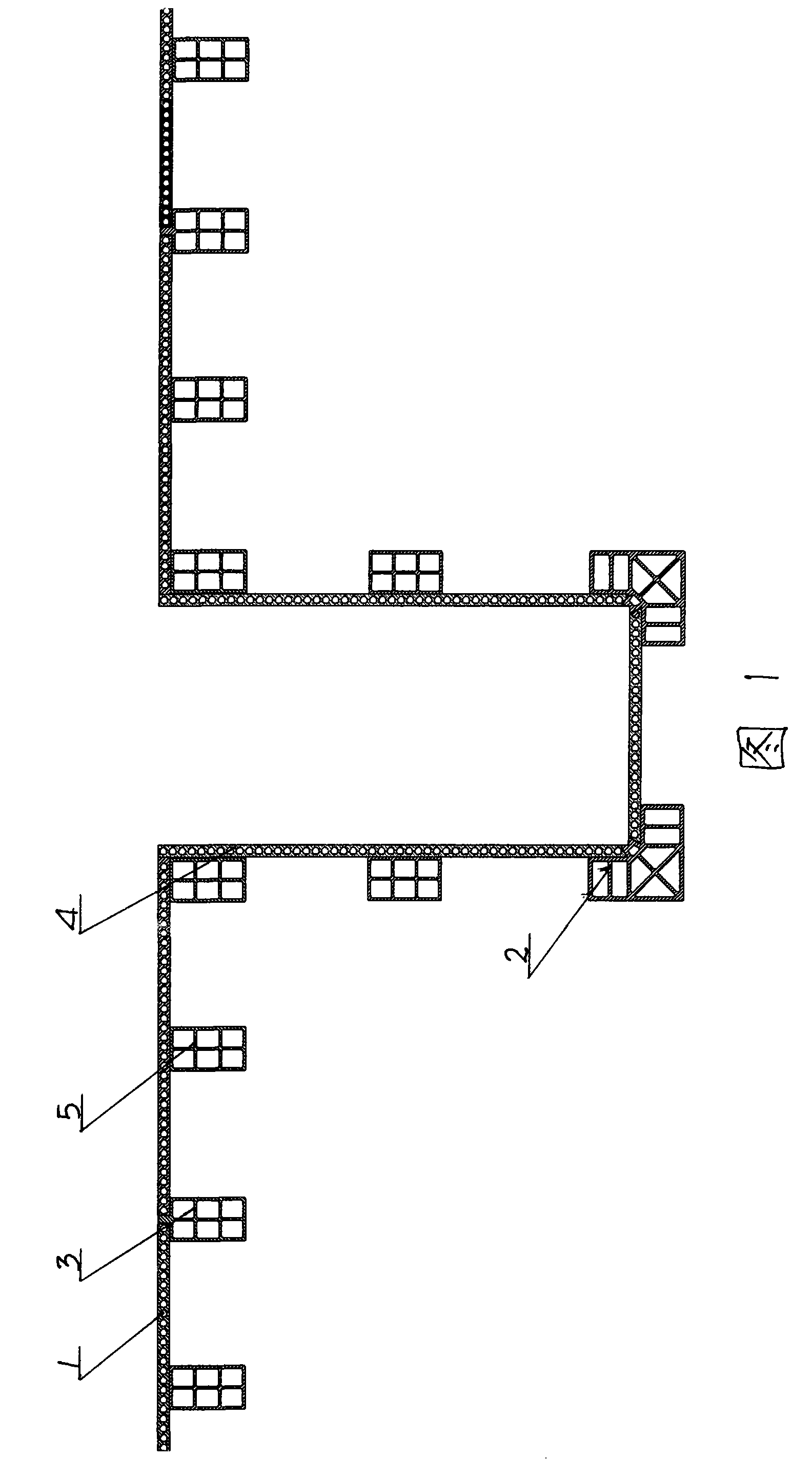

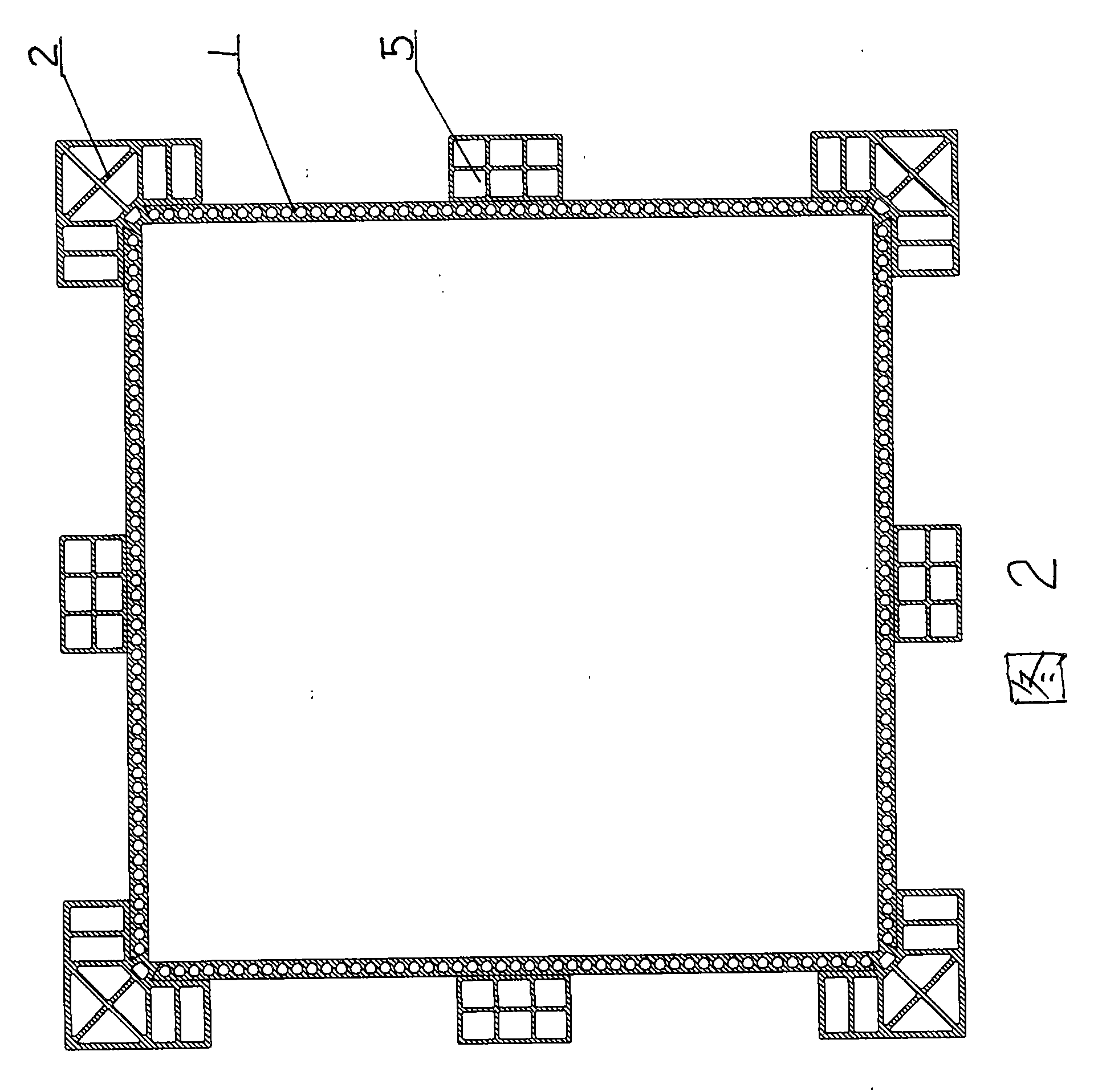

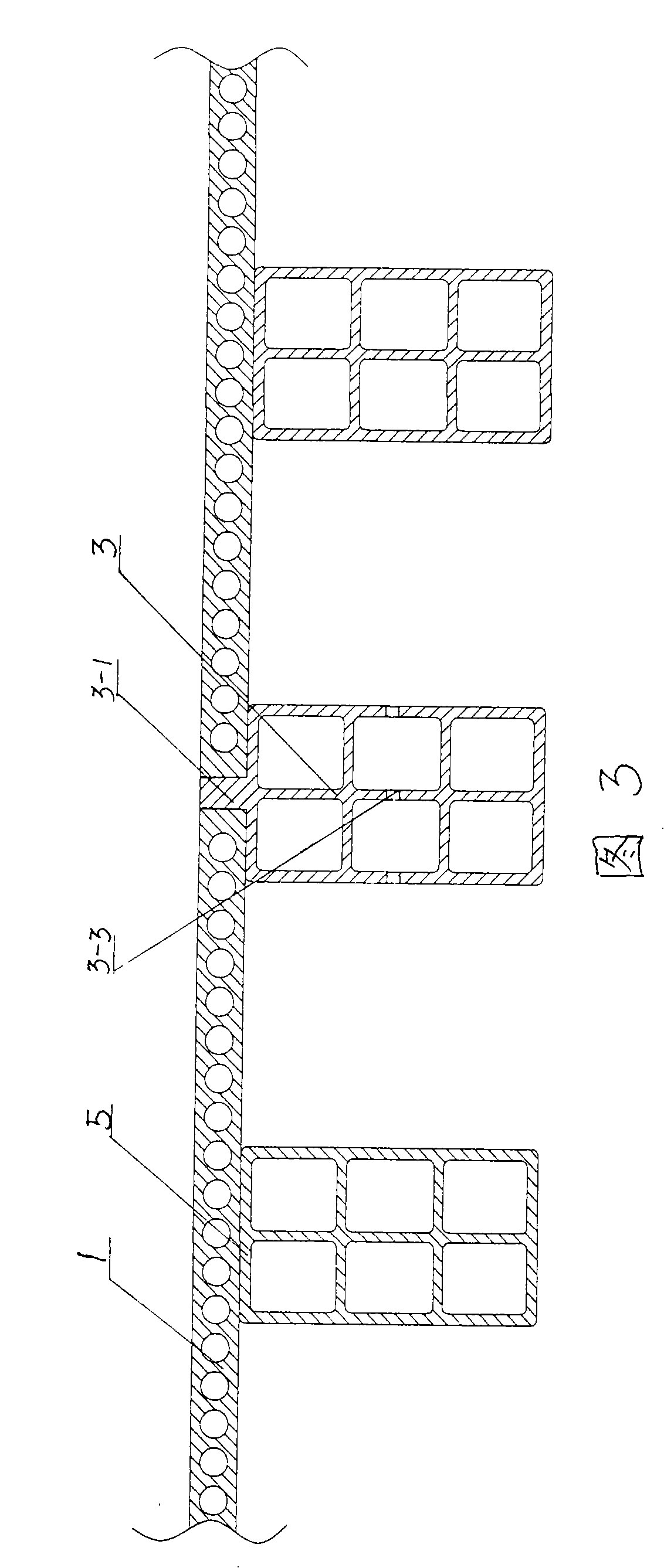

[0032] see Figure 1-Figure 13 , Combined polyvinyl chloride building engineering formwork, including hollow orifice plate 1 made of extruded polyvinyl chloride material, special-shaped male corner 2, special-shaped square edge 3, beam side 4, square wood 5, beam side 4 and The template cover 6 is a basic structural unit, which can be assembled and combined according to the shape of the architectural design component to form an engineering template that conforms to the shape of the architectural design component. Combination of three basic structural units of hollow orifice plate 1, special-shaped male corner 2 and square wood 5 can be assembled to form a formwork for beam and column building components; combination of three basic structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com