A fabric elastic floor and its processing method

A technology of elastic floor and processing method, which is applied in the direction of elastic floor, chemical instruments and methods, synthetic resin layered products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

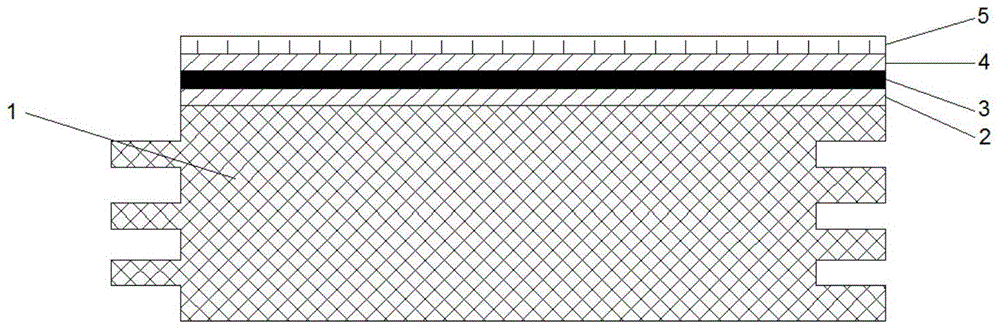

[0028] refer to figure 1 As shown, the present invention provides a kind of cloth art elastic floor, the top of described primer layer 1 is lower floor EVA film layer 2, the top of described lower floor EVA film layer 2 is cloth layer 3, the top of described cloth layer 3 is upper floor EVA Film layer 4, above the upper layer of EVA film layer 4 is a wear-resistant layer 5, and the bottom material layer 1, cloth layer 3 and wear-resistant layer 5 form a whole by vacuum thermal compounding of the upper and lower layers of EVA film layers; The total thickness of the fabric elastic floor is 6 mm, and the base material layer 1 is made of wood-plastic composite material with a thickness of 2 mm. The lower EVA film layer 2 and the upper EVA film layer 4 are ethylene-vinyl acetate copolymers, and the sum of the thicknesses of the lower EVA film layer 2 and the upper EVA film layer 4 is 2 mm. The cloth layer 3 adopts non-woven fabric, and the thickness of the cloth layer 3 is 1.9mm. ...

Embodiment 2

[0030] refer to figure 1 , the present invention provides a fabric elastic floor. The total thickness of the fabric elastic floor in this embodiment is 8mm. . The sum of the thicknesses of the lower EVA film layer 2 and the upper EVA film layer 4 is 3mm. The cloth layer 3 adopts calico, and the thickness of the cloth layer 3 is 1.8mm. The wear-resistant layer 5 adopts polyvinyl chloride with a thickness of 0.2.

Embodiment 3

[0032] refer to figure 1 , the present invention provides a kind of cloth art elastic floor, the total thickness of the cloth art elastic floor of this embodiment is 10mm, this embodiment is basically the same as embodiment 1, the different place is that the base material layer 1 of this embodiment adopts the polystyrene layer with a thickness of 4mm. vinyl chloride. The sum of the thicknesses of the lower EVA film layer 2 and the upper EVA film layer 4 is 4mm. The cloth layer 3 adopts woven cloth, and the thickness of the cloth layer 3 is 1.7mm. The wear-resistant layer 5 adopts polyurethane with a thickness of 0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com