PVC stone-plastic floor with round corners and round corner processing equipment of PVC stone-plastic floor

A stone-plastic floor and processing equipment technology, applied in metal processing, layered products, construction, etc., can solve the problems of high thickness requirements, difficult control of thermal expansion and contraction of the floor, poor floor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

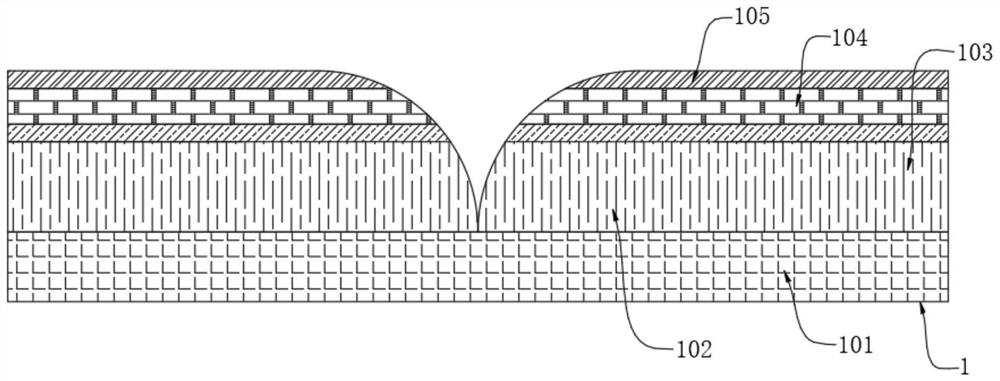

[0029] see figure 1 , the present invention provides a PVC floor with rounded corners, including a floor body 1, the floor body 1 is composed of a bottom material layer 101, a reinforced middle material layer 102, a color film layer 103, a wear-resistant layer 104 and a UV protection layer 105 , the bottom material layer 101, the reinforced middle material layer 102, the color filter layer 103, the wear-resistant layer 104 and the UV protection layer 105 are sequentially pressed together from bottom to top, and the bottom material layer 101 and the reinforced middle material layer 102 both include PVC Processing aids such as resin, heavy calcium carbonate, calcined kaolin, DOTP plasticizer, calcium zinc stabilizer, carbon fiber, petroleum resin and carbon black.

[0030] Its main production process is as follows:

[0031] Calendering: Through the automatic metering and mixing system, PVC resin, 325 mesh ground calcium carbonate, 800 mesh calcined kaolin, DOTP plasticizer, cal...

Embodiment 2

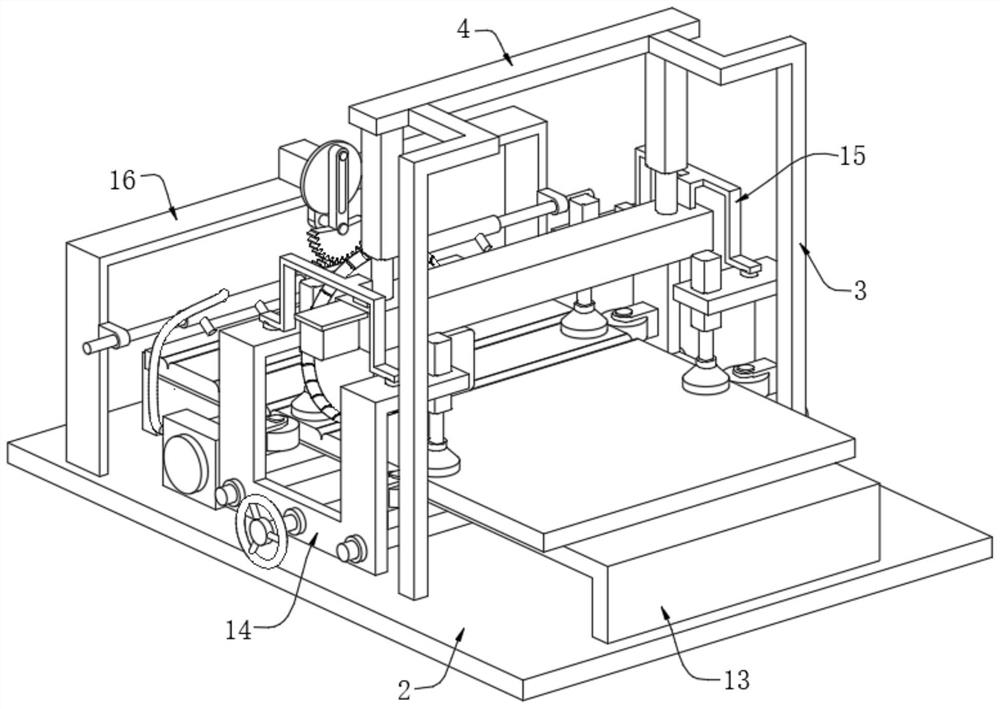

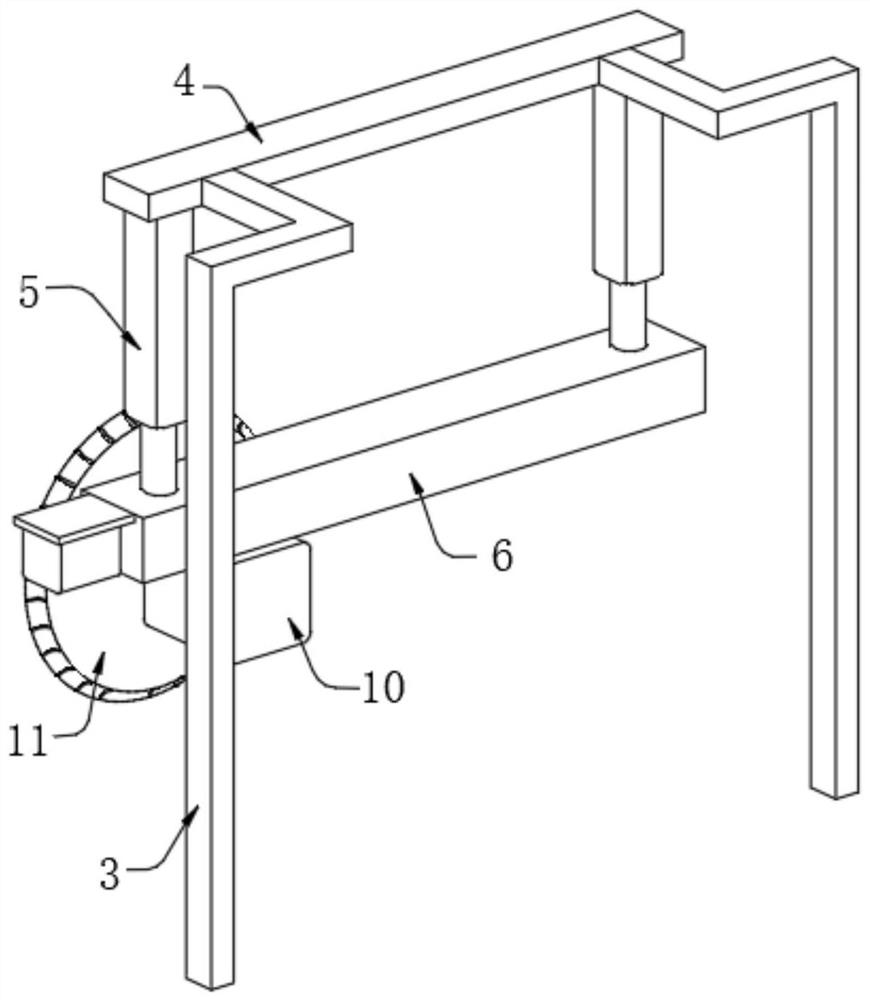

[0036] see Figure 2-7, the present invention provides a rounded corner processing equipment for PVC stone-plastic floor with rounded corners, comprising a bottom plate 2, two support columns 3 are fixedly connected to the bottom plate 2, and a top plate 4 is fixedly connected to the two support columns 3, and the top plate 4 Two electric push rods 5 are installed at the bottom of the bottom, and the telescopic shafts of the two electric push rods 5 are fixedly connected to the upper surface of the linear guide rail 6. One side of the linear guide rail 6 is installed with a motor one 7, and the output shaft of the motor one 7 extends To the linear guide rail 6 and fixedly connected with one end of the linear screw 8, the other end of the linear screw 8 is connected to the linear guide 6 through the rotation of the bearing seat. The block 9 is limited and slidingly connected in the linear guide rail 6, the threaded block 9 is fixed on the outer wall of the motor two 10, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com