Patents

Literature

40 results about "Calcium carbonate+kaolin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TiO2 complex ore powder and preparation method thereof

InactiveCN101041748AReasonable cooperationGood effectInorganic pigment treatmentKaolin clayPhysical chemistry

The invention discloses a composite powder body with titanium oxide nature and preparing method in paint, plastic and paper making domain, which comprises the following steps: mixing 30-50% ultra-fine heavy calcium carbonate, 5-15% calcining porcelain clay or washing porcelain clay and 5-10% baritic rock; getting coated basal body; adding into organic surface modifier and water; producing slurry; grinding with wet method stripper; adding into inorganic surface modifier; grinding the material to suitable particle diameter; choosing 25-60% titanium dioxide as enveloped material; adding into organic and inorganic surface modifier and water; producing slurry; mixing the titanium dioxide slurry with composite powder body slurry; grinding the composite powder body slurry to demanded fineness with wet method stripper; cooling the slurry directly; disintegrating; getting the product.

Owner:HUBEI PUYUAN CHEM

Carbon crystal composite microporous ceramic filter core and preparation method thereof

ActiveCN103381326AInhibition of reproductionHigh temperature resistantOther chemical processesFiltration separationFiltrationChlorinated paraffins

The invention provides a carbon crystal composite microporous ceramic filter core and a preparation method thereof. The invention is characterized in that the ceramic filter core is prepared from the following raw materials by weight: 12 to 14 parts of light calcium carbonate, 9 to 12 parts of kaolin, 7 to 9 parts of diatomite, 10 to 12 parts of bamboo charcoal powder, 4 to 6 parts of charcoal dust, 1 to 2 parts of straw ash, 12 to 14 parts of celestine powder, 6 to 8 parts of talcum powder, 3 to 5 parts of mica powder, 10 to 12 parts of chlorinated paraffin, 12 to 14 parts of ethanol, 25 to 35 parts of modified bentonite and a proper amount of water. The ceramic filter core provided by the invention has a plurality of functions like filtration, adsorption and suppression of bacterial reproduction and has the protruding advantages of high purification efficiency, high temperature resistance, small pressure loss, corrosion resistance, a long service life, removal of dust in air, etc.

Owner:ANHUI PHOENIX INT CO LTD

Low-quantification and high-strength coating white board paper and preparation process thereof

InactiveCN104389235AGuaranteed low quantitative high strengthPaper banner uniformCoatings with pigmentsCalendersSizingCalcium carbonate

Embodiments of the present invention disclose low-quantification and high-strength coating white board paper and a preparation process thereof. The low-quantification and high-strength coating white board paper comprises raw paper and a surface coating layer, wherein the surface coating layer further comprises a pre-coating, a middle coating and a surface coating, the coating materials of the pre-coating and the middle coating comprise 70-90% of calcium carbonate, 10-30% of kaolin, 0.1-0.3% of a dispersant, 8-12% of an adhesive, 0.3-0.7% of a water resistant agent, and 0-0.5% of a lubricant, and the coating materials of the surface coating comprise 50-70% of calcium carbonate, 20-50% of kaolin, 0-10% of a plastic pigment, 0.1-0.3% of a dispersant, 10-14% of an adhesive, 0.4-1.0% of a water resistant agent, and 0.4-1.0% of a lubricant. According to the present invention, with the optimized design of the pulps in each layer of the coating white board paper, the core pulp ratio is preferably selected, the coating material formula and the filler adding process are improved, the reliable film transfer type surface sizing is adopted, and the low-quantification and the high-strength of the paper board are ensured.

Owner:浙江光明纸业有限公司

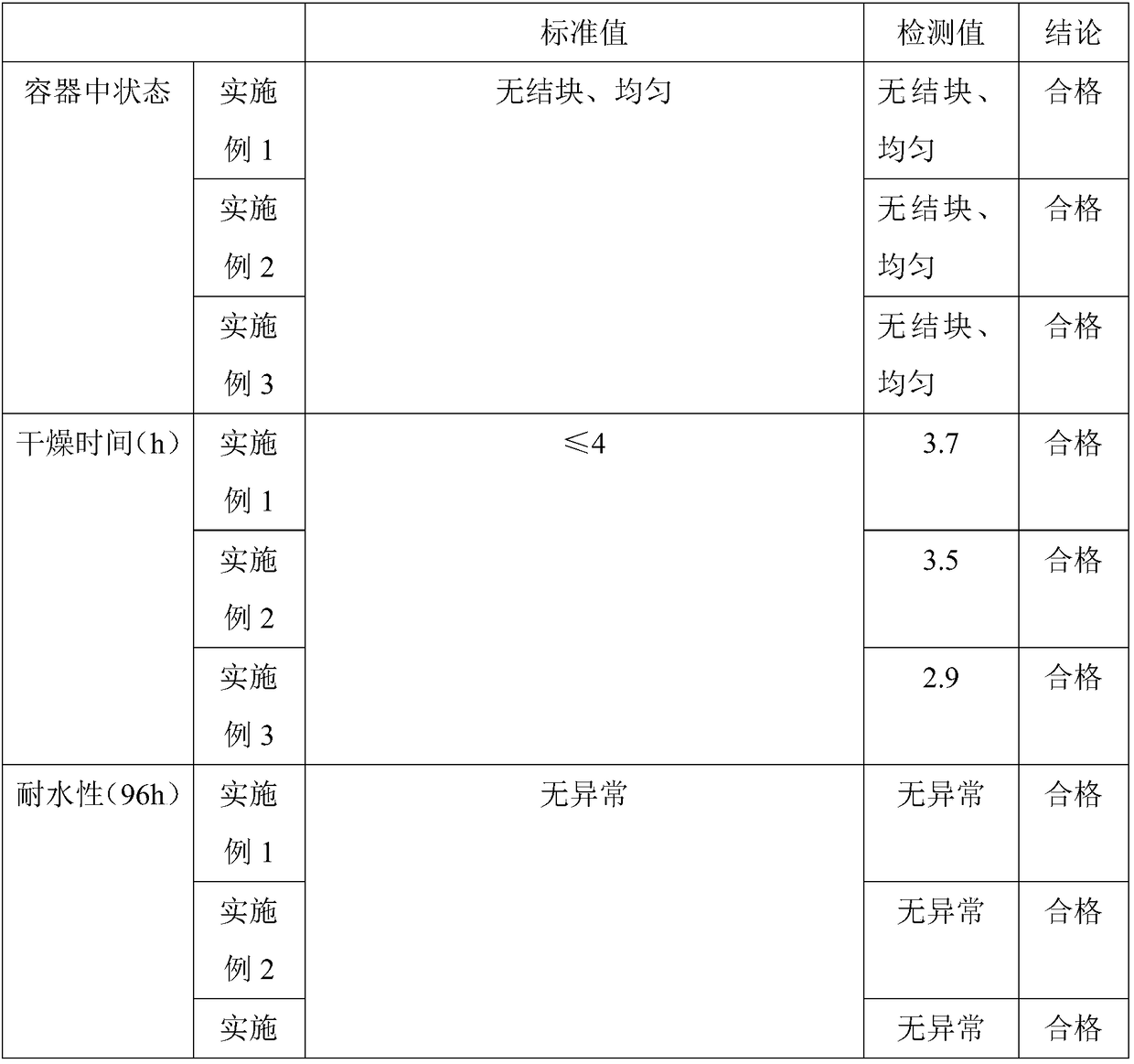

Preparation method for cationic silicone/acrylic emulsion alkali resistant seal primer

The invention relates to a preparation method for a cationic silicone / acrylic emulsion alkali resistant seal primer. The basic formula of the seal primer is as follows: 30% to 50% of emulsion, 4% to 8% of titanium dioxide, 5% to 12% of ground limestone, 5% to 10% of kaolin, 1% to 3% of talcum powder, 2% to 6% of coalescing agent, 1% to 5% of propylene glycol, 0.5% to 3% of thickening rheological agent, 2% to 5% of assistant and 20% to 35% of deionized water. The seal primer has the advantages of strong permeability, excellent weather and water resistance, good adhesion with substrate and paint, good self cleanness and environmental friendliness, excellent sealing performance, excellent alkali resistance and higher alkali and salting-out resisting performance. Therefore, the seal primer is suitable for being coated on the surfaces of external walls, internal walls, cement walls, concrete, gypsum boards, asbestos plates and the like.

Owner:UNION FOSHAN CHEM

High-turning-speed multi-layer coating paint

InactiveCN104313939AFulfill development needsSatisfy the rheologyCoatings with pigmentsCoatingsKaolin clayPaper sheet

The invention discloses a high-turning-speed multi-layer coating paint. The paint formula mainly comprises precoating paint, middle-coating paint and surface-coating paint. The paint formula comprises the compositions in parts by weight: 70-100 parts of heavy calcium carbonate, 0-30 parts of kaolin, 5-12 parts of latex, 5-8 parts of coating starch, and 0.1-0.5 part of a thickening agent. Paper is subjected to machine coating by employing a coating manner of two layers of precoating, one layer of middle coating and one layer of surface coating or a coating manner of one layer of precoating, one layer of middle coating and one layer of surface coating. Bottom coating employs metered glue-applying coating, and the coating amount is relatively low; and the middle / surface coating employs scraper coating, and the coating amount is relatively high. The formula helps to effectively reduce resistance of paint during coating, and improve the smoothness and the glossiness of coated paper. The paint is applicable to machine coating, is capable of effectively improving coating amount, improving surface properties of finished paper, enabling the cost per ton of paper to be substantial reduced and improve the competitiveness of the product.

Owner:HAINAN JINHAI PULP & PAPER

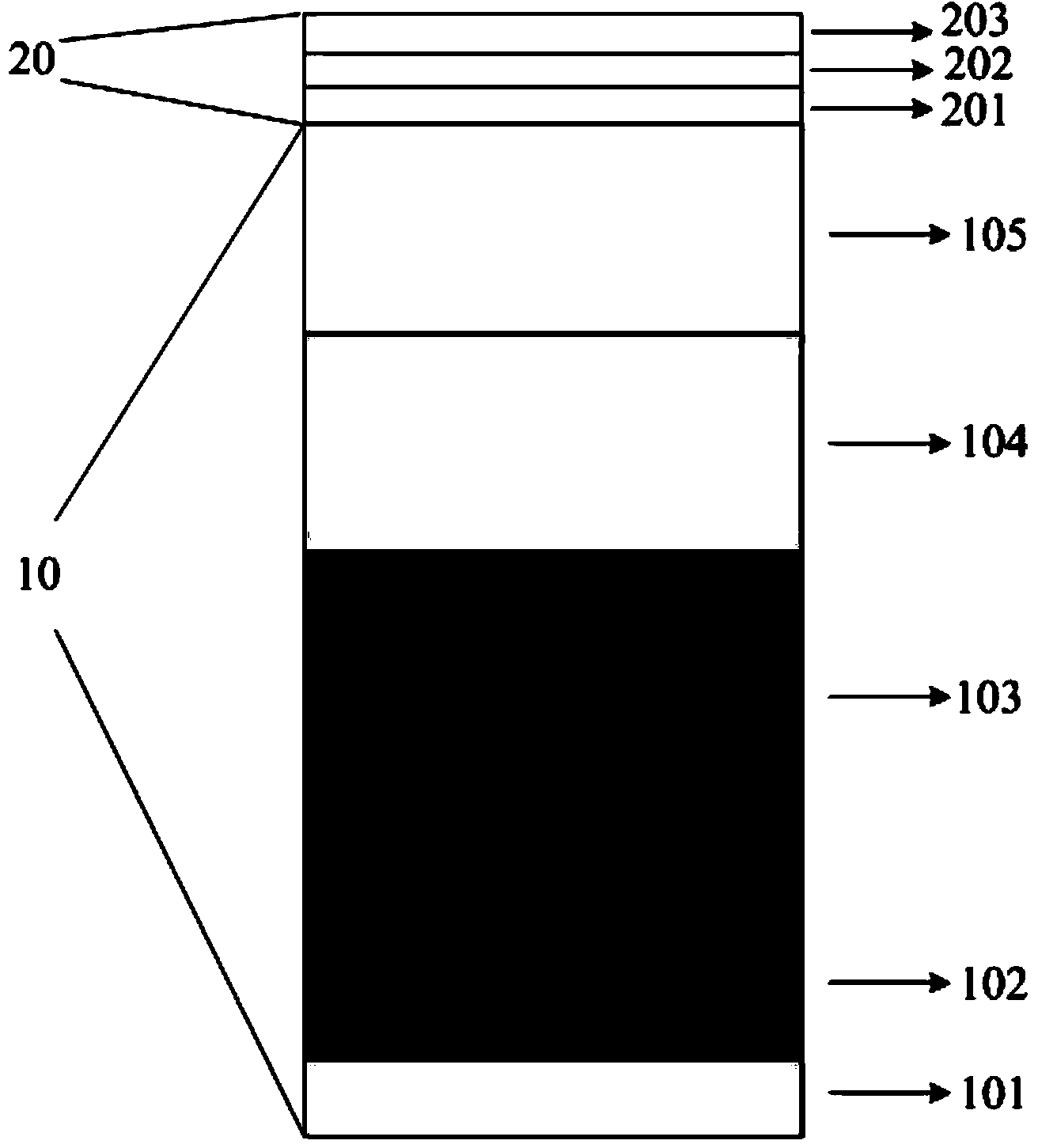

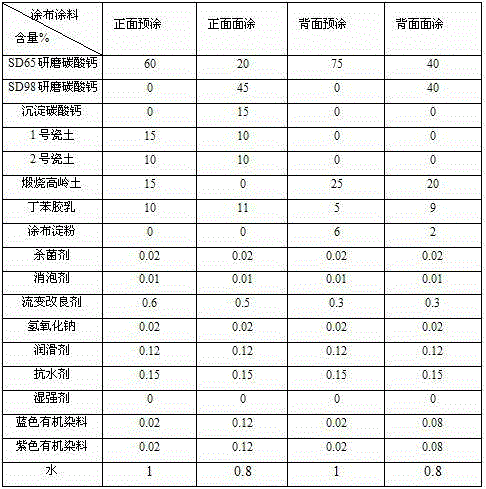

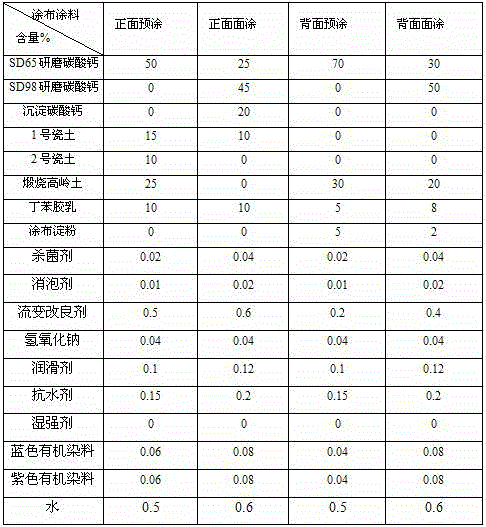

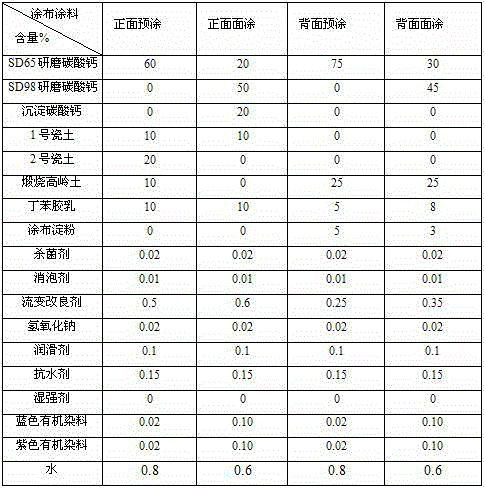

Coating composition for blister coated whiteboard with white back, and preparation process of coating composition

InactiveCN104928981AImprove breathabilityImprove permeabilityCoatings with pigmentsPaper/cardboardPolymer scienceKaolin clay

The invention discloses a coating composition for a blister coated whiteboard with a white back, and a preparation process of the coating composition. The coating composition comprises four coatings namely a front pre-coating, a front top-coating, a back pre-coating and a back top-coating, wherein components of the four coatings include calcium carbonate, kaolin, latex, sodium hydroxide, an antifoaming agent, a dispersing agent, a bactericide, a rheological modifier, a lubricant and the like in different percentages by weight; the corresponding positions of the whiteboard are coated with the four coatings, so that the prepared blister whiteboard is lower in cost and high in air permeability, the interlayer bonding strength of coating layers is high, the permeability of the coating layers is high, and the blister effect is good.

Owner:DONGGUAN NINE DRAGONS PAPER IND

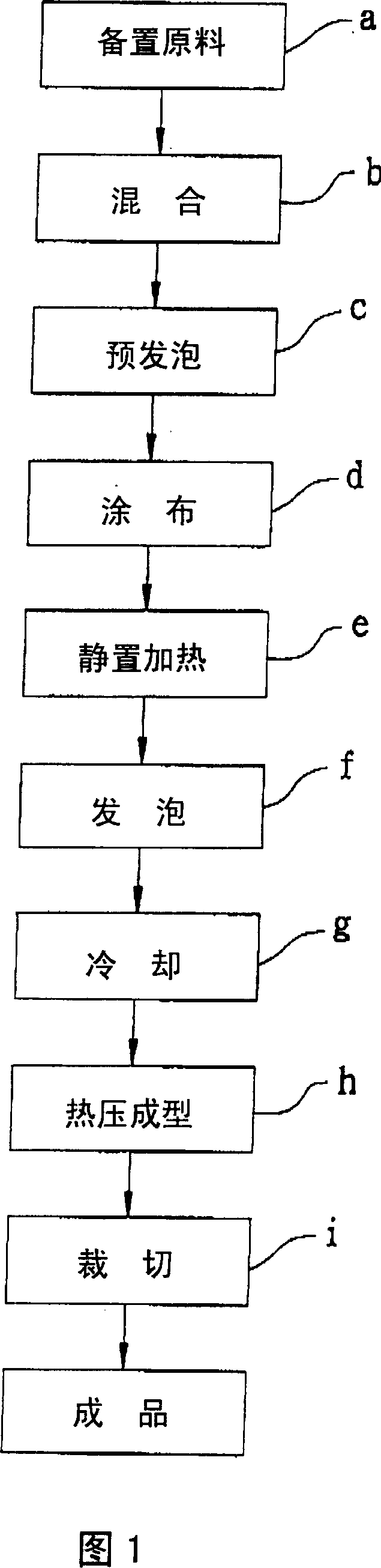

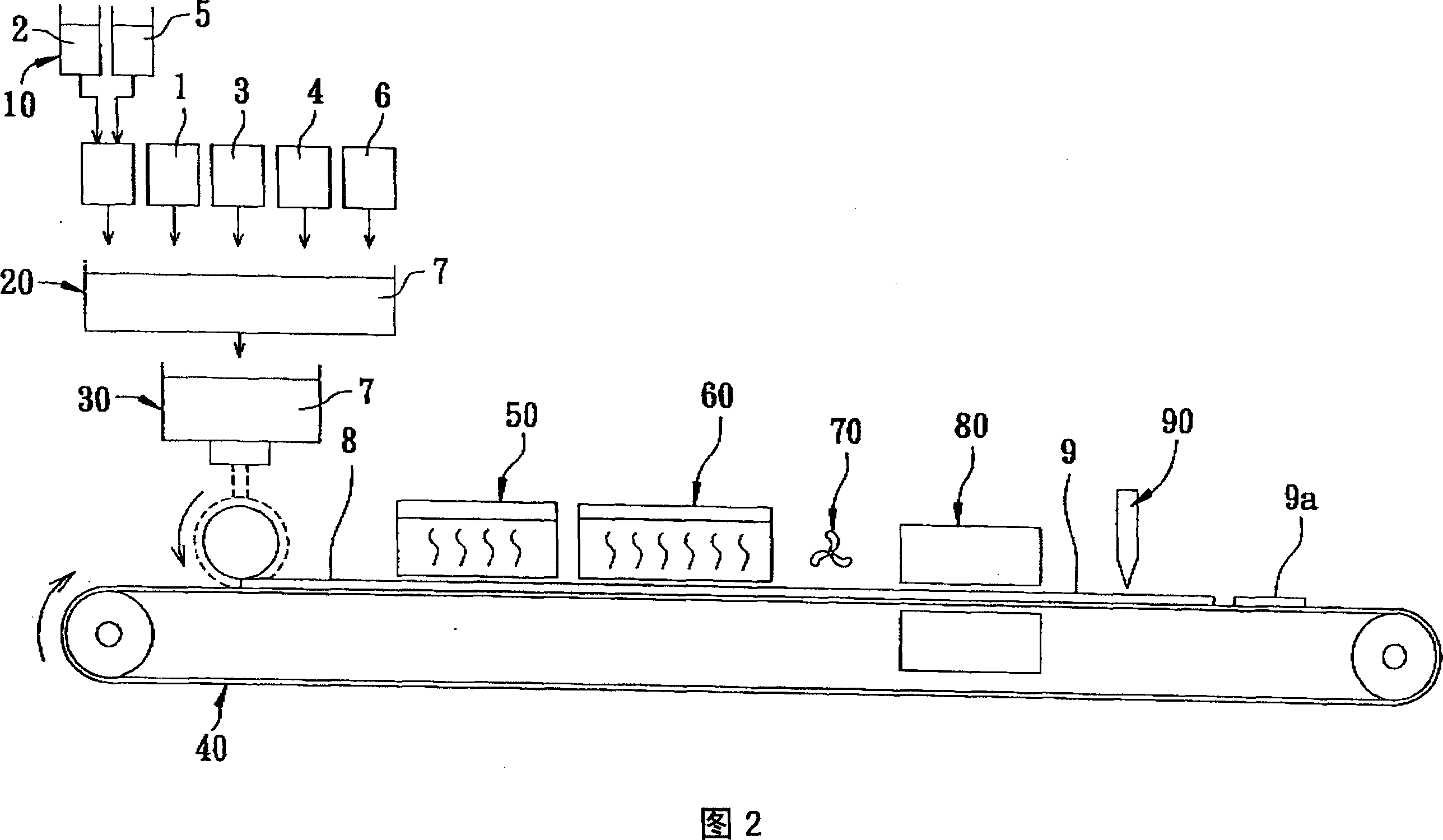

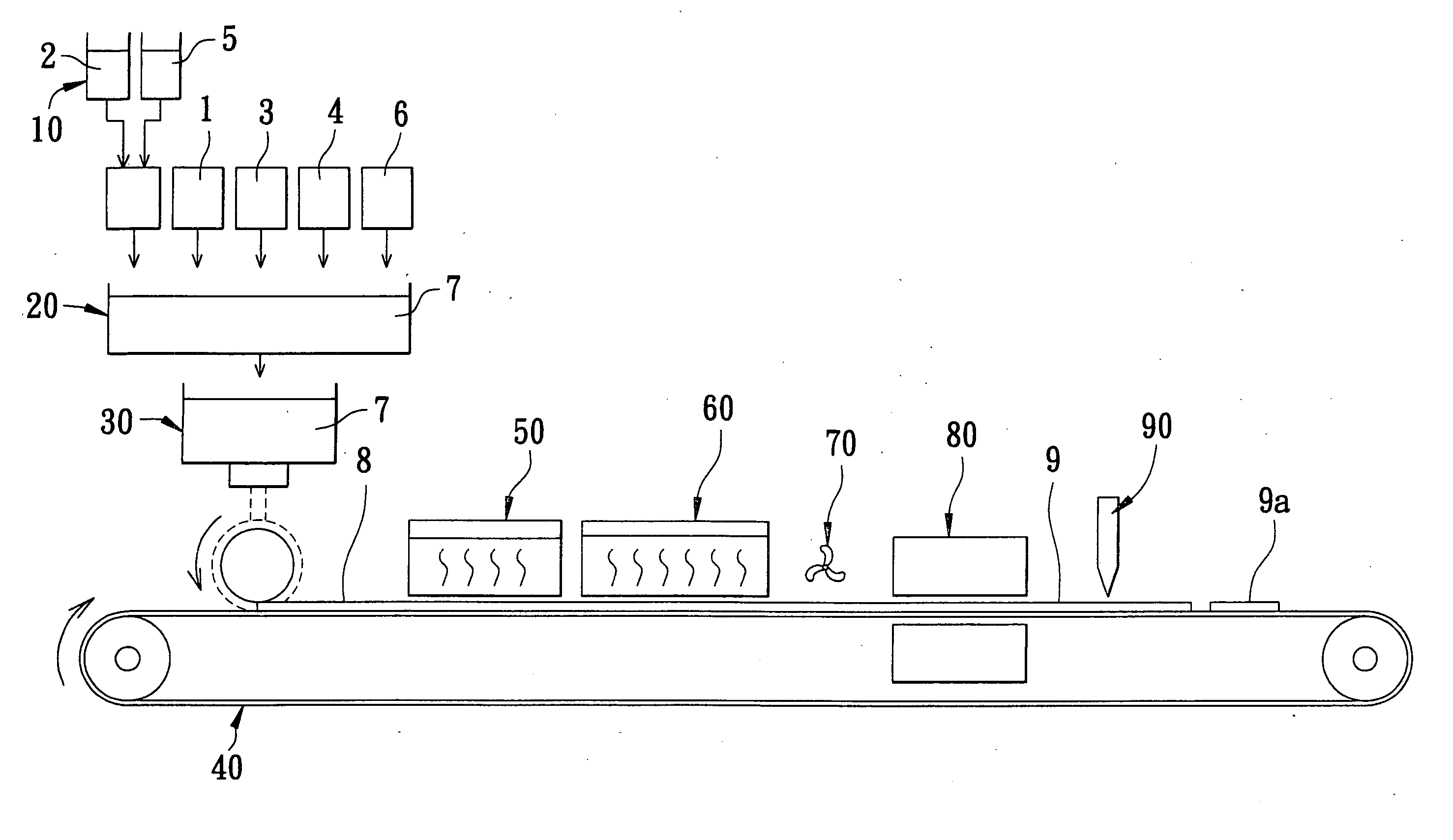

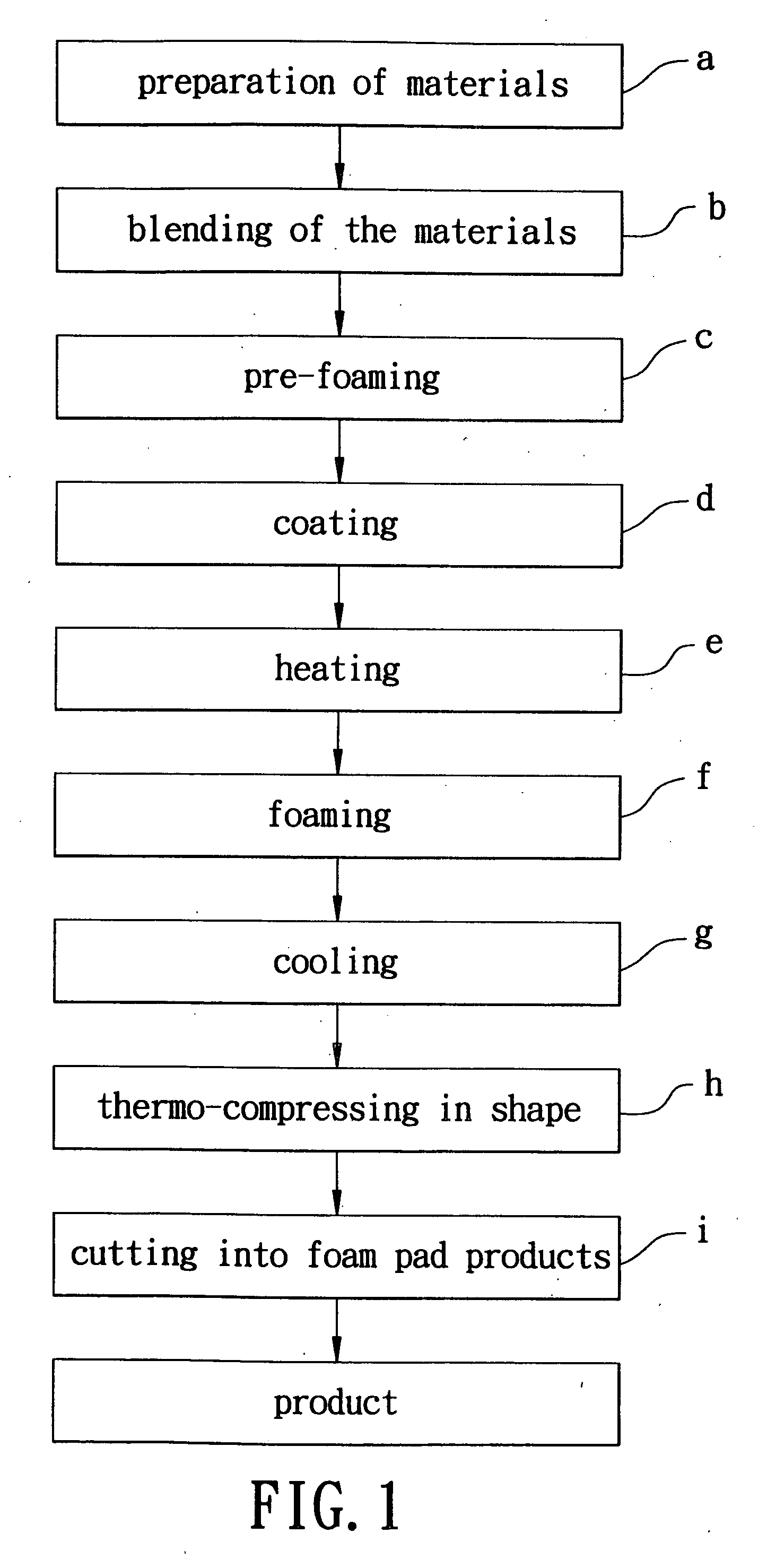

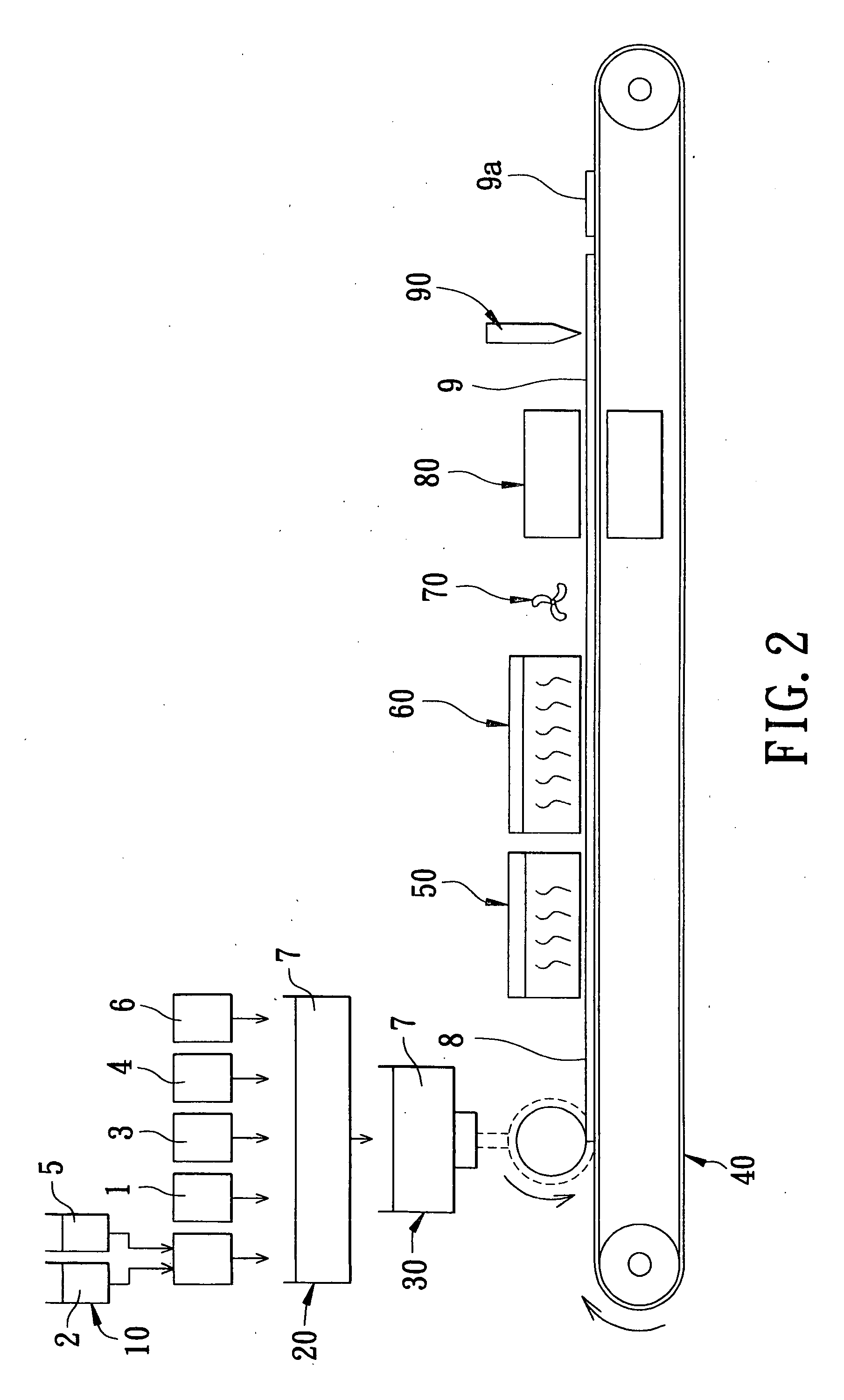

Method for producing foaming cushion

The invention discloses a preparing method of foaming pad, which comprises the following steps: allocating fitful PVC powder, DOP plastic agent, light-weight calcium carbonate, kaolin, foamer and pigment, casting in the composite device to form liquid slurry, transmitting in the middle material barrel, stewing at normal temperature for 8h, prefoaming, coating the transmitting belt to form slurry layer, stewing the slurry layer at 80-90 deg.c for 3-10min, heating at 185-200 deg.c for 20-30 min, foaming entire foam pad, cooling, punching, moulding the outline shape and distinctive line of surface, cutting, obtaining foaming pad product.

Owner:TAICANG ALL MATS PLASTIC IND

External wall elastic water-resistant putty powder and preparation process thereof

InactiveCN109385130ANo releaseNo pollution in the processFilling pastesPolyvinyl alcoholCarboxymethyl cellulose

The invention discloses external wall elastic water-resistant putty powder and a preparation process thereof, and belongs to the technical field of building materials, wherein the external wall elastic water-resistant putty powder comprises the following raw materials: modified heavy calcium carbonate, kaolin powder, quartz sand, ash calcium powder, whiting powder, cement, modified talc powder, rubber powder, bentonite powder, latex powder, titanium dioxide, sodium carboxymethyl cellulose, polyvinyl alcohol, sodium alginate, a natural resin, a high-water-absorption resin, lignocellulose, polypropylene short fiber, an auxiliary agent, a defoamer, and a lubricant. According to the present invention, the external wall elastic water-resistant putty powder is prepared through mixing, stirring,grinding and other steps; the raw material combination is suitable, the preparation method is simple, and the production process is safe and environmentally friendly; and the external wall elastic water-resistant putty powder can well protect walls, cannot produce hollowing, peeling, cracking and dust shedding after being wet, can be organically combined with various coating materials, and has broad application value and market prospects.

Owner:王再青

Coating with high speed and solid content

InactiveCN101538422AReduce energy consumptionImproved paper qualityCoatingsChemistryCalcium carbonate

The invention discloses a coating with high speed and solid content, comprising heavy calcium carbonate, light calcium carbonate, kaolin pigment, polyvinyl alcohol, latex and thickening agents, wherein the solid content is in the range of 69-71 percent, and the pH value is 8.5-10; the coating includes the following components according to the parts by weight: 65-100 of heavy calcium carbonate, 5-100 of light calcium carbonate, 0-15 of kaolin pigment, 0.1-0.6 of polyvinyl alcohol, 9-11.5 of latex and 0.1-0.55 of thickening agents. The invention effectively reduces the high shearing resistance of the coating with high solid content and can satisfy higher coating speed and relatively lower coating quantity by a scraper. The coating integrally uses the theories of surface chemistry and hydromechanics of coating, the particle encapsulation of coating suspension, and the like, and has a certain performance-required rheological property and viscous modulus. The invention is applied to coating machines, obviously reduces the cost of paper per ton and greatly improves the quality of finished paper.

Owner:GOLD EAST PAPER JIANGSU

Herbal sterilizing anticorrosive coating and preparation method thereof

InactiveCN102911562AGuaranteed storage stabilityNo side effectsAntifouling/underwater paintsPaints with biocidesCelluloseHydroxyethyl cellulose

The invention discloses a herbal sterilizing anticorrosive coating and a preparation method thereof. The herbal sterilizing anticorrosive coating is prepared from water, hydroxyethyl cellulose, amine neutralizer, propylene glycol, wetting agent, dispersing agent, antifoaming agent, titanium dioxide, ground limestone, kaoline, polymer emulsion, film coalescing agents, allicin and flavor covering agent. The herbal sterilizing anticorrosive coating is good in stability, strong in practicability, persistent, broad-spectrum and efficient in sterilization and anticorrosion, wide in application, safe and environment-friendly, has no side effect to environment and human bodies, and storage stability can be guaranteed.

Owner:WEIFANG HUANYU PAINT IND

Mosquito repelling coating

The invention discloses a mosquito repelling coating which is characterized in that a raw material for preparing the coating contains a DEET solution; the DEET solution is prepared from DEET and an ethanol solution with the concentration of 97%-99% according to the weight part ratio of (10-40):(60-90); and the raw material for preparing the coating also comprises water, a dispersant, a wetting agent, a defoaming agent, a thickening agent, titanium dioxide, a PH regulator, heavy calcium carbonate, kaoline, talcum powder, an emulsion, a film forming additive, an anti-freezing agent, an anti-mildew agent and a leveling agent. The mosquito repelling coating not only has an effect of repelling insects, but also is harmless to human bodies and is also capable of properly purifying indoor air and meeting the requirement of indoor decoration.

Owner:谢菊荣

Anti-ultraviolet coating

InactiveCN105802429AImprove non-polarityImproves UV resistanceRadiation-absorbing paintsEmulsionChemistry

The invention discloses an anti-ultraviolet coating. The anti-ultraviolet coating is prepared from, by weight, 80-100 parts of modified epoxy resin emulsion, 15-25 parts of water, 3-5 parts of propylene glycol methyl ether acetate, 8-12 parts of light calcium carbonate, 20-25 parts of kaolin, 2-3 parts of dodecyl ethoxy sulfo glycine betaine, 1-2 parts of sodium dodecyl sulfate, 0.03-0.05 part of dimethicone, 0.05-0.07 part of defoamer Tego Foamex 843, 0.2-0.4 part of wetting agent Wet265, 0.1-0.2 part of wetting agent Wet500, 0.4-0.5 part of leveling agent, 0.3-0.5 part of polyacrylamide, 0.1-0.2 part of methylcellulose, 0.02-0.04 part of 1,2-benzoisothiazolinone-3-ketone and 0.1-0.3 part of ultraviolet absorbent UV-P. The anti-ultraviolet coating is high in anti-ultraviolet property, good in bactericidal performance and good in corrosion resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Waterborne solid predispersed pigment and preparation process thereof

ActiveCN106634041ABalance Tint StrengthGood dispersionOrganic dyesPigment treatment with macromolecular organic compoundsInorganic pigmentsSodium sulfate

The invention relates to a waterborne solid predispersed pigment and a preparation process thereof, belonging to the technical field of pigment production. The predispersed pigment comprises the following raw materials in percentages by weight: 50% to 90% of a pigment, 2% to 15% of an auxiliary agent, 0% to 40% of resin and 3% to 10% of an auxiliary material, wherein the pigment is a mixture of one or more selected from the group consisting of various organic pigments, inorganic pigment carbon black and inorganic pigment titanium dioxide; the auxiliary agent is a mixture of one or more selected from the group consisting of triethanolamine, quaternary ammonium salt, N,N-dimethyl propylene diamine, and dispersants like NNO, FM, BYK190 and BYK192; the resin is a mixture of two or more selected from the group consisting of waterborne acrylic acid, waterborne alcohol acid, acrylate and polyether; and the auxiliary material is a mixture of one or more selected from the group consisting of calcium carbonate, kaolin and sodium sulfate. The preparation process comprises the following steps: subjecting the above-mentioned raw materials to mixing and stirring, and carrying out grinding and spray drying so as to obtain a waterborne solid predispersed pigment product. The waterborne solid predispersed pigment product has the advantages of good wettability, dispersibility and stability, no dust pollution, and accurate measurement.

Owner:美利达颜料工业有限公司

Environmentally-friendly healthy interior wall putty powder and preparation process thereof

The invention discloses an environmentally-friendly healthy interior wall putty powder and a preparation process thereof, and belongs to the technical field of building materials, wherein the environmentally-friendly healthy interior wall putty powder comprises the following raw materials: modified heavy calcium carbonate, kaolin, bentonite, ash calcium powder, modified talc powder, lignocellulose, soluble starch, titanium dioxide, sodium carboxymethyl cellulose, a high water absorbing resin, an antibacterial agent, peppermint leaf powder, hedera nepalensis powder, and folium artemisiae argyipowder. According to the present invention, the environmentally-friendly healthy interior wall putty powder is prepared through mixing, stirring, grinding and other steps, does not release harmful gas, has characteristics of refreshing odor, formaldehyde absorbing, health benefiting, safety, environmental protection and long service life, cannot produce hollowing and peeling after being wet, can well protect wall, can be organically combined with various coating materials, and further has broad application value and market prospects.

Owner:王再青

External wall soft elastic anti-cracking putty powder and preparation process thereof

The invention discloses external wall soft elastic anti-cracking putty powder and a preparation process thereof, and belongs to the field of building materials, wherein the external wall soft elasticanti-cracking putty powder comprises the following raw materials: modified heavy calcium carbonate, kaolin powder, silicate, calcium hydroxide, ash calcium powder, whiting powder, modified talc powder, quartz, diatomaceous earth, rubber powder, bentonite powder, pure acrylic elastic emulsion, polyvinyl alcohol, zinc white powder, sodium carboxymethyl cellulose, ethylene glycol, redispersible latexpowder, an auxiliary agent, and an antifoaming agent. According to the present invention, the external wall soft elastic anti-cracking putty powder is prepared through mixing, stirring, grinding andother steps; the ratio of the raw materials is rational, the preparation method is simple, and the production process is safe and environmentally friendly; and the external wall soft elastic anti-cracking putty powder can well protect walls, wherein the wall cannot produce cracks, cannot produce hollowing, peeling and dust shedding after being wet, and has long service life.

Owner:王再青

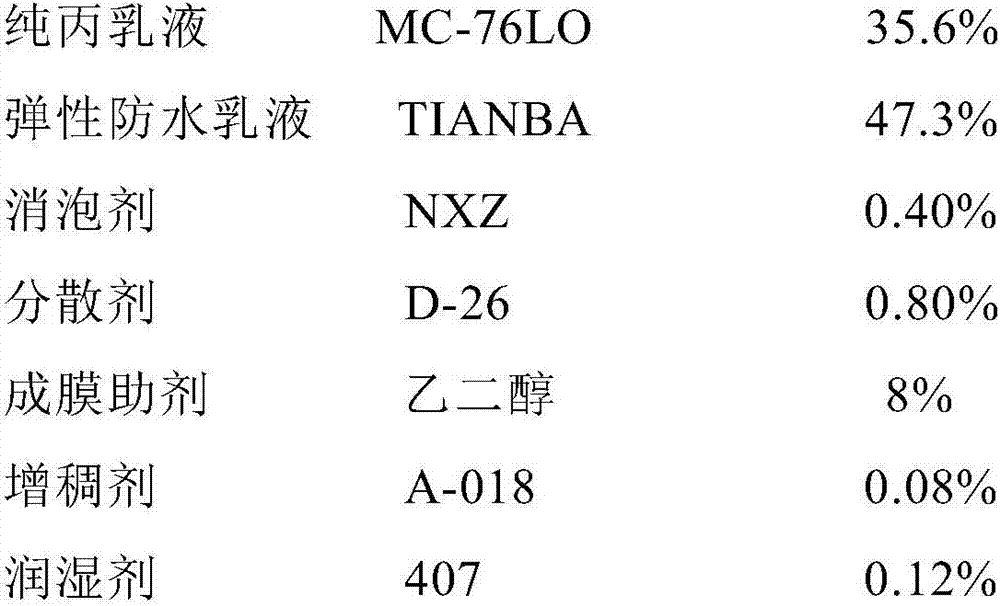

Waterproof mortar for exterior wall decoration and preparation process thereof

The invention relates to waterproof mortar for exterior wall decoration and a preparation process thereof. The waterproof mortar is prepared by mixing a liquid material and a powder material according to a weight ratio of 1: (1-1.5), wherein the liquid material is composed of the following components in parts by weight: 20 to 40 parts of a pure acrylic emulsion, 30 to 50 parts of an elastic waterproof emulsion, 0.3 to 0.5 part of an antifoaming agent, 0.5 to 1.0 part of a dispersant, 5 to 10 parts of a film-forming auxiliary agent, 0.05 to 0.1 part of a thickening agent, 0.10 to 0.15 part of a wetting agent, 2 to 5 parts of a pigment and 3 to 5 parts of water; and the powder material is composed of the following components in parts by weight: 30 to 50 parts of high-alumina cement, 30 to 40 parts of quartz sand, 10 to 20 parts of calcium carbonate and 5 to 10 parts of kaolin. Compared with the prior art, the waterproof mortar provided by the invention solves the technical problems of complicated construction process, complicated process, high cost, poor waterproof performance, etc. The waterproof mortar provided by the invention is especially applicable to application in exterior wall maintenance, can be directly constructed on an original external layer without the need of removing the original external layer, and realizes one-step formation of water prevention and decoration.

Owner:上海北新月皇新材料集团有限公司

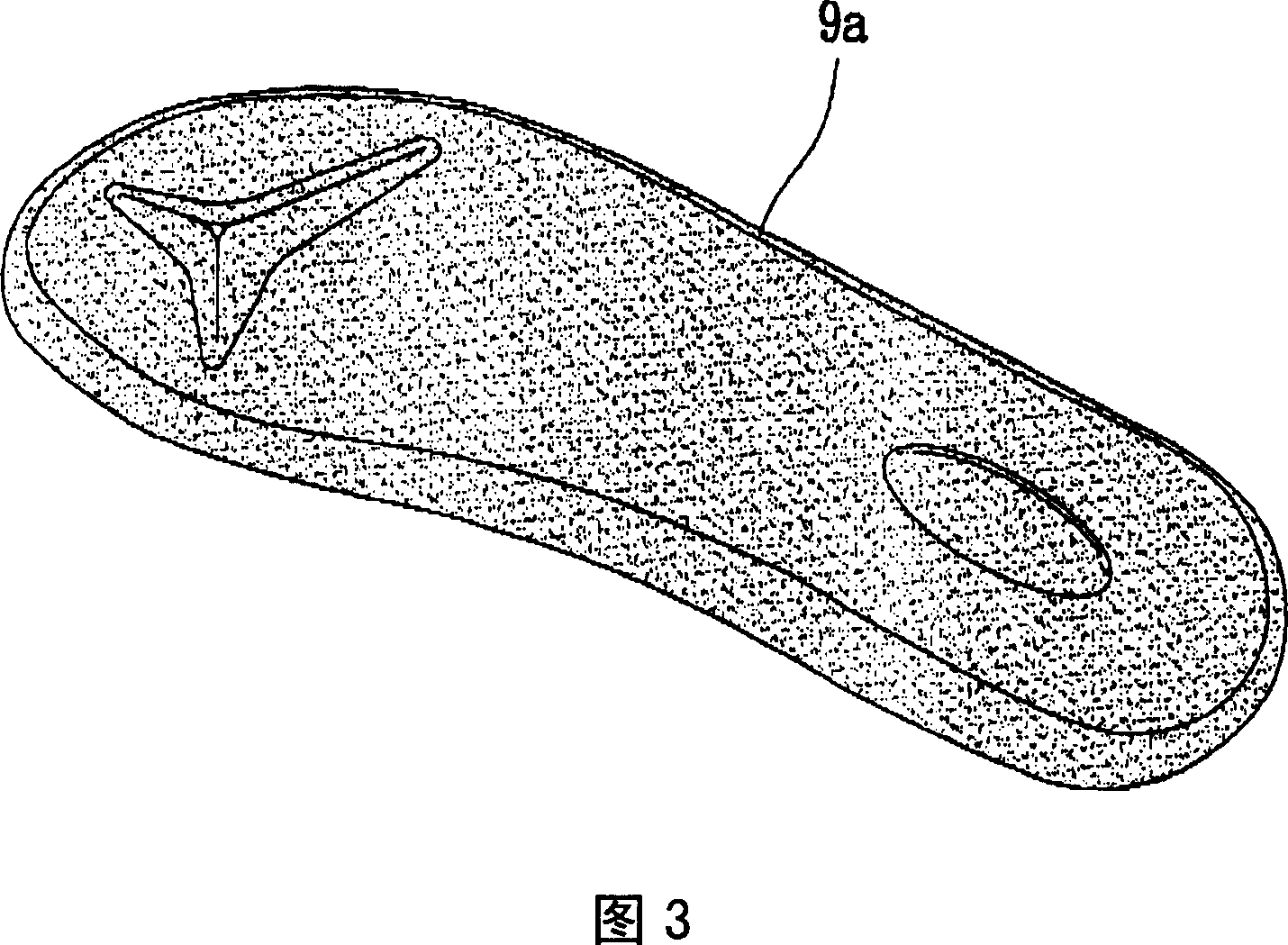

Method for manufacturing foam pads

ActiveUS20070069410A1Improve fatigue resistanceSlow forceSemi-permeable membranesInsolesFoaming agentPulp and paper industry

A method for manufacturing foam pads includes a first step of preparing a proper amount of PVC power, DOP curing agent, light calcium carbonate, kaolin, foaming agent and pigment and pouring them into a blending device to be blended and form a liquid starchy material. Next, the liquid starchy material is conveyed into an intermediate material barrel and kept stationary for pre-foaming at normal temperature for about 8 hours and then coated on a conveyer pelt to form a starchy material layer. Subsequently, the starchy material layer is kept stationary and heated at 80-90° C. for about 3-10 minutes and then continuously heated at 185-200° C. for about 20-30 minutes to form an integral-sheeted foam pad. After cooled, the integral-sheeted foam pad is thermo-compressed and cut into various foam pad products.

Owner:UNION LOOPER

High-strength water-resistant odorless putty powder and preparation process thereof

The invention discloses a high-strength water-resistant odorless putty powder and a preparation process thereof, and belongs to the technical field of building materials, wherein the high-strength water-resistant odorless putty powder comprises the following raw materials: modified heavy calcium carbonate, kaolin, ash calcium powder, white cement, modified talc powder, bentonite, a high water absorption resin, a natural resin, lignocellulose, polypropylene cellulose, redispersible latex powder, polyvinyl alcohol, sodium carboxymethyl cellulose, murraya paniculata powder, hedera nepalensis powder, bamboo charcoal fiber, pomelo peel powder, seaweed soil, a whitening agent, an auxiliary agent, an antifoaming agent, a preservative, and a retarder. According to the present invention, the high-strength water-resistant odorless putty powder is prepared through mixing, stirring, grinding and other steps, has strong water resistance, cannot produce hollowing and peeling after being wet, has characteristics of refreshing odor, formaldehyde absorbing, health benefiting and long service life, can be organically combined with various coating materials, and has broad application value and marketprospects.

Owner:王再青

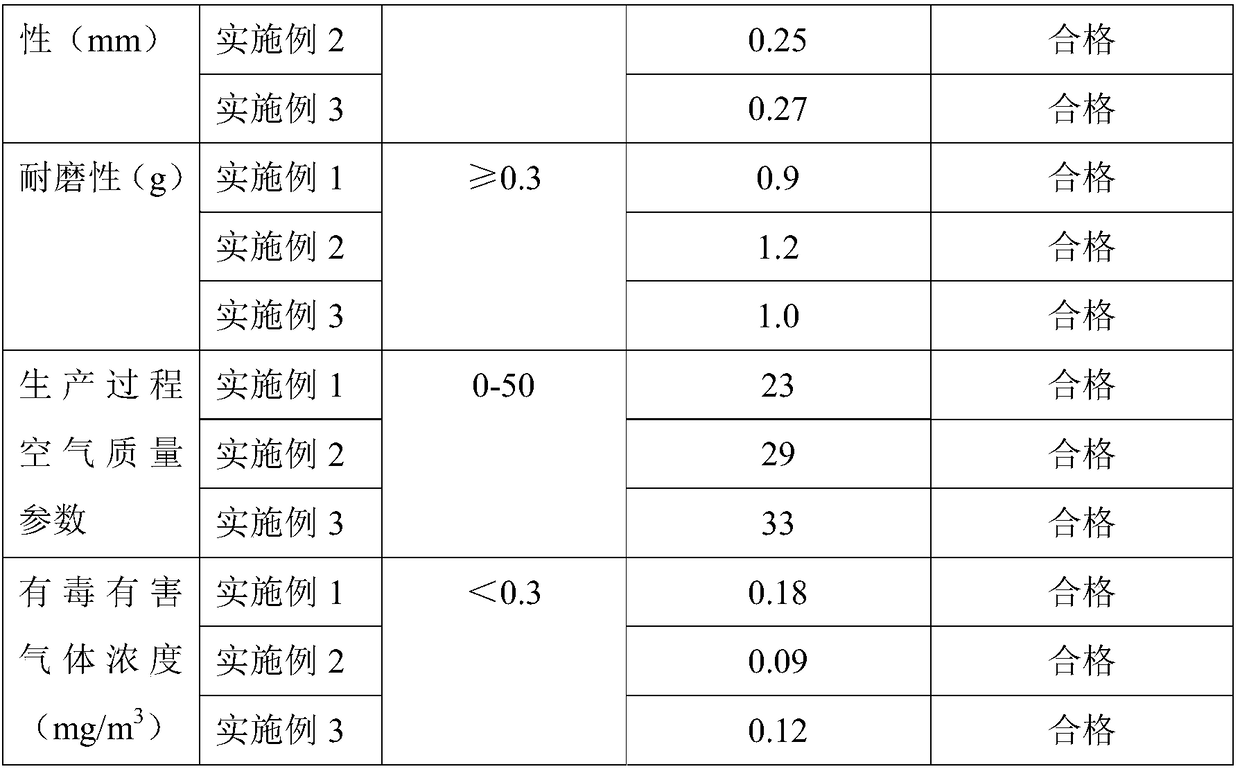

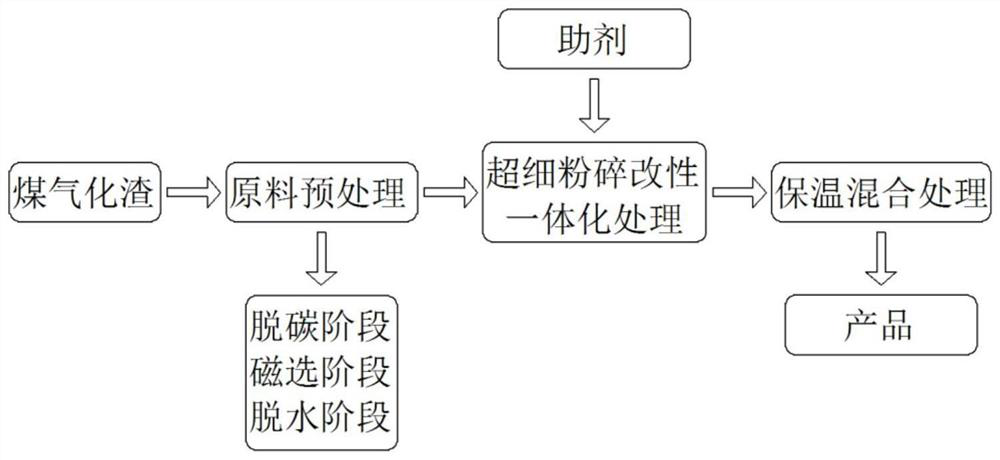

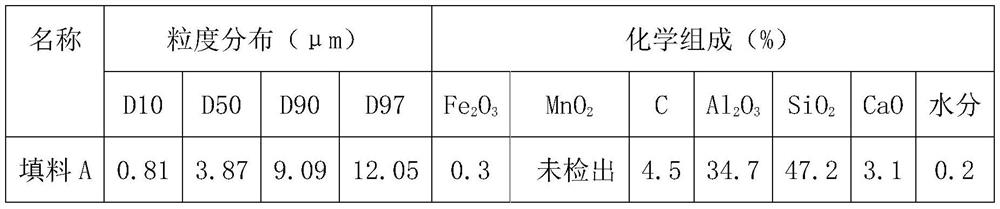

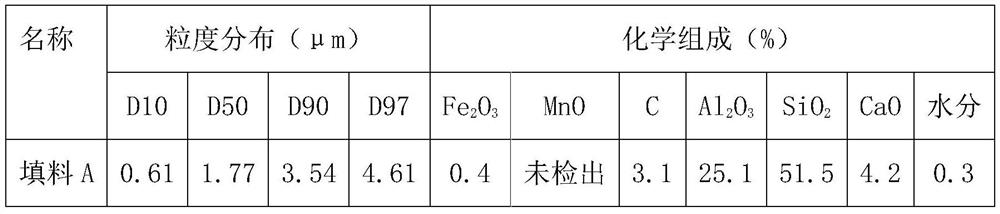

Method for preparing plastic filler by taking gasified slag as raw material

ActiveCN112916200ANarrow particle sizeNarrow distributionFlotationMagnetic separationSlagKaolin clay

The invention discloses a method for preparing a plastic filler by taking gasified slag as a raw material. The method comprises the following steps: (1) carrying out raw material pretreatment: directly treating the gasified slag or preparing the gasified slag into slurry for treatment, wherein the raw material pretreatment process comprises a decarburization stage, a magnetic separation stage and a dehydration stage; (2) carrying out ultrafine crushing and modification integrated treatment: carrying out ultrafine crushing on the coarsely crushed coal gasified slag subjected to raw material pretreatment by utilizing crushing and modification integrated equipment under the action of a proper auxiliary agent to a certain particle size; and (3) carrying out heat-preservation mixing treatment: fully mixing the crushed ultrafine coal gasified slag at a certain temperature for a period of time, and removing residual water in the material to finally prepare the inorganic filler for the plastic product. The product produced by the invention can replace heavy calcium carbonate, light calcium carbonate, nano calcium carbonate, kaolin, argil and other inorganic fillers commonly used in the current plastic industry, natural mineral resources are saved, and green high-added-value utilization of the coal gasified slag is really realized.

Owner:山西奇色环保科技股份有限公司

Environment-friendly coating material used for interior decoration, and preparation method thereof

The invention discloses an environment-friendly coating material used for interior decoration. The environment-friendly coating material used for interior decoration comprises 1 to 3% of an emulsion paint emulsion, 15 to 25% of an ammonium polyacrylate salt, 0.8 to 2.0% of a thickening agent, 0.2 to 0.5% of silicon dioxide, 0.1 to 0.2% of hydroxyethyl cellulose, 0.6 to 0.8% of mica powder, 7 to 9% of pigment titanium dioxide, 25 to 30% of filling material heavy calcium carbonate, 8 to 10% of kaolin, 4 to 5% of talcum powder, 0.8 to 1.0% of zeolite powder, 1.8 to 2.0% of titanium dioxide, 0.5 to 1.0% of short fiber, and the balance solvent water. The environment-friendly coating material is prepared via mixing and stirring of the pollution-free materials, and possesses wear resistance; a preparation method is simple, and is friendly to the environment; the ingredients are uniform; glossiness is high; the coating service life is prolonged; and shedding is not easily caused.

Owner:浙江金棕榈建设有限公司

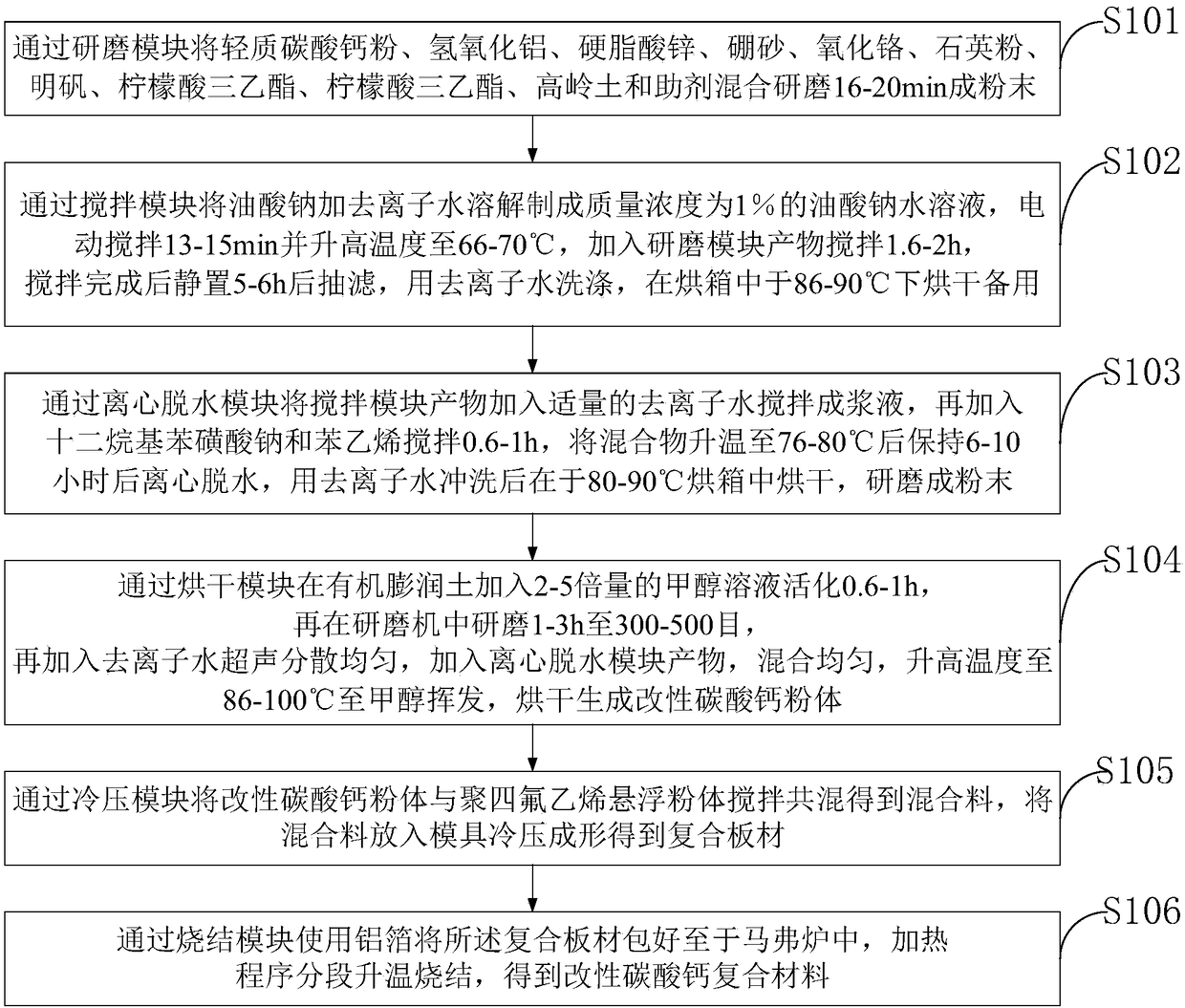

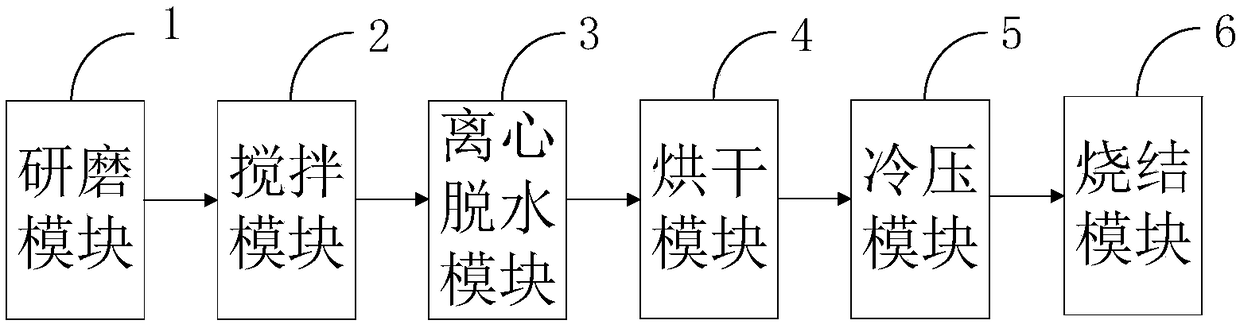

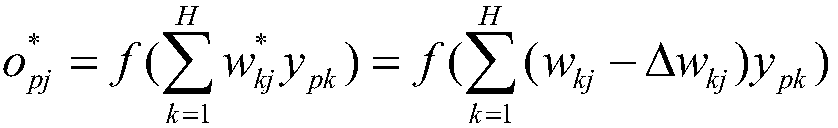

Porous volatile organic compound absorbing calcium carbonate-kaolin composite material and preparation method thereof

InactiveCN108579700AImprove the lubrication effectImprove water resistanceGas treatmentOther chemical processesSodium BentoniteFluoride

The invention belongs to the technical field of chemical materials and discloses a porous volatile organic compound absorbing calcium carbonate-kaolin composite material and a preparation method thereof. An applied preparation system comprises a grinding module, a stirring module, a centrifugal dewatering module, a drying module, a cold pressing module and a sintering module. The porous volatile organic compound absorbing calcium carbonate-kaolin composite material enhances cladding property of styrene around calcium carbonate composite particles and adherence of the styrene onto the surface of calcium carbonate, and meanwhile, through organic bentonite, can further enhance the lubricating, waterproof and thermal-resisting performance of the calcium carbonate and broaden application of thecalcium carbonate in industry. Besides, by means of the auxiliaries of methyltriethoxysilane, zirconium fluoride, quartz powder and basswood ash, the porous volatile organic compound absorbing calcium carbonate-kaolin composite material can greatly improve the breaking elongation and the tensile strength compared with unmodified calcium carbonate filled polytetrafluoroethylene composite materials.

Owner:JIMEI UNIV

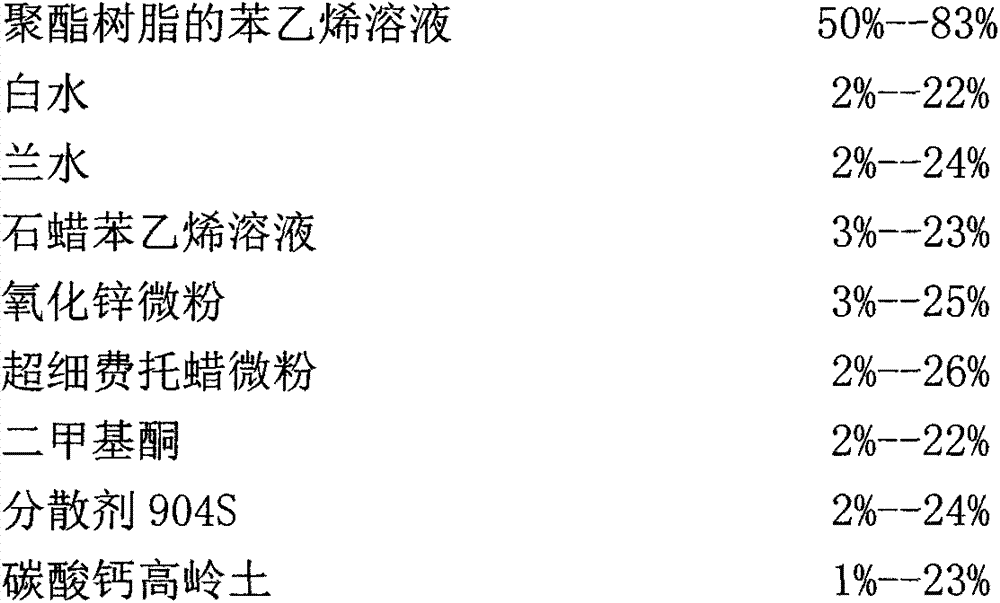

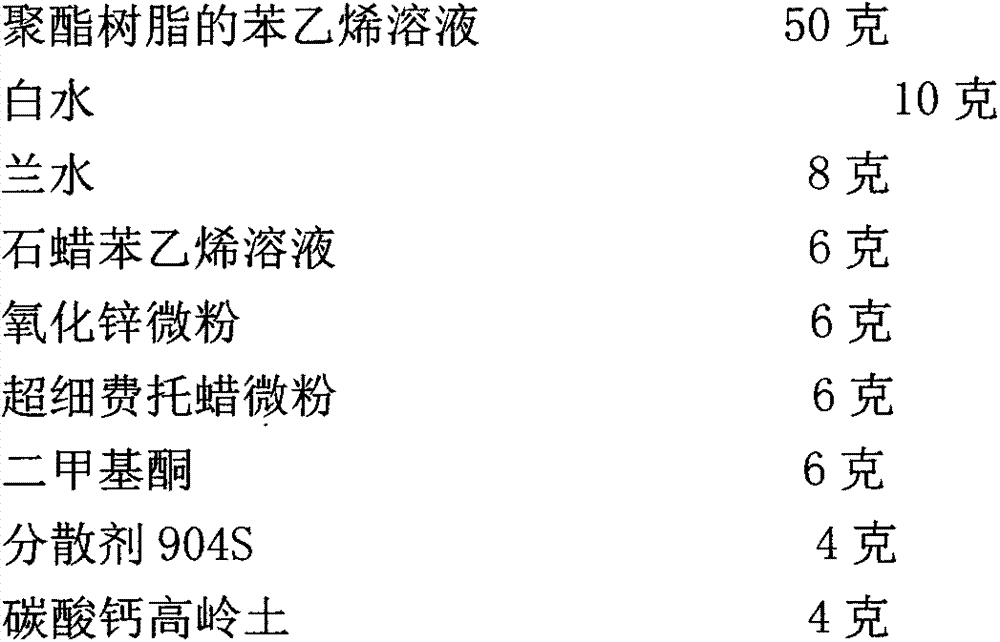

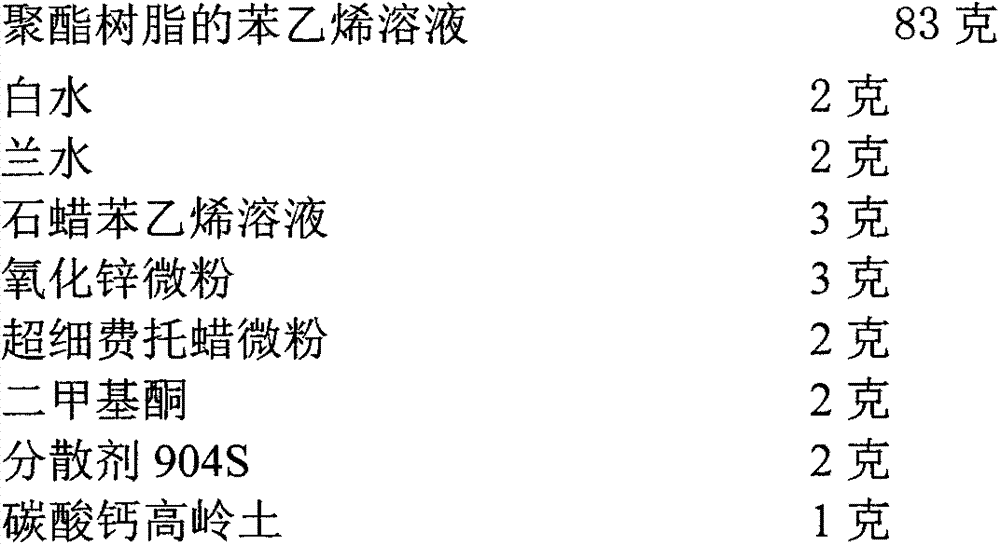

Super-hydrophobic polyester protective paint

InactiveCN107141979AExtended service lifeImprove performanceAntifouling/underwater paintsPaints with biocidesLacquerKetone

The invention discloses super-hydrophobic polyester protective paint, and belongs to the technical field of chemical engineering. The super-hydrophobic polyester protective paint is characterized by being composed of a styrene solution of polyester resin, whitewater, methyl ethyl ketone peroxide, a paraffin styrene solution, zinc oxide micropowder, ultrafine Fischer Tropsch wax micropwder, dimethyl ketone, a dispersing agent 904S, calcium carbonate and kaolin. The finished product super-hydrophobic polyester protective paint can be applied to resisting corrosion of steel materials and wood materials, and resisting carbonation of concrete, and can be also applied to surfaces of various kinds of outdoor and indoor ironmongery goods in ships, bridges and the like as the paint for protecting the surfaces. The super-hydrophobic polyester protective paint has both a micro-scale coarse structure and a nano-scale coarse structure, and thus has the super-hydrophobic function with a lotus leaf effect. After the super-hydrophobic polyester protective paint is utilized, the surface of an object does not need to be artificially cleaned and painted repeatedly so that the object can be returned to a new one for a long time, and thus a lot of labor and materials are saved; meanwhile, the super-hydrophobic polyester protective paint is not eroded by wind and rain, and the service life of the super-hydrophobic polyester protective paint is three folds that of common polyester protective paint, and thus the super-hydrophobic polyester protective paint is indeed the paint which is long in service life and excellent in performance.

Owner:冯智勇

Ardealite ceramsite with good filler effect and preparation method of the ardealite ceramsite

InactiveCN110606765AEasy to handleImprove qualityCeramic materials productionCeramicwareGypsumMaterials science

The invention discloses ardealite ceramsite with a good filler effect. The ardealite ceramsite is prepared from, by weight, 30-60 parts of ardealite, 5-10 parts of clay, 5-15 parts of calcium carbonate kaolin, 2-5 parts of shale and 2-8 parts of acorn powder, wherein the clay is powder formed by mixing with aluminum sol according to the mass ratio of 1:(0.4-0.8) and then grinding the mixture. Experiments prove that the ardealite, the clay, the calcium carbonate kaolin, the shale, the acorn powder and the clay are mixed and ground by adopting alumina sol, then mixing, granulation and firing areperformed to obtain the ceramsite, the tap density of the ceramsite is 380-450 kg / m<3>, and the numerical tube pressure reaches 11.8-13 MPa.

Owner:武穴市诚润祥科技有限公司

Plastic product material

ActiveCN104086967AImprove mechanical propertiesGood compatibilityGlycidyl methacrylatePolyethylene terephthalate

The invention relates to a plastic product material which comprises the following components in parts by weight: 90-100 parts of polyethylene terephthalate, 100-120 parts of polylactic acid, 150-160 parts of polycarbonate, 20-30 parts of polycaprolactam, 50-60 parts of polyphenyl thioether, 30-40 parts of ethylene-acrylate-glycidyl methacrylate copolymer, 25-35 parts of modifier and 1-10 parts of mixed filler composed of calcium carbonate, kaolin and talcum powder in a weight ratio of 1.2:1.5:3. The polyethylene terephthalate, polylactic acid, polycarbonate, polycaprolactam, polyphenyl thioether, ethylene-acrylate-glycidyl methacrylate copolymer, modifier and mixed filler composed of calcium carbonate, kaolin and talcum powder are reasonably proportioned to enhance the mechanical properties of the material, thereby improving the compatibility and greatly enhancing the mechanical properties of the composite material.

Owner:江苏远通塑胶制品有限公司

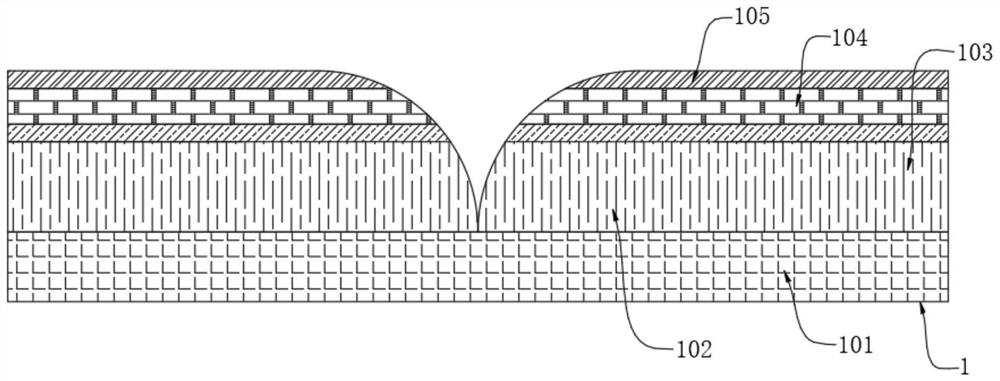

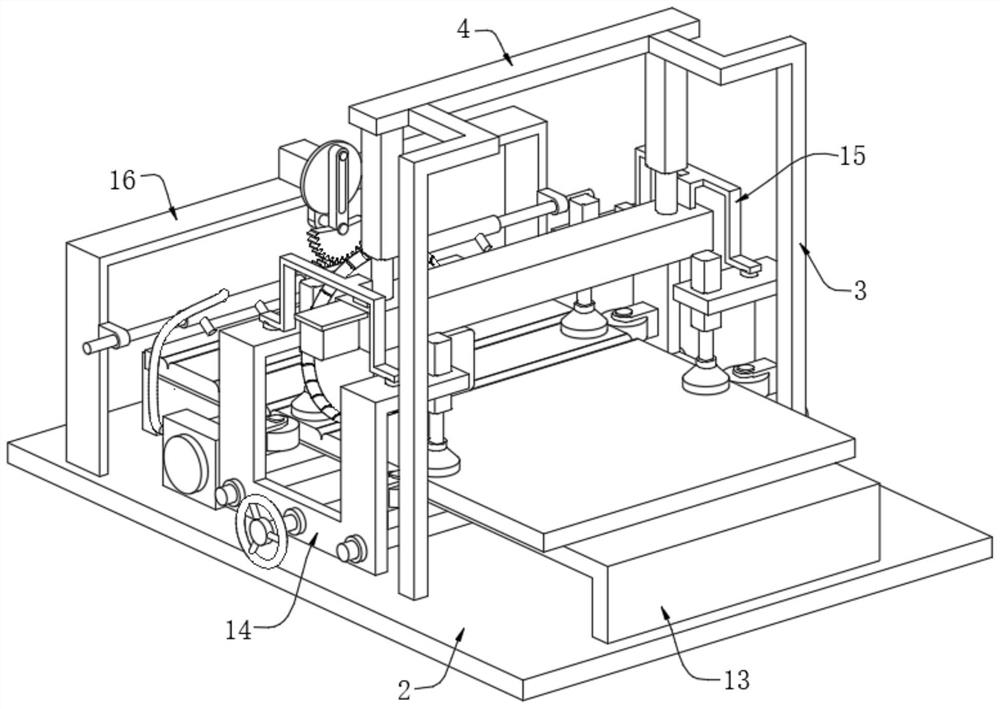

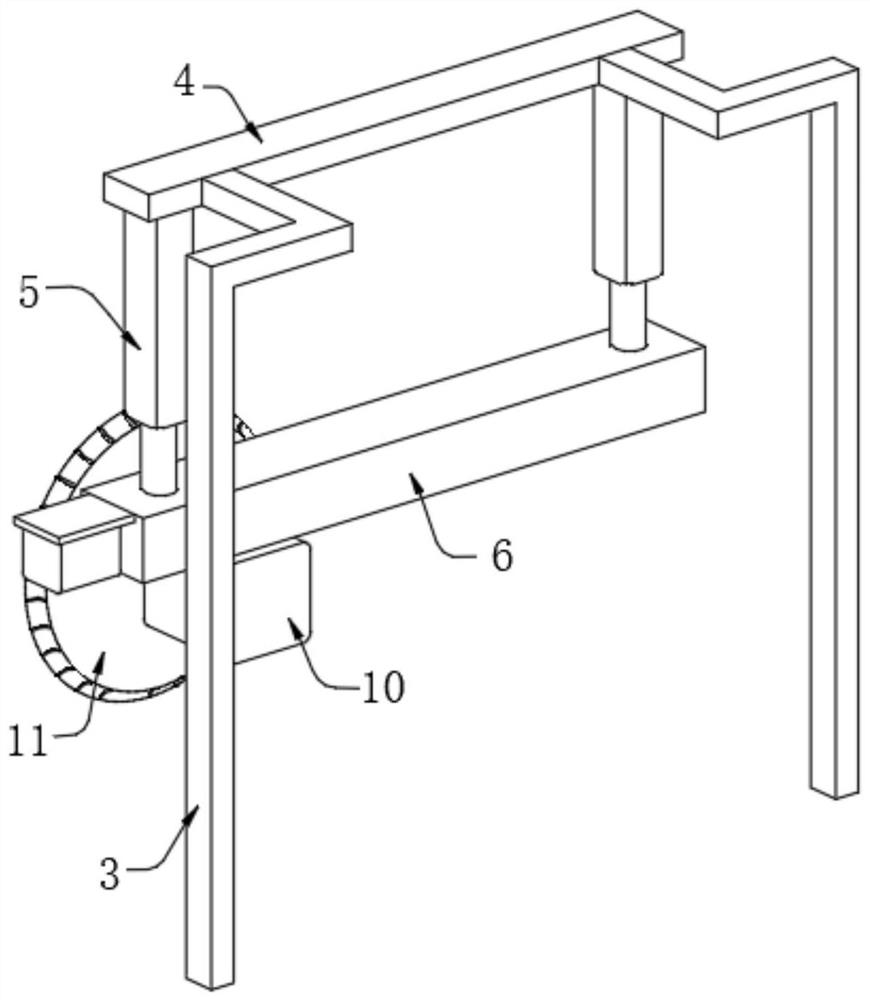

PVC stone-plastic floor with round corners and round corner processing equipment of PVC stone-plastic floor

PendingCN113386435AControl thermal expansion and contractionPrevent reboundSynthetic resin layered productsMetal working apparatusFiberCarbon fibers

The invention discloses a PVC stone-plastic floor with round corners and round corner processing equipment of the PVC stone-plastic floor, and belongs to the technical field of floors. The PVC stone-plastic floor comprises a floor body; the floor body is composed of a backing material layer, a reinforced middle material layer, a color film layer, a wear-resistant layer and a UV protective layer; the backing material layer, the reinforced middle material layer, the color film layer, the wear-resistant layer and the UV protective layer are sequentially laminated from bottom to top; each of the backing material layer and the reinforced middle material layer comprises processing aids such as PVC resin, ground calcium carbonate, kaolin, a DOTP plasticizer, a calcium-zinc stabilizer, carbon fibers, petroleum resin and carbon black; the carbon fiber material and the calcined kaolin are introduced as auxiliary filling materials, the problem of thermal expansion and cold contraction of the floor is better controlled by utilizing the stability of the carbon fibers and the porcelainization effect of the kaolin after high-temperature calcination, the situation that the floor fillet effect rebounds along with temperature change is avoided, and the equipment can be applied to production of the stone-plastic floor with a wear-resistant layer with the thickness being 0.30 mm or below; and the thinner the wear-resistant layer is, the better the fillet effect is.

Owner:福建思嘉新材料科技有限公司

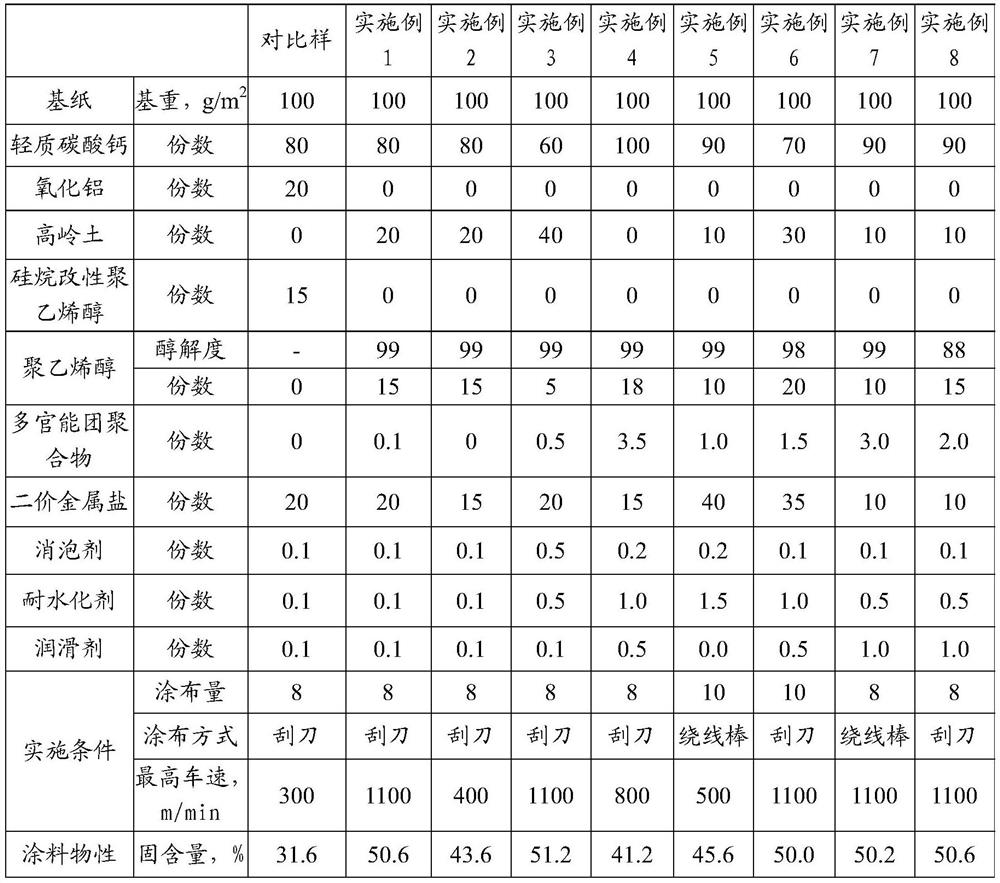

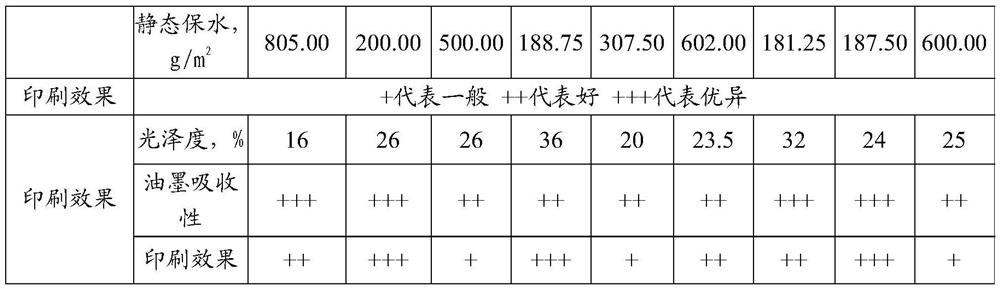

A kind of preparation method of paper coating, coated paper and paper coating

ActiveCN108611921BHigh solid contentHigh viscositySpecial paperPaper/cardboardPolyvinyl alcoholDivalent metal

The invention discloses a paper coating, coating paper and a preparing method for the paper coating. The paper coating is prepared from, by mass, 60-100 parts of light calcium carbonate, 0-40 parts ofkaolin, 3-30 parts of polyvinyl alcohol with the alcoholysis degree larger than or equal to 88%, 0.1-3 parts of a polyfunctional group polymer and 5-40 parts of divalent metal salt, wherein the totalmass of the light calcium carbonate and the kaolin is 100 parts. By means of the paper coating, the coating paper and the preparing method for the paper coating in the mode, the solid content of thepaper coating can be increased, and the running performance of the paper costing is improved.

Owner:GOLD EAST PAPER JIANGSU

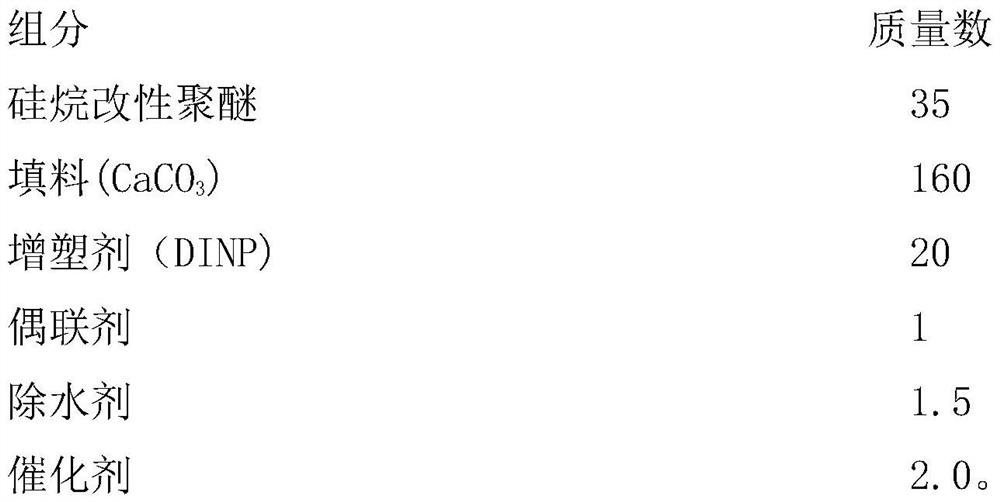

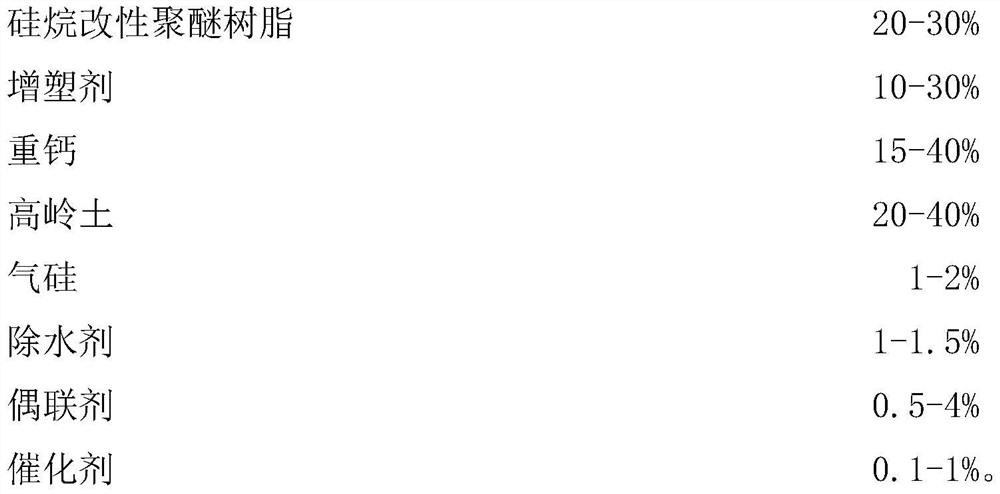

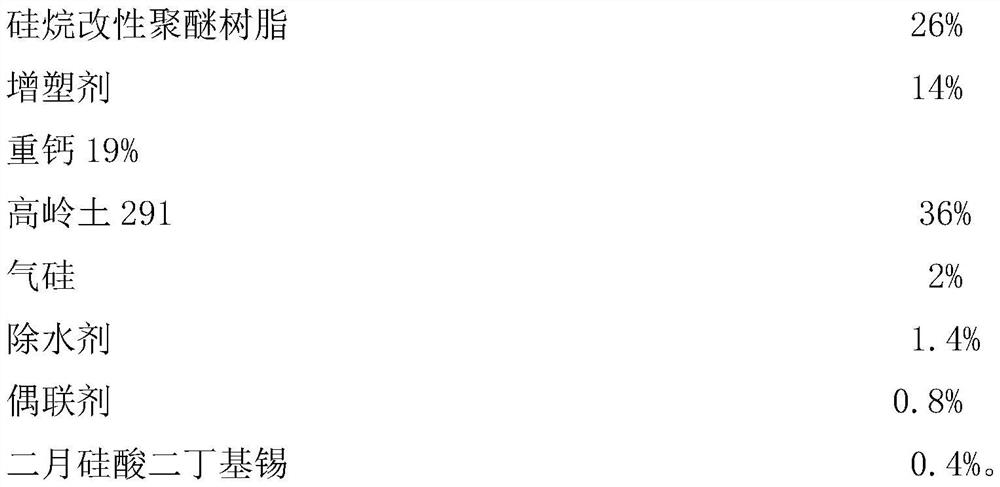

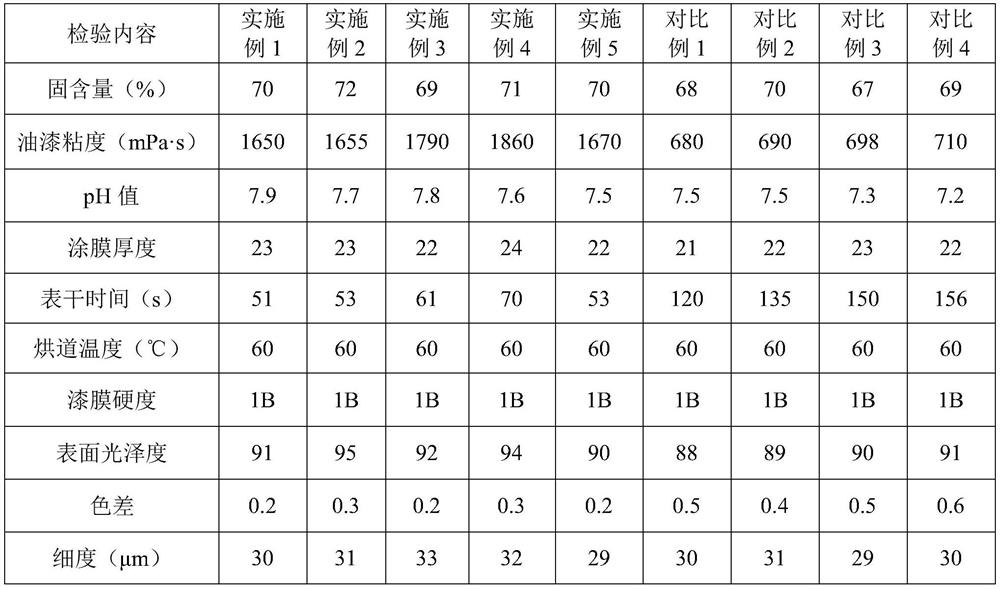

A kind of high-strength silane-modified polyether sealant and preparation method thereof

ActiveCN109294505BImprove mechanical propertiesGood storage stabilityNon-macromolecular adhesive additivesPolyether adhesivesPolymer sciencePtru catalyst

The application relates to a high-strength silane-modified polyether sealant. The present application also relates to a method for preparing high-strength silane-modified polyether sealant, which includes mixing silane-modified polyether resin, heavy calcium carbonate, kaolin, fumed silica, plasticizer and water remover to obtain the first Mixture; at a temperature of 100-150°C, the first mixture is stirred and mixed and then subjected to negative pressure defoaming treatment to obtain a second mixture; the temperature is lowered to below 50°C, and a coupling agent is added to the first mixture and catalyst, after stirring evenly, further degassing and gelling under negative pressure to obtain the high-strength silane-modified polyether sealant. The application also provides the application of a high-strength silane-modified polyether sealant on building joints or in door and window sealing joints.

Owner:SHANGHAI DONGDA CHEM

Q235B hot-rolled steel plate enamel and preparation method thereof

The invention discloses a Q235B hot-rolled steel plate enamel and a preparation method thereof, which comprises the following raw materials in weight percentage: porcelain powder: 60% to 75%, antiknock agent: 0.5% to 2%, pigment: 1 %~3%, sodium nitrite: 0.15%~0.35%, borax: 0.15%~0.4%, calcium carbonate: 0.1~0.5%, kaolin: 4%~5%, quartz powder: 3.6%~5.5%, urea: 0.5%~1.5%, water: 27%~45%. The present invention uses ordinary Q235B hot-rolled steel plate as the base material of enamel products, and the manufacturing cost is relatively low, which is more conducive to the popularization and use of enamel products; The surface has anti-corrosion ability, and the glaze body has stable properties, low cost and simple process.

Owner:山东金仓搪瓷制品科技有限公司

A kind of environment-friendly cold-setting black ink and its production process

The invention relates to the technical field of cold-set black ink, in particular relates to environment-friendly cold-set black ink and a production process thereof. The environment-friendly cold-set black ink is prepared from the following components in percentage by weight: 20 percent to 35 percent of carbon black, 5 percent to 25 percent of rosin modified phenolic resin, 1 percent to 15 percent of petroleum resin, 15 percent to 45 percent of vegetable oil, 5 percent to 25 percent of mineral oil, 1 percent to 10 percent of alkyd resin, 1 percent to 25 percent of calcium carbonate, 1 percent to 25 percent of kaolin, and 1 percent to 5 percent of antidesiccant. The proportion of the petroleum resin, the calcium carbonate, and the kaolin in printing ink is improved, the production cost is reduced, due to the calcium carbonate and the kaolin, the solid-containing content of raw materials is improved, and the control of the petroleum resin to viscosity is improved, so that the ink has good ink piling adaptability. A kneader is used for dispersing the solid-containing content in the raw materials, the fineness of the solid-containing content is strictly controlled, and the adaptability of image weakening of the ink is enhanced.

Owner:茂名阪田油墨有限公司

Environment-friendly water-based pencil color paint suitable for wood pencils and its preparation method and application

The invention discloses environment-friendly waterborne pencil colored paint suitable for a wooden pencil as well as a preparation method and an application of the environment-friendly waterborne pencil colored paint. The environment-friendly waterborne pencil colored paint is prepared from raw materials as follows: waterborne polyurethane, a coalescing agent, color paste, filler and water, wherein the filler is prepared from 5%-25% by mass of calcium carbonate, 3%-20% by mass of kaolin and 3%-10% by mass of wax powder, and a feeding mass ratio of calcium carbonate, kaolin and the wax powder is (3-6):(1.2-2):1. The preparation method comprises the step that the raw materials are mixed uniformly, and the environment-friendly waterborne pencil colored paint is prepared. The invention furtherprovides the application of the colored paint to a painting pencil and the wooden pencil prepared from the colored paint by painting. The colored paint integrates properties of uniform color, short surface drying time, high hardness and the like on the premise of safety and environmental protection, and has good film-forming property.

Owner:苏州马培德办公用品制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com