External wall soft elastic anti-cracking putty powder and preparation process thereof

A crack-resistant putty and soft technology, applied in the direction of filling slurry, etc., can solve the problems of low acid and alkali resistance, low anti-ultraviolet coefficient, and cracking of exterior wall coatings for external wall putty powder, so as to achieve good health and short curing time , Not easy to crack and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

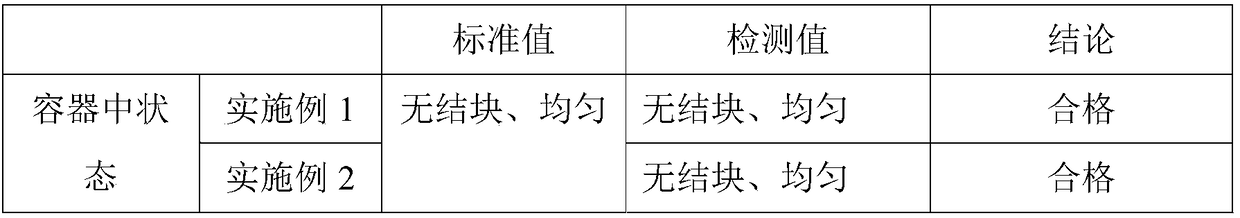

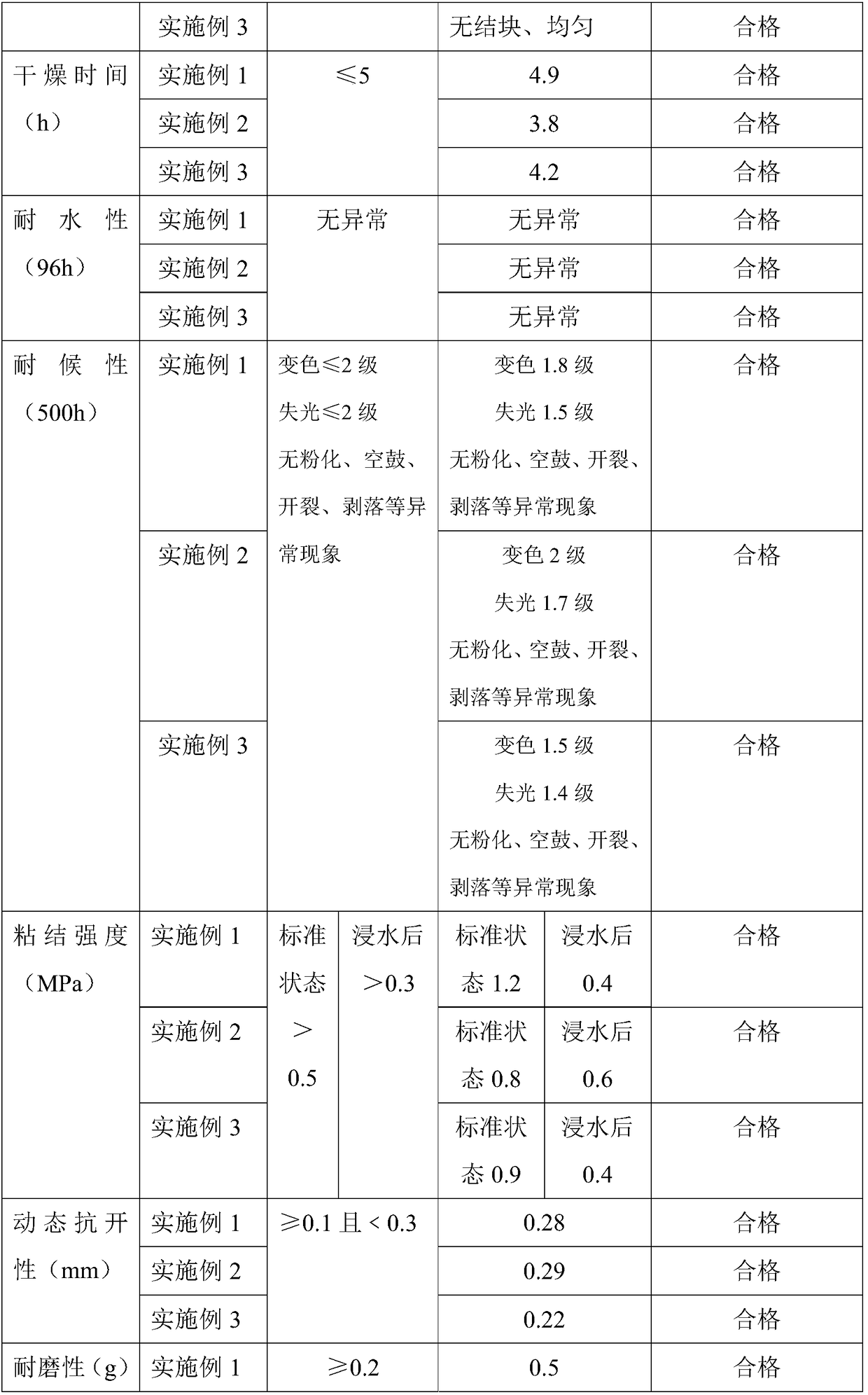

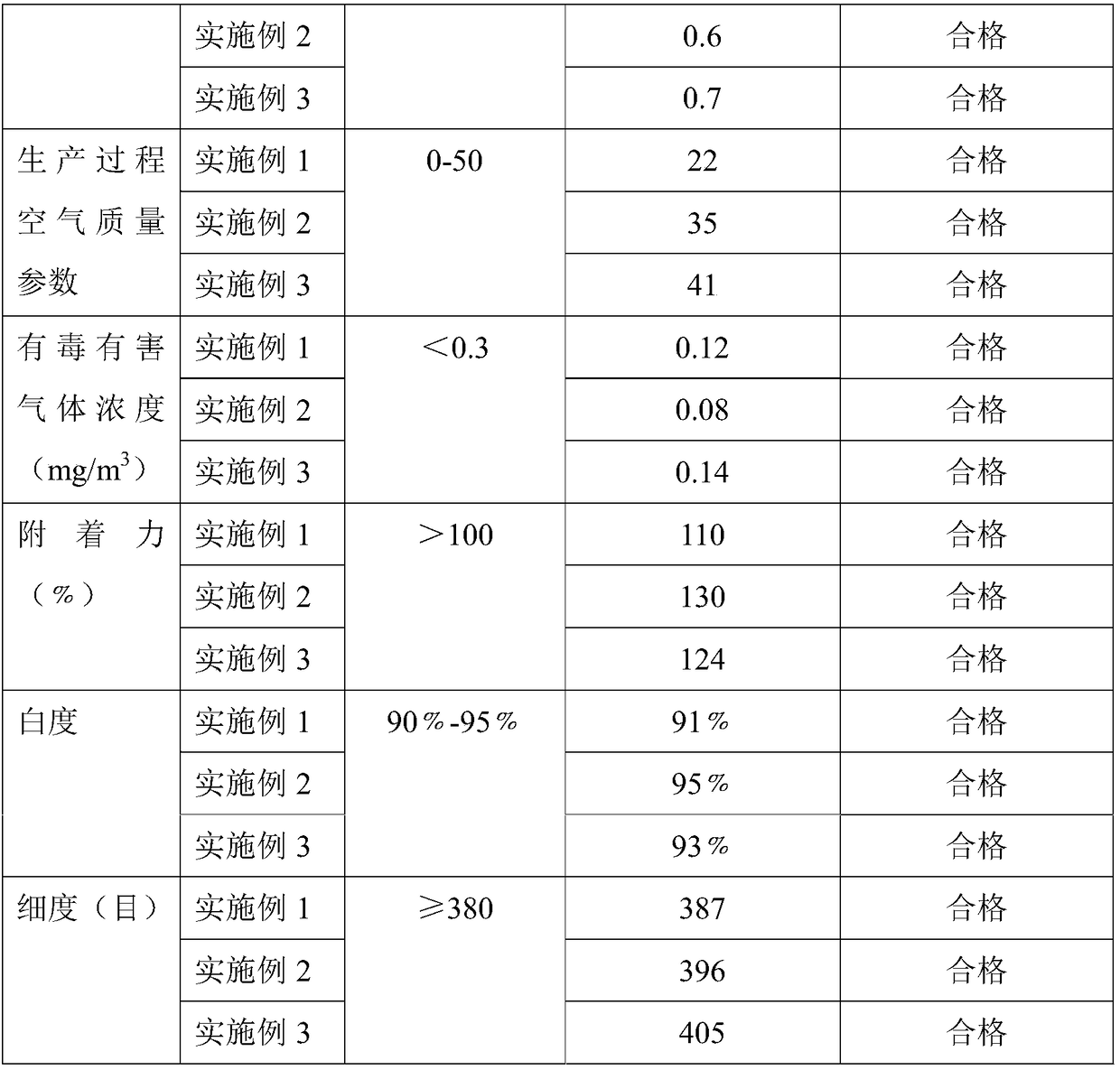

Examples

Embodiment 1

[0043] A soft, elastic, crack-resistant putty powder for external walls, comprising the following raw materials in parts by weight: 100 parts of modified heavy calcium carbonate, 60 parts of kaolin powder, 80 parts of silicate, 90 parts of calcium hydroxide, 60 parts of ash calcium powder, 80 parts of Shuangfei powder, 85 parts of modified talcum powder, 40 parts of quartz, 40 parts of diatomaceous earth, 10 parts of rubber powder, 10 parts of bentonite powder, 15 parts of pure acrylic elastic emulsion, 8 parts of polyvinyl alcohol, 5 parts of zinc white powder, 3 parts of sodium carboxymethyl cellulose, 3 parts of ethylene glycol, 3 parts of redispersible latex powder, 2 parts of additives, 2 parts of defoamer.

[0044] The silicate is 20 parts of sodium silicate, 20 parts of aluminum silicate, 20 parts of magnesium silicate and 20 parts of calcium silicate.

[0045] The ash calcium powder is 30 parts of calcium hydroxide, 30 parts of calcium oxide and 30 parts of calcium carbo...

Embodiment 2

[0060] A soft, elastic, crack-resistant putty powder for exterior walls, comprising the following raw materials in parts by weight: 110 parts of modified heavy calcium carbonate, 70 parts of kaolin powder, 90 parts of silicate, 115 parts of calcium hydroxide, 65 parts of ash calcium powder, 90 parts of Shuangfei powder, 95 parts of modified talcum powder, 50 parts of quartz, 45 parts of diatomite, 15 parts of rubber powder, 12 parts of bentonite powder, 20 parts of pure acrylic elastic emulsion, 9 parts of polyvinyl alcohol, 10 parts of zinc white powder, 4 parts of sodium carboxymethyl cellulose, 4 parts of ethylene glycol, 4 parts of redispersible latex powder, 3 parts of additives, 2.5 parts of defoamer.

[0061] The silicate is 45 parts of sodium silicate and 45 parts of aluminum silicate.

[0062] Described ash calcium powder is 65 parts of calcium carbonate.

[0063] The auxiliary agent is 1.5 parts of borax and 1.5 parts of alum.

[0064] Described defoamer is 2.5 par...

Embodiment 3

[0077] A soft, elastic, crack-resistant putty powder for exterior walls and its preparation process, characterized in that: the putty powder includes the following raw materials in parts by weight: 120 parts of modified heavy calcium carbonate, 80 parts of kaolin powder, 100 parts of silicate, 120 parts of calcium hydroxide, 70 parts of ash calcium powder, 100 parts of Shuangfei powder, 100 parts of modified talc powder, 60 parts of quartz, 50 parts of diatomaceous earth, 20 parts of rubber powder, 15 parts of bentonite powder, 25 parts of pure acrylic elastic emulsion , 10 parts of polyvinyl alcohol, 15 parts of zinc white powder, 5 parts of sodium carboxymethyl cellulose, 5 parts of ethylene glycol, 5 parts of redispersible latex powder, 5 parts of additives, and 3 parts of defoamer.

[0078] The silicate is 100 parts of sodium silicate.

[0079] Described ash calcium powder is 70 parts of calcium carbonate.

[0080] The auxiliary agent is 5 parts of borax.

[0081] Descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com