A kind of high-strength silane-modified polyether sealant and preparation method thereof

A technology of silane-modified polyether and sealant, which is applied in the field of sealant and can solve problems such as high cost and complicated operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

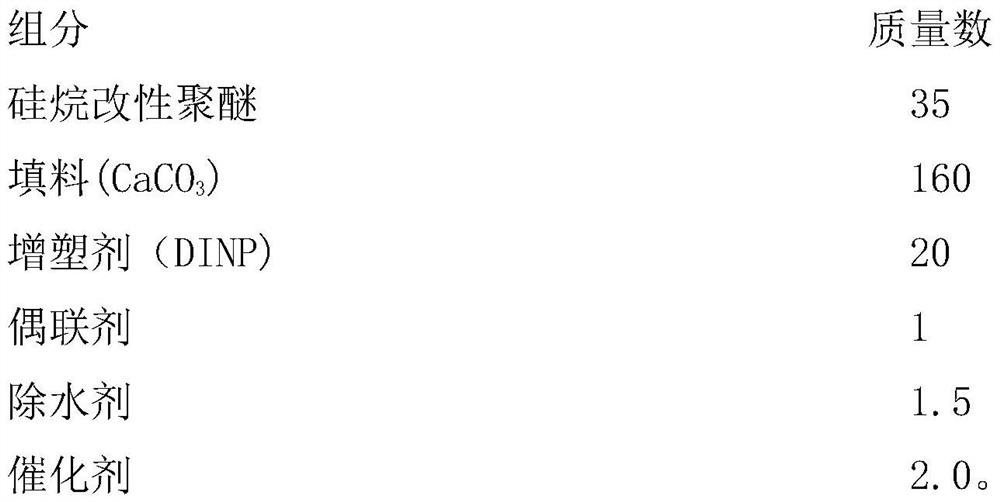

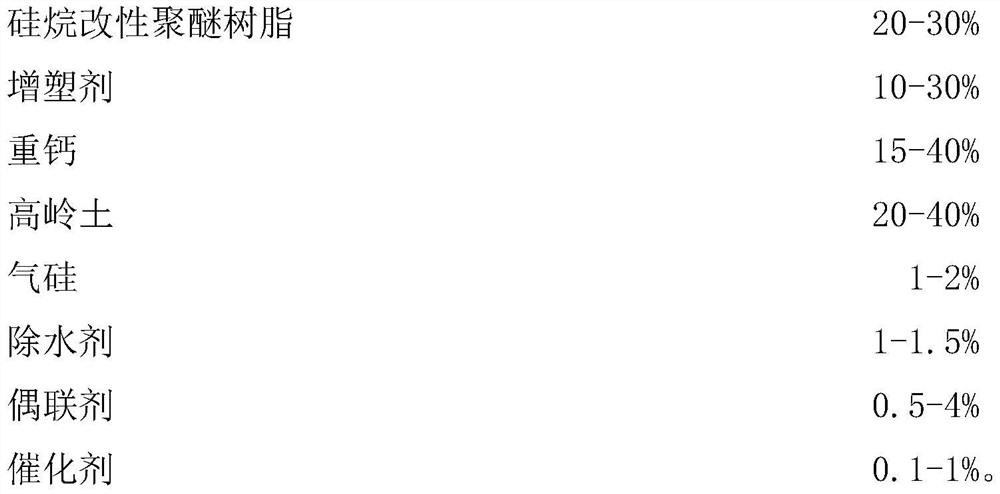

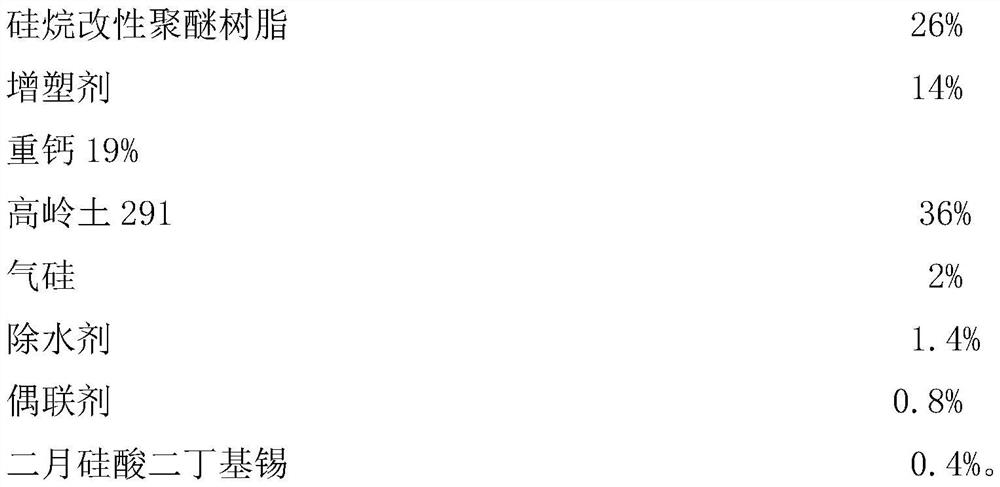

[0049] In a specific embodiment, the application provides a method for preparing a high-strength one-component silane-modified polyether sealant, which includes the following steps: silane-modified polyether resin, ground calcium carbonate, kaolin (Souli International Trading Co., Ltd. 291, Vm), plasticizer and dewatering agent, stir evenly, vacuumize and defoam; after cooling down to 50°C, add coupling agent and catalyst and stir evenly; finally negative pressure defoam The glue is produced to obtain a high-strength one-component silane-modified polyether sealant; the plasticizer is DINP (diisononyl phthalate).

[0050] In a specific embodiment, the silane-modified polyether resin can be a conventional resin in this field, and the preferred performance parameter is viscosity: 8000mpa.s-10000mpa.s (cone and plate viscometer, 25°C), without Silane-modified polyether resin of NCO. The amount of said silane-modified polyether resin can be the conventional amount of this type of ...

Embodiment

[0071] The technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. All reagents and raw materials used were purchased commercially unless otherwise specified. For the experimental methods that do not specify specific conditions in the following examples, select according to conventional methods and conditions, or according to the product instructions.

[0072] In the following examples, the preparation method of silane-modified polyether sealant is as follows:

[0073] (1) Prepare materials: prepare materials according to the mass percentage of silane-modified polyether sealant;

[0074] (2) Use a double planetary mixer for mixed production: put heavy calcium carbonate, kaolin, fumed silicon, silane-modified polyether resin, plasticizer and water remover into the stirring pot, stir until uniformly dispersed, and no particles;

[0075] (4) heat up to 100-150°C, vacuumize and keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com