A kind of preparation method of paper coating, coated paper and paper coating

A coating and paper technology, which is applied in the preparation of coated paper and paper coatings, and in the field of paper coatings, can solve the problems of insufficient drying capacity, easy backflow, and difficulty in dispersion, and achieve enhanced film-forming performance, improved bonding effect, The effect of increasing the solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

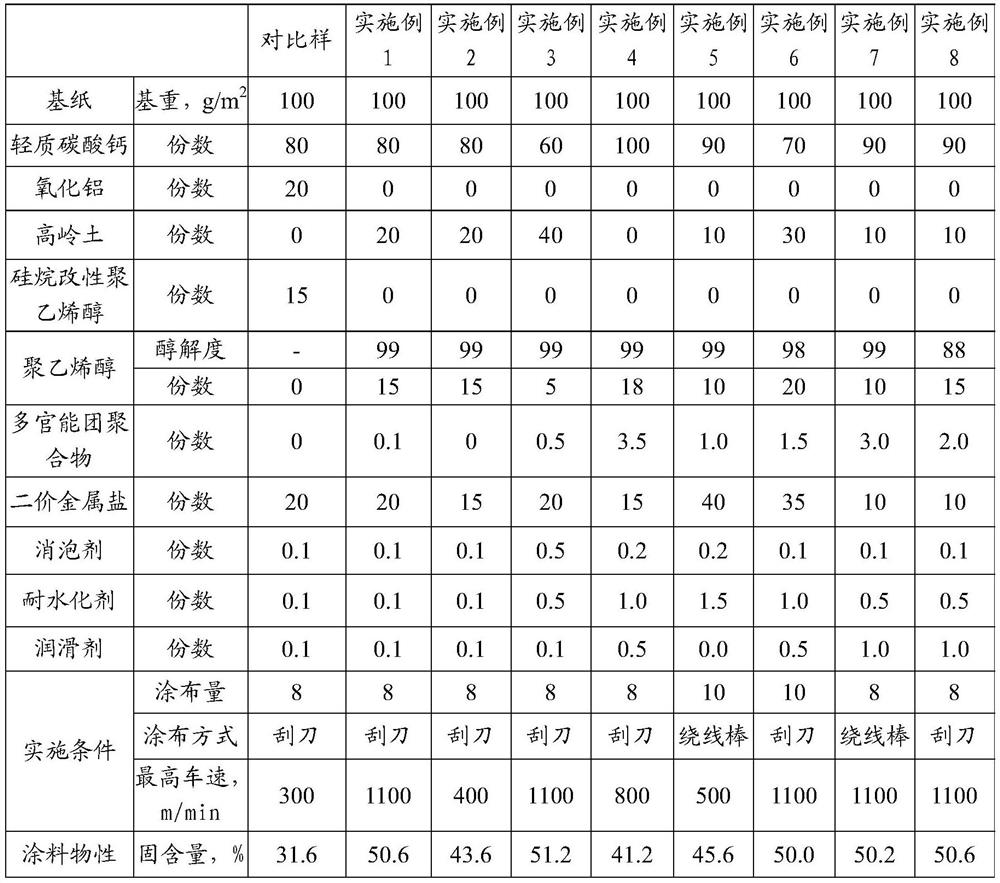

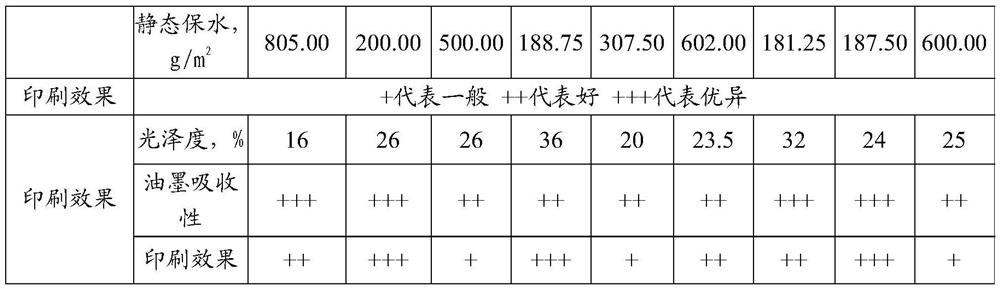

Embodiment 1

[0035] Prepare paper coating, comprise light calcium carbonate 80g, kaolin 20g, polyvinyl alcohol 15g of degree of alcoholysis 99%, polyfunctional polymer 0.1g, divalent metal salt 20g, defoamer 0.1g, water resistance agent 0.1g, Lubricant 0.1g; the basis weight is 100g / m 2 The paper coating is coated on the base paper with a scraper, and the coating amount is 8g / m 2 , the maximum speed of the coating machine is 1100m / min. At room temperature, the measured solid content of the paper coating is 50.6%, and the static water retention rate is 200g / m 2 ; At room temperature, the measured gloss of the coated paper is 26%, the ink absorption is excellent, and the printing effect is excellent.

Embodiment 2

[0037] Prepare paper coating, comprise light calcium carbonate 80g, kaolin 20g, polyvinyl alcohol 15g of alcoholysis degree 99%, divalent metal salt 15g, defoamer 0.1g, water resistance agent 0.1g, lubricant 0.1g; Weight is 100g / m 2 The paper coating is coated on the base paper with a scraper, and the coating amount is 8g / m 2 , the maximum speed of the coating machine is 400m / min. At room temperature, the measured solid content of the paper coating is 43.6%, and the static water retention rate is 500g / m 2 ; At room temperature, the measured gloss of the coated paper is 26%, the ink absorption is good, and the printing effect is general.

Embodiment 3

[0039] Prepare paper coating, comprise light calcium carbonate 60g, kaolin 40g, polyvinyl alcohol 5g of degree of alcoholysis 99%, polyfunctional polymer 0.5g, divalent metal salt 20g, defoamer 0.5g, water resistance agent 0.5g, Lubricant 0.1g; the basis weight is 100g / m 2 The paper coating is coated on the base paper with a scraper, and the coating amount is 8g / m 2 , the maximum speed of the coating machine is 1100m / min. At room temperature, the measured solid content of the paper coating is 51.2%, and the static water retention rate is 188.75g / m 2 ; At room temperature, the measured gloss of the coated paper is 36%, the ink absorption is good, and the printing effect is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com