Low-quantification and high-strength coating white board paper and preparation process thereof

A high-strength, low-weight technology, applied in the field of papermaking, can solve problems such as thickness reduction, low-weight paper and cardboard, and stiffness reduction, and achieve the effect of ensuring low-weight, high-strength, and uniform paper banners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

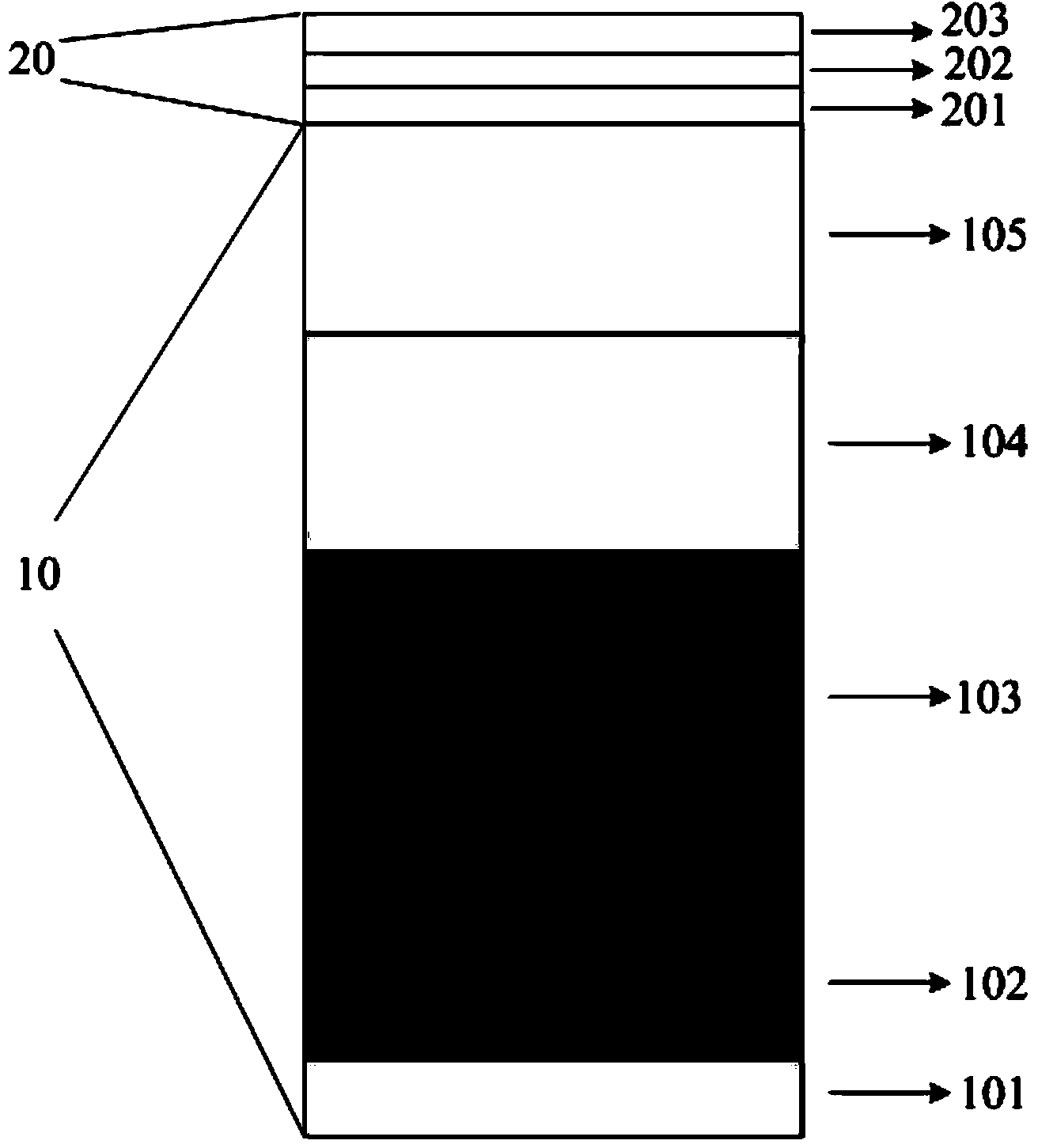

Image

Examples

Embodiment 1

[0045] (1) Preparation of surface bleached wood pulp

[0046] The bleached commercial wood pulp boards of bleached hardwood pulp LBKP and bleached softwood pulp NBKP are transported to the hydraulic pulper for disintegration by the chain plate machine, and then enter the pulp storage tower for storage. The pulp is pumped to the high-consistency desander Heavy impurities are sent to pulping after being beaten in series by a refiner, and are used as the surface layer of the cardboard to bleach the chemical pulp layer;

[0047] Wherein the proportioning amount of bleached hardwood pulp is 50%, the proportioning amount of bleached softwood pulp is 50%, and the beating degree of the slurry is controlled at 40°SR.

[0048] (2) Preparation of waste paper pulp

[0049] The waste paper is conveyed by the chain plate machine to the drum pulper for disintegration, and then enters the pulp storage tower for storage. The pulp is pumped to the high-concentration desander to remove heavy im...

Embodiment 2

[0054] Its operation step is identical with embodiment 1, and difference is:

[0055] (3) Preparation and molding of layered slurry

[0056] The slurry sent from the pulping workshop is added with auxiliary materials including retention aid and enhancer. The enhancer is mainly added to the surface layer slurry, and each layer of retention aid needs to be added, and then sent to the paper machine by frequency conversion and speed regulation slurry pump The white water tank outside the machine is mixed and diluted with concentrated white water, and is sent to the pressure screen for screening through the slurry pump, and then enters the headbox. Layer 0.8%; After the slurry is online, it is formed by four-fold net, pressed, dried, surface sizing, re-dried, and calendered, and then enters the coating system. After surface sizing, surface pre-coating, mid-coating and top-coating, the base paper is dried in a hot air drying oven and then enters the conditioning tank, soft calender...

Embodiment 3

[0059] Its operation step is identical with embodiment 1, and difference is:

[0060] (3) Preparation and molding of layered slurry

[0061] The slurry sent from the pulping workshop is added with auxiliary materials including retention aid and enhancer. The enhancer is mainly added to the surface layer slurry, and each layer of retention aid needs to be added, and then sent to the paper machine by frequency conversion and speed regulation slurry pump The white water tank outside the machine is mixed and diluted with concentrated white water, and is sent to the pressure screen for screening through the slurry pump, and then enters the headbox. Layer 0.8%; After the slurry is online, it is formed by four-fold net, pressed, dried, surface sizing, re-dried, and calendered, and then enters the coating system. After surface sizing, surface layer pre-coating, mid-coating and top-coating, the raw paper is dried in a hot air drying oven and then enters the conditioning cylinder, soft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lateral stiffness | aaaaa | aaaaa |

| Burst resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com