Method for producing foaming cushion

A manufacturing method and technology of foam pads, which are applied to household components, household appliances, and other household appliances, can solve problems such as discomfort, rebound, or slow strength, and achieve the goal of avoiding foot soreness and discomfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

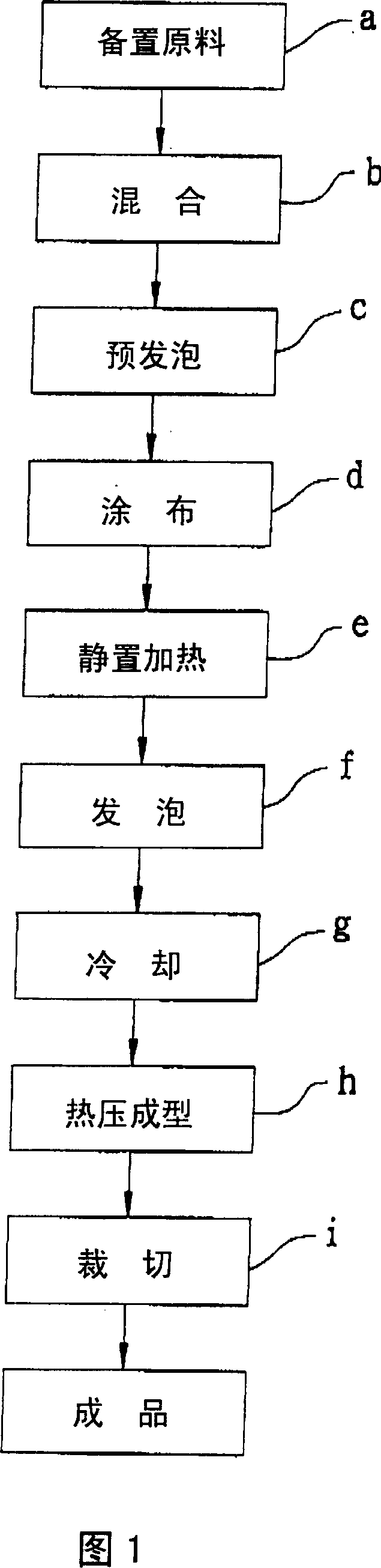

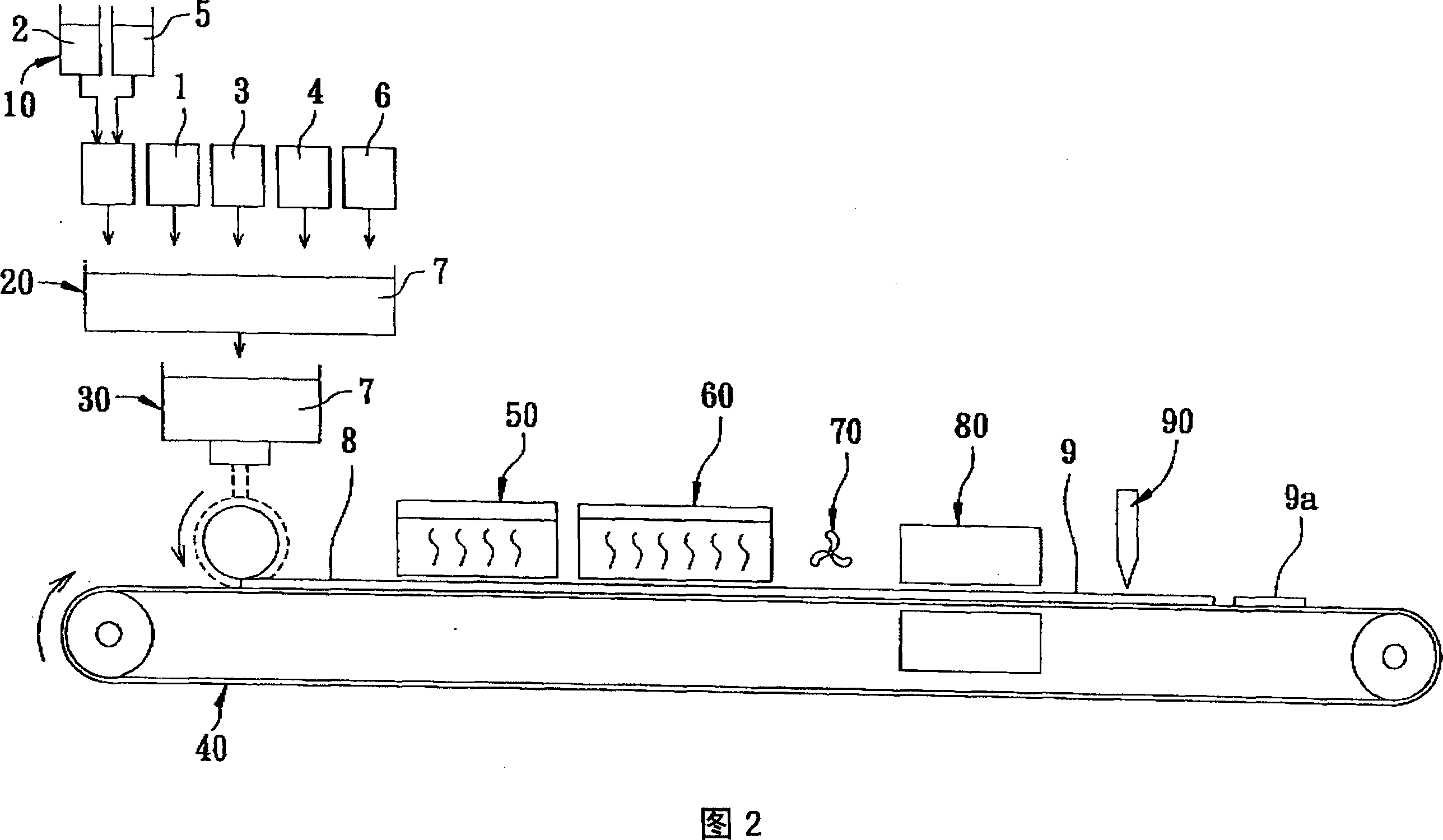

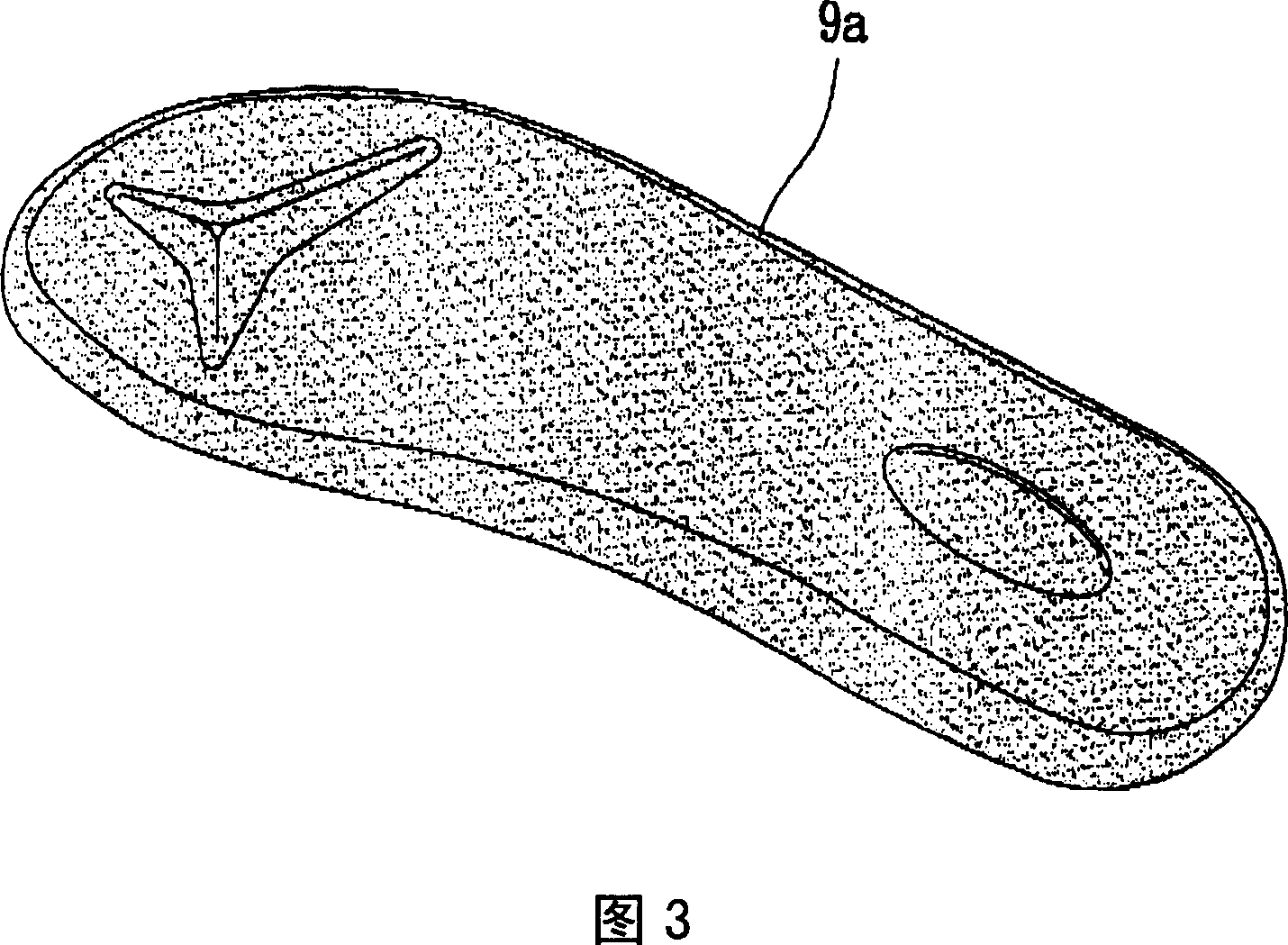

[0024] Please refer to Figures 1 and 2, the present invention provides a preferred embodiment of a method for manufacturing a foamed cushion, the manufacturing process of the foamed cushion includes the following method steps:

[0025] a. Steps of preparing raw materials

[0026] Prepare an appropriate amount of polyvinyl chloride (abbreviated as PVC) powder 1, dioctyl phthalate (abbreviated as DOP) plasticizer 2, light calcium carbonate 3, kaolin 4, foaming agent 5 and colorant 6; wherein, the above raw materials It can be pre-packed with material barrel 10;

[0027] b. Mixing step

[0028] The above-mentioned raw materials are injected into a mixing device 20 and mixed with each other to form a liquid slurry 7; wherein, the foaming agent 5 and the dioctyl phthalate (DOP) plasticizer 2 in the above-mentioned raw materials must be pre-mixed, Inject into the mixing device 20 and mix with other raw materials;

[0029] c, pre-foaming step

[0030] Put the mixed liquid slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com