Electrode sheet forming machine

A molding machine and molding mechanism technology, applied in electrode manufacturing, feeding device, positioning device, etc., can solve the problems of reduced production efficiency, single shape, high mold production cost, and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with preferred specific embodiments.

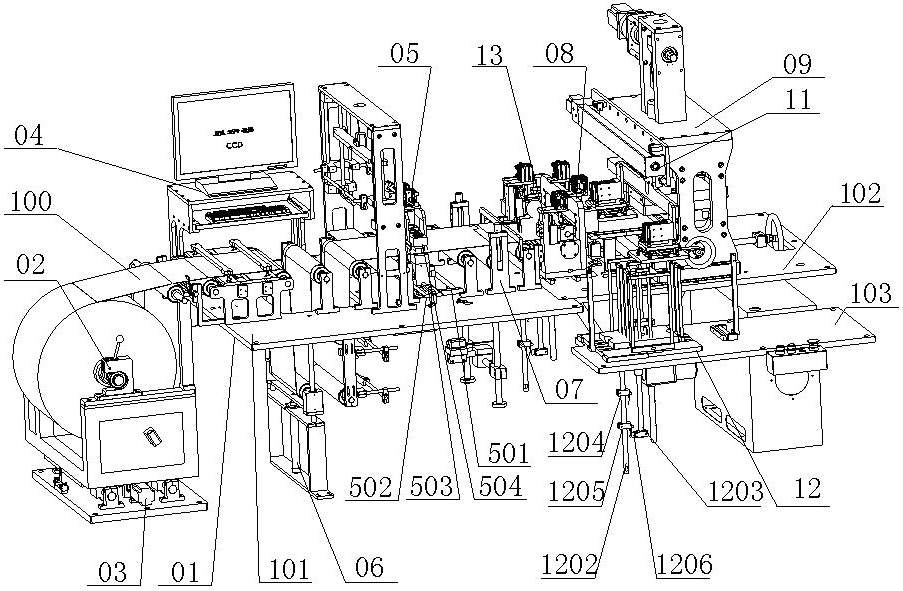

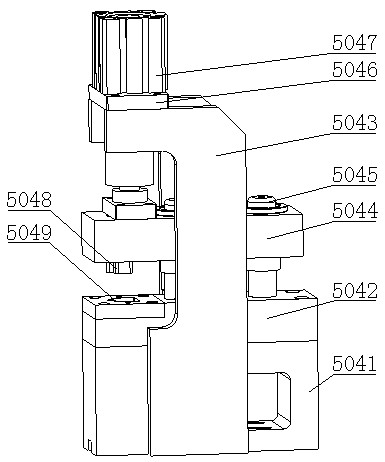

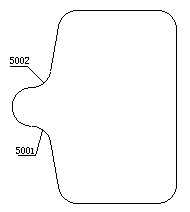

[0021] like figure 1 , 2 , 3 and 4, the structure of the pole piece forming machine in this preferred embodiment includes a support mechanism 01, a control system, an unwinding mechanism 02, an unwinding correction mechanism 03, an unwinding traction mechanism 13, a CCD detection system 04, chamfering and cutting Mechanism 05, tension mechanism 06, buffer mechanism 07, fixed-length cutting mechanism 08, tab punching mechanism 09, waste collection mechanism (not shown), blanking mechanism 11 and material box 12; chamfering and cutting mechanism 05, pole The ear punching mechanism 09 and the fixed-length cutting mechanism 08 are arranged sequentially in the unwinding direction of the pole piece strip, and together constitute the forming mechanism of the pole piece forming machine, which is used to cut the pole piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com