Method, system, and apparatus for transfer of dies using a pin plate

a technology of pin plate and transfer die, applied in the field of electronic device assembly, can solve the problems of limited throughput volume drawback, limited placement accuracy of pick and place techniques,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] 1. Overview

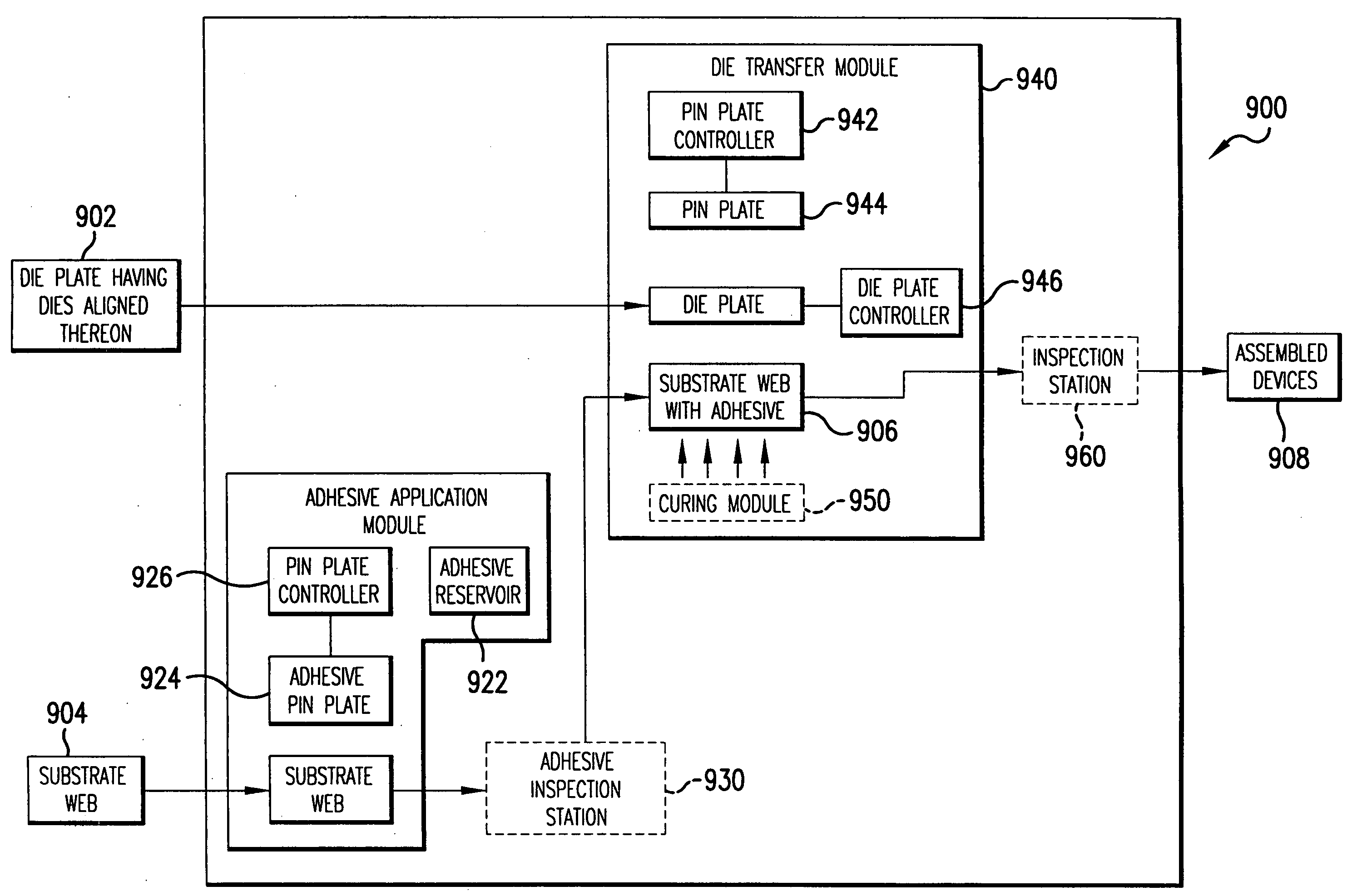

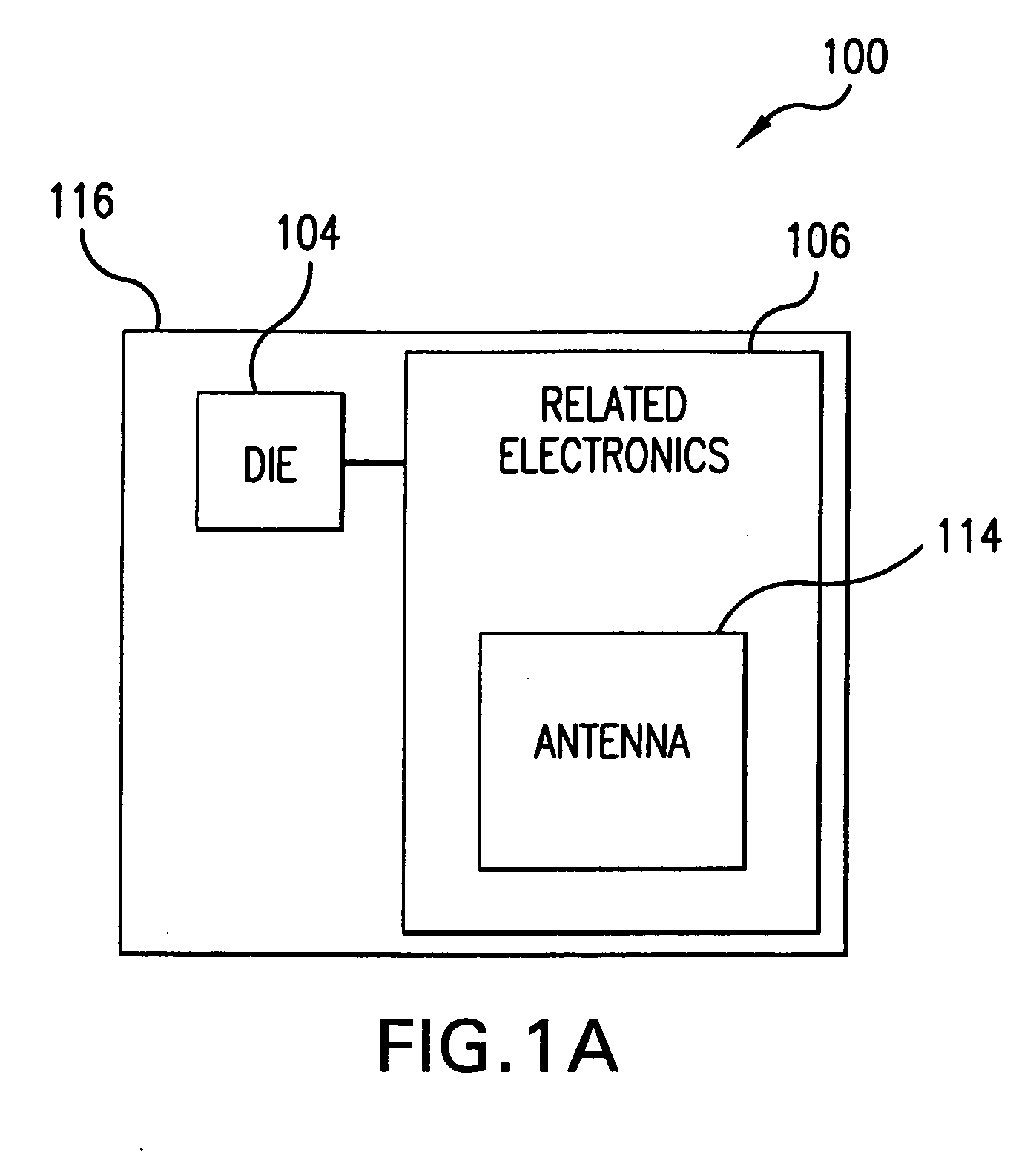

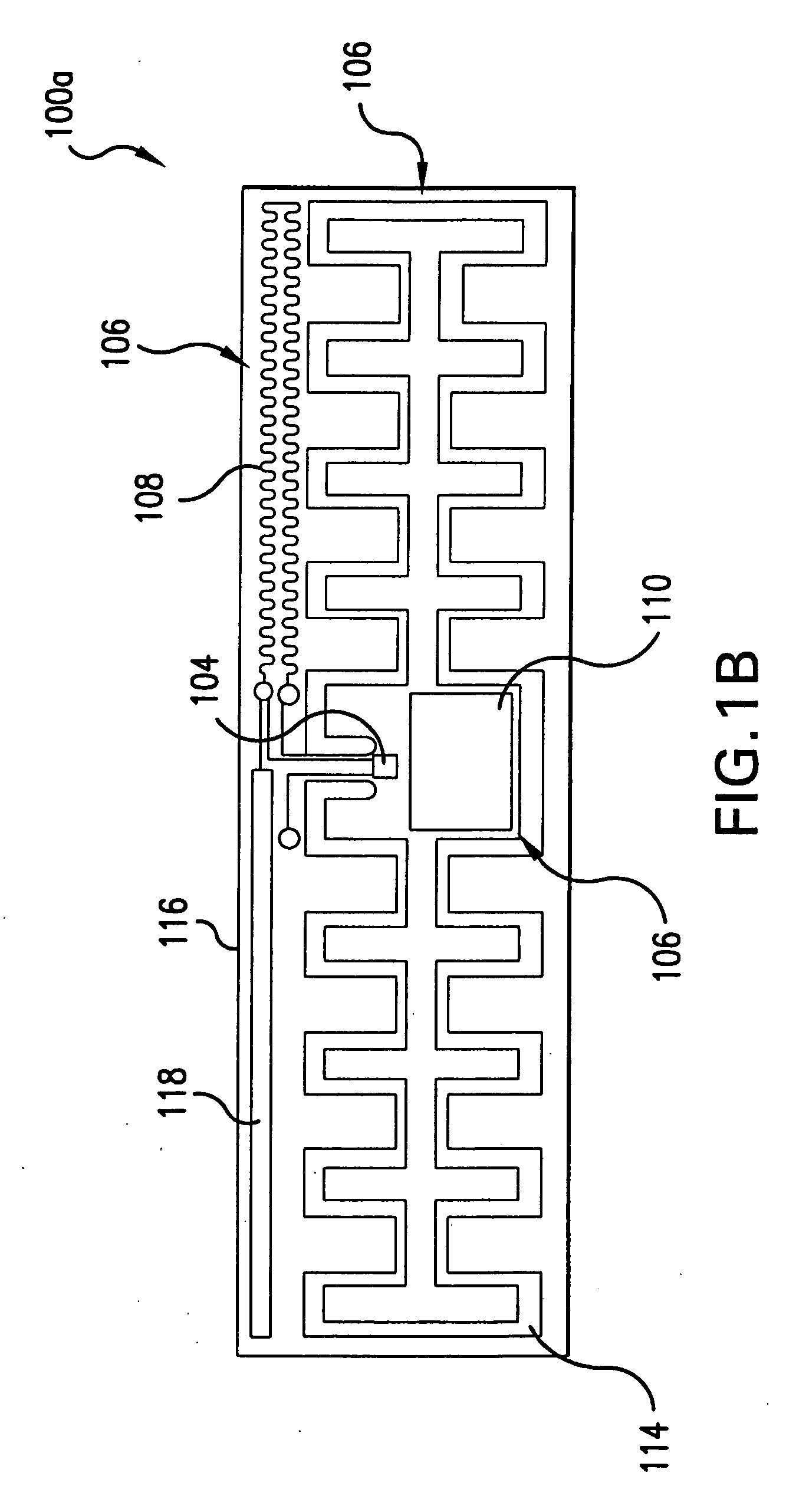

[0072] The present invention provides improved processes and systems for assembling electronic devices, including RFID tags. The present invention provides improvements over current processes. Conventional techniques include vision-based systems that pick and place dies one at a time onto substrates. The present invention can transfer multiple dies simultaneously. Vision-based systems are limited as far as the size of dies that may be handled, such as being limited to dies larger than 600 microns square. The present invention is applicable to dies 100 microns square and even smaller. Furthermore, yield is poor in conventional systems, where two or more dies may be accidentally picked up at a time, causing losses of additional dies. The present invention allows for improved yield values.

[0073] The present invention provides an advantage of simplicity. Conventional die transfer tape mechanisms may be used by the present invention. Furthermore, much higher fabricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com