Coating composition for blister coated whiteboard with white back, and preparation process of coating composition

A technology of white board and composition, applied in paper coating, paper, papermaking and other directions, can solve the problems of low bonding strength, poor ink absorption, poor air permeability, etc., and achieve the effects of good ink absorption, good air permeability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

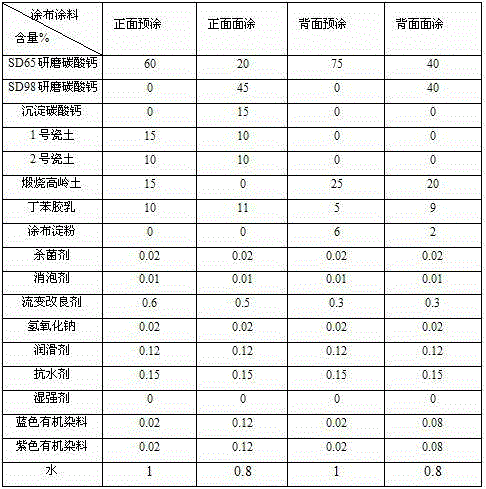

[0040] A coating composition for blister coating white paperboard: It includes four coating coatings, namely front pre-coating, front top coating, back pre-coating and back top coating. The coating formulations for each layer are as follows:

[0041]

[0042] Among them, the glass transition temperature of styrene butadiene latex is 25°C.

[0043] The coating starch is added to the back coating to replace part of the latex as the adhesive of the coating coating, which can reduce the cost and meet the technical index requirements of the coating coating.

[0044] The price of SD65 ground calcium carbonate is relatively low, and its grinding process is relatively mature, which can achieve the same technical effect.

[0045] The prepared front pre-coating paint has a viscosity of 870cP / 25℃, a solid content of 66.8%, and a pH of 8.67;

[0046] Coating on the front surface, viscosity is 660cP / 25℃, solid content is 65.2%, pH is 8.68;

[0047] Pre-coated paint on the back, viscosity is 880cP / 25℃...

Embodiment 2

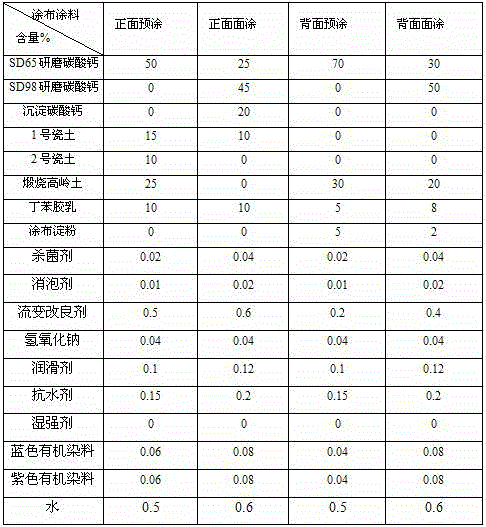

[0051] A coating composition for blister coating white paper board: includes four coating coatings, which are front precoating, front top coating, back precoating and back top coating.

[0052]

[0053] The glass transition temperature of styrene-butadiene latex is 25°C.

[0054] The prepared front pre-coated paint has a viscosity of 860cP / 25℃, a solid content of 66.7%, and a pH of 8.73;

[0055] Paint on the front surface, viscosity is 670cP / 25℃, solid content is 65.8%, pH is 8.62;

[0056] Pre-coated paint on the back, viscosity is 880cP / 25℃, solid content is 66.1%, pH is 8.69;

[0057] Paint on the back surface, viscosity is 890cP / 25℃, solid content is 67.2%, pH is 8.76.

[0058] After four-layer coating, the whiteness of the blister white paper is ≥80, the gloss is ≥87, the roughness is ≤1.8μm, the ink absorption is 23±3%, and the surface strength is ≥0.9m / s.

Embodiment 3

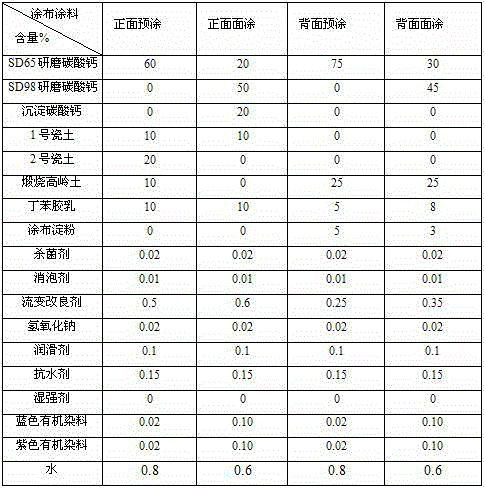

[0060] A coating composition for blister coating white paperboard: It includes four coating coatings, namely front pre-coating, front top coating, back pre-coating and back top coating. The coating formulations for each layer are as follows:

[0061]

[0062] Among them, the glass transition temperature of styrene-butadiene latex is 30°C.

[0063] The prepared front pre-coating paint has a viscosity of 870cP / 25℃, a solid content of 66.8%, and a pH of 8.65;

[0064] Coating on the front surface, viscosity is 640cP / 25℃, solid content is 65.6%, pH is 8.68;

[0065] Pre-coated paint on the back, viscosity is 890cP / 25℃, solid content is 66.3%, pH is 8.60;

[0066] The back surface is coated with paint, the viscosity is 940cP / 25℃, the solid content is 66.1%, and the pH is 8.66.

[0067] After four-layer coating, the whiteness of the blister white paper is ≥80, the gloss is ≥87, the roughness is ≤1.8μm, the ink absorption is 23±3%, and the surface strength is ≥0.9m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com