Water-cooling pressure head on mobile phone display screen bonding equipment

A display screen and water-cooling technology, applied in lighting and heating equipment, household refrigeration equipment, coil equipment, etc., can solve quality problems, poor contact of electronic pin lines, and reduce the connection strength and stress of FPC and liquid crystal glass circuits and other issues to achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

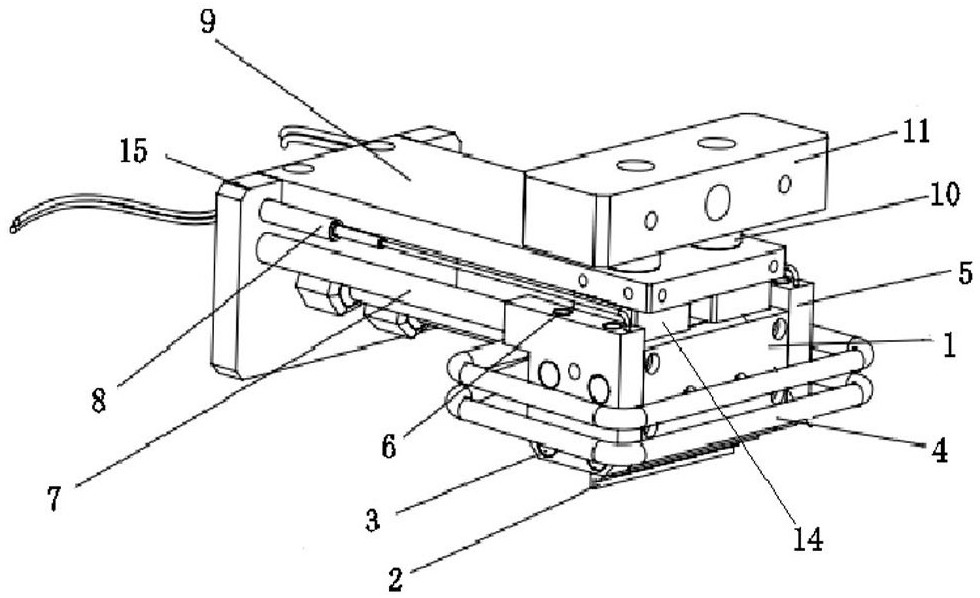

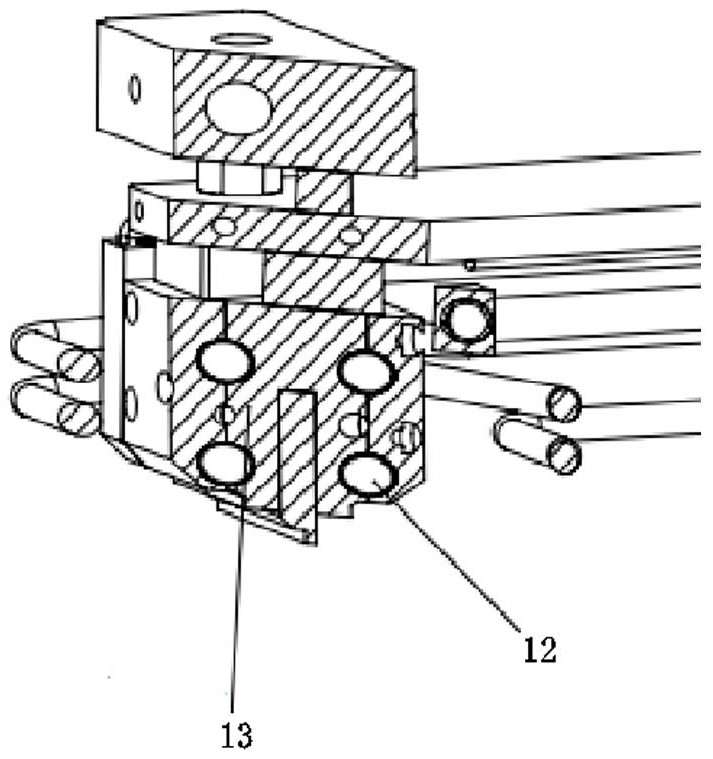

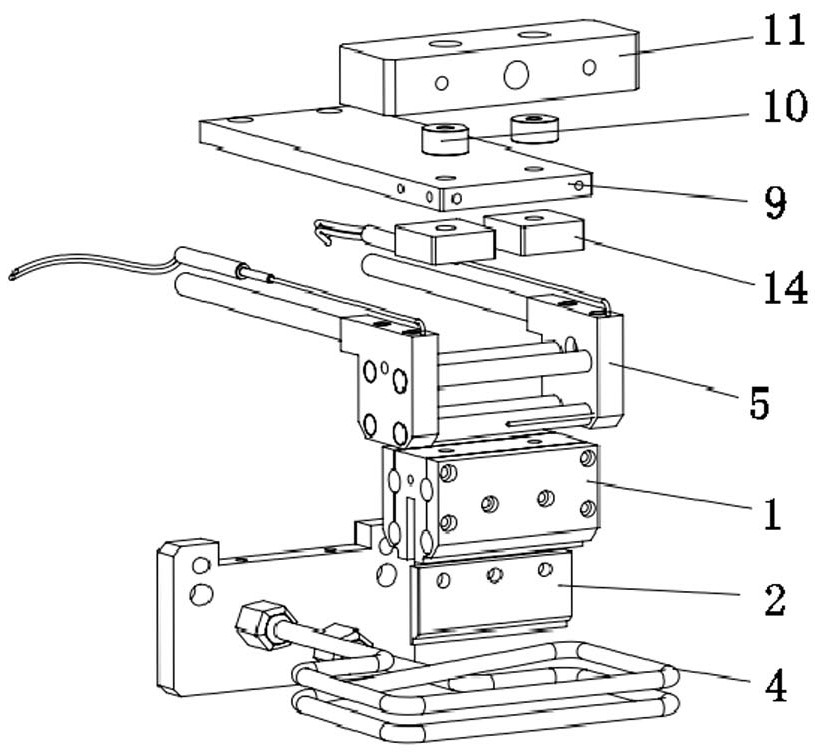

[0026] Please refer to Figure 1-3 , the present invention provides a technical solution: a water-cooled indenter on a mobile phone display bonding device, including two water-cooled glands 1, and an indenter mounting block 13 is provided on the side where the two water-cooled glands 1 are close to each other. The indenter mounting block 13 is fixedly connected with the two water-cooled glands 1, the indenter mounting block 13 is fixedly equipped with a cutter head 2, and both sides of the indenter mounting block 13 are fixedly installed with end caps 5, two end caps 5 They are in contact with both sides of the two water-cooled glands 1 respectively, and the first cooling water pipe 7 is fixedly installed on the same side of the two end covers 5;

[0027] A second cooling water pipe 12 is fixedly installed on the side close to each other of the two end covers 5, and the two ends of the second cooling water pipe 12 are respectively fixedly connected with the two first cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com