Process and equipment for producing external adhesive type composite plate

A production process and production equipment technology, applied in the field of production process and equipment of externally attached composite panels, can solve the problems of insufficient bonding strength and other problems, and achieve the effects of good thermal insulation effect, fast construction speed, and easy on-site installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

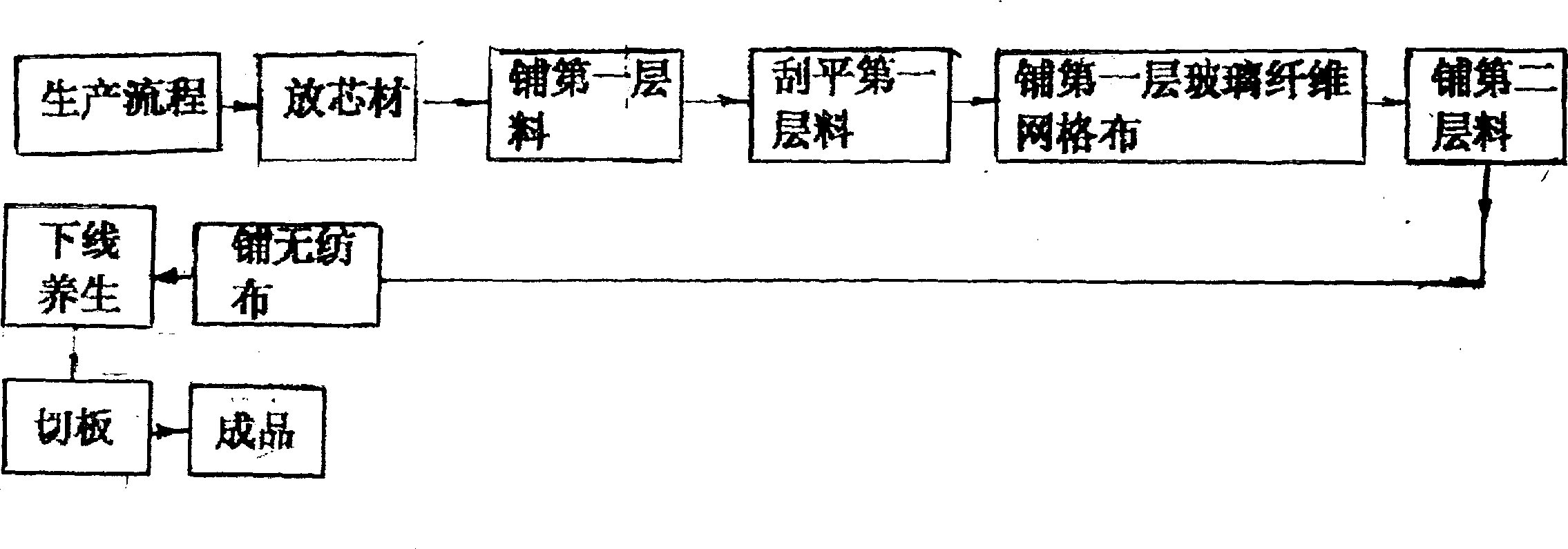

Method used

Image

Examples

Embodiment

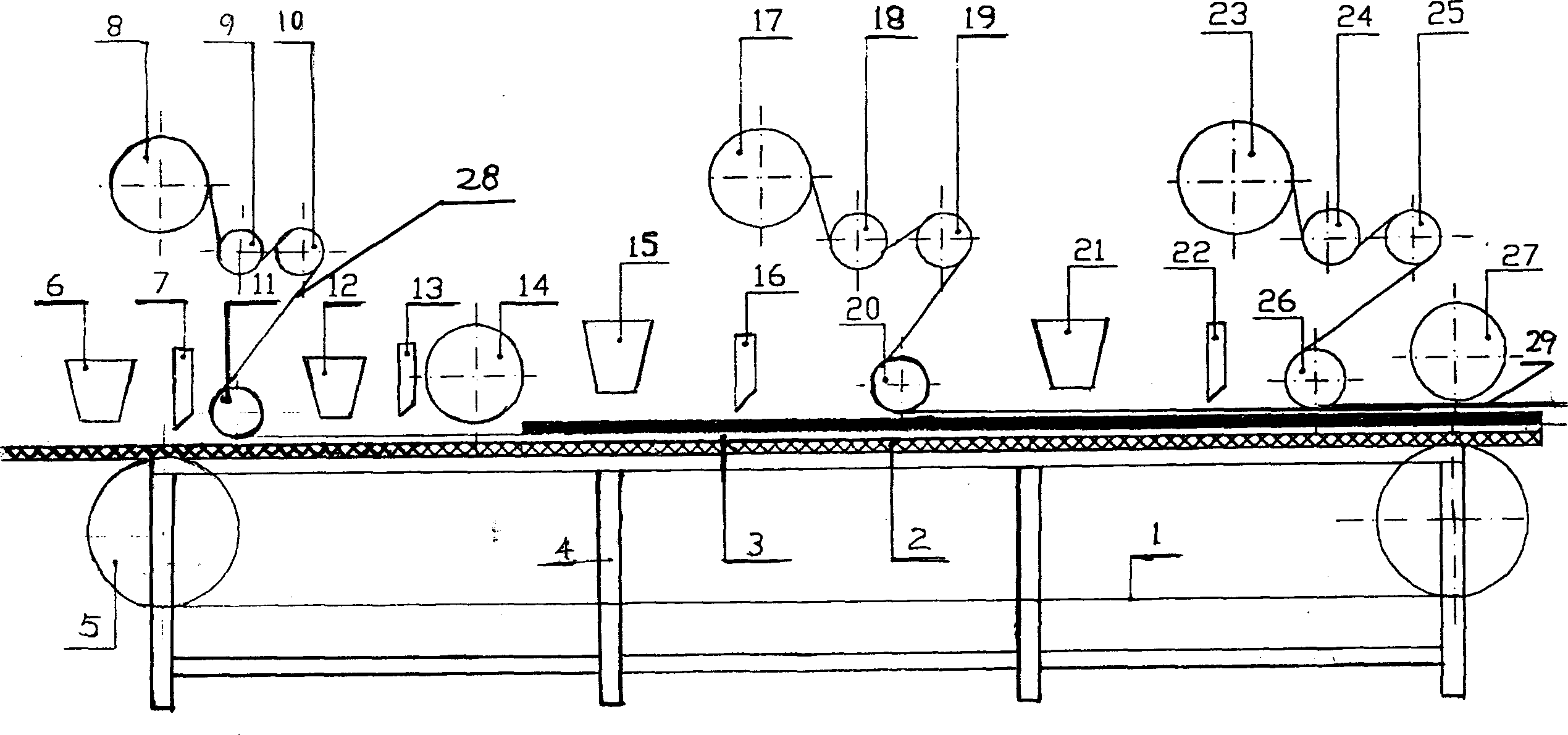

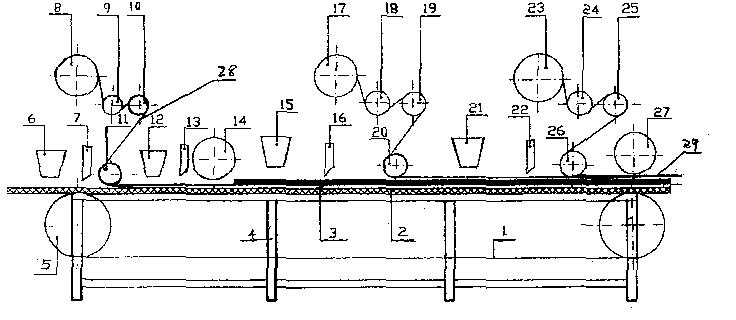

[0008] The transmission device in the production equipment of the present invention is a common belt conveyor, and only the glass fiber mesh cloth supporting wheel shaft and the glass fiber mesh cloth flattening device are respectively installed on the frame according to the required parts of the process flow to assist the glass fiber mesh It is also equipped with non-woven fabric supporting axles, non-woven fabric flattening device to assist non-woven fabrics, and a vibrating hopper and vibrating scraper to supplement and flatten the material, and a thickness-setting roller to ensure that the product thickness of. The speed of the specific mechanical beat can be adjusted according to the needs of the process. The number of scrapers, supporting axles and flattening device axles can be set according to the number of auxiliary layers. The optimal belt line speed is: 2.44 m / min, the frequency of vibrating the hopper is: 1000-1500 Hz, and the frequency of vibrating the scraper is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com