CuO-Cu2O/graphene nano compound material and preparation method thereof

A nanocomposite material, cuo-cu2o technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unfavorable hollow structure morphology and structure, scarcity of templates, pollution, etc. Achieve excellent electrochemical lithium storage performance, short reaction time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

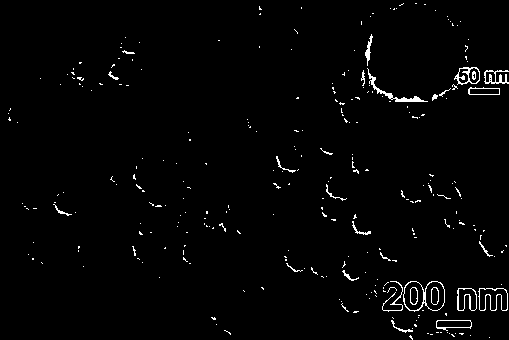

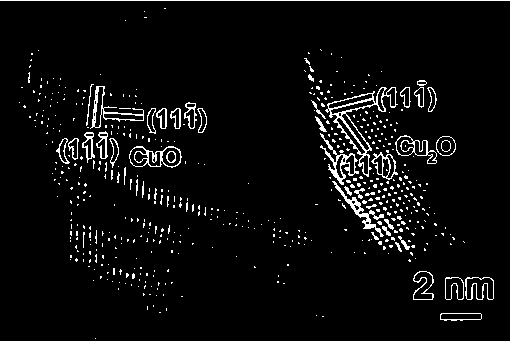

[0034] A kind of copper nitrate, graphite oxide is raw material to prepare CuO-Cu 2 The steps of the O / graphene nanocomposite are as follows:

[0035] (1) Weigh respectively 0.8g copper nitrate and 0.12g graphite oxide and ultrasonically disperse them in 80ml absolute ethanol;

[0036] (2) Slowly add 8ml of ammonia water (10M) and continue to sonicate for 10 minutes;

[0037] (3) reactant is transferred in the round bottom flask that reflux device is arranged, and the power of control microwave reactor is 500W, reacts 10min;

[0038] (4) After the reaction is finished, the precipitate in the flask is centrifugally washed and dried to obtain a precursor;

[0039] (6) Calcining the obtained precursor in argon at a high temperature of 500°C for 2h, and then calcining in an air atmosphere at a low temperature of 250°C for 1h to obtain CuO-Cu 2 O / graphene nanocomposites.

[0040]

Embodiment 2

[0042] A kind of copper acetate, graphite oxide is raw material preparation CuO-Cu 2 The steps of the O / graphene nanocomposite are as follows:

[0043] (1) Weigh 0.66g copper acetate and 0.15g graphite oxide respectively, and ultrasonically disperse them in a mixed solution of 40ml absolute ethanol and 40ml water;

[0044] (2) Slowly add 9ml of ammonia water (10M) and continue to sonicate for 10 minutes;

[0045] (3) reactant is transferred in the round bottom flask that reflux device is arranged, the power of control microwave reactor is 400W, reacts 15min;

[0046] (4) After the reaction is finished, the precipitate in the flask is centrifugally washed and dried to obtain a precursor;

[0047] (5) Calcining the obtained precursor at a high temperature of 450°C in nitrogen for 2h, and then calcining at a low temperature of 200°C in an air atmosphere for 2h to obtain CuO-Cu 2 O / graphene nanocomposites.

[0048]

Embodiment 3

[0050] A kind of copper chloride, graphite oxide is raw material preparation CuO-Cu 2 The steps of the O / graphene nanocomposite are as follows:

[0051] (1) Weigh 0.6g copper chloride and 0.2g graphite oxide respectively, and ultrasonically disperse them in 100ml deionized water;

[0052] (2) Slowly add 10ml of ammonia water (10M) and continue to sonicate for 15 minutes;

[0053] (3) reactant is transferred in the round bottom flask that reflux device is arranged, and the power of control microwave reactor is 700W, reacts 10min;

[0054] (4) After the reaction is finished, the precipitate in the flask is centrifugally washed and dried to obtain a precursor;

[0055] The obtained precursor is calcined at a high temperature of 550 °C in nitrogen for 1 h, and then at a low temperature of 200 °C in an air atmosphere for 3 h to obtain CuO-Cu 2 O / graphene nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microwave power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com