Method for preparing nano/micron gold hierarchical structure material

A technique for preparing gold with a hierarchical structure, which is applied in the field of preparing nano/micro-scale gold hierarchical structure materials, can solve the problems of low yield, complicated preparation process, and poor monodispersity, and achieve high yield, simple operation, and stable shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

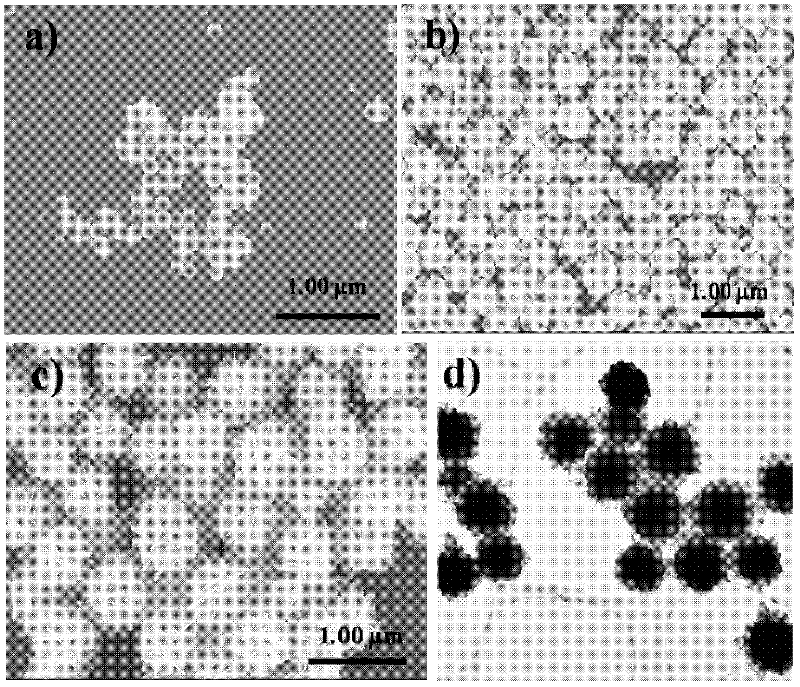

[0036] Embodiment 1, preparation meatball type, the multi-protrusion type on the surface and the spherical gold hierarchical structure material with sheet-like structure on the surface

[0037] (1) Dissolve C18N3 in twice distilled water to prepare a 0.5 mM C18N3 aqueous solution.

[0038] (2) At room temperature, add 30 μ L (or 70 μ L, or 80 μ L) mass concentration of 2% (48 mM) chloroauric acid aqueous solution to 2.45 mL C18N3 aqueous solution, make the concentration of chloroauric acid in the mixed solution be 0.58 Mm (or 1.33 mM, 1.52mM)

[0039] (3) After the above mixed solution was mixed for 30 seconds, 0.25 mL (20 mM) of ascorbic acid aqueous solution was quickly added, shaken gently, and allowed to stand for 1 hour.

[0040] (4) The above product solution was centrifuged at 3000r / min for 5min, the supernatant was removed, and the precipitated product was washed with twice distilled water. So cycle 3 times.

[0041] (5) Drop each sample washed by centrifugation ont...

Embodiment 2

[0042] Embodiment 2, the preparation surface multi-protrusion type gold nanostructure material and the nano gold flower that the surface is sheet-like structure

[0043] (1) Dissolve C18N3 in twice distilled water to prepare a 0.5 mM C18N3 aqueous solution.

[0044] (2) At room temperature, 80 μL of 2% (48 mM) chloroauric acid aqueous solution was added to 2.45 mL of C18N3 aqueous solution, so that the concentration of chloroauric acid in the mixed solution was 1.52 mM.

[0045] (3) After mixing the above mixed solution for 30 seconds, quickly add 0.25 mL (or 0.3 mL, or 0.35 mL) of 20 mM ascorbic acid aqueous solution, shake gently, and let stand for 1 hour.

[0046] (4) The above product solution was centrifuged at 3000r / min for 5min, the supernatant was removed, and the precipitated product was washed with twice distilled water. So cycle 3 times.

[0047] (5) The sample of centrifugation washing is dropped on silicon chip, room temperature is dried, obtains the electron mi...

Embodiment 3

[0049] Embodiment 3, the preparation method of the gold nano single crystal with many protrusions on the surface is as follows:

[0050] (1) Dissolve C18N3 in twice distilled water to prepare a 0.5 mM C18N3 aqueous solution.

[0051] (2) Add 10 μL (or 20 μL, or 30 μL) of 2% (48 mM) chloroauric acid aqueous solution to 2.45 mL of C18N3 aqueous solution at room temperature.

[0052] (3) After mixing the above mixed solution for 30 seconds, quickly add 0.25 (20 mM) ascorbic acid aqueous solution, shake gently, and let stand for 1 hour.

[0053] (4) The above product solution was centrifuged at 6000r / min for 5min, the supernatant was removed, and the precipitated product was washed with double distilled water. So cycle 3 times.

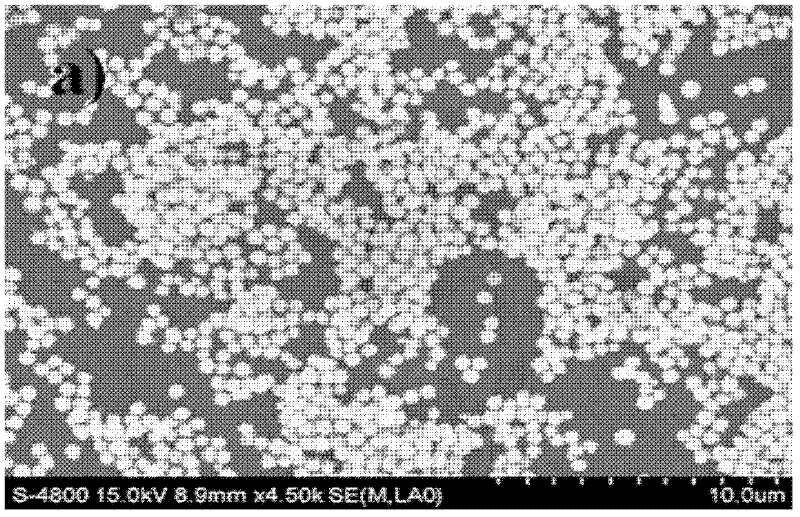

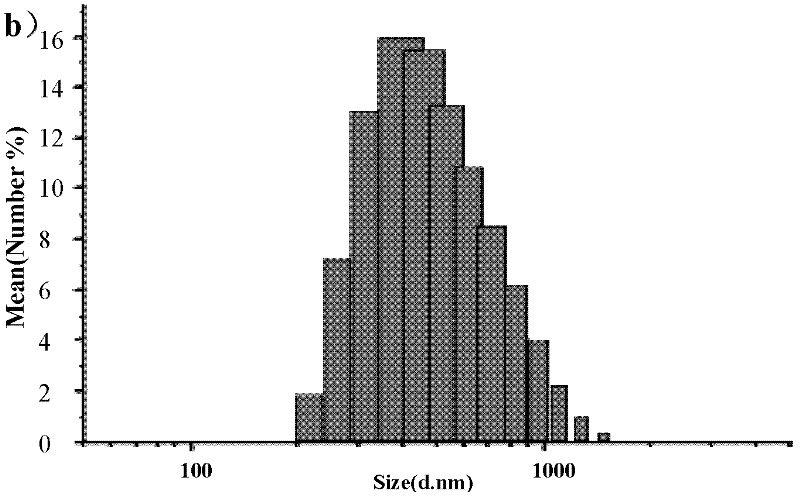

[0054] (5) Drop the centrifuged washed sample onto the silicon wafer and dry it at room temperature. The scanning electron micrograph of the product of adding 20 μ L of chloroauric acid solution is as follows Figure 5 As shown, it can be seen that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com