Method for processing impact cylinder of pneumatic tool

A technology of pneumatic tools and processing methods, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., and can solve problems such as part fracture, shape and position tolerance, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

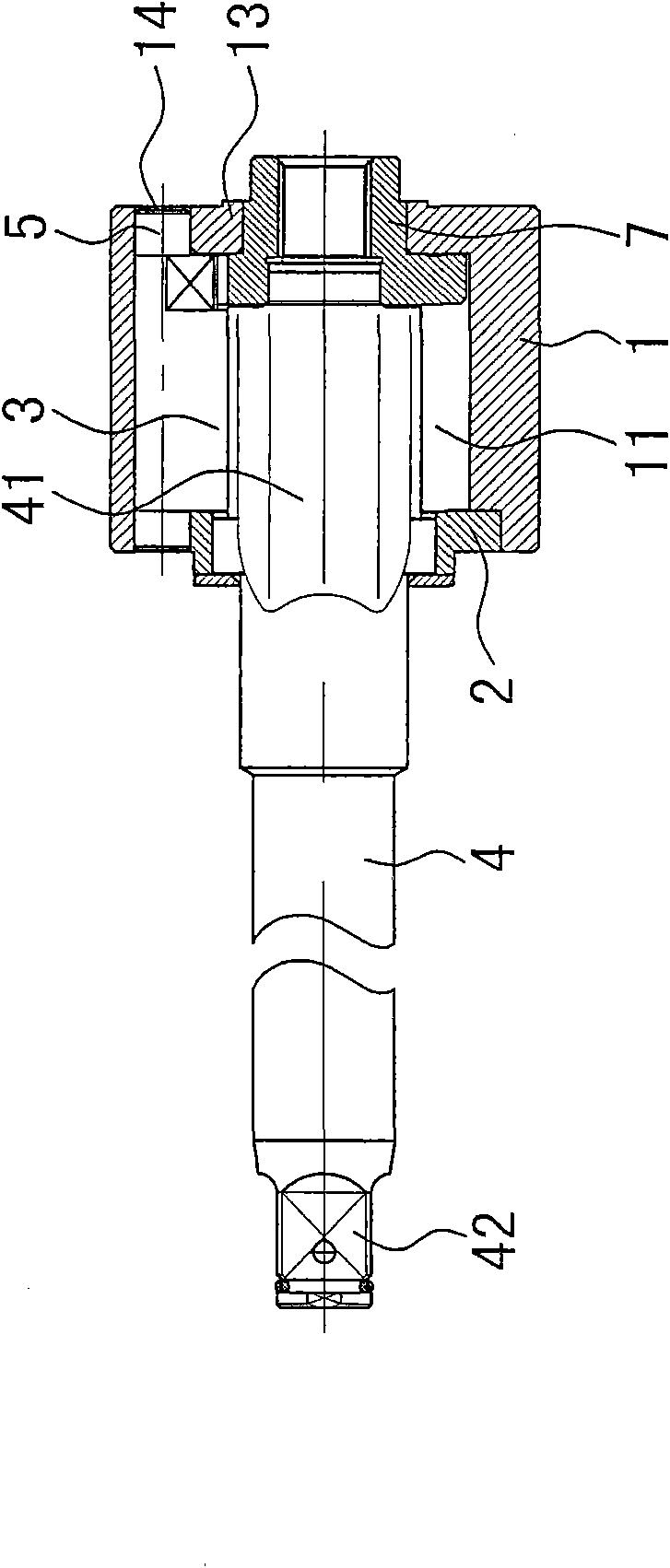

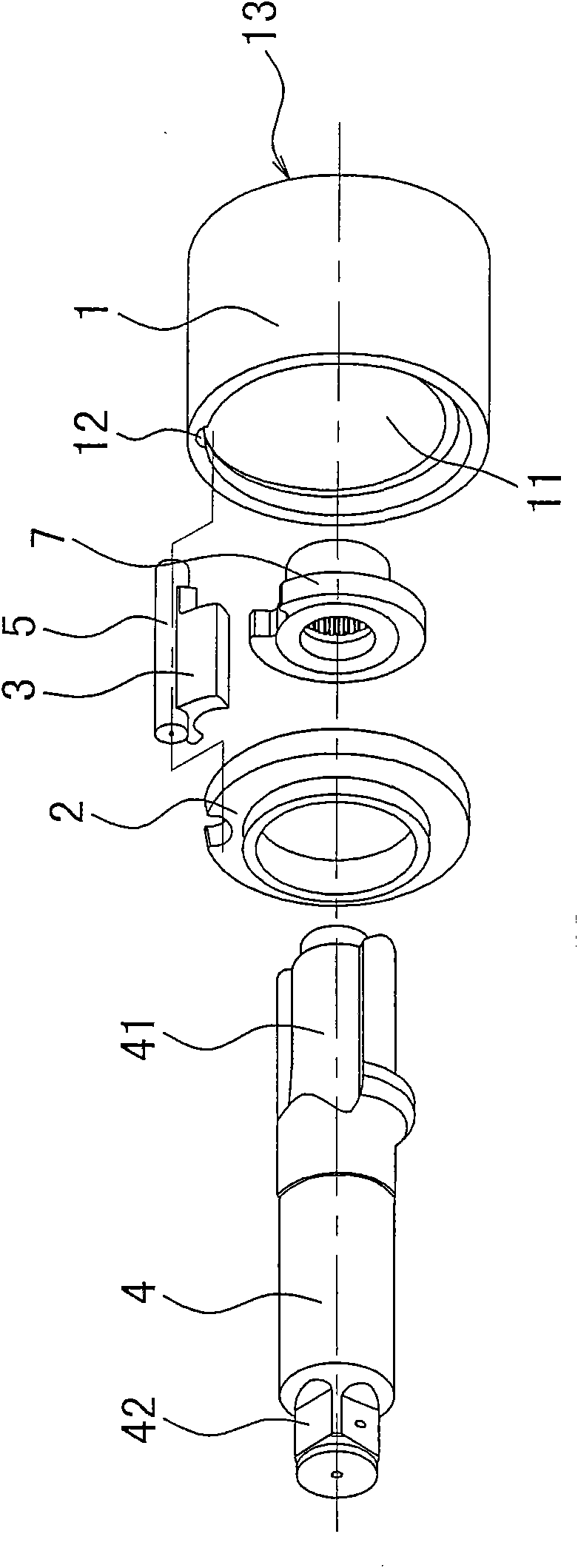

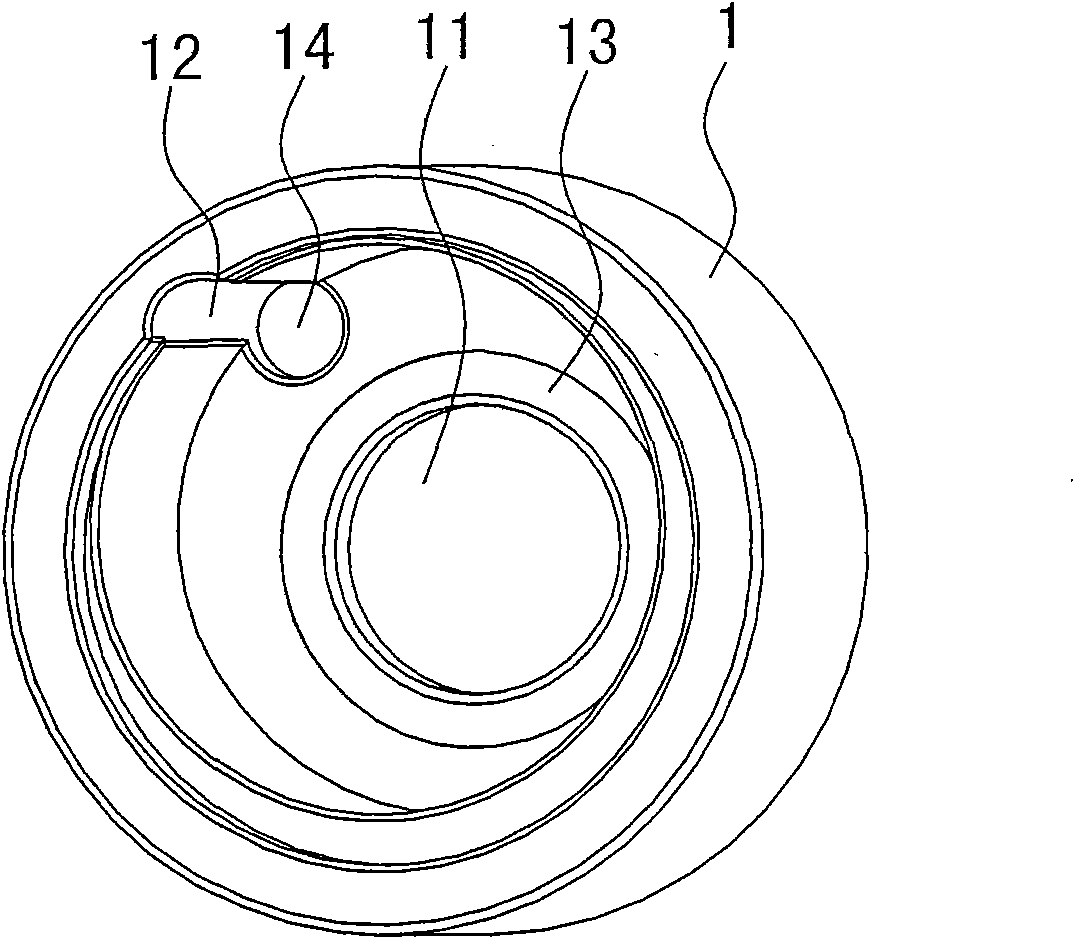

[0018] The invention discloses a processing method of an impact cylinder of an air tool. The air tool is composed of a power source and an impact mechanism. The power source is provided by an air motor. The air motor is composed of blades, rotors and cylinders, such as figure 1 , figure 2 As shown, the impact mechanism includes a striking shaft 4, and one end of the striking shaft is formed with a striking surface 41, the striking surface 41 is matched with the striking block 3, and the striking block 3 is provided with a striking pin 5, and the two ends of the striking pin are respectively passed through the inner lining 2 and the striking block 3. The transmission sleeve 7 is fixed in the impact cylinder 1, the transmission sleeve 7 is engaged with the rotor, the other end of the impact shaft 4 is made into a square head 42, and the square head is connected to the sleeve. It is characterized in that the processing steps of the impact cylinder are:

[0019] a. Take the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com