Automobile half-axle pendulum rolling formation technology mould

An automobile half shaft and forming process technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. Convenient operation and the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

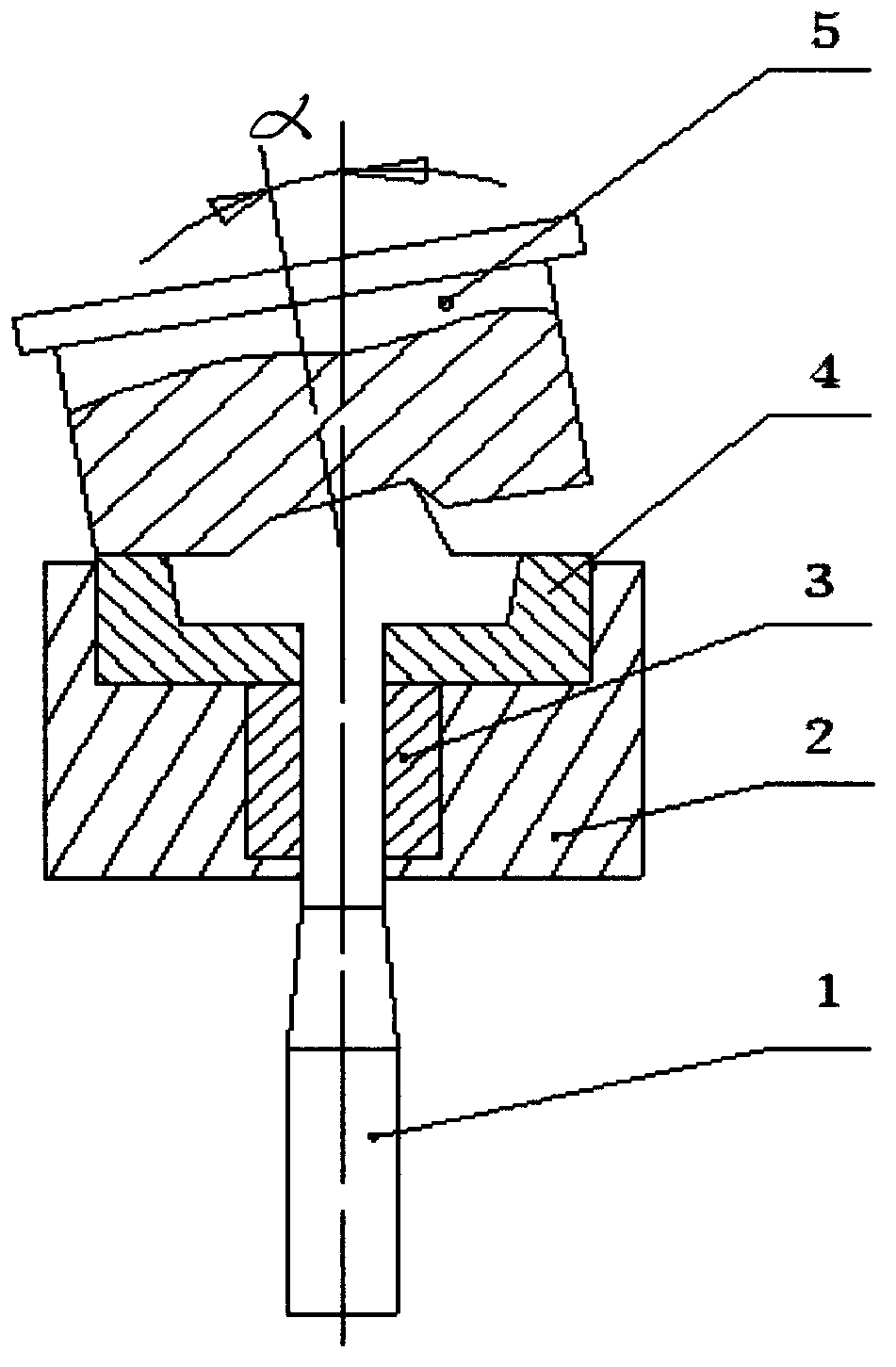

[0010] As shown in the figure, the semi-axis rotary rolling forming process mold of the vehicle includes a semi-axis blank 1, a clamp body 2, a mold core 3, a lower mold 4, and an upper mold 5, and the mold core 3 and the lower mold 5 are installed in the clamp body 2 , The centerline of the upper mold 5 when installed and the centerline of the lower mold 4 are at an inclination angle of 10°.

[0011] In the automotive semi-shaft swing forming process mold of the present invention, the lower side of the semi-shaft blank 1 is fixed and does not move.

[0012] In the mold of the present invention, the semi-shaft blank 1 is rotated and gradually pressed into shape.

[0013] The beneficial effects of the invention are: the quality of the half shaft is obviously improved, the geometric dimension is stable, the surface is smooth, the material is saved, the cost is reduced, the process is convenient to operate, safe and reliable, and the qualified rate of the forging is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com