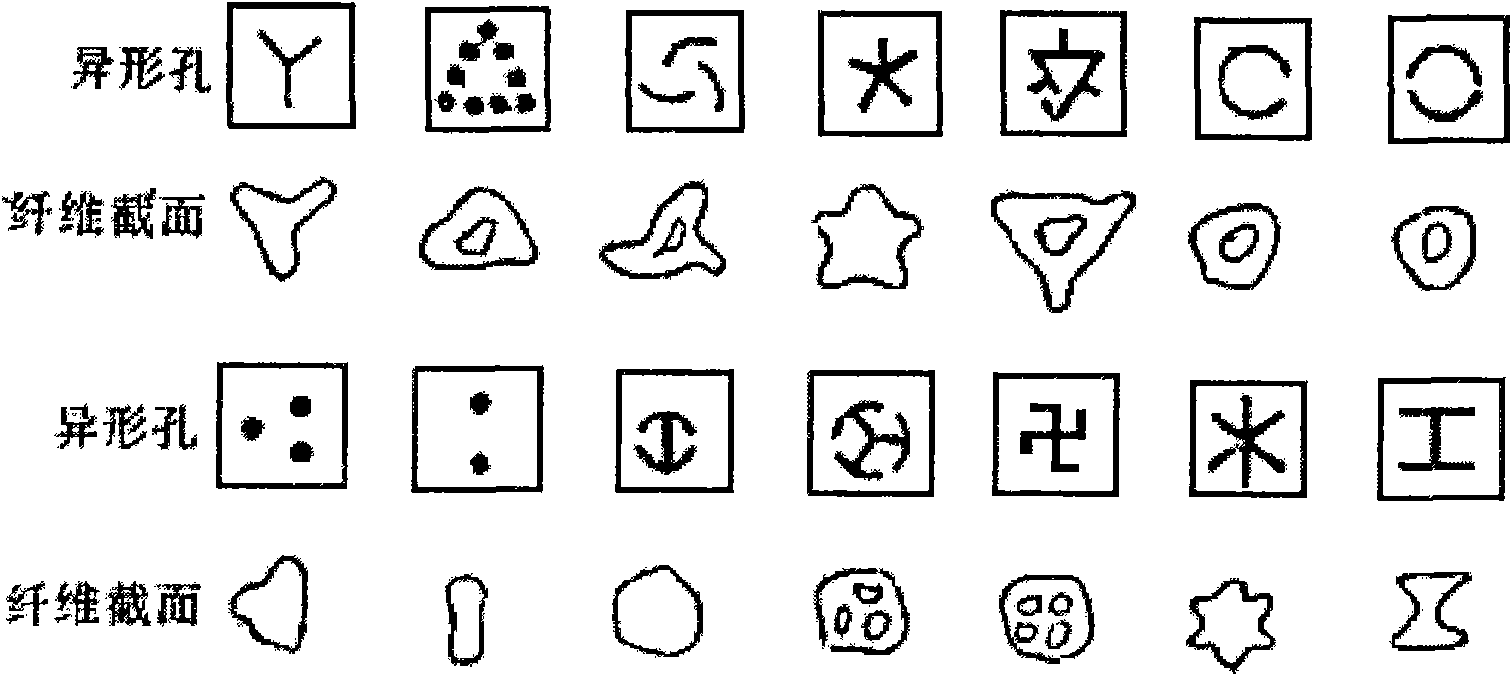

Colored non-conventional type polyester monofilament with stable size and preparing method thereof

A dimensionally stable, monofilament fiber technology, applied in the fiber field, can solve the problems of no fiber preparation, poor surface gloss, non-absorbent coverage, etc., and achieve the effects of rich color, clean surface, and improved fabric size uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The spun chip consists of 91.8 parts of polyethylene terephthalate (PET) spun chip, and Jinshan Petrochemical provides a molecular weight of 20,000. 5 parts of color masterbatch and 3 parts of polyethylene 2,6-diethyl naphthalate (PEN) chip (DuPont PENQ3000) and 0.2 parts of barium sulfate powder (Yufeng Powder Material Co., Ltd. ultrafine barium sulfate YF-10000), cut and prepared after screw blending, put the slices prepared by blending in a VC358 rotating pot, and first pump Vacuum to within 30 Pa, then heat to 120°C for 8 hours for drying and dehydration, keep the water content below 35PPM for 8 hours; masterbatch (Lihe Chemical Fiber Plastic Factory T1714), gradually heat to 120°C at a constant speed for 8 hours Carry out drying and dehydration, heat preservation for 8 hours, and the water content is below 35PPM. The drying process is a well-known technology in the industry. Using VC406 spinning machine, polyester chips and color masterbatch are extruded, blended a...

Embodiment 2

[0037] Spinning chip is made of 97.5 parts of polyethylene terephthalate (PET) spinning chip, Jinshan Petrochemical provides masterbatch with molecular weight of 20,000, Lihe Chemical Fiber Plastic Factory T1173, 2 parts, 0 parts of poly-2,6-naphthalene dicarboxylic acid Diethyl ester (PEN) slices and 0.5 parts of barium sulfate powder, Yufeng Powder Material Co., Ltd. ultrafine barium sulfate YF-10000), were prepared by cutting after screw blending, and polyethylene terephthalate (PET ) The spun chips are heated to 120°C for 8 hours for drying and dehydration, and the water content is kept below 35PPM for 8 hours; the color masterbatch is heated for 8 hours to 140°C for drying and dehydration, and the heat preservation is for 8 hours. The water content is below 35PPM; the polyester chip and the color masterbatch are extruded, blended and melted by a screw machine to form a melt, and then spun through the spinneret assembly, and the extrusion temperature of the screw machine is...

Embodiment 3

[0039] The spun chip is made of 88 parts of polyethylene terephthalate (PET) spun chip, Jinshan Petrochemical provides a molecular weight of 20,000. 3 parts of color masterbatch, Lihe Chemical Fiber Plastic Factory T1614. 8 parts of polyethylene 2,6-diethyl naphthalate (PEN) chips, DuPont PEN Q3000, and 1 part of barium sulfate powder, Yufeng Powder Material Co., Ltd. Ultra-fine barium sulfate YF-10000, prepared by cutting after screw blending, heating the blended slices to 120-160°C for 8-12 hours for drying and dehydration, keeping the water content below 35PPM for 8-10 hours; color The master batch is heated to 120-160°C for drying and dehydration in 8-12 hours, and kept for 8-10 hours. The water content is below 35PPM; the polyester chip and the color masterbatch are extruded, blended and melted by a screw machine to make a melt, and then spun through the spinneret assembly, and the extrusion temperature of the screw machine is: 280°C in the first zone, The second zone is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com