Hydraulic cylinder provided with mechanical lock

A technology of hydraulic cylinders and cylinder barrels is applied in the field of hydraulic cylinders with mechanical locks, which can solve the damage to the hydraulic system of emergency release of external hoses, the inability of floating flanges to achieve rotational unloading, and the leakage of crude oil from external flanges. problem, to achieve the effect of good locking effect, accurate locking and opening, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

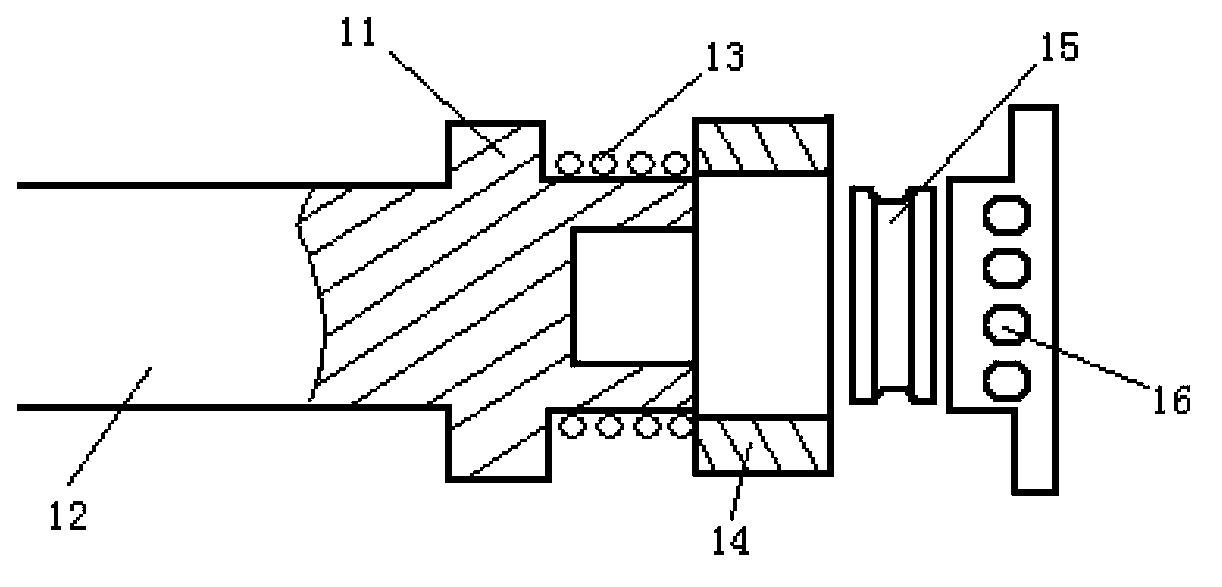

[0033] like figure 1 As shown, it is the hydraulic cylinder of the emergency release system of the external hose in the prior art. Before installation, it is subjected to a tensile test with a tensile force of 10T, and there is no abnormality. After being installed on the equipment, it repeatedly acts, causing damage to the hydraulic cylinder. The specific reasons are analyzed as follows:

[0034] When the hydraulic cylinder is retracted, oil is supplied to the front chamber of the hydraulic cylinder, the piston 11 of the hydraulic cylinder begins to retract, and the piston of the hydraulic cylinder makes the locking cylinder head contact the positioning steel ball 16 first, and the positioning steel ball is in a free state at this time. When the locking cylinder head continues to retract, The positioning steel ball 16 is pressed out by the locking column head, and the movable sleeve 14 contacts the positioning steel ball 16. Because the spring 13 behind the movable sleeve 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com