Cover device for a power tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

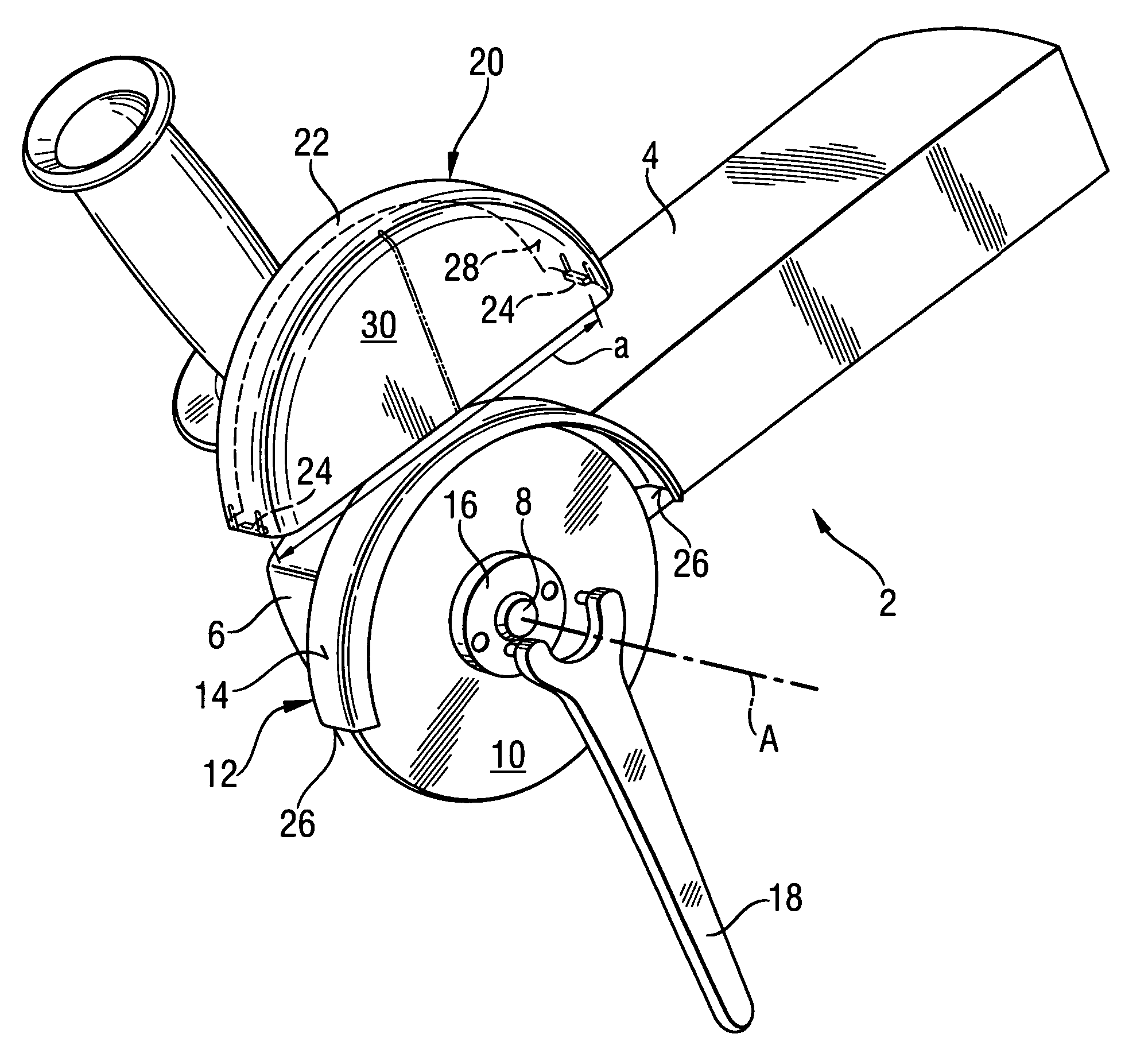

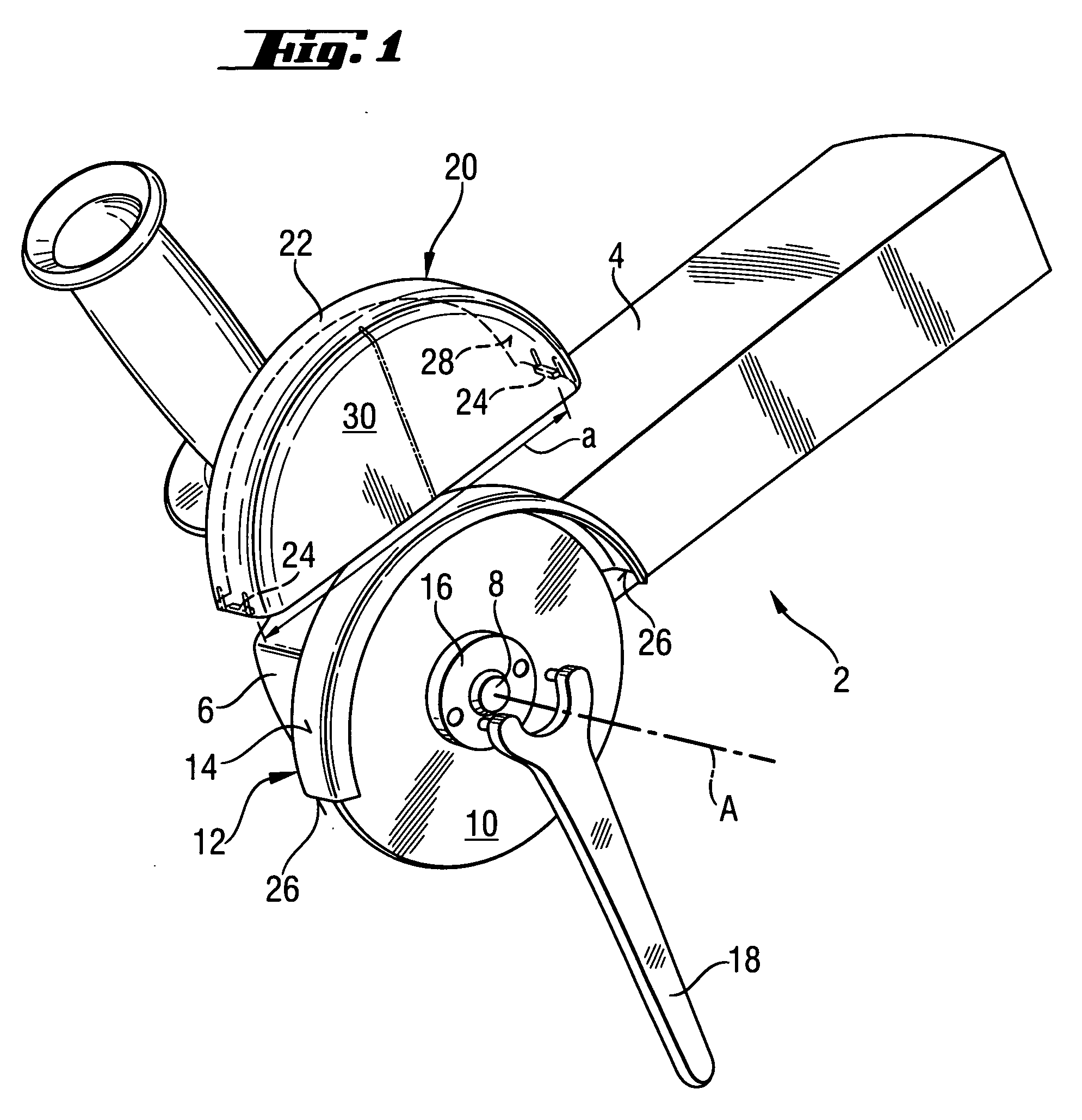

first embodiment

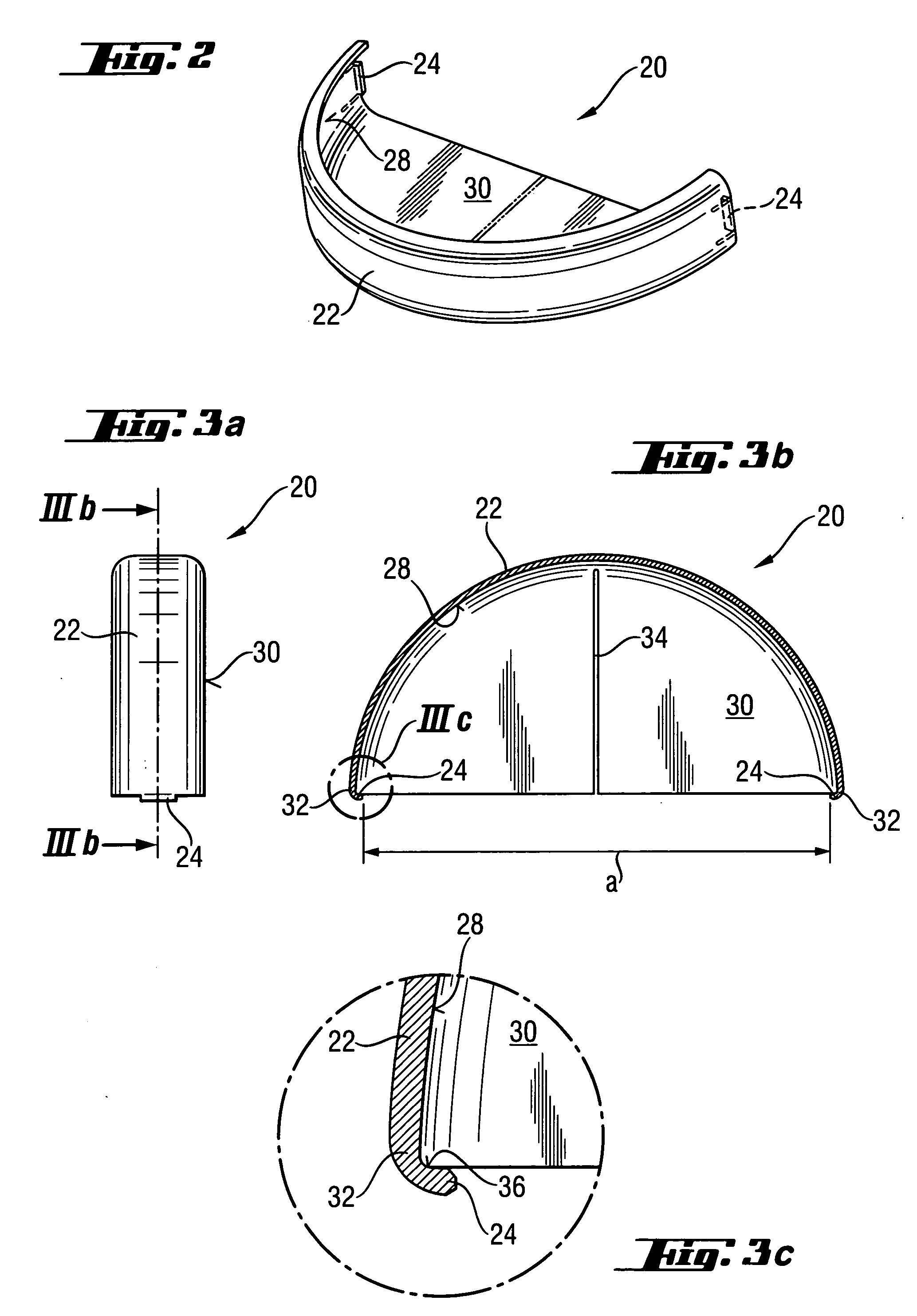

[0036]FIGS. 3a-3c shows the engaging-from-behind elements 24. The elements 24 have, at their respective free ends, two hook-shaped elements 32 which are formed at the tangential ends of the bearing means 22. The hook-shaped elements 32, together with the engaging-from-behind elements 24, are formed, together with the bearing means 22, as a substantially formstable single piece. In order to be able to displace the engaging-from-behind elements 24 away from each other to increase the distance a therebetween for hooking the cover device 20 on the limiting edges 26 of the shielding member 12 and for removing the cover device 20 off the shielding member 12, there is formed, in the protective disc 30, a radial slot 34. The slot 34 permits to deform, the bearing means 22 during mounting of the cover device 20 on the shielding member 12 and dismounting of the cover device 20 from the shielding member 12. The slot 34 provides for a radial pivotal movement of the engaging-from-behind elements...

second embodiment

[0038]FIGS. 4a-4c show an alternative, second embodiment of the engaging-from-behind elements 24. According to this embodiment, the engaging-from-behind elements 24 are formed on a locking nose 38 of an elastically resilient locking element 40. The locking element 40 has a spring arm 42 that is formed by two tangentional, extending parallel to each other, cut-ins 44 provided at respective tangential ends of the bearing means 22. The cut-ins 44 provide for elastic pivotal movement of the engaging-from-behind elements 24 in the radial direction relative to the bearing means 22 in order to change the distance a therebetween.

[0039] With both embodiments of the engaging-from-behind elements 24, the cover device 20 can be rapidly pinned on the shielding member 12, without using any additional tools.

[0040] In both embodiments, the engaging-from-behind elements 24 engage the limiting edges 26 in order to secure the cover device 20 on the shielding member 12 in the tangential and radial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com