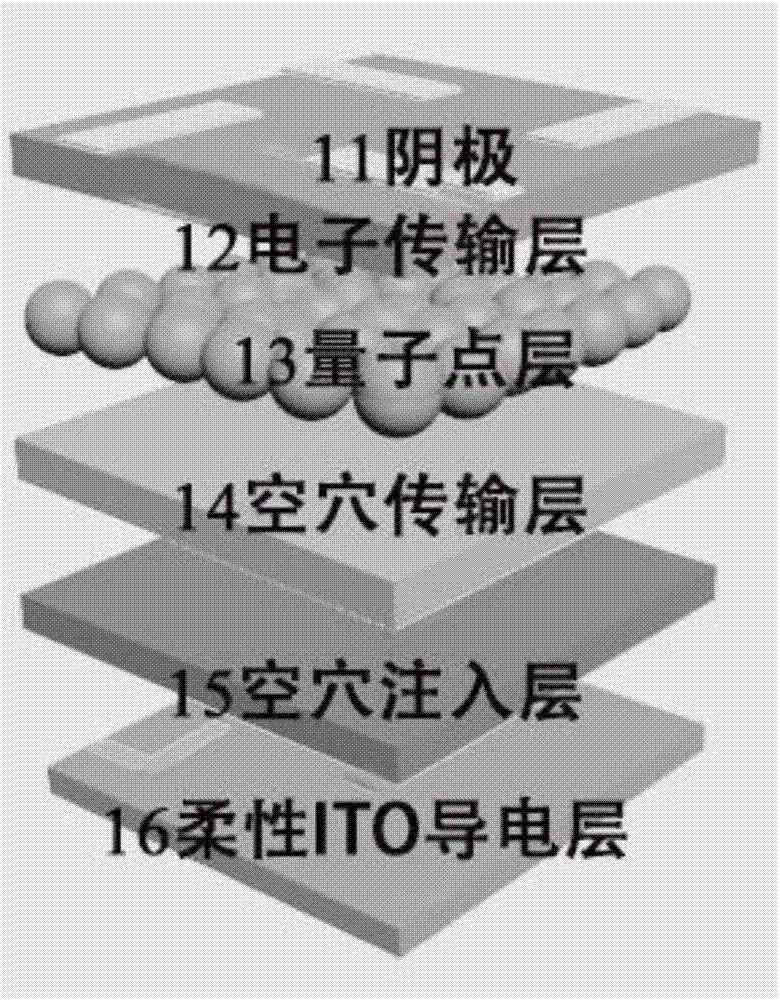

Multiplex quantum dot, preparing method thereof and flexible display device

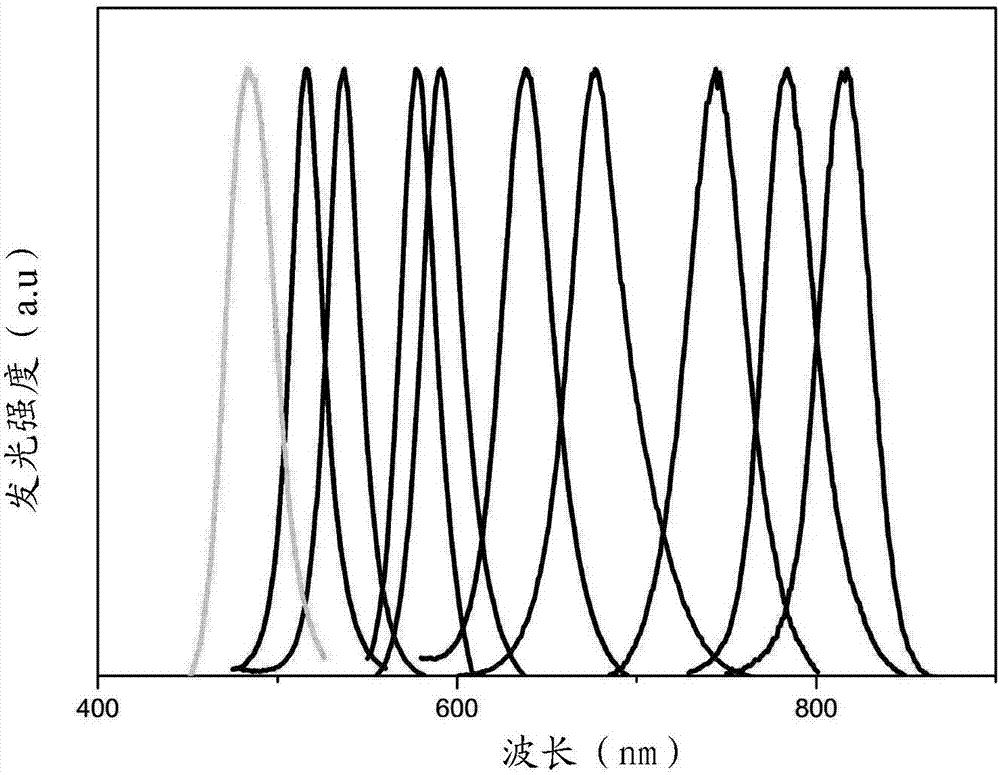

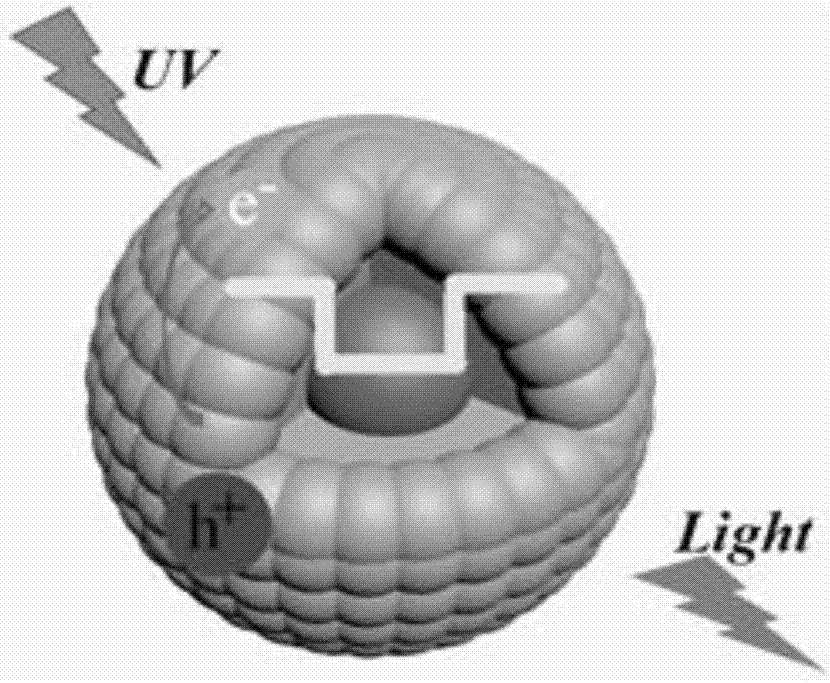

A flexible display, quantum dot technology, applied in electrical components, electrical solid devices, chemical instruments and methods, etc., can solve the problems of unstable emission spectrum, short fluorescence lifetime, poor stability of quantum dots, and achieve symmetrical emission spectrum, fluorescence Long life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a method for preparing multivariate quantum dots, which includes the following steps:

[0030] (1) Mix the first zinc source, sulfur source and the first non-coordinating solvent, heat it and keep it warm to obtain a quantum dot precursor;

[0031] (2) Mix the quantum dot precursor prepared in the step (1) with the second non-coordinating solvent and the second zinc source, and heat it to obtain the multi-element quantum dot.

[0032] In the present invention, the first zinc source, the sulfur source and the first non-coordinating solvent are mixed, heated and kept warm to obtain a quantum dot precursor. The present invention does not specifically limit the heating operation, as long as the technical solution for heating well known to those skilled in the art can be used. In the present invention, it is heated to the synthesis temperature of the quantum dot precursor and the temperature is kept; in the present invention, the temperature of the h...

Embodiment 1

[0085] (1) Put 1mmol of CdO, 10mmol of zinc acetate, 7mL of oleic acid and 15mL of 1-octadecene into a 100mL four-necked flask, vacuum for 40min to a vacuum of 0.1KPa, heat to 100℃, and ventilate After heating to 280°C for three times, 1 mL of sulfur 1-octadecene solution was injected, and the concentration of the sulfur 1-octadecene solution was 0.5 mmol / mL.

[0086] (2) Keep the above mixed solution at 280°C for 10 minutes to obtain the CdZnS quantum dot solution and then cool it to room temperature. According to the volume ratio of the quantum dot solution to oleic acid 1:1, add oleic acid to the quantum dot solution; Divide the mixture of dot and oleic acid into 5mL centrifuge tubes, centrifuge at 4000rpm / min for 5min;

[0087] (3) Remove the lower layer of precipitation, add n-hexane to dissolve it, add the n-hexane solution to acetonitrile to promote precipitation, and perform centrifugal separation again according to the above-mentioned centrifugal method;

[0088] (4) Repeat...

Embodiment 2

[0097] (1) Put 0.1mmol zinc stearate, 0.5mmolS powder and 10mL 1-octadecene solution into a 100mL four-necked flask, vacuum for 40min to a vacuum of 0.1KPa, heat to 100℃, ventilate three times and heat to 280 After 1 mL of sulfur 1-octadecene solution was injected.

[0098] (2) Keep the above mixed solution at 280℃ for 10 minutes to obtain the ZnS quantum dot solution and then cool it to room temperature. According to the volume ratio of the quantum dot solution to oleic acid 1:1, add oleic acid to the quantum dot solution; Divide the mixture of dot and oleic acid into 5mL centrifuge tubes, centrifuge at 4000rpm / min for 5min;

[0099] (3) Remove the lower layer of precipitation, add n-hexane to dissolve it, add the n-hexane solution to acetonitrile to promote precipitation, and perform centrifugal separation again according to the above-mentioned centrifugal method;

[0100] (4) Repeat step (3) 4 times, and the obtained precipitate is the quantum dot precursor;

[0101] (5) Add the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com