A kind of iron-based nanocrystalline thin ribbon and its manufacturing method

An iron-based nanocrystalline and thin ribbon technology, applied in the field of amorphous alloys, can solve the problems of low coercivity, high price, large magnetostriction, etc., and achieve good comprehensive magnetic properties, good temperature stability, and crystallization. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Fe, Si, ferroboron (24wt% B), Zr, Nb, Cr, Cu, ferrovanadium, Al are divided into Fe a Si b Zr c Nb d B e M x (at%) chemical composition ratio configuration, melted in a medium frequency vacuum induction furnace, and the melted alloy ingot is made into an amorphous thin strip by a single-roll extremely cold method. 40m / s, the thickness of the produced amorphous ribbon is about 20-30 microns, and the width is about 6mm. The obtained amorphous thin ribbon was wound into a ring with an outer diameter of 20 mm and an inner diameter of 10 mm, and was placed in a heat treatment furnace at 510° C. for 1 hour. The specific manufacturing steps are as follows:

[0043] 1. Smelting the master alloy. The industrial pure iron, ferroboron, silicon, zirconium, niobium, copper, chromium, ferrovanadium, and aluminum are prepared according to the chemical composition ratio to prepare the master alloy, and smelted in the intermediate frequency vacuum induction melting furnace into t...

Embodiment 2

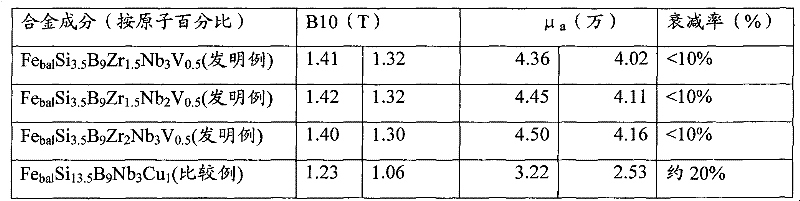

[0053] Fe, Si, ferroboron (24wt% B), Zr, Nb, Cr, Cu, ferrovanadium, Al are divided into Fe a Si b Zr c Nb d B e M x (at%) chemical composition ratio configuration, melted in a medium frequency vacuum induction furnace, and the melted alloy ingot is made into an amorphous thin strip by a single-roll extremely cold method. 40m / s, the thickness of the produced amorphous ribbon is about 20-30 microns, and the width is about 6mm. The obtained amorphous thin ribbon was wound into a ring with an outer diameter of 20 mm and an inner diameter of 10 mm, and was placed in a heat treatment furnace at 550° C. for 0.5 hours. The Curie temperature of the iron-based nanocrystalline thin ribbons obtained by VSM, its composition and the corresponding Curie temperature are listed in Table 3; the magnetic properties were measured after 120 hours of heat preservation at 300°C, and Table 4 shows the aging without 120 hours of heat preservation. Comparison table between the data values measu...

Embodiment 3

[0060] Fe, Si, ferric boron (24wt% B), Zr, Nb, Al, V, Cr, Cu as Fe a Si b Zr c Nb d B e M x (at%) chemical composition ratio configuration, melt into a master alloy ingot in an intermediate frequency vacuum induction furnace, and use a single-roll extremely cold method to make an amorphous thin strip of the alloy ingot. The surface line speed is 40m / s, and the thickness of the produced amorphous ribbon is about 20-30 microns, and the width is about 10mm. The obtained amorphous thin ribbon was wound into a ring with an outer diameter of 25 mm and an inner diameter of 10 mm, and was placed in a heat treatment furnace for heat preservation.

[0061] alloy composition

distinguish

Heat treatment process

μ a (Ten thousand)

B10(T)

Fe bal Si 3.5 B 9 Zr 1.5 Nb 1.5 Cr 0.5

Invention example

539℃, 25min

4.60

1.46

Fe bal Si 3.5 B 9 Zr 1.5 Nb 1.5 Cr 1

Invention example

542℃, 20min

4.61 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com