Salt gypsum crystal transformation activator as well as preparation method and application thereof

A technology of salt gypsum and activator, which is applied in the field of salt gypsum crystal transformation, salt gypsum crystal transformation activator, and preparation field, to achieve the effect of improving crystal transformation effect, increasing activity, and reducing environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

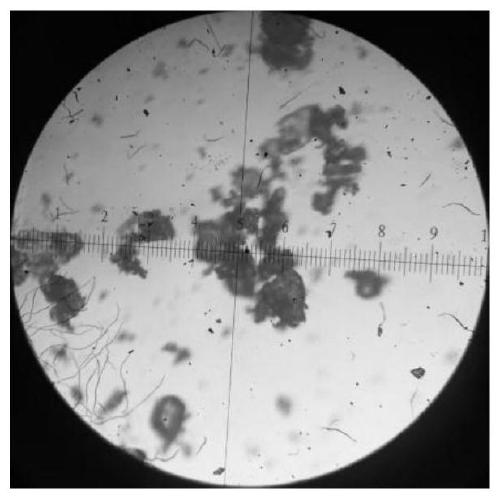

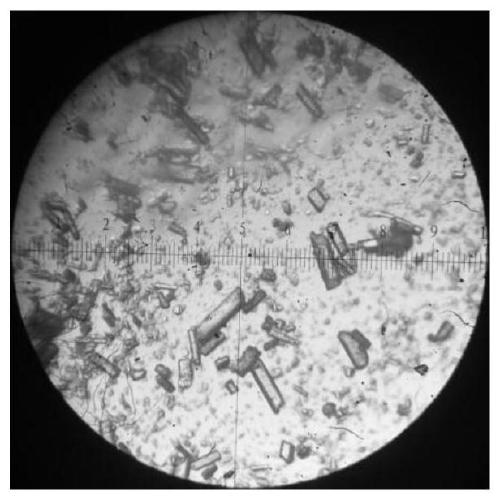

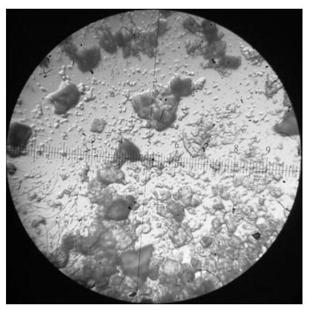

Image

Examples

Embodiment 1

[0056] Add 50g of industrial-grade common cornstarch and 75g of water to make starch milk, add 2g of 98% concentrated sulfuric acid, then heat it in a water bath to 50°C, stop heating after 2h, let it cool down to room temperature without neutralization, keep the residual sulfuric acid, and use vacuum pumping After filtering, washing and drying, the acid-thinned starch can be obtained and stored at low temperature.

[0057] Add 2.5g maleic anhydride and 1.5g triethanolamine to the four-necked bottle, and add 0.1g p-toluenesulfonic acid, slowly raise the temperature to 80°C, the reaction time is 6h, and cool down to obtain maleic anhydride triethanolamine ester and maleic anhydride mixture.

[0058] Dissolve 0.2g of sodium carbonate in 5g of water, add acid-thinned starch and stir evenly, heat to 60°C for 0.5h, then add maleic anhydride triethanolamine ester and maleic anhydride mixture, mix well, stir evenly, and synthesize by semi-dry method , placed in an oven at 80°C for 3...

Embodiment 2

[0061] Add 40g of industrial-grade common cornstarch and 75g of water to make starch milk, add 1g of 98% concentrated sulfuric acid, then heat it in a water bath to 45°C, stop heating after 1.5h, let it cool down to room temperature without neutralization, keep the residual sulfuric acid, and use vacuum After suction filtration, washing and drying, the acid-thinned starch can be obtained and stored at low temperature. Add 2g of maleic anhydride and 1.7g of triethanolamine to a four-neck flask, and add 0.1g of p-toluenesulfonic acid, slowly raise the temperature to 82°C, and the reaction time is 5h, then cool down to obtain a mixture of maleic anhydride triethanolamine ester and maleic anhydride . Dissolve 0.2g of sodium carbonate in 7g of water, add acid-thinned starch and stir evenly, heat to 65°C for 0.5h, then add maleic anhydride triethanolamine ester and maleic anhydride mixture, mix well, stir evenly, and synthesize by semi-dry method , placed in an oven at 80°C for 2.5...

Embodiment 3

[0064] Add 45g of industrial-grade common cornstarch and 70g of water to make starch milk, add 1.5g of 98% concentrated sulfuric acid, then heat it in a water bath to 50°C, stop heating after 2h, let it cool down to room temperature without neutralization, keep the residual sulfuric acid, and use vacuum After suction filtration, washing and drying, the acid-thinned starch can be obtained and stored at low temperature. Add 2.5g maleic anhydride and 1.5g triethanolamine to the four-necked bottle, and add 0.1g p-toluenesulfonic acid, slowly raise the temperature to 80°C, the reaction time is 6h, and cool down to obtain maleic anhydride triethanolamine ester and maleic anhydride mixture. Dissolve 0.2g of sodium carbonate in 5g of water, add acid-thinned starch and stir evenly, heat to 70°C for 0.5h, then add maleic anhydride triethanolamine ester and maleic anhydride mixture, mix well, stir evenly, and synthesize by semi-dry method , placed in an oven at 80°C for 3 hours, cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com