Molecular sieve catalyst for synthesizing triisopropylbenzene, and preparation method thereof, and synthesis method of triisopropylbenzene

A technology of triisopropylbenzene and molecular sieves, which is applied in the direction of molecular sieve catalysts, including molecular sieve catalysts, catalyst activation/preparation, etc., can solve the problems of poor crystallization effect, high crystallization temperature, and long crystallization time, and achieve gelation Good effect, good water solubility, short time required for crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

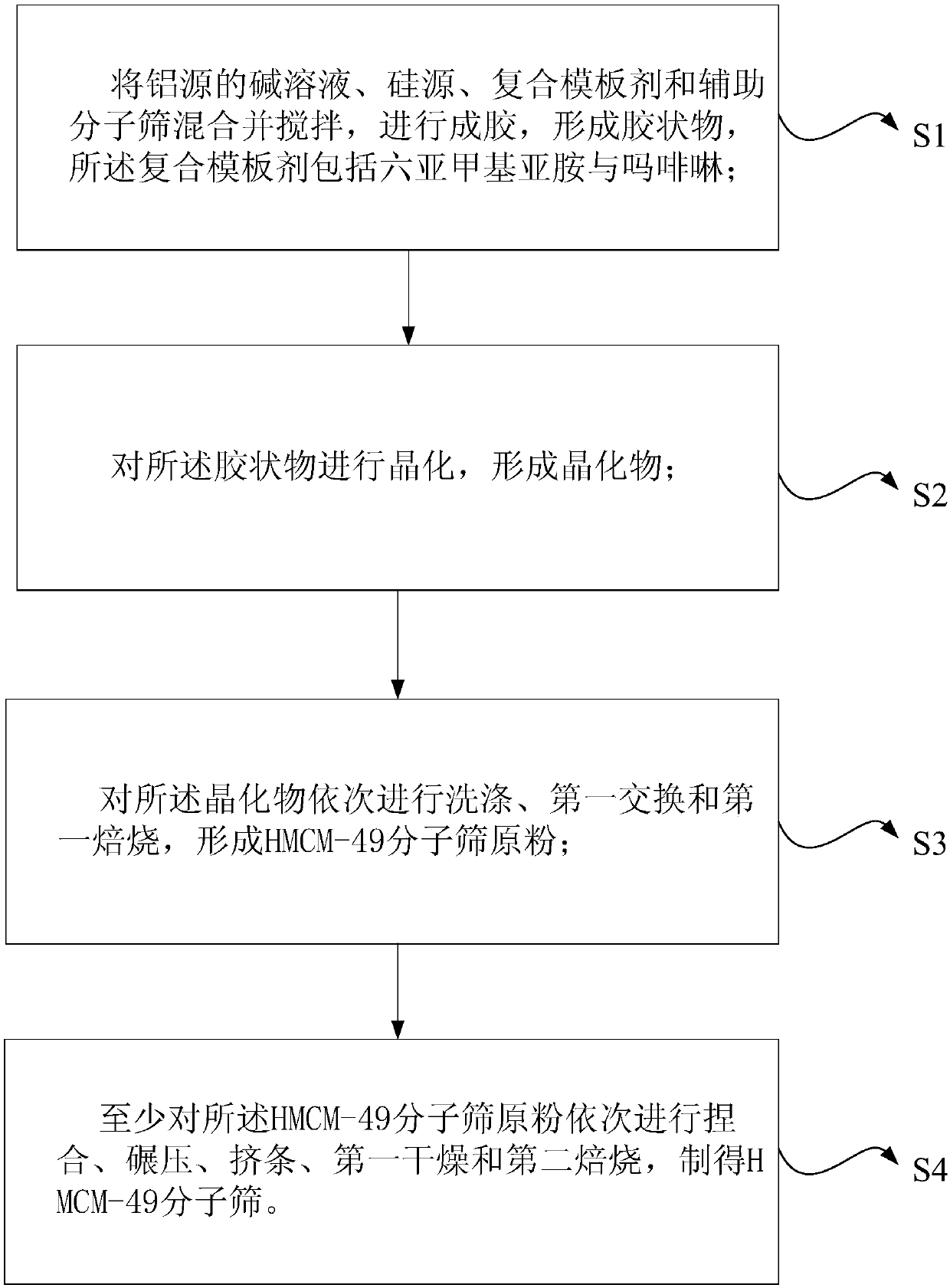

[0039] In a typical implementation of the present application, a method for preparing a molecular sieve catalyst for synthesizing triisopropylbenzene is provided, such as figure 1 As shown, the preparation method includes: step S1, mixing and stirring the alkaline solution of the aluminum source, the silicon source, the composite template agent and the auxiliary molecular sieve to form a gel, and the above composite template agent includes hexamethylene methylene Amine and morpholine; step S2, crystallize the above-mentioned jelly to form a crystallization; step S3, sequentially wash, first exchange and first roast the above-mentioned crystallization to form the original powder of HMCM-49 molecular sieve; step S4 , at least carry out sequentially kneading, rolling, extruding, first drying and second roasting to the above-mentioned HMCM-49 molecular sieve raw powder to obtain HMCM-49 molecular sieve.

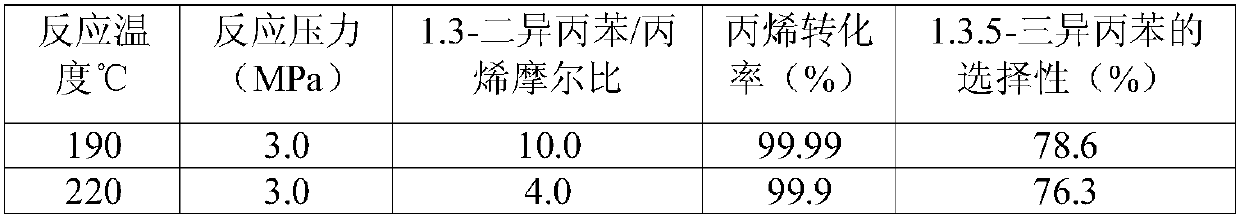

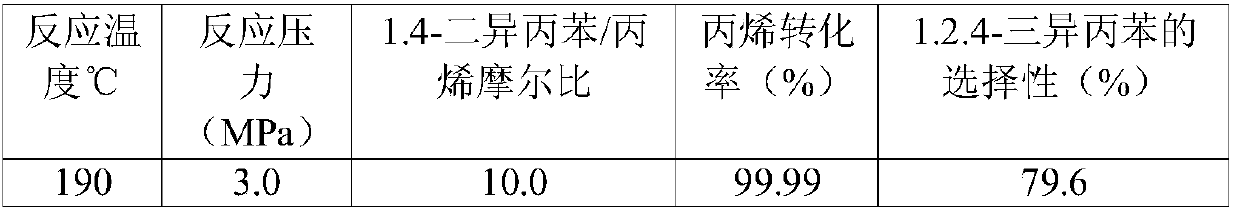

[0040] The catalyst is used in the reaction of propylene and diisopropylbenz...

Embodiment 1

[0064] Dissolve 0.10kg sodium metaaluminate and 0.02kg sodium hydroxide completely in 0.6kg desalted water to prepare sodium metaaluminate-sodium hydroxide aqueous solution; 0.50kg morpholine is added in 0.10kg hexamethyleneimine, fully Stir to prepare a composite template. Add 1 kg of silica sol with a mass content of 30% into the gel forming tank, start stirring, add the composite template agent, stir evenly, add sodium metaaluminate-sodium hydroxide aqueous solution dropwise to the "thick point", increase the stirring speed, turn on the condensation Glue, slowly add the remaining silica sol; then add 6g NaMCM-49 molecular sieve, stir for 2h to form gel.

[0065]Put the gelled slurry into a 5L crystallization kettle, start stirring at a stirring speed of 40r.p.m, and press the feeding port tightly; turn on the heat-conducting oil circulation pump and heat-conducting oil heater, and heat the temperature in the crystallization kettle to 150°C. Keep the temperature constant fo...

Embodiment 2

[0075] Dissolve 0.10kg sodium metaaluminate and 0.012kg sodium hydroxide completely in 1.20kg desalted water to prepare sodium metaaluminate-sodium hydroxide aqueous solution; add 0.30kg morpholine to 0.1kg hexamethyleneimine, fully Stir to prepare a composite template. Add 1 kg of silica sol with a mass content of 30% into the gel forming tank, start stirring, add the composite template agent, stir evenly, add sodium metaaluminate-sodium hydroxide aqueous solution dropwise to the "thick point", increase the stirring speed, turn on the condensation Add the remaining silica sol slowly; then add 0.005kg NaMCM-49 molecular sieve, stir for 2 hours to form gel.

[0076] Put the gelled slurry into a 5L crystallization kettle, start stirring at a stirring speed of 70r.p.m, and press the feeding port tightly; turn on the heat-conducting oil circulation pump and heat-conducting oil heater, and heat the temperature in the crystallization kettle to 140°C. Keep the temperature constant f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com