Method for preparing sulfur coated selenium hollow nanotube

A nanotube and selenium nanotechnology is applied in the field of preparing sulfur-coated selenium hollow nanotubes, which can solve the problems of insufficient Li+ diffusion and electrical conductivity, selenium cannot fully provide theoretical capacity, fast capacity decay, etc., so as to improve the mass ratio. The effect of low capacity, good crystallinity and repeatability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

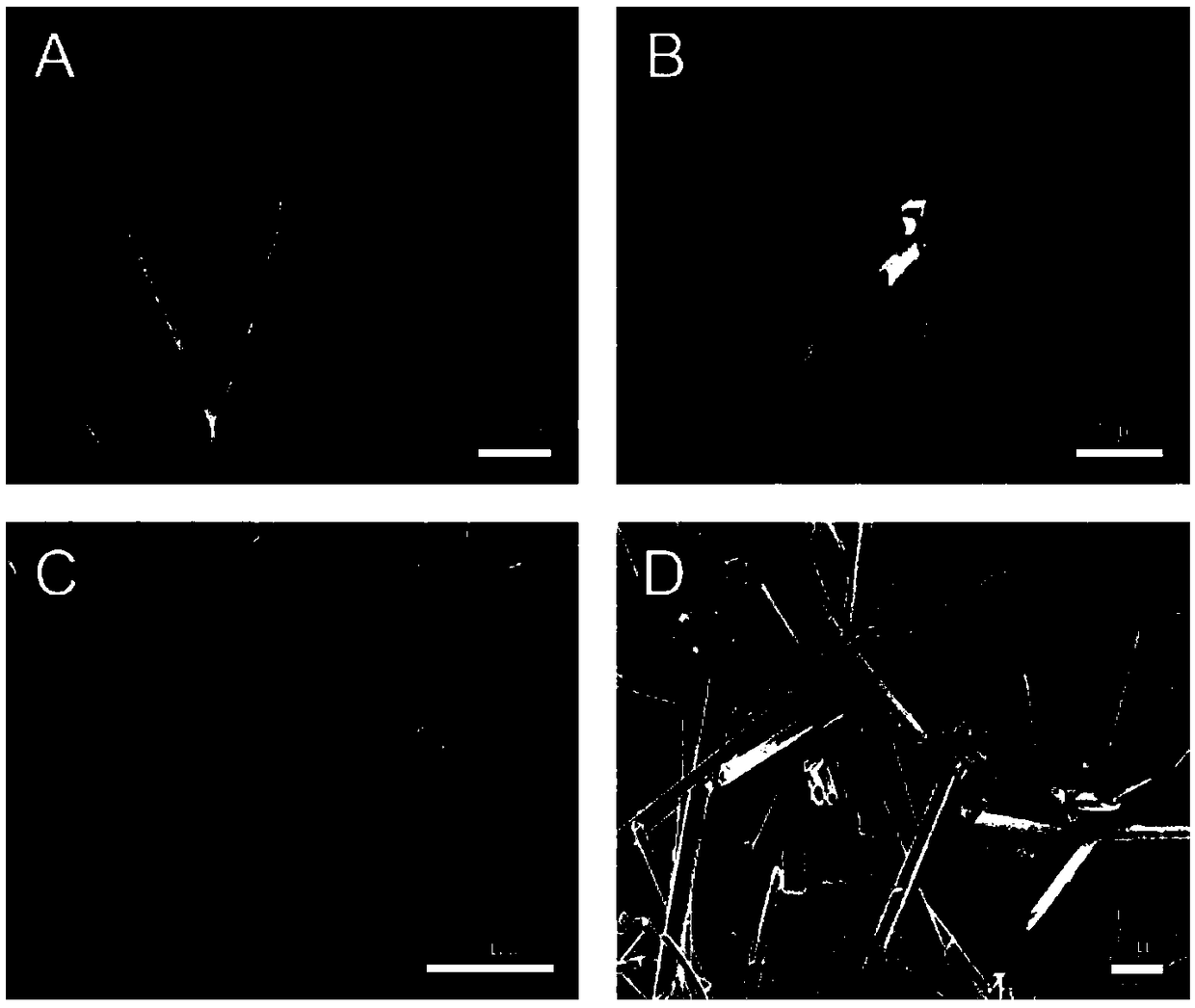

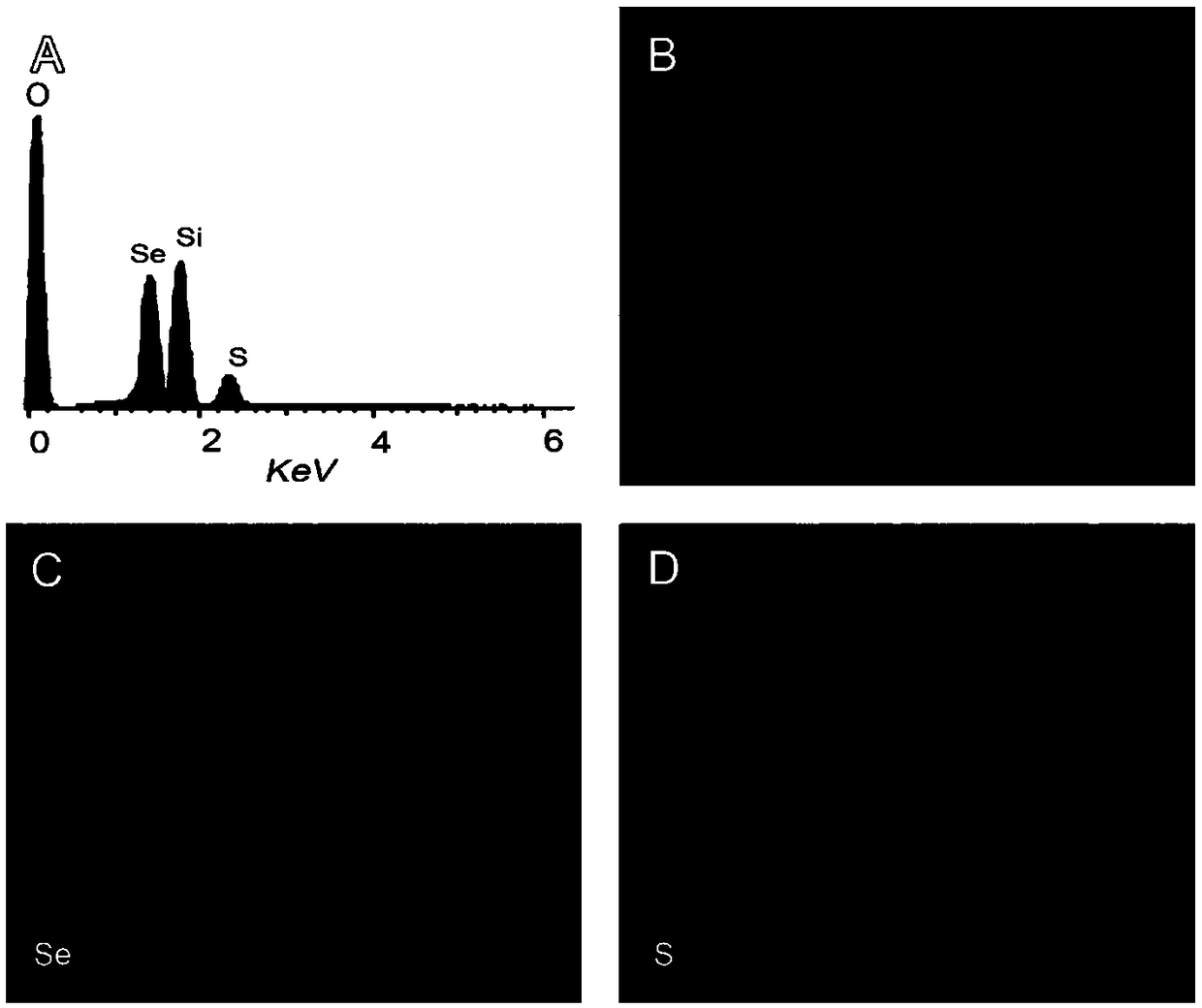

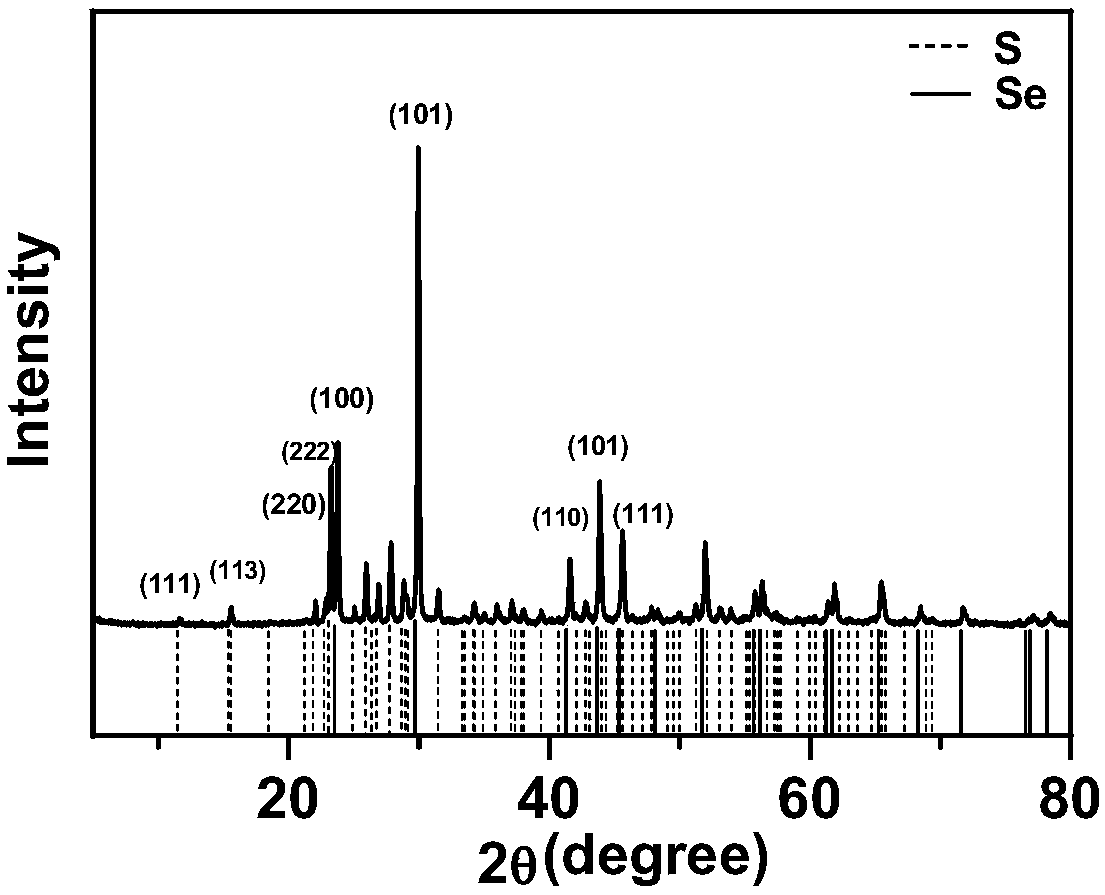

Embodiment 1

[0023] Dissolve 1 gram of selenium powder and 5 grams of sodium sulfite in 80 milliliters of water, stir at 75 degrees for 24 hours to form a uniform sodium selenosulfite solution; take out 4 milliliters and add to 45 milliliters containing 1 gram of non-ionic surfactant polyoxyethylene In the solution of lauryl ether and 60 microliters of acetic acid, after ultrasonication and aging, hexagonal selenium nanotubes were obtained by centrifugal washing; 0.05 grams of selenium nanotubes were dissolved in 28 milliliters of 0.1 mol / liter dilute hydrochloric acid for 10 Minutes; Dissolve 2 grams of sublimed sulfur in 10 milliliters of ethylenediamine to form a thiamine solution, slowly drop 2 milliliters of the thiamine solution into the acidic solution of selenium nanotubes, stir vigorously for 15 minutes under airtight conditions, filter, water and After washing with ethanol three times alternately, transfer to a drying oven at 60°C for 12 hours. The mass ratio of sulfur to seleniu...

Embodiment 2

[0025] Dissolve 1 gram of selenium powder and 5 grams of sodium sulfite in 80 milliliters of water, stir at 75 degrees for 24 hours to form a uniform sodium selenosulfite solution; take out 4 milliliters and add to 45 milliliters containing 1 gram of non-ionic surfactant polyoxyethylene In the solution of lauryl ether and 60 microliters of acetic acid, after ultrasonication and aging, hexagonal selenium nanotubes were obtained by centrifugal washing; 0.07 grams of selenium nanotubes were dissolved in 28 milliliters of 0.1 mol / liter dilute hydrochloric acid for 10 Minutes; Dissolve 2 grams of sublimed sulfur in 10 milliliters of ethylenediamine to form a thiamine solution, slowly drop 2 milliliters of the thiamine solution into the acidic solution of selenium nanotubes, stir vigorously for 15 minutes under airtight conditions, filter, water and After washing with ethanol three times alternately, transfer to a drying oven at 60°C for 12 hours. The mass ratio of sulfur to seleniu...

Embodiment 3

[0027] Dissolve 1 gram of selenium powder and 5 grams of sodium sulfite in 80 milliliters of water, stir at 75 degrees for 24 hours to form a uniform sodium selenosulfite solution; take out 4 milliliters and add to 45 milliliters containing 1 gram of non-ionic surfactant polyoxyethylene In the solution of lauryl ether and 60 microliters of acetic acid, after ultrasonication and aging, hexagonal selenium nanotubes were obtained by centrifugal washing; 0.08 grams of selenium nanotubes were dissolved in 28 milliliters of 0.1 mol / liter dilute hydrochloric acid for 10 Minutes; Dissolve 2 grams of sublimed sulfur in 10 milliliters of ethylenediamine to form a thiamine solution, slowly drop 2 milliliters of the thiamine solution into the acidic solution of selenium nanotubes, stir vigorously for 15 minutes under airtight conditions, filter, water and After washing with ethanol three times alternately, transfer to a drying oven at 60°C for 12 hours. The tubular structure is basically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com