Nano micropore corundum film and preparation method thereof

A nano-microporous and corundum technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor stability of physical and chemical properties, complex preparation process, complex chemical composition, etc., and achieve crystallization Good chemical effect, simple process and low temperature requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the content of the present invention will be further clarified in conjunction with specific examples below, but the content of the present invention is not limited to the following examples.

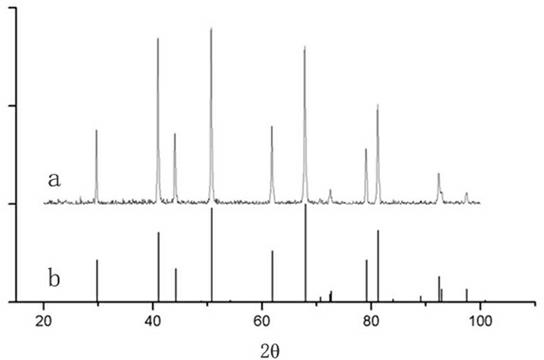

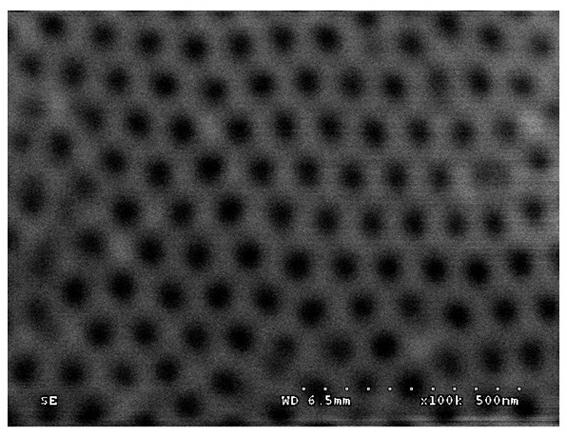

[0019] Such as figure 1 As shown, the thickness of the nanoporous corundum film in the embodiment of the present invention is about 70 microns, and the diameter of the nanopores is about 100 nm. The preparation process of the nano-microporous corundum film is described below:

[0020] 1. Preparation of porous anodized alumina template

[0021] 1. Pretreatment: high-purity 10cm 2 The aluminum sheet was annealed at 500° C. for 4 hours under nitrogen protection. The annealed aluminum sheet was ultrasonically cleaned with acetone and pure water respectively. Corrosion in 5% NaOH solution for 8 minutes to remove the oxide layer, followed by rinsing with water.

[0022] 2. Polishing: Electrochemical cross-flow polishing of alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com